Professional Documents

Culture Documents

Evaporators: Waste Heat Recovery

Uploaded by

Jitendra Kumar0 ratings0% found this document useful (0 votes)

51 views8 pagesEat energy is lost in the cooling systems and e!haust gas but some can be recovered whether it is worth recovering depends upon a number of factors. There are two methods for generating fresh water, (everse )smosis ()+ and distillation. The most commonly used form of shipboard freshwater generation is evaporative distillation, which uses engine %acket cooling water.

Original Description:

Original Title

Evaporators.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEat energy is lost in the cooling systems and e!haust gas but some can be recovered whether it is worth recovering depends upon a number of factors. There are two methods for generating fresh water, (everse )smosis ()+ and distillation. The most commonly used form of shipboard freshwater generation is evaporative distillation, which uses engine %acket cooling water.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

51 views8 pagesEvaporators: Waste Heat Recovery

Uploaded by

Jitendra KumarEat energy is lost in the cooling systems and e!haust gas but some can be recovered whether it is worth recovering depends upon a number of factors. There are two methods for generating fresh water, (everse )smosis ()+ and distillation. The most commonly used form of shipboard freshwater generation is evaporative distillation, which uses engine %acket cooling water.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 8

Evaporators

Waste heat recovery

Even with a very efficient engine, only about 50% of the heat in the fuel is converted into useful work at

the crankshaft. The remainder I potentially wasted. eat energy is lost in the cooling systems and e!haust

gas but some can be recovered whether it is worth recovering depends upon a number of factors including

the amount of energy available, the time for which it is available, capitol costs of recovery plant. "odern

highly pressure charged engines have a large amount of energy in scavenge air cooling water and this can

provide a primary heating source for bunker fuel tanks.

#acket cooling water also contains a considerable $uantity of heat this may be recovered in

fresh water evaporators provided operates at a pressure giving a corresponding saturation temperature

for water lower than the %acket water entering the heating element. &y heating the water to its saturation

temperature gasses dissolved in it are liberated. Thus there is the re$uirement for air e%ection to maintain

a low pressure.

'ny low temperature evaporator will operate over prolonged periods because scale does not

form to any great e!tent. #oints and seals do not deteriorate.

Types of plant

There are two methods for generating fresh water, (everse )smosis *()+ and distillation. (everse osmosis

is generally used were large $uantities of relatively low $uality water is re$uired. Typical e!amples of

water produced are,

Treatment Total ardness -alcium ardness .ilica .odium -hloride T/.

.ea 0ater 150 100 23 25000 25000

Evaporator 40.1 40.1 40.1 410 410

(everse )smosis 10 5 42 4550 4550

'fter /emineraliser 0 42 Trace 41 46

Distillation

The most commonly used form of shipboard freshwater generation is evaporative distillation, which uses

engine %acket cooling water or steam heat from e!haust or gas fired boilers to evaporate sea water, which

is then condensed into fresh water.

Evaporation distillers comes in two main forms, multistage flash *".7+ and multi effect *"E+

evaporators.

Simple single effect evaporator

.ingle *and "ulti8effect+ submerged tube distillation was one of the early types of fresh water generation.

It uses heat passing through submerged coils or tube bundles immersed in sea water to produce the

distillate, which when condensed becomes the fresh water.

The system above shows an evaporator typically heated by "ain Engine #acket water with

means to supply steam when the engine is shut down.

To start this evaporator

Open sea water cooling to the coiling coils

a take off line from the outlet of the cooler goes to the ejector booster pump. After shutting any

vents the booster pump is started. The vacuum in the shell should begin to drop.

A take off from the eductor booster pump is led to the shell via a flow control valve. This

should be cracked to fill the unit increasing to a design level gradually as the vacuum

increases.It should be noted that it is possible on some systems to increase feed to a point

where the eductor can no longer cope and the shell is overfilled. This should be avoided as the

possibility exists of getting saltwater on the demister this is a mesh arrangement designed to

remove wetness from the steam. Should this happen then it can take considerably longer

before the salinity of the distillate falls to an acceptable level.

Treatment chemical in the feed should now be added

!hen the water reaches working level in the shell the heating coils may be warmed through. It

should be noted that it is rarely the case the eductor is able to provide all the vacuum re"uired#

instead as the unit begins to steam# the condensing of this steam assists to pull the down the

shell pressure.

The heating should be increase as the shell pressure reduced. The maximum temperature in

the shell is governed by design and to a maximum of $%&' to reduce scaling

the salinometer may be switched on once condensate is detected in the distillate pump

suction.

the distillate pump control may be switched to auto. On some installations a recirc is fitted

which dumps the outlet from the distillate pump back to the evaporator. This may take the

form of an automatic three way valve operated by the salinometer. In addition a manual dump

to bilge may be fitted to dump the initial charge of distillate out of the unit reducing the time to

online

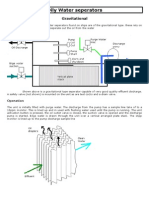

Single Stage (lash )vaporator

'n alternative arrangement to the shell evaporator is the flash evaporator were heating takes place

e!ternally, the hot brine enters the low pressure chamber into a weir where some of the water flashes off.

0ater overflowing the weir is either educted out or passed on to a second stage.

"ulti stage units with each stage maintained at a lower pressure allow improved efficiency

and high outputs.

*ulti Stage (lash )vaporator

' typical multi stage flash system is based upon preheating of a pressurised sea water stream, or more

typically a recycle brine stream to which the feed sea water is added, the stream is heated in the heat

input section brine heater. 7rom here the recycle stream is passed into the first stage of a series of flash

chambers. ere the pressure is released, permitting a portion of the brine stream to flash to form salt8

free vapour which is condensed to give the fresh water. In condensing the vapour gives off its latent heat

to the recycle brine stream. 7rom the first stage the flashing brine stream is passed to the second stage

which is kept at a slightly lower pressure, more vapour flashes off. In the same way the flashing brine

stream passes to the ne!t stage and so on through the plant with a portion of the vapour flashing off at

each stage. ' heat balance shows that the heat supplied in the brine heater has to be re%ected. This is

done in the last two stages of the plant which are cooled by a sea water stream which subse$uently

passes to waste.

Modern Developments

.ince the introduction of ".7, more efficient types of "E evaporators have been introduced.

+arge *ultieffect Alfa laval evaporator

In 2990 'lfa8:aval /esalt introduced its /8T; concept8a "E desalination system based on

tube type distillers, using evaporation under vacuum with the rising film principle. This means that the

inner surfaces of the tube are always covered with a then film of feed water, preventing formation of

scale.

The heating medium *hot water<steam+ circulates on the outside of the tubes in the heat

e!changer. The vacuum is created by water e%ectors connected to each effect.

' controlled amount of sea feed water is led to the bottom of each effect, where it is mi!es

with the brine from the previous effect and into the tubes in the heat e!changer, where it is heated.

The generated vapours enter a separator where the brine droplets from the wet vapour are

separated. The dry vapour pass through the separator to the following effect where they condense. Th

remaining sea water which has been converted to brine, flows to the ne!t effect as feed water. The brine

is taken out and discharged overboard.

The latent heat in the vapours from the previous effect is used as a heating medium in the

following effects. The process continues until the last effect where the generated vapours condense cooled

by sea water. The condensate vapours flow from one effect to the ne!t, and are retained in a collecting

tank as distilled water.

If a low temperature evaporator is to be used for domestic purposes certain restrictions apply.

)peration is not allowed within 15 miles of the coast or 50 miles of an estuary. -hromate %acket water

treatment must never be used. The condensate must be treated in order to destroy bacteria. -are must

be taken if chemicals are used to inhibit marine growth in pipework.

Vapor Compression

The boiler section is initially filled with fresh water. 0hen the system is operating feed water is

supplied via the level control valve. ot steam is created in the boiler which passes over into the main

section. ere the steam is mi!ed with a brine spray. .ome of the steam is condensed and some of the

brine spray is flashed off. The combined steam passes over to the vapour section via a scrubber. 7low of

vapour occurs due to the action of the compressor which increases the vapour pressure increaseing its

saturation temperature. The compressed vapour has a tendency to condense out and latent heat is given

up to the brien spray in the evaporator main section.

The produced condensate is pumped via the distillate pump, a proportion is fed to a desuperheater at the

compressor inlet, a further proportion passes to the boiler section maintaining water level. 'ny e!cess is

then delivered to distillate system via a heat e!changer were it is cooled by the e!hausted brine.

' recirculation pump draws brine from the brine well, a proportion of this is fed back to the well to maintin

a level, anouther proportion passes to the brine spray. E!cess is passed out of the brine blowdown

overboard.

The above description has been formed from interpretation of a not to great drawing. If anybody has

actually sailed with this system I would be grateful for a more accurate description.

Reverse Osmosis

)smosis describes the process whereby a fluid will pass from a more dense to a less dense solution

through a semi8permeable membrane. It is very important to the water absorbtion processes of plants.

() is a process which uses a semipermeable membrane which retains both salt and impurities from sea

water while allowing water molecules to pass. 7iltration of up to 90% is possible thus making the

produced water unsuitable for boiler feed without further conditioning. Improved $uality is possible using

a two or more pass system.

'n e!periment to determine this osmotic head is shown.

The parchment paper acts as the semi8permeable membrane and allows the water molecules

to pass but not the larger salt molecules.

(everse osmosis is the process whereby a pressure greater than the osmotic head pressure is

applied to a solution of high density. 7luid is forced from the high density side to the less dense side. 7or

desalination plants the pressure is applied to sea water and the water is forced through the semi8

permeable membrane.

The semi permeable membrane which is typically made of polyamide membrane sheets

wrapped in a spiral form around a perforated tube resembling a loosely wound toilet roll.

/esign of the cartridges is therefore such that the sea water feed passes over the membrane

sheets so that the washing action keeps the surfaces clear of deposits. ' dosing chemical is also in%ected

to assist the action.

The two membranes sealed on the outer three edges, enclose porous under8layer through

which the permeate spirals to central collecting tube

=ressurised feedwater passes lengthways through the tubular spiral wound membrane

element. 7reshwater permeate travels through the membrane layers as directed along a spiral bath inot a

central perforated tube, while brine is discharged out the end of the membrane element..

The fluid could be water and the solutions sea water. ;nder normal conditions the water would

pass from the less saline soultion to the more saline solution until the salinity was the same. This process

will cease however if the level in the more saline side raises to give a difference greater than the )smotic

height.

7or practical use to allow the generation of large $uantities of water. It is necessary to have a

large surface area of membrane which has sufficient mechanical strength to resist the pressurised sea

water.. The material used for sea water purification is spirally wound polyamide or polysulphonate sheets.

)ne problem with any filtration system is that deposits accumulate and gradually blocks the filter. The sea

water is supplied at a pressure of >0bar, a relief valve is fitted to the system. The )smosis production

plant is best suited to the production of large $uantities of water rather than smaller $uantities of steam

plant feed $uality.

Pretreatment and post treatment.

.ea water feed for reverse osmosis plant is pretreated before being passed through. The chemical sodium

he!a phosphate is added to assist wash through of salt deposits on the surface of the elements and the

sea water is steriliased to remove bacteria which could otherwise become resident in the filter. -hlorine is

reduced by compressed carbon filter while solids are removed by other filters. Treatment is also necessary

to make the water drinkable.

Rochem disc tube reverse osmosis plant

The disc tube module is supposed to have the main advantage over the spiral wound type in that it avoids

the need for the difficult cleaning processes re$uired. 0ith long lasting membranes, typically 5 years and

in built cleaning system the unit will recover 60% as pure water from sea water passing through it

You might also like

- Fresh Water Generator On Ships 2Document16 pagesFresh Water Generator On Ships 2Hamilton RamaNo ratings yet

- Function of Flash Evaporator & Fresh Water Generators For Ship Service SystemDocument3 pagesFunction of Flash Evaporator & Fresh Water Generators For Ship Service Systemmister_no34No ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Fresh Water Production Plants 1 DMOE2002Document16 pagesFresh Water Production Plants 1 DMOE2002Yohannes DennisNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Naval DiagramsDocument39 pagesNaval DiagramsAsif AliNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- FreshWater Generator On ShipsDocument22 pagesFreshWater Generator On Shipschristian pope100% (1)

- Flash Evaporator) : Fresh Water GeneratorDocument8 pagesFlash Evaporator) : Fresh Water Generatorpranab sakarNo ratings yet

- Fresh Water Generator On ShipsDocument11 pagesFresh Water Generator On ShipsGuruNo ratings yet

- Fresh Water Generator On ShipsDocument19 pagesFresh Water Generator On ShipsSheshraj VernekarNo ratings yet

- Fresh Water Geberator and Osmosis ProcessesDocument62 pagesFresh Water Geberator and Osmosis ProcessesSuhas KassaNo ratings yet

- FWG Explained (Autosaved)Document21 pagesFWG Explained (Autosaved)Junehenry YalduaNo ratings yet

- MArine Boiler Steam and WaterDocument3 pagesMArine Boiler Steam and Watermohammed ramzi CHAHBINo ratings yet

- BoilerDocument77 pagesBoilerChoudhry Waqas Uddin.No ratings yet

- This Doc. Is in Used Base On Simulator Class TutorialsDocument9 pagesThis Doc. Is in Used Base On Simulator Class TutorialsFatih KayalarNo ratings yet

- Fresh Water Generator GME 37Document30 pagesFresh Water Generator GME 37srinidhi246100% (1)

- Presentation Report-Converted 1Document11 pagesPresentation Report-Converted 1S.k. YadavNo ratings yet

- Feed Water System What Is A Feed System ?Document3 pagesFeed Water System What Is A Feed System ?Aayush AgrawalNo ratings yet

- Unit 5 - Freshwater From SeawaterDocument40 pagesUnit 5 - Freshwater From Seawaterbhauh4586No ratings yet

- Evaporators 2020Document28 pagesEvaporators 2020Rakesh SainiNo ratings yet

- Oily Water SeperatorsDocument38 pagesOily Water Seperatorsakusuper67% (3)

- Blowdown Systems EG 9 - 2 PDFDocument4 pagesBlowdown Systems EG 9 - 2 PDFcvolkan1No ratings yet

- Boiler Design and Operation PDFDocument8 pagesBoiler Design and Operation PDFChungNguyenNo ratings yet

- Steam Jet Refrigeration SystemDocument9 pagesSteam Jet Refrigeration SystemHenok GhidayNo ratings yet

- Fresh Water Generator or EvaporatorDocument3 pagesFresh Water Generator or EvaporatorAshenNo ratings yet

- Lesson System Theory and ConstructionDocument6 pagesLesson System Theory and Constructionmister pogiNo ratings yet

- Turbine AuxillariesDocument139 pagesTurbine AuxillariesAwez RanaNo ratings yet

- Steam and Condensate SystemDocument5 pagesSteam and Condensate SystemAayush AgrawalNo ratings yet

- Chapter A 07 Domestic SystemsDocument5 pagesChapter A 07 Domestic SystemsСергей КороткийNo ratings yet

- Unit 5 Auxiliaries 5.1. Distillation SystemsDocument8 pagesUnit 5 Auxiliaries 5.1. Distillation SystemsAlex CarlyNo ratings yet

- Spatty Desalination ProcessesDocument3 pagesSpatty Desalination ProcessesJohnNo ratings yet

- Marine Fresh Water GeneratorDocument6 pagesMarine Fresh Water Generatorazeezur100% (2)

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocument10 pagesEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNo ratings yet

- PPS Steam Boiler Operation and AuxiliariesDocument9 pagesPPS Steam Boiler Operation and AuxiliariesAraNo ratings yet

- Mech NotesDocument8 pagesMech NotesNihal AhamedNo ratings yet

- Basic Desuperheater TypesDocument28 pagesBasic Desuperheater Typesshan07011984100% (1)

- Fresh Water Generator or Evaporator Used On Ships BRAVO 2Document5 pagesFresh Water Generator or Evaporator Used On Ships BRAVO 2Dan EzraNo ratings yet

- Deaerator Working Principle: What Is Deaeration?Document4 pagesDeaerator Working Principle: What Is Deaeration?Freddy Mendoza CoronelNo ratings yet

- Boiler and Turbine For BOE ExamDocument71 pagesBoiler and Turbine For BOE Examkeerthi dayarathnaNo ratings yet

- Tip Sheet March R3Document2 pagesTip Sheet March R3Jorge MartinezNo ratings yet

- Basic Design and Cost Data On MEA Treating UnitsDocument6 pagesBasic Design and Cost Data On MEA Treating UnitsTuesou MachereNo ratings yet

- Main Steam System: Piping SystemsDocument10 pagesMain Steam System: Piping SystemssenakaNo ratings yet

- Lesson 2 PPSDocument6 pagesLesson 2 PPSmarpelNo ratings yet

- FWGDocument8 pagesFWGSWASTIK MISHRANo ratings yet

- Drum in BoilerDocument18 pagesDrum in BoilerRuban Kumar100% (1)

- Desuperheaters BasicsDocument16 pagesDesuperheaters Basicsaamer6789No ratings yet

- Forced Circulation EvaporatorDocument8 pagesForced Circulation EvaporatorNIDHARSHANA S100% (2)

- Condensate & UtilisationDocument3 pagesCondensate & Utilisationmohamed faragNo ratings yet

- B1 Freshwater GeneratorDocument32 pagesB1 Freshwater GeneratorAhmad Aslam MohamadNo ratings yet

- A Report On Boiler Feed WaterDocument11 pagesA Report On Boiler Feed WaterAustin UdofiaNo ratings yet

- UntitledDocument7 pagesUntitledafifiNo ratings yet

- High Pressure BoilerDocument8 pagesHigh Pressure BoilerAnand KalaniNo ratings yet

- Power Plant Instrumentation Unit 3Document4 pagesPower Plant Instrumentation Unit 3Mohit RanaNo ratings yet

- BKLT DeaeratorDocument24 pagesBKLT Deaeratormalikgaurav01No ratings yet

- 2004-07 Care & Maintenance of Water HeatersDocument2 pages2004-07 Care & Maintenance of Water HeatersMike PerryNo ratings yet

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Hydraulic SystemsDocument4 pagesHydraulic SystemsJitendra KumarNo ratings yet

- LiftingDocument5 pagesLiftingJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Halon 1301 Bromotrichlhoromethane CF3BrDocument2 pagesHalon 1301 Bromotrichlhoromethane CF3BrJitendra Kumar0% (1)

- Hull ConstructionDocument4 pagesHull ConstructionJitendra KumarNo ratings yet

- Hydraulic GovernorsDocument6 pagesHydraulic GovernorsJitendra KumarNo ratings yet

- Holding Down ArrangementsDocument3 pagesHolding Down ArrangementsJitendra KumarNo ratings yet

- Annex 6Document16 pagesAnnex 6Manusha MaureeNo ratings yet

- Gop-Uty-09 (CT 1)Document39 pagesGop-Uty-09 (CT 1)Warda YousafNo ratings yet

- Four Realms of Earth by SheefaDocument8 pagesFour Realms of Earth by SheefaDil Afroz100% (1)

- Course Outline: CHAPTER ONE (0.5 Week)Document4 pagesCourse Outline: CHAPTER ONE (0.5 Week)nimcanNo ratings yet

- Land Use and Water Quality Ciliwung RiverDocument8 pagesLand Use and Water Quality Ciliwung RiverTimmszdNo ratings yet

- Wicomico River Watershed Report 2020 PDFDocument8 pagesWicomico River Watershed Report 2020 PDFapi-251332269No ratings yet

- Efrigeration IR Ryer: RD SeriesDocument5 pagesEfrigeration IR Ryer: RD Seriesshanu vermaNo ratings yet

- Read The Material Below! 2. Make Sure That You Understand What The Material's Talking About!Document2 pagesRead The Material Below! 2. Make Sure That You Understand What The Material's Talking About!M FARHAN SNo ratings yet

- Design of An Atmospheric Water GeneratorDocument5 pagesDesign of An Atmospheric Water GeneratorBala Murali100% (1)

- Case StudiesDocument3 pagesCase StudiesMishti WadheraNo ratings yet

- PumpsDocument106 pagesPumpscarloNo ratings yet

- Pengukuran Boiler Pt. Bio Farma UNITDocument5 pagesPengukuran Boiler Pt. Bio Farma UNITfadhillafarizhaNo ratings yet

- Groundwater On Zanzibar - Erik HanssonDocument41 pagesGroundwater On Zanzibar - Erik Hanssonogamin5270% (1)

- Goulds PumpsDocument44 pagesGoulds PumpsCarlos Sagrit100% (1)

- FOSTER Et Al. 2010 Conjunctive Use of Groundwater and Surface WaterDocument26 pagesFOSTER Et Al. 2010 Conjunctive Use of Groundwater and Surface WaterNoman MustafaNo ratings yet

- MCQ Type QuestionDocument3 pagesMCQ Type QuestionSamuel DoggelaNo ratings yet

- Lesson 4.4 HeatDocument18 pagesLesson 4.4 HeatRais RahimiNo ratings yet

- Low-E Coated Glass U-Value and SHGC Value CalculationDocument1 pageLow-E Coated Glass U-Value and SHGC Value CalculationSatrio PrakosoNo ratings yet

- Some Liquid Holdup Experimental Data in Trickle-BedDocument6 pagesSome Liquid Holdup Experimental Data in Trickle-BedKrittini IntoramasNo ratings yet

- LNG Process Overview ShortDocument46 pagesLNG Process Overview ShortRobert Waters100% (2)

- Hydraulic Engineering Assignment-Week 3 Number of Questions: 12 Total Mark: 12 X 1 12Document7 pagesHydraulic Engineering Assignment-Week 3 Number of Questions: 12 Total Mark: 12 X 1 12gowricivilNo ratings yet

- Lab Petchem (Exp 4)Document13 pagesLab Petchem (Exp 4)Hafiz ImranNo ratings yet

- Caño Rondon-1 - PVT Final - ReportDocument51 pagesCaño Rondon-1 - PVT Final - ReportKarol RamirezNo ratings yet

- THAKURGAON GEO Code, DPHEDocument37 pagesTHAKURGAON GEO Code, DPHEMunnaf HossainNo ratings yet

- Meoh Dehydratation Reactor For Dme Production R-201Document3 pagesMeoh Dehydratation Reactor For Dme Production R-201ingegnere1234No ratings yet

- Outgassing of Vacuum materials-IIDocument15 pagesOutgassing of Vacuum materials-IIAbhik BhattacharyaNo ratings yet

- Science 3 PDFDocument12 pagesScience 3 PDFJelyn CandoNo ratings yet

- Pump Practice ProblemsDocument16 pagesPump Practice ProblemsKhaled SolimanNo ratings yet

- Townsend DischargeDocument5 pagesTownsend Dischargehermas67No ratings yet

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Roxane Gay & Everand Originals Presents: Good Girl: Notes on Dog RescueFrom EverandRoxane Gay & Everand Originals Presents: Good Girl: Notes on Dog RescueRating: 4.5 out of 5 stars4.5/5 (29)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- Merle's Door: Lessons from a Freethinking DogFrom EverandMerle's Door: Lessons from a Freethinking DogRating: 4 out of 5 stars4/5 (326)

- Roxane Gay & Everand Originals Presents: Good Girl: Notes on Dog RescueFrom EverandRoxane Gay & Everand Originals Presents: Good Girl: Notes on Dog RescueRating: 5 out of 5 stars5/5 (3)

- The Dog Who Couldn't Stop Loving: How Dogs Have Captured Our Hearts for Thousands of YearsFrom EverandThe Dog Who Couldn't Stop Loving: How Dogs Have Captured Our Hearts for Thousands of YearsNo ratings yet

- Will's Red Coat: The Story of One Old Dog Who Chose to Live AgainFrom EverandWill's Red Coat: The Story of One Old Dog Who Chose to Live AgainRating: 4.5 out of 5 stars4.5/5 (18)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- Show Dog: The Charmed Life and Trying Times of a Near-Perfect PurebredFrom EverandShow Dog: The Charmed Life and Trying Times of a Near-Perfect PurebredRating: 3.5 out of 5 stars3.5/5 (13)

- The Dog Listener: Learn How to Communicate with Your Dog for Willing CooperationFrom EverandThe Dog Listener: Learn How to Communicate with Your Dog for Willing CooperationRating: 4 out of 5 stars4/5 (37)

- An Eagle Named Freedom: My True Story of a Remarkable FriendshipFrom EverandAn Eagle Named Freedom: My True Story of a Remarkable FriendshipNo ratings yet

- Inside of a Dog: What Dogs See, Smell, and KnowFrom EverandInside of a Dog: What Dogs See, Smell, and KnowRating: 4 out of 5 stars4/5 (390)

- Your Dog Is Your Mirror: The Emotional Capacity of Our Dogs and OurselvesFrom EverandYour Dog Is Your Mirror: The Emotional Capacity of Our Dogs and OurselvesRating: 4 out of 5 stars4/5 (31)

- Dogland: Passion, Glory, and Lots of Slobber at the Westminster Dog ShowFrom EverandDogland: Passion, Glory, and Lots of Slobber at the Westminster Dog ShowNo ratings yet

- Lucky Dog Lessons: Train Your Dog in 7 DaysFrom EverandLucky Dog Lessons: Train Your Dog in 7 DaysRating: 4.5 out of 5 stars4.5/5 (41)

- Animals Make Us Human: Creating the Best Life for AnimalsFrom EverandAnimals Make Us Human: Creating the Best Life for AnimalsRating: 4.5 out of 5 stars4.5/5 (2)

- What Cats Want: An Illustrated Guide for Truly Understanding Your CatFrom EverandWhat Cats Want: An Illustrated Guide for Truly Understanding Your CatRating: 4.5 out of 5 stars4.5/5 (13)

- Edward's Menagerie: Dogs: 50 canine crochet patternsFrom EverandEdward's Menagerie: Dogs: 50 canine crochet patternsRating: 3 out of 5 stars3/5 (5)

- The Good Good Pig: The Extraordinary Life of Christopher HogwoodFrom EverandThe Good Good Pig: The Extraordinary Life of Christopher HogwoodRating: 4 out of 5 stars4/5 (282)

- Puppy Training 101: How to Train a Puppy, Training Your Own Psychiatric Service Dog, A Step-By-Step Program so your Pup Will Understand You!From EverandPuppy Training 101: How to Train a Puppy, Training Your Own Psychiatric Service Dog, A Step-By-Step Program so your Pup Will Understand You!Rating: 5 out of 5 stars5/5 (85)

- How to Be Your Dog's Best Friend: A Training Manual for Dog ownersFrom EverandHow to Be Your Dog's Best Friend: A Training Manual for Dog ownersRating: 4 out of 5 stars4/5 (120)

- I Am Bunny: How a ""Talking"" Dog Taught Me Everything I Need to Know About Being HumanFrom EverandI Am Bunny: How a ""Talking"" Dog Taught Me Everything I Need to Know About Being HumanRating: 4.5 out of 5 stars4.5/5 (8)

- Julia's Cats: Julia Child's Life in the Company of CatsFrom EverandJulia's Cats: Julia Child's Life in the Company of CatsRating: 4.5 out of 5 stars4.5/5 (24)

- Our Dogs, Ourselves: The Story of a Singular BondFrom EverandOur Dogs, Ourselves: The Story of a Singular BondRating: 4 out of 5 stars4/5 (21)