Professional Documents

Culture Documents

Jake Brake 1998 PDF

Uploaded by

victover0 ratings0% found this document useful (0 votes)

223 views10 pagesSERIES 60 SERVICE MANUAL All information subject to change without notice. FUEL INJECTOR HEIGHTS Models: 606XGKXX-Premium HP (1998 DDEC IV) 80. Mm (3.161 in.) Use tool J 42697 77. - 79.05 mm (3.092 - 3.112 in.)

Original Description:

Original Title

Jake Brake 1998.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSERIES 60 SERVICE MANUAL All information subject to change without notice. FUEL INJECTOR HEIGHTS Models: 606XGKXX-Premium HP (1998 DDEC IV) 80. Mm (3.161 in.) Use tool J 42697 77. - 79.05 mm (3.092 - 3.112 in.)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

223 views10 pagesJake Brake 1998 PDF

Uploaded by

victoverSERIES 60 SERVICE MANUAL All information subject to change without notice. FUEL INJECTOR HEIGHTS Models: 606XGKXX-Premium HP (1998 DDEC IV) 80. Mm (3.161 in.) Use tool J 42697 77. - 79.05 mm (3.092 - 3.112 in.)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 2-60-98 Rev. 12-7

The fuel injector height is measured using the required Injector Height Gage as listed

in Table 12-2. On engines equipped with a Jake Brake, move the handle on the

injector height gage to the alternate position, 90 to the shank. A height gage locating

hole is provided in the injector body on the machined surface contacted by the injector

clamp near the solenoid. See Figure 12-3.

Figure 12-3 Using Timing Gage on DDEC II, DDEC III, and DDEC IV

12.2 VALVE LASH, INJECTOR HEIGHT (TIMING) AND JAKE BRAKE LASH ADJUSTMENT

All information subject to change without notice.

12-8 From Bulletin 2-60-98 Rev. 6SE483 9610 1996 DETROIT DIESEL CORPORATION

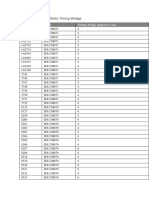

COMPONENTS SETTING DIMENSION TOLERANCE

FUEL INJECTOR HEIGHTS

Models: 6067GT40, 6067WT40,

6067WU40,6067GU40,

6063WU00,

6063GU00,6067WU60,

6067GU60, 6067GU91

(All DDEC I and DDEC II / 1986

- 1993)

78.2 mm

(3.078 in.)

Use tool J 35637-A

77.95 - 78.45 mm

(3.068 - 3.088 in.)

FUEL INJECTOR HEIGHTS

Models: 606XGKXX,

606XWKXX, 606XSKXX

(Most all DDEC III 1994-1997)

78.8 mm

(3.102 in.)

Use tool J 39697

77.55 - 79.05 mm

(3.092 - 3.112 in.)

FUEL INJECTOR HEIGHTS

Models: 606XGKXX-Premium

HP (1998 DDEC IV)

80.3 mm

(3.161 in.)

Use tool J 42665.

80.05 - 80.55 mm

(3.151 - 3.171 in.)

FUEL INJECTOR HEIGHTS

Models: 606XTKXX,

606XPKXX, 606XGKXX (1997

DDEC IV and later 1997 DDEC

III)

80.3 mm

(3.161 in.)

Use tool J 42665.

80.05 - 80.55 mm

(3.151 - 3.171 in.)

FUEL INJECTOR HEIGHTS

Models: 606XEKXX (1998

DDEC IV)

81.0 mm

(3.189 in.)

Use tool J 42749.

80.75 - 81.25 mm

(3.179 - 3.199 in.)

INTAKE VALVE CLEARANCE 0.203 mm

(.008 in.)

0.127 - 0.280 mm

(.005 - .011)

EXHAUST VALVE

CLEARANCE - * "U" Models:

6067GT40, 6067WT40,

6067WU40, 6067GU40,

6063XX00, (1986 - 1990 All

DDEC I & Early DDEC II)

0.508mm

(.020 in.)

0.432 - 0.584 mm

(.017 - .023 in.)

EXHAUST VALVE

CLEARANCE - * "H" Models:

6067WUXX, 606XGUXX,

606XGKXX, 606XWKXX,

606XSKXX, 606XTKXX,

606XPKXX, 606XEKXX

(1991 - 1998 All DDEC IV, III

and later DDEC II)

.660mm

(.026 in.)

0.584 - 0.736 mm

(.023 - .029 in.)

* "H" valves have a machined identification ring above the valve lock groove. "U" valves do not. Refer to section 1.4

for valve identification.

When setting injector heights or valve clearances, the component should be set to the "Setting Dimension"

shown.

XX Any character in these positions, set to the adjacent column.

Table 12-2 Checking Tolerance Chart

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 2-60-98 Rev. 12-9

NOTE:

When setting valve lash clearance or injector height, always set them to the dimension

listed in Table 12-2.

Adjust the valves and set the fuel injector heights as follows:

1. Disconnect starting power for engine.

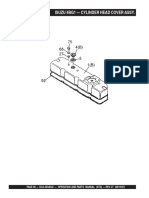

2. Remove the engine valve rocker cover as outlined. Refer to section 1.6.2 for

one-piece, refer to section 1.6.3 for two-piece rocker cover, and refer to section 1.6.5 for

three-piece rocker cover.

3. Insert a 3/4 in. drive breaker bar or ratchet into the square hole in the center of the

crankshaft pulley.

4. Bar the engine in the direction of rotation and observe the intake and exhaust valve rollers

at any cylinder that is close to TDC (top dead center). See Figure 12-4. Choose a

cylinder that has the exhaust valves almost completely closed. Just as the exhaust valves

are closing, the intake valves will start to open. This is the valve overlap period.

12.2 VALVE LASH, INJECTOR HEIGHT (TIMING) AND JAKE BRAKE LASH ADJUSTMENT

All information subject to change without notice.

12-10 From Bulletin 2-60-98 Rev. 6SE483 9610 1996 DETROIT DIESEL CORPORATION

1. Exhaust Valve Rocker Arm Assembly 4. Rocker Arm Shaft

2. Fuel Injector Rocker Arm Assembly 5. Cylinder Head

3. Camshaft 6. Intake Valve Rocker Arm Assembly

Figure 12-4 Valve Overlap Period

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 2-60-98 Rev. 12-11

5. Stop engine rotation at the time of valve overlap. Note which cylinder this is,

and follow the sequence listed in Table 12-2a to correctly set valves and injector

heights. The timing can be started with any cylinder in valve overlap.

Cylinder with

Valve Overlap

Set Valves on

Cylinder No.

Set Injector Height

on Cylinder No.

6 1 5

2 5 3

4 3 6

1 6 2

5 2 4

3 4 1

Table 12-2a Valve Lash and Injector Height Adjustment Sequence

NOTICE:

Never set the valves and injector of the same cylinder at the

same time. Doing this will result in engine damage.

6. To adjust the intake valves, insert a 0.203 mm (.008 in.) feeler gage between the

tip of the valve stem and the valve button at the end of the rocker arm. See

Figure 12-5.

12.2 VALVE LASH, INJECTOR HEIGHT (TIMING) AND JAKE BRAKE LASH ADJUSTMENT

All information subject to change without notice.

12-12 From Bulletin 2-60-98 Rev. 6SE483 9610 1996 DETROIT DIESEL CORPORATION

1. Intake Valve 4. Locknut

2. Valve Button 5. Feeler Gage

3. Intake Valve Rocker Arm Assembly 6. Tip of Intake Valve

Figure 12-5 Intake Valve Adjustment

7. Loosen the locknut, and turn the adjusting set screw until the feeler gage

produces an even smooth pull between the valve stem and valve button.

8. Tighten the locknut to 41 - 47 Nm (30 - 35 lbft) and remove the feeler gage.

Reinsert the feeler gage to ensure that the adjustment did not change when the

locknut was tightened. Readjust as necessary.

9. The exhaust valves are adjusted the same way as the intake valves, except use a

0.660 mm (.026 in.) feeler gage (1991 and later models only). Early models (pre-

1991 models) use 0.508 mm (.020 in.) feeler gage as listed in Table 12-2. See

Figure 12-6.

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 2-60-98 Rev. 12-13

1. Location of Identification Groove 5. Locknut

2. Valve Button 6. Exhaust Rocker Arm Assembly

3. Allen Wrench 7. Feeler Gage

4. Adjusting Screw 8. Tip of Exhaust Valve

Figure 12-6 Exhaust Valve Adjustment

NOTE:

Effective with all 1991 model year engines, a change was made to the exhaust valve

material which requires a different exhaust valve lash setting. Refer to section 1.4 for

exhaust valve identification.

10. After each set of intake and exhaust valves is adjusted, adjust the corresponding

injector listed in Table 12-2a. Injector height settings and tools are listed in Table

12-2.

11. For natural gas applications the valves are adjusted the same way as on the

diesel engine, except that a .032 in. (0.813 mm) feeler gage is used for exhaust

valves and a .011 in. (0.279 mm) feeler gage is used for intake valves.

12. Adjust the fuel injector height for the engine models in parentheses by placing

the small end of the height gage in the hole provided in the fuel injector body,

with the flat of the gage toward the fuel injector plunger. See Figure 12-3. The

injector height settings for Series 60 engines are listed in Table 12-2.

12.2 VALVE LASH, INJECTOR HEIGHT (TIMING) AND JAKE BRAKE LASH ADJUSTMENT

All information subject to change without notice.

12-14 From Bulletin 2-60-98 Rev. 6SE483 9610 1996 DETROIT DIESEL CORPORATION

13. Loosen the fuel injector rocker arm locknut and turn the adjusting set screw until

the extended part (flag) of the gage will just pass over the top of the injector

follower. An accurate "feel" will be developed. The objective is to adjust all six

injectors to the same feel. See Figure 12-7.

14. Tighten the locknut to 41 - 47 Nm (30 - 35 lbft). Check the adjustment with the

height gage and, if necessary, readjust the set screw. Remove the height gage.

1. Height Gage Flag 4. Set Screw

2. Height Gage 5. Locknut

3. Allen Wrench (3/16") 6. Fuel Injector Follower

Figure 12-7 Fuel Injector Height Adjustment

15. Refer to the adjusting sequence listed in Table 12-2a and proceed to the next

cylinder in the adjustment sequence.

16. Bar the engine over in the direction of normal rotation until the next cylinder in

the adjustment sequence is in its valve overlap period.

17. Repeat the valve adjustment and fuel injector height adjustments procedures

until all the valves and fuel injectors have been adjusted.

18. Replace the engine rocker cover.

19. Reconnect starting power to the engine.

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 2-60-98 Rev. 12-15

12.2.1 Slave Piston Adjustment (Jake Brake Lash)

Refer to information listed in Table 12-3 for the correct slave piston adjustment

specification.

NOTICE:

The slave piston adjustment procedure must be strictly followed.

Failure to use the proper adjustment procedure will result in poor

engine brake performance, serious engine damage, or both.

NOTE:

Slave piston clearance settings for the different engine models are not the same.

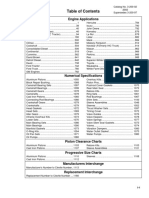

MODEL NUMBER/

DISPLACEMENT/MODEL

YEAR

ENGINE

BRAKE

SLAVE

PISTON ADJUSTMENT

6067WU40 11.1L PRE - 1991 760/760A 0.660 mm (.026 in.)

6067GU40 12.7L PRE - 1991 760/760A 0.508 mm (.020 in.)

6067WU60 11.1L 1991 - 93 760A 0.660 mm (.026 in.)

6067GU60 12.7L 1991 - 93 765 0.660 mm (.026 in.)

6067WK60 11.1L 1994 760A 0.660 mm (.026 in.)

6067GK60 12.7L 1994 765 0.660 mm (.026 in.)

6067WK28 11.1L 1994 760A 0.660 mm (.026 in.)

6067GK28 12.7L 1994 765 0.660mm (.026 in.)

6067EK60 11.1L 1998 DDEC IV 760B 0.6584mm (.023 in.)

6067TK60 12.7L 1998 DDEC IV 765A 0.6584mm (.023 in.)

6067PK60 12.7L 1998 DDEC IV 765A 0.6584mm (.023 in.)

Table 12-3 Jake Brake Models and Slave Piston Settings

NOTE:

Make the following adjustment with the engine stopped and cold with oil temperature

140F (60C) or below. The exhaust valves on the cylinder to be adjusted must be in

the closed position (rocker arm loose).

1. Back out the bridge leveling screw in the slave piston assembly until the end of

the screw is beneath the surface of the bridge in the slave piston assembly. See

Figure 12-8.

12.2 VALVE LASH, INJECTOR HEIGHT (TIMING) AND JAKE BRAKE LASH ADJUSTMENT

All information subject to change without notice.

12-16 From Bulletin 2-60-98 Rev. 6SE483 9610 1996 DETROIT DIESEL CORPORATION

1. Rocker Arm Adjusting Screw and Locknut 4. Bridge Leveling Screw Locknut

2. Slave Piston Adjusting Screw 5. Bridge

3. Locknut

Figure 12-8 Adjusting Slave Piston Screw

2. Place the required feeler gage listed in Table 12-3 between the solid side of the

bridge (the side without the leveling screw) and the exhaust rocker arm

adjusting screw.

NOTE:

The slave piston adjusting screws used in the Series 60 engine brake prior to August

1994 were reset screws. Reset screws are not to be dissembled in the field. Effective

with August 1994 engines, reset screw assemblies were replaced with Power-Lash

assemblies.

3. Turn the slave piston adjusting screw clockwise until a light drag is felt on the

feeler gage.

4. Hold the screw in this position and tighten the locknut to 34 Nm (25 lbft).

Remove the feeler gage.

Power-Lash is a registered trademark of Jacobs Vehicle Systems.

You might also like

- Adjust The Valves and N3 Fuel Injector Settings As Follows:: Series 60 Service ManualDocument4 pagesAdjust The Valves and N3 Fuel Injector Settings As Follows:: Series 60 Service ManualJavier Leyva Yuco100% (1)

- Ajuste de Valvulas PDFDocument8 pagesAjuste de Valvulas PDFRoberto Rincon RoblesNo ratings yet

- EUI Unit Injector AdjustmentDocument1 pageEUI Unit Injector AdjustmentPedro AparicioNo ratings yet

- DD15 and DD16 Axial Power Turbine Gear Box ManualDocument7 pagesDD15 and DD16 Axial Power Turbine Gear Box ManualRaul Gerardo Delatour CarreroNo ratings yet

- TT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselDocument2 pagesTT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselIonut-alexandru Iordache100% (1)

- Calibracion Inyector n3 Ddec VDocument6 pagesCalibracion Inyector n3 Ddec VJosue Juaniquina LucanaNo ratings yet

- 3122 ISX CM570 CM870 CM871 Static Injection Timing MeasureDocument7 pages3122 ISX CM570 CM870 CM871 Static Injection Timing Measureralph aris100% (1)

- Guia - Aplicacion - Frenos Jacobs - Detroit DieselDocument18 pagesGuia - Aplicacion - Frenos Jacobs - Detroit DieselJorge Castillo HdzNo ratings yet

- FAULT CODE 254 - Engine Fuel Shutoff Valve Driver Circuit - Voltage Below Normal or Shorted To Low SourceDocument7 pagesFAULT CODE 254 - Engine Fuel Shutoff Valve Driver Circuit - Voltage Below Normal or Shorted To Low Sourcemohammed abbasNo ratings yet

- 1127 Mid Stop Counterbore CuttingDocument7 pages1127 Mid Stop Counterbore Cuttingralph arisNo ratings yet

- 7SA742-0203 C2002 CH7 DDEC-IV Application and InstallationDocument38 pages7SA742-0203 C2002 CH7 DDEC-IV Application and Installationtgit28No ratings yet

- Especificaciones Motor Caterpillar C15Document2 pagesEspecificaciones Motor Caterpillar C15juan carlos rojas cadenaNo ratings yet

- DDEC V Wiring Diagram Updates: Engine & Vehicle Harness ChangesDocument1 pageDDEC V Wiring Diagram Updates: Engine & Vehicle Harness Changesrinho2013No ratings yet

- Axial Power Turbine (09TS13)Document2 pagesAxial Power Turbine (09TS13)ПавелNo ratings yet

- Detroit Diesel Serial Numbers DatabaseDocument17 pagesDetroit Diesel Serial Numbers DatabaseEduardo ColinNo ratings yet

- Dd15 FaultDocument19 pagesDd15 FaultSsNo ratings yet

- Ddec VDocument30 pagesDdec VeduardonemoNo ratings yet

- CPC Veh Int PDFDocument1 pageCPC Veh Int PDFHạcLãoNo ratings yet

- Installation of the Gear Train on a DD15 EngineDocument7 pagesInstallation of the Gear Train on a DD15 Enginefreddy100% (1)

- Cylinder Head: C15 On Highway EngineDocument11 pagesCylinder Head: C15 On Highway EngineJohan Ricardo HUANCA ESPINOZANo ratings yet

- Detroit DD15 Engine Demand DetroitDocument1 pageDetroit DD15 Engine Demand Detroitziad khalilNo ratings yet

- Detroit Series 60 EPA07 Engine Service ManualDocument945 pagesDetroit Series 60 EPA07 Engine Service ManualLarry100% (2)

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- Isuzu Engine - 4he1-Tc (Valve Adjustment) PDFDocument3 pagesIsuzu Engine - 4he1-Tc (Valve Adjustment) PDFTadas P100% (3)

- Detroit - 60 Series Service Tech ManualDocument4 pagesDetroit - 60 Series Service Tech Manualdot341100% (1)

- DDC SVC Bro 0002Document35 pagesDDC SVC Bro 0002SonthiMNo ratings yet

- 003-004 Overhead Set: General InformationDocument16 pages003-004 Overhead Set: General InformationIgoen YandriNo ratings yet

- Engine Throttle Model: Ela100: With Display and Monitoring SystemDocument35 pagesEngine Throttle Model: Ela100: With Display and Monitoring SystemNa HaNo ratings yet

- Additions, Revisions, or Updates: Subject DateDocument10 pagesAdditions, Revisions, or Updates: Subject DateEduardo TorresNo ratings yet

- Cummins T425a-Sct Service Manual PDFDocument2 pagesCummins T425a-Sct Service Manual PDFrectificamosNo ratings yet

- 21 60 03arevDocument4 pages21 60 03arevAdal VeraNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- MX13 PACCAR TorqueDocument8 pagesMX13 PACCAR TorqueMarcos Vinicius BinottoNo ratings yet

- DDC SVC MAN 0074 2007.application and Instalation S60Document348 pagesDDC SVC MAN 0074 2007.application and Instalation S60Antony MorenoNo ratings yet

- Injectores S 60 PDFDocument18 pagesInjectores S 60 PDFfranciscoNo ratings yet

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocument20 pagesDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNo ratings yet

- DieselNet Technology GuideDocument5 pagesDieselNet Technology Guidealoksemail2011No ratings yet

- Internal or External Leakage of The High Pressure Fuel System 2Document11 pagesInternal or External Leakage of The High Pressure Fuel System 2SatooAtheiNo ratings yet

- Cat C13, C15, C16,3408eDocument6 pagesCat C13, C15, C16,3408eMert KaygusuzNo ratings yet

- Detroit Diesel - Low Power Bulletin - MBE4000-07Document40 pagesDetroit Diesel - Low Power Bulletin - MBE4000-07Juan Pablo Montaño Rivas100% (1)

- Injector s60Document15 pagesInjector s60Alex Forero100% (7)

- No.: 04 TS-43Rev3: Detroit Diesel 13400 Outer Drive, West / Detroit, Michigan 48239-4001Document9 pagesNo.: 04 TS-43Rev3: Detroit Diesel 13400 Outer Drive, West / Detroit, Michigan 48239-4001Gutierrez EfrainNo ratings yet

- Tabla Timing Isx CumminsDocument3 pagesTabla Timing Isx CumminsRonald Gomez100% (3)

- Fault Code 2274: EGR Valve Differential Pressure Sensor Circuit - Shorted LowDocument3 pagesFault Code 2274: EGR Valve Differential Pressure Sensor Circuit - Shorted LowSuryadiNo ratings yet

- Detroit DD15 Engine: Horsepower LB-FT Torque LitersDocument10 pagesDetroit DD15 Engine: Horsepower LB-FT Torque Litersramsi17100% (1)

- Cylinder Head Removal D13A 211 76 1-8-06Document12 pagesCylinder Head Removal D13A 211 76 1-8-06Minn Thet NaingNo ratings yet

- DDEC FOR MBE (MBE 900/4000) Vehicle Interface Harness: Power WiringDocument1 pageDDEC FOR MBE (MBE 900/4000) Vehicle Interface Harness: Power WiringDayro Jose Geney OrtizNo ratings yet

- Eaton Ultrashift DM Heavy Duty Clutch Installation Guide Installation Instructions enDocument2 pagesEaton Ultrashift DM Heavy Duty Clutch Installation Guide Installation Instructions enSatooAtheiNo ratings yet

- Disassembly and Assembly Turbocharger RemovalDocument8 pagesDisassembly and Assembly Turbocharger RemovalВячеслав ШапочкаNo ratings yet

- 2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132 PDFDocument13 pages2013-12-09 220734 Mack mp8 Valve and Injector Adj pv776-89119132 PDFCristian Andrés Silva Salgado100% (1)

- Section 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModelDocument10 pagesSection 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModeldanyNo ratings yet

- 06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFDocument4 pages06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFSuryadiNo ratings yet

- 1-60-04 JacobsDocument2 pages1-60-04 JacobsRuben Antonio Huaranca CruzNo ratings yet

- Liner ProtrusionDocument8 pagesLiner Protrusionsidhu100% (1)

- Valve Lash For Cummins Engine K38Document9 pagesValve Lash For Cummins Engine K38Youssef Ali100% (1)

- Installation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsDocument4 pagesInstallation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsSean DuncanNo ratings yet

- Frlo Lightning Series Manual ServiceDocument98 pagesFrlo Lightning Series Manual ServiceAdal Vera100% (1)

- C15 E-Oil PressureDocument11 pagesC15 E-Oil PressureAndiNo ratings yet

- Figure12-10Usingtiminggageonddecii, Ddeciii, Andddeciv: Series 60 Service ManualDocument4 pagesFigure12-10Usingtiminggageonddecii, Ddeciii, Andddeciv: Series 60 Service ManualCris VenturaNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Water Pump PDFDocument2 pagesWater Pump PDFvictoverNo ratings yet

- Water Pump 2 PDFDocument2 pagesWater Pump 2 PDFvictoverNo ratings yet

- 6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyDocument2 pages6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyvictoverNo ratings yet

- Service Manual PDFDocument2 pagesService Manual PDFvictoverNo ratings yet

- Jake Brake 1998 PDFDocument10 pagesJake Brake 1998 PDFvictoverNo ratings yet

- Figure 6-18A Checking Wastegate CalibrationDocument6 pagesFigure 6-18A Checking Wastegate Calibrationvictover100% (2)

- Two-Bolt Camshaft PDFDocument7 pagesTwo-Bolt Camshaft PDFvictoverNo ratings yet

- Steel Piston 2 PDFDocument2 pagesSteel Piston 2 PDFvictoverNo ratings yet

- Two-Bolt Camshaft 2 PDFDocument1 pageTwo-Bolt Camshaft 2 PDFvictoverNo ratings yet

- Steel Piston PDFDocument14 pagesSteel Piston PDFvictoverNo ratings yet

- Series 60 Service Manual: From Bulletin 19-60-98 1-288cDocument2 pagesSeries 60 Service Manual: From Bulletin 19-60-98 1-288cvictoverNo ratings yet

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionDocument2 pages8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverNo ratings yet

- Guidelines Water Pump 2 PDFDocument2 pagesGuidelines Water Pump 2 PDFvictoverNo ratings yet

- Figure 12-9 Adjusting Leveling Screw: Series 60 Service ManualDocument2 pagesFigure 12-9 Adjusting Leveling Screw: Series 60 Service ManualvictoverNo ratings yet

- Figure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service ManualDocument2 pagesFigure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service Manualvictover100% (1)

- Tool Number Tool Name: Table 1-43 Engine-Cylinder BlockDocument2 pagesTool Number Tool Name: Table 1-43 Engine-Cylinder BlockvictoverNo ratings yet

- Jake Brake 1998 3 PDFDocument2 pagesJake Brake 1998 3 PDFvictoverNo ratings yet

- 13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualDocument2 pages13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualvictoverNo ratings yet

- This Page Intentionally Left Blank.: Series 60 Service ManualDocument2 pagesThis Page Intentionally Left Blank.: Series 60 Service ManualvictoverNo ratings yet

- Guidelines Water Pump 3 PDFDocument2 pagesGuidelines Water Pump 3 PDFvictoverNo ratings yet

- Figure 2-12 Electronic Unit Injector Terminal InstallationDocument2 pagesFigure 2-12 Electronic Unit Injector Terminal InstallationvictoverNo ratings yet

- 13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualDocument2 pages13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualvictoverNo ratings yet

- Figure 1-301 Gasket Eliminator Application: Series 60 Service ManualDocument2 pagesFigure 1-301 Gasket Eliminator Application: Series 60 Service ManualvictoverNo ratings yet

- 1.16.1 Repair or Replacement of Flywheel HousingDocument2 pages1.16.1 Repair or Replacement of Flywheel HousingvictoverNo ratings yet

- Front Camshaft 2 PDFDocument2 pagesFront Camshaft 2 PDFvictoverNo ratings yet

- Engine Coolant PDFDocument1 pageEngine Coolant PDFvictoverNo ratings yet

- Forged Steel Piston PDFDocument14 pagesForged Steel Piston PDFvictoverNo ratings yet

- Engine Coolant 2 PDFDocument3 pagesEngine Coolant 2 PDFvictoverNo ratings yet

- Flywheel 2 PDFDocument4 pagesFlywheel 2 PDFvictoverNo ratings yet

- Drain Water Pump PDFDocument2 pagesDrain Water Pump PDFvictoverNo ratings yet

- Manual Doosan P126TI DP126 PU126TIDocument238 pagesManual Doosan P126TI DP126 PU126TIFederico FigueroaNo ratings yet

- EG6500CXS13Z30B03Document119 pagesEG6500CXS13Z30B03Duala ServiciosNo ratings yet

- Part Cat-Soil Compactor BW 212Document218 pagesPart Cat-Soil Compactor BW 212Dhru Ti100% (7)

- Regulagem de Válvulas (C15 C18)Document3 pagesRegulagem de Válvulas (C15 C18)caiocunhaconquistaNo ratings yet

- Crane Cams Master CatalogDocument366 pagesCrane Cams Master CatalogcehaiguNo ratings yet

- 2.7L Dohc EngineDocument327 pages2.7L Dohc EngineJuan Mederos50% (2)

- Vocational Teacher (Maintenance and Repairs of Automobiles)Document7 pagesVocational Teacher (Maintenance and Repairs of Automobiles)Brandon AllenNo ratings yet

- VIS Standard and Wheel Motors 45 Series: Parts and Repair InformationDocument14 pagesVIS Standard and Wheel Motors 45 Series: Parts and Repair Informationeaglego00No ratings yet

- TTR110 2012 PDFDocument46 pagesTTR110 2012 PDFBrayan smith Torres ramirezNo ratings yet

- Catalogue Clevite PDFDocument969 pagesCatalogue Clevite PDFSARL MEHMELNo ratings yet

- Isuzu 4Bg1 - Cylinder Head Cover AssyDocument75 pagesIsuzu 4Bg1 - Cylinder Head Cover AssyTasha RozsokhaNo ratings yet

- Service Buletin 07-2965DDocument29 pagesService Buletin 07-2965DAgustinus KNo ratings yet

- Manual de Mantenimiento de Motor Mitsubishi S4S de Mini Cargador CATDocument12 pagesManual de Mantenimiento de Motor Mitsubishi S4S de Mini Cargador CATchristian100% (1)

- 2016 Flomatic Valve Price ListDocument40 pages2016 Flomatic Valve Price ListShahlan Anuar100% (2)

- 1mzfe Engine - Technical - Description (Toyota Camry) PDFDocument138 pages1mzfe Engine - Technical - Description (Toyota Camry) PDFleonel.nunez7651100% (5)

- Hydraulic Directional Control and Check Valves PDFDocument28 pagesHydraulic Directional Control and Check Valves PDFjagoda gjorgjevicNo ratings yet

- Ford Ranger PX MK II SpecificationsDocument62 pagesFord Ranger PX MK II SpecificationsTulio MooreNo ratings yet

- Lista de Peças Novas PT2 C PreçoDocument3 pagesLista de Peças Novas PT2 C PreçovitrinetecnicaNo ratings yet

- Northen LightDocument67 pagesNorthen Lightmohd tawfikNo ratings yet

- Product - Selection - Guide RexrothDocument76 pagesProduct - Selection - Guide RexrothTokowi AutopartsNo ratings yet

- Parts Manual: Shibaura Diesel EngineDocument44 pagesParts Manual: Shibaura Diesel EngineFelipe donosoNo ratings yet

- JISS Exam 1EDocument6 pagesJISS Exam 1ESpasojeNo ratings yet

- Parts Manual Perkins 404c-22Document136 pagesParts Manual Perkins 404c-22Julio Ramirez100% (4)

- Jl150 70c Comanche Spare Parts CatalogueDocument107 pagesJl150 70c Comanche Spare Parts CataloguePalata VipNo ratings yet

- WSM - ttx25 - 3 (Uputstvo Za Rukovanje Sa Amortizerima Olnix TTX 25)Document24 pagesWSM - ttx25 - 3 (Uputstvo Za Rukovanje Sa Amortizerima Olnix TTX 25)AmiljkovicviNo ratings yet

- Engine Parts: Laboratory Exercise 3Document5 pagesEngine Parts: Laboratory Exercise 3Milx Jyms AvilaNo ratings yet

- Manual D4EBDocument91 pagesManual D4EBDaniel Martinez100% (1)

- Manual de Partes Motor 6.8lDocument55 pagesManual de Partes Motor 6.8lIgnacio50% (2)

- EM-2900DQ Generator Service ManualDocument7 pagesEM-2900DQ Generator Service Manualrahmat teaNo ratings yet

- 924K Wheel Loader PWR00001-UP (MACHINE) POWERED BY C6.6 Engine (SEBP5135 - 70) - Sistemas y Componentes 1 PDFDocument2 pages924K Wheel Loader PWR00001-UP (MACHINE) POWERED BY C6.6 Engine (SEBP5135 - 70) - Sistemas y Componentes 1 PDFubaldo caraballoNo ratings yet