Professional Documents

Culture Documents

Turbo Jet Engine

Uploaded by

Silvano Villarroel Pineda67%(3)67% found this document useful (3 votes)

290 views33 pagesThe group designed and built a jet turbine engine using an automotive turbocharger. They encountered issues with ignition, fuel distribution, and structural integrity during testing. While the engine did not achieve self-sustained operation, the project provided valuable experience in jet engine design and helped identify areas for improvement. Moving forward, the group would implement changes like additional spark plugs, water cooling, and full instrumentation to optimize performance.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe group designed and built a jet turbine engine using an automotive turbocharger. They encountered issues with ignition, fuel distribution, and structural integrity during testing. While the engine did not achieve self-sustained operation, the project provided valuable experience in jet engine design and helped identify areas for improvement. Moving forward, the group would implement changes like additional spark plugs, water cooling, and full instrumentation to optimize performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

290 views33 pagesTurbo Jet Engine

Uploaded by

Silvano Villarroel PinedaThe group designed and built a jet turbine engine using an automotive turbocharger. They encountered issues with ignition, fuel distribution, and structural integrity during testing. While the engine did not achieve self-sustained operation, the project provided valuable experience in jet engine design and helped identify areas for improvement. Moving forward, the group would implement changes like additional spark plugs, water cooling, and full instrumentation to optimize performance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 33

T J Turbocharger Jet

Turbine Engine Turbine Engine

James Ravesi Brandon Berntsen

Tony Cerqueira

Group 1

1

Presentation Overview PresentationOverview

ProposalofSeniorDesignProject/Objectives p g j / j

Estimated/ActualBudget

How Does a Jet Engine Work? HowDoesaJetEngineWork?

PartsRequired

HypotheticalDataandAcquisitionMethods

BuildProcessandSpecifications p

TestingProblems/Ramifications

What We Would Do Differently WhatWeWouldDoDifferently

2

Proposed Project ProposedProject

Turbocharger Jet Engine TurbochargerJetEngine

Objectives

Design and build a jet Designandbuildajet

turbineengineutilizinga

standardautomotiveturbo

Haveafunctioningjet

enginethatwecanuseto

measure power output, measurepoweroutput,

shaftspeed,exhaustgas

temperature,andthrust.

3

Homemade Jet Turbine Engine HomemadeJetTurbineEngine

4

Were Objectives Met? WereObjectivesMet?

Were we successful at building a working jet Werewesuccessfulatbuildingaworkingjet

engine?

Yes Yes

W f l t tt i i l ? Werewesuccessfulatattainingvalues?

No?

5

Budget Budget

Estimated: $300400 Estimated:$300 400

Actual:

Item Supplier Quantity Cost

($)

pp y

Turbocharger Rick'sTruckCenter 1 Free

FuelPump JimRavesi 1 Free

OilPump JimRavesi 1 Free

FuelNozzle AES BMA 1 Free

EGT Digital Readout AES BMA 1 Free EGTDigitalReadout AES BMA 1 Free

StainlessSteel:Tubingand

Flanges

AES BMA 23ft Free

3/8"BallValve Lowe's 1 7.58

FittingsandRubberTubing Lowe's 5 8.40

1.5"FlexibleCoupling Lowe's 1 3.80

SparkPlugBung ConsumerAutoParts 1 8.49

LongThrowPlug HomeDepot 1 12.99

OmronSensor Ebay 1 29.99

Misc.Hardware/Materials TonyCerqueira N/A Free

Total $71.25

6

How Does a Jet Engine Work? HowDoesaJetEngineWork?

AJetengineiscomprisedof: Jet e g e s co p sed o :

o Anaircompressor comprisedoffanbladesthat

rotateinordertoincreasethemassflowofairinto

th i theengine;

o Acombustionchamber wherefuelisinjectedand

mixedwiththecompressedairtoinitiatethe p

combustionprocess;

o Anexhaust alsocomprisedoffanbladesthatusethe

h t d i f th b ti h b t t t exhaustedairfromthecombustionchambertorotate

theshaftthatrotatesthecompressorbladestoallow

forselfpropulsionofthejetengine.

7

PartsRequiredtoBuildaWorkingJet

Engine

Major components: Majorcomponents:

aTurbocharger

Combustion Chamber CombustionChamber

CombustionShell

Flame tube Flametube

IgnitionSystem

Fuel Pump Motor FuelPumpMotor

8

Hypothetical Data HypotheticalData

PrimaryValues:

Thrust=23.2lbs

ShaftSpeed=144,000RPM

MaxMassFlowRateofAir=0.558lbs/s

ExhaustGasTemperature(EGT)=1195F

ValueswereattainedusingaprogramcalledJetSpecs

TurboAnalysis y

Valuesweredependentondiametersofinducer,hub,and

exhaustoutlet.

9

Sensors for Data Acquisition SensorsforDataAcquisition

Omron Optical Sensor connected to a OmronOpticalSensorconnectedtoa

Multimeter

RecordRotationalShaftSpeed p

ThermocouplewithaDigitalReadout

RecordEGT

AnalogPressureGage

Combustion Chamber Pressure CombustionChamberPressure

LiquidFilledAnalogFuelPressureGage

Record Fuel Inlet Pressure RecordFuelInletPressure

10

Omron Optical Sensor OmronOpticalSensor

To determine EGT Thrust Fuel Pressure and TodetermineEGT,Thrust,FuelPressureand

CombustionPressureatgivenRPMto

determine efficiencies determineefficiencies.

OpticalSensor/PhotoInterruptor

H f h f 5000 l d Hasarefreshrateof5000cyclespersecond

Howwoulditwork:

Hookeduptomultimetertomeasurefrequency

(Hz),multiplythisvalueby60toattainRPMvalue

11

Series40TDigitalThermocouple/RTD

h TemperatureSwitch

JseriesThermocouple p

TemperatureRange:40 1500F

ConnectedtoaLoveController

120Voltinput

12

Analog Pressure Gage AnalogPressureGage

Measure Air Pressure of air entering Combustion MeasureAirPressureofairenteringCombustion

Chamber

13

Liquid Filled Analog Pressure Gage LiquidFilledAnalogPressureGage

Measure Fuel Pressure MeasureFuelPressure

goingintoFuelNozzle

HelptoregulateFuel p g

Pressure

Allowforgraph

correlationsofShaft

SpeedandEGTafter

steadystatehasbeen steady state as bee

reached

PressureRange:0100psi

14

Build and Specifications BuildandSpecifications

Turbocharger Turbocharger

CombustionChamber

Shell and Flame tube ShellandFlametube

IgnitionSystem

Fuel Pump System FuelPumpSystem

15

Turbocharger Turbocharger

Type: Garrett Turbo TB28 Type:GarrettTurboTB28

AcquiredfromRicksTruckCenter

C ff f t t l d Ni UD120 4 6L 4 l CameoffofatotaledNissanUD1204.6L4cyl

TurboDieselboxtruck

R i d di bl d l b f Requireddisassemblyandcleanupbefore

properfunctioncouldbeachieved.

16

Sandblasting Sandblasting

Before After Before After

17

Corrosion Clean CorrosionClean

Before After Before After

18

Combustion Chamber CombustionChamber

CombustionShell

Comprised of 304L 0.060 Stainless Comprisedof304L0.060 Stainless

Steel.

Lasercuttospecifications,rolledand

weldedtocombustionchamber

shape.

Di i 6 Di X 12 L th Dimensions 6Dia.X12Length

Flametube

Comprisedof304L0.125wall

StainlessSteeltubing.

Required drilling of holes to allow for Requireddrillingofholestoallowfor

airflowintoflametube.

Dimensions 5Dia.X11.5Length

HoleSpecifications:

Primary 24 x 0.201 Dia. Primary 24x0.201 Dia.

Secondary 15x0.209Dia.

Tertiary 21x0.2813Dia.

o Specificationsacquiredfrom

Combustorprogram p g

19

Combustion Shell CombustionShell

Combustion Shell Flame tube CombustionShell Flametube

20

Ignition System IgnitionSystem

ForcedAir Heater Spark Plug and Fuel Nozzle Forced AirHeaterSparkPlugandFuelNozzle

Comprisedofafuelnozzleandasparkplug

inserted in the back of the flame tube insertedinthebackoftheflametube.

Nozzleatomizesdieselfuelforcombustion,

h f 0 8 h 80 hasasprayrateof0.8gphat80.

Sparkplugusedtoignitefuel.

21

Ignition System IgnitionSystem

22

Fuel Delivery System FuelDeliverySystem

Sundstrand Oil Burning SundstrandOilBurning

FurnacePump

100psipumping

pressure

Pumprotatesat3450

RPM RPM

120Volts

23

Turbocharger Jet Engine Assembly TurbochargerJetEngineAssembly

24

Testing Obstacles TestingObstacles

Initialconditionofturbocharger

Ignitionandcombustionissuesduetoplacementoffuelinjectorandspark

plug

Modifiedsparkplugdidnotthreadinwithoutbending p p g g

Neededastrongsparkandacapandrotorwasntworking

0.6gphnozzledidnthaveenoughspread.0.8gphdistributedthefuel

better for more efficient combustion betterformoreefficientcombustion

Fuellinesrupturing/blowingofffittings

StartingissuesduetoinsufficientRPMs

W i d h h i b i ll d li d f l Wenoticedthattheenginewasnotcombustingalldeliveredfuel

Fuelpumpfailurebecauseofinternalissuesandbleeding

25

Preliminary Testing PreliminaryTesting

Testing Stages TestingStages

Stage1 IgnitionSystem:Testedhowtogenerate

enough voltage for the spark plug to function enoughvoltageforthesparkplugtofunction

Stage2 Testedhowtoeffectivelyignitespecified

fuels (gasoline and diesel) fuels(gasolineanddiesel)

Stage3 Testedplacementoffuelnozzleand

sparkplug:determiningsufficientairflowthrough p p g g g

flametubeorifices

Stage4 TestedwhetherJetEnginewasself

sustaining

26

What Went Wrong WhatWentWrong

Although it is unknown the exact cause of the failure, Althoughitisunknowntheexactcauseofthefailure,

themostlikelyreasonsare:

ExcessiveRPMsthatweremuchhigherthanwhatthe

turbowascapableofpossiblyproducedadestructive

rotationalresonanceoftheshaft.

Intense heat rate without letting metal gradually increase Intenseheatratewithoutlettingmetalgraduallyincrease

intemperature.

Destructivefailureinwhichtheheatcausedthemetal

bladestoexpandandcomeincontactwiththeturbine

housingwalls.

27

What We Would Do Differently WhatWeWouldDoDifferently

Add another spark plug to burn fuel more Addanothersparkplugtoburnfuelmore

symmetrically.

Have water cooling set up to reduce the heat Havewatercoolingsetuptoreducetheheat

withintheturbinebearings.

U l l l ll f i Useacontrolpaneltocontrolallfunctions

andindicatorsoftheenginestatus.

28

Future Direction FutureDirection

Use a larger turbo to attain higher thrust Usealargerturbotoattainhigherthrust

value.

Have full instrumentation rigged during all Havefullinstrumentationriggedduringall

testingphases.

T i b i h b i Tryvariouscombustionchambersizesto

acquirepeakefficiencyforthespecified

bi turbine.

29

Was Our Project Successful? WasOurProjectSuccessful?

Ourprojectwasasuccessbecauseweresearched,designed, p j , g ,

built,andfullyunderstoodthemethodsandprocessinvolved

inengineeringajetturbineengine.

Alth h bl t if d t i d l Althoughwewereunabletoverifyourpredeterminedvalues,

weareconfidentthat,givenanotheropportunity,wewould

meetallofourgoals.

Wehavelearnedtheriskandpossiblemalfunctionsthatcan

ariseduringturbineoperation.

F k d d i W h FromourcourseworkandeducationatWentworthwewere

abletosuccessfullycompletetheengineeringprocess

involvedindesigningaprototypefromwhichwecouldcollect

data.

30

Summary Summary

Successfully researched designed and built a Successfullyresearched,designedandbuilta

functioningJetTurbineEngineutilizingan

automotive Turbocharger automotiveTurbocharger.

Wewereunabletoacquireexpecteddatadue

to the physical failure of the engine tothephysicalfailureoftheengine.

Providedadetailedbuildlogofallnecessary

d d i difi i componentsanddesignmodificationsto

illustratetheabilitytoconstructajetengine.

OurWebsite

31

Special Thank to: SpecialThankto:

AssociatedEnvironmentalSystems BMA y

BeranPeter

DavidRockyRockwood

Matt Linder MattLinder

JimNolan

NathanSimmers

MikeAmato

RowlandInstituteatHarvard

Don Rogers DonRogers

Family

VictorPereira

AntonioCerqueira

32

Visual Representation VisualRepresentation

33

You might also like

- Electronic Injection Diagnostic Ebook PDFDocument65 pagesElectronic Injection Diagnostic Ebook PDFscan soft100% (1)

- 2019 RAM 2500 3500 HD SPECb9pubslq0dtc0jv02h78j270gkDocument13 pages2019 RAM 2500 3500 HD SPECb9pubslq0dtc0jv02h78j270gkAnthony Da Silva GuglielmettoNo ratings yet

- Thomas Kamps - Model Jet Engines - 190037191XDocument109 pagesThomas Kamps - Model Jet Engines - 190037191Xllagosti94% (17)

- Build Your Own TurbineDocument16 pagesBuild Your Own TurbineJack D'Roca100% (5)

- Fuel Injection SystemDocument32 pagesFuel Injection SystemVamsidhar GannavarapuNo ratings yet

- Model Aeroplane Building: Ffi$Ruqilj - Rrulnry - (LDocument189 pagesModel Aeroplane Building: Ffi$Ruqilj - Rrulnry - (LMohammad ZolghadrNo ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinultimatesrNo ratings yet

- Basic Aeronautics For ModellersDocument150 pagesBasic Aeronautics For Modellersasturkong100% (6)

- Home Built Model Turbines (WWW - Asec.ir)Document104 pagesHome Built Model Turbines (WWW - Asec.ir)motaznasser117100% (5)

- Engine DesignDocument15 pagesEngine DesignAbdul-Wahab Anwar100% (10)

- Ignition SystemDocument10 pagesIgnition SystemParag100% (1)

- EM - DX12 - Engine Manual (950106-072001EN) - ENDocument140 pagesEM - DX12 - Engine Manual (950106-072001EN) - ENIfan saputroNo ratings yet

- Configuration Design and Optimisation Study of A Compound GyroplaneDocument9 pagesConfiguration Design and Optimisation Study of A Compound Gyroplaneteuap100% (1)

- Hornet Planos Ensamble FuselajeDocument24 pagesHornet Planos Ensamble FuselajeJorge Gonzalez100% (1)

- SPinfo 1 PDFDocument127 pagesSPinfo 1 PDFSteven PollardNo ratings yet

- Scrib RamjetDocument34 pagesScrib RamjetNafis Zahran Ed100% (1)

- Fabrication of Remote Control PlaneDocument37 pagesFabrication of Remote Control Planekaushal24420% (1)

- RC Plane Engine-1Document1 pageRC Plane Engine-1api-269386057No ratings yet

- Model AirplaneDocument66 pagesModel Airplanerandom person97% (33)

- MW54 ModellingDocument141 pagesMW54 ModellingThomas Dickinson67% (3)

- PC40MR-2: IntroductoryDocument2 pagesPC40MR-2: IntroductoryFrederikusNo ratings yet

- EAA - EAA Experimenter - A Tool For Understanding Power, Drag, and Prop Design PDFDocument4 pagesEAA - EAA Experimenter - A Tool For Understanding Power, Drag, and Prop Design PDFdjaverNo ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew Skillinpinchi877012No ratings yet

- Available ComponentsDocument8 pagesAvailable ComponentsMolly Hegarty-PetersenNo ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinguruseenuNo ratings yet

- Wren 44i Gold Thrust Instructions - 2016Document27 pagesWren 44i Gold Thrust Instructions - 2016AurangzebNo ratings yet

- MW 54 Turbo Jet Engine InstructionsDocument39 pagesMW 54 Turbo Jet Engine InstructionsPREVISTONo ratings yet

- Mtosport Maintenance PDFDocument191 pagesMtosport Maintenance PDFBen FriskneyNo ratings yet

- Combustion in Si EngineDocument20 pagesCombustion in Si EngineAliza BalochNo ratings yet

- KJ-66 DRW Pics SetupDocument29 pagesKJ-66 DRW Pics Setupandressosa157% (7)

- Parts Catalogue: SUPER Splendor (May, 2012)Document96 pagesParts Catalogue: SUPER Splendor (May, 2012)JimJiang100% (3)

- Thomas Kamps Model Jet EnginesDocument109 pagesThomas Kamps Model Jet EnginesMustafa Umut Sarac100% (2)

- Jet Powered Models, Pulse JetsDocument5 pagesJet Powered Models, Pulse JetsBalaji AeroNo ratings yet

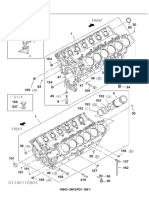

- SK210 LC8Document675 pagesSK210 LC8MEHA6502100% (33)

- Advanced Vibration Analysis On Gear Box TrainDocument25 pagesAdvanced Vibration Analysis On Gear Box Trainoded98100% (1)

- Service Manual Classic 500 & 350 PDFDocument229 pagesService Manual Classic 500 & 350 PDFAvinash Kumar100% (1)

- GiroplanoDocument14 pagesGiroplanooscarin1119No ratings yet

- Constructing A Turbocharger Turbojet EngineDocument52 pagesConstructing A Turbocharger Turbojet Enginerocketman19911No ratings yet

- Gbeer 50Document132 pagesGbeer 50Audinda LeiniaNo ratings yet

- Pulse Detonation Engine: Nitish Kumar Regd No:-0701223318Document16 pagesPulse Detonation Engine: Nitish Kumar Regd No:-0701223318Vishal KumarNo ratings yet

- Technical Specification Jet-288 - ENDocument21 pagesTechnical Specification Jet-288 - ENAndi PurwantoNo ratings yet

- Flight and Operation Manualfor Gyroplane CalidusDocument132 pagesFlight and Operation Manualfor Gyroplane CaliduslegouluNo ratings yet

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- RC Airplane Radio SystemsDocument8 pagesRC Airplane Radio SystemsDanh Le CongNo ratings yet

- Jet EnginesDocument32 pagesJet EnginesFelichi Dacumos Balajadia50% (2)

- Optimizing Blended Winglet Radii On Homebuilt Canard Aircraft PDFDocument9 pagesOptimizing Blended Winglet Radii On Homebuilt Canard Aircraft PDFYvess100% (1)

- f32 Am1a Briz Motors Technical and Repair ManualDocument131 pagesf32 Am1a Briz Motors Technical and Repair ManualAndres Sorin100% (2)

- Choosing A Turbo - For TurbojetDocument4 pagesChoosing A Turbo - For TurbojetavinashmenonNo ratings yet

- Export Sites Kitplanes 03 Data Media Pdfs Kitplanes 1214Document108 pagesExport Sites Kitplanes 03 Data Media Pdfs Kitplanes 1214Ahmad UsmanNo ratings yet

- PK 404 - GN65629NDocument149 pagesPK 404 - GN65629NLidianeNo ratings yet

- Ramjets & Pulse JetsDocument10 pagesRamjets & Pulse JetsInterogator5No ratings yet

- Nozzle Design Optimization To Reduce Noice For Turbo Jet EngineDocument16 pagesNozzle Design Optimization To Reduce Noice For Turbo Jet EngineSri Tech EngineeringNo ratings yet

- 2007 CatalogDocument129 pages2007 CatalogmendperNo ratings yet

- Kitfox Model 5 With ExtrasDocument20 pagesKitfox Model 5 With ExtrasrcbifNo ratings yet

- Chap4 InstructionsDocument19 pagesChap4 InstructionscriNo ratings yet

- A600 Talon Info Pac PDFDocument12 pagesA600 Talon Info Pac PDFRuham Pablo ReisNo ratings yet

- T-100D Mariah Q&ADocument8 pagesT-100D Mariah Q&AJorge BarnettNo ratings yet

- Development in The Performance of Valve Less Pulsejet EngineDocument3 pagesDevelopment in The Performance of Valve Less Pulsejet EngineInternational Journal of Science and Engineering InvestigationsNo ratings yet

- CH750 Parts ListDocument107 pagesCH750 Parts Listefetheace100% (1)

- Voievozi RomaniDocument81 pagesVoievozi RomaniRăzvan CurcăNo ratings yet

- Engine Components and Operation: AGME 1613 Fundamentals of Agricultural Systems TechnologyDocument37 pagesEngine Components and Operation: AGME 1613 Fundamentals of Agricultural Systems TechnologyBest NnodimNo ratings yet

- AT Tractor Division Hindustan Machine ToolsDocument31 pagesAT Tractor Division Hindustan Machine ToolsRahul HansNo ratings yet

- UNIT I: Basic of I C EngineDocument142 pagesUNIT I: Basic of I C EngineAnand KesarkarNo ratings yet

- Industial Training PPT On Shri Ram PistonsDocument30 pagesIndustial Training PPT On Shri Ram PistonsSanjog Singh33% (6)

- Topic1 ICEDocument41 pagesTopic1 ICEsheilaNo ratings yet

- Engine SystemsDocument87 pagesEngine SystemsprabhjotbhangalNo ratings yet

- Project Pulse Jet EngineDocument18 pagesProject Pulse Jet EngineJoel Kevin SaldanhaNo ratings yet

- Converting Energy To PowerDocument43 pagesConverting Energy To PowerAunaunZaa'No ratings yet

- Cummins ISL-G Webinar 2018 - Final-V2Document42 pagesCummins ISL-G Webinar 2018 - Final-V2Kadir Koray BozyelNo ratings yet

- Deutz Engine B-F L 1011F B-FM 1011F Operation Manual - Faults, Causes and RemediesDocument4 pagesDeutz Engine B-F L 1011F B-FM 1011F Operation Manual - Faults, Causes and RemediesJuan SayagoNo ratings yet

- M111 TimingChainDocument2 pagesM111 TimingChainmongolskykunNo ratings yet

- DC Integrated Flywheel Starter Motor GeneratorsDocument8 pagesDC Integrated Flywheel Starter Motor GeneratorsCasey FordyceNo ratings yet

- 1989 Engine Performance On-Vehicle AdjustmentsDocument14 pages1989 Engine Performance On-Vehicle AdjustmentsJose PichinteNo ratings yet

- UM12PD1 BlockDocument3 pagesUM12PD1 BlockBurik8No ratings yet

- X HeadDocument5 pagesX Headkyaw yaNo ratings yet

- KTA50 M2 1600hkDocument2 pagesKTA50 M2 1600hkGabriel Andres ValenciaNo ratings yet

- Beam Engine Hack SawDocument20 pagesBeam Engine Hack SawRif Riz100% (2)

- Engine Data Sheet PDFDocument2 pagesEngine Data Sheet PDFabhay dubeyNo ratings yet

- Jet EnginesDocument3 pagesJet EnginesYemaneDibetaNo ratings yet

- 24.03 Parte 2Document22 pages24.03 Parte 2Alberto GilNo ratings yet

- Fuel Pump CavitationDocument3 pagesFuel Pump Cavitationstergios meletisNo ratings yet

- TE Series Power Unit Controller Start InstructionsDocument13 pagesTE Series Power Unit Controller Start InstructionsFrances SalongaNo ratings yet

- R7320306 Thermal Engineering - IIDocument1 pageR7320306 Thermal Engineering - IIsivabharathamurthyNo ratings yet

- 400 - Pages From 13KFV1V2-2Document85 pages400 - Pages From 13KFV1V2-2ÔngBụtNo ratings yet

- 1 s2.0 S1359431115012430 MainDocument8 pages1 s2.0 S1359431115012430 Main20me91r01No ratings yet

- I. C. EngineDocument26 pagesI. C. Enginenoelmecwan0% (1)

- OJT2 - Steam Turbine Part & Components (Part 1)Document17 pagesOJT2 - Steam Turbine Part & Components (Part 1)Azizul IshakNo ratings yet

- Puma 8.1 B Kit QL 8Document1 pagePuma 8.1 B Kit QL 8SaraMeineckeNo ratings yet

- ME ProgramDocument21 pagesME Programadyro12No ratings yet