Professional Documents

Culture Documents

Uc 3909

Uploaded by

Amarnath M DamodaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uc 3909

Uploaded by

Amarnath M DamodaranCopyright:

Available Formats

UC2909

UC3909

DESCRIPTION

The UC3909 family of Switchmode Lead-Acid Battery Chargers accurately

controls lead acid battery charging with a highly efficient average current

mode control loop. This chip combines charge state logic with average cur-

rent PWM control circuitry. Charge state logic commands current or voltage

control depending on the charge state. The chip includes undervoltage

lockout circuitry to insure sufficient supply voltage is present before output

switching starts. Additional circuit blocks include a differential current sense

amplifier, a 1.5% voltage reference, a 3.9mV/C thermistor linearization

circuit, voltage and current error amplifiers, a PWM oscillator, a PWM com-

parator, a PWM latch, charge state decode bits, and a 100mA open collec-

tor output driver.

Switchmode Lead-Acid Battery Charger

FEATURES

Accurate and Efficient Control of

Battery Charging

Average Current Mode Control from

Trickle to Overcharge

Resistor Programmable Charge

Currents

Thermistor Interface Tracks Battery

Requirements Over Temperature

Output Status Bits Report on Four

Internal Charge States

Undervoltage Lockout Monitors VCC

and VREF

1/99

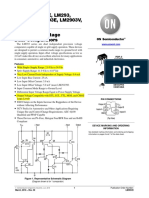

BLOCK DIAGRAM

UDG-95007-1

Pin numbers refer to J, N, DW packages.

2

UC2909

UC3909

DIL-20, (Top View)

J or N, DW Packages

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VCC), OUT, STAT0, STAT1 . . . . . . . . . . . 40V

Output Current Sink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1A

CS+, CS- . . . . . . . . . . . . . . . . . . . . . . . . . . -0.4 to VCC (Note 1)

Remaining Pin Voltages. . . . . . . . . . . . . . . . . . . . . . -0.3V to 9V

Storage Temperature . . . . . . . . . . . . . . . . . . . -65C to +150C

Junction Temperature . . . . . . . . . . . . . . . . . . . -55C to +150C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300C

All currents are positive into, negative out of the specified ter-

minal. Consult Packaging Section of Databook for thermal limi-

tations and considerations of packages.

Note 1: Voltages more negative than -0.4V can be tolerated if

current is limited to 50mA.

CONNECTION DIAGRAMS

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

A

= 40C to +85C for

UC2909; 0C to +70C for UC3909; C

T

= 330pF, R

SET

= 11.5k, R10 = 10k, R

THM

= 10k, V

CC

= 15V, Output no load, R

STAT0

=

R

STAT1

= 10k, CHGENB = OVCTAP = VLOGIC, T

A

= T

J

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Sense AMP (CSA) Section V

ID

= CS+ CS

DC Gain CS = 0, CS+ = -50mV; CS+ = 250mV 4.90 5 5.10 V/V

CS+ = 0, CS = 50mV; CS- = 250mV 4.90 5 5.10 V/V

V

OFFSET

(V

CSO

V

CAO

) CS+ = CS = 2.3V, CAO = CA 15 mV

CMRR V

CM

= 0.25 to VCC 2, 8.8 < VCC < 14 50 dB

V

CM

= 0.25 to VCC, 14 < VCC < 35 50 dB

V

OL

V

ID

= 550mV, 0.25V < VCM < VCC2,

I

O

= 500A

0.3 0.6 V

V

OH

V

ID

= +700mV, 0.25V < VCM < VCC2,

I

O

= 250A

5.2 5.7 6.2 V

Output Source Current V

ID

= +700mV, CSO = 4V 1 0.5 mA

Output Sink Current V

ID

= 550mV, CSO = 1V 3 4.5 mA

3dB Bandwidth V

ID

= 90mV, V

CM

= 0V 200 kHz

LCC-28, PLCC-28 (Top View)

L, Q Packages

3

UC2909

UC3909

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

A

= 40C to +85C for

UC2909; 0C to +70C for UC3909; C

T

= 330pF, R

SET

= 11.5k, R10 = 10k, R

THM

= 10k, V

CC

= 15V, Output no load, R

STAT0

=

R

STAT1

= 10k, CHGENB = OVCTAP = VLOGIC, T

A

= T

J

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Error Amplifier (CEA) Section

I

B

8.8V < VCC < 35V, V

CHGENB

= V

LOGIC

0.1 0.8 A

V

IO

(Note 2) 8.8V < VCC < 35V, CAO = CA 10 mV

A

VO

1V < VAO < 4V 60 90 dB

GBW T

J

= 25C, F = 100kHz 1 1.5 MHz

V

OL

I

O

= 250A 0.4 0.6 V

V

OH

I

O

= 5mA 4.5 5 V

Output Source Current CAO = 4V 25 12 mA

Output Sink Current CAO = 1V 2 3 mA

I

CA

, I

TRCK_CONTROL

V

CHGENB

= GND 8.5 10 11.5 A

Voltage Amplifier (CEA) Section

I

B

Total Bias Current; Regulating Level 0.1 1 A

V

IO

(Note 2) 8.8V < VCC < 35V, VCM = 2.3V, VAO = VA 1.2 mV

A

VO

1V < CAO < 4V 60 90 dB

GBW T

J

= 25C, F = 100kHz 0.25 0.5 MHz

V

OL

I

O

= 500A 0.4 0.6 V

V

OH

I

O

= 500A 4.75 5 5.25 V

Output Source Current CAO = 4V 2 1 mA

Output Sink Current CAO = 1V 2 2.5 mA

VAO Leakage: High Impedance State V

CHGENB

= GND, STAT0 = 0 & STAT1 = 0,

VAO = 2.3V

1 1 A

Pulse Width Modulator Section

Maximum Duty Cycle CAO = 0.6V 90 95 100 %

Modulator Gain CAO = 2.5V, 3.2V 63 71 80 %/V

OSC Peak 3 V

OSC Valley 1 V

Oscillator Section

Frequency 8.8V < VCC < 35V 198 220 242 kHz

Thermistor Derived Reference Section V

ID

= V

RTHM

V

R10

Initial Accuracy, VAO (RTHM = 10k) V

ID

= 0, R10 = RTHM =10k (Note 3) 2.2655 2.3 2.3345 V

V

ID

= 0, R10 = RTHM =10k, 40C T

A

< 0C

(Note 3)

2.254 2.3 2.346 V

Line Regulation V

CC

= 8.8V to 35V 3 10 mV

VAO RTHM = 138k, R10 = 10k 2.458 2.495 2.532 V

RTHM = 138k, R10 = 10k, -40C T

A

< 0C 2.445 2.495 2.545 V

RTHM = 33.63k, R10 = 10k 2.362 2.398 2.434 V

RTHM = 33.63k, R10 = 10k, -40C T

A

< 0C 2.350 2.398 2.446 V

RTHM = 1.014k, R10 = 10k 2.035 2.066 2.097 V

RTHM = 1.014k, R10 = 10k, -40C T

A

< 0C 2.025 2.066 2.107 V

Charge Enable Comparator Section (CEC)

Threshold Voltage As a function of VA 0.99 1 1.01 V/V

Input Bias Current CHGENB = 2.3V 0.5 0.1 A

4

UC2909

UC3909

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

A

= 40C to +85C for

UC2909; 0C to +70C for UC3909; C

T

= 330pF, R

SET

= 11.5k, R10 = 10k, R

THM

= 10k, V

CC

= 15V, Output no load, R

STAT0

=

R

STAT1

= 10k, CHGENB = OVCTAP = VLOGIC, T

A

= T

J

.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Voltage Sense Comparator Section (VSC)

Threshold Voltage STAT0 = 0, STAT1 = 0, Function of V

REF

0.945 0.95 0.955 V/V

STAT0 = 1, STAT1 = 0, Function of V

REF

0.895 0.9 0.905 V/V

Over Charge Taper Current Comparator Section (OCTIC)

Threshold Voltage Function of 2.3V REF, CA- = CAO 0.99 1 1.01 V/V

Input Bias Current OVCTAP = 2.3V 0.5 0.1 A

Logic 5V Reference Section (VLOGIC)

VLOGIC VCC = 15V 4.875 5.0 5.125 V

Line Regulation 8.8V < V

CC

< 35V 3 15 mV

Load Regulation 0 < I

O

< 10mA 3 15 mV

Reference Comparator Turn-on Threshold 4.3 4.8 V

Short Circuit Current V

REF

= 0V 30 50 80 mA

Output Stage Section

I

SINK

Continuous 50 mA

I

PEAK

100 mA

V

OL

I

O

=50mA 1 1.3 V

Leakage Current V

OUT

=35V 25 A

STAT0 & STAT1 Open Collector Outputs Section

Maximum Sink Current V

OUT

= 8.8V 6 10 mA

Saturation Voltage I

OUT

= 5mA 0.1 0.45 V

Leakage Current V

OUT

= 35V 25 A

STATLV Open Collector Outputs Section

Maximum Sink Current V

OUT

= 5V 2.5 5 mA

Saturation Voltage I

OUT

= 2mA 0.1 0.45 V

Leakage current V

OUT

= 5V 3 A

UVLO Section

Turn-on Threshold 6.8 7.8 8.8 V

Hysteresis 100 300 500 mV

I

CC

Section

I

CC

(run) (See Fig. 1) 13 19 mA

I

CC

(off) VCC = 6.5V 2 mA

Note 2: VIO is measured prior to packaging with internal probe pad.

Note 3: Thermistor initial accuracy is measured and trimmed with respect to VAO; VAO = VA.

CA: The inverting input to the current error amplifier.

CAO: The output of the current error amplifier which is

internally clamped to approximately 4V. It is internally

connected to the inverting input of the PWM comparator.

CS, CS+: The inverting and non-inverting inputs to the

current sense amplifier. This amplifier has a fixed gain of

five and a common-mode voltage range of from 250mV

to +VCC.

CSO: The output of the current sense amplifier which is

internally clamped to approximately 5.7V.

CHGENB: The input to a comparator that detects when

battery voltage is low and places the charger in a trickle

charge state. The charge enable comparator makes the

output of the voltage error amplifier a high impedance

while forcing a fixed 10A into CA to set the trickle

charge current.

PIN DESCRIPTIONS

5

UC2909

UC3909

GND: The reference point for the internal reference, all

thresholds, and the return for the remainder of the de-

vice. The output sink transistor is wired directly to this

pin.

OVCTAP: The overcharge current taper pin detects

when the output current has tapered to the float thresh-

old in the overcharge state.

OSC: The oscillator ramp pin which has a capacitor (C

T

)

to ground. The ramp oscillates between approximately

1.0V to 3.0V and the frequency is approximated by:

frequency

C R

T SET

=

1

1 2 .

OUT: The output of the PWM driver which consists of an

open collector output transistor with 100mA sink capabil-

ity.

R10: Input used to establish a differential voltage corre-

sponding to the temperature of the thermistor. Connect

a 10k resistor to ground from this point.

RSET: A resistor to ground programs the oscillator

charge current and the trickle control current for the oscil-

lator ramp.

The oscillator charge current is approximately

1 75 .

R

SET

.

The trickle control current (I

TRCK_CONTROL

) is approxi-

mately

0115 .

R

SET

.

RTHM: A 10k thermistor is connected to ground and is

thermally connected to the battery. The resistance will

vary exponentially over temperature and its change is

used to vary the internal 2.3V reference by 3.9mV/C.

The recommended thermistor for this function is part

number L1005-5744-103-D1, Keystone Carbon Com-

pany, St. Marys, PA.

STAT0: This open collector pin is the first decode bit

used to decode the charge states.

STAT1: This open collector pin is the second decode bit

used to decode the charge states.

STATLV: This bit is high when the charger is in the float

state.

VA: The inverting input to the voltage error amplifier.

VAO: The output of the voltage error amplifier. The up-

per output clamp voltage of this amplifier is 5V.

VCC: The input voltage to the chip. The chip is opera-

tional between 7.5V and 40V and should be bypassed

with a 1F capacitor. A typical I

CC

vs. temperature is

shown in Figure 1.

VLOGIC: The precision reference voltage. It should be

bypassed with a 0.1F capacitor.

Charge State Decode Chart

STAT0 and STAT1 are open collector outputs. The out-

put is approximately 0.2V for a logic 0.

STAT1 STAT0

Trickle Charge 0 0

Bulk Charge 0 1

Over Charge 1 0

Float Charge 1 1

PIN DESCRIPTIONS (cont.)

Figure 1. I

CC

vs. temperature.

6

UC2909

UC3909

APPLICATION INFORMATION

A Block Diagram of the UC3909 is shown on the first

page, while a Typical Application Circuit is shown in Fig-

ure 2. The circuit in Figure 2 requires a DC input voltage

between 12V and 40V.

The UC3909 uses a voltage control loop with average

current limiting to precisely control the charge rate of a

lead-acid battery. The small increase in complexity of

average current limiting is offset by the relative simplicity

of the control loop design.

CONTROL LOOP

Current Sense Amplifier

This amplifier measures the voltage across the sense re-

sistor RS with a fixed gain of five and an offset voltage of

2.3V. This voltage is proportional to the battery current.

The most positive voltage end of RS is connected to CS-

ensuring the correct polarity going into the PWM com-

parator.

CSO = 2.3V when there is zero battery current.

RS is chosen by dividing 350mV by the maximum allow-

able load current. A smaller value for RS can be chosen

to reduce power dissipation.

Maximum Charge Current, Ibulk, is set by knowing the

maximum voltage error amplifier output, V

OH

= 5V, the

maximum allowable drop across RS, and setting the re-

sistors RG1 and RG2 such that;

(1)

RG

RG

V

VLOGIC CA

V

V V

V

V

RS RS

RS

1

2

5 5

5 2 3

5

2 7

185

=

=

=

=

.

.

. 2 I RS

BULK

The maximum allowable drop across RS is specified to

limit the maximum swing at CSO to approximately 2.0V

to keep the CSO amplifier output from saturating.

No charge/load current: V

CSO

= 2.3V,

Max charge/load current: V

max(CSO)

= 2.3V2.0V = 0.3V

Voltage Error Amplifier:

The voltage error amplifier (VEA) senses the battery

voltage and compares it to the 2.3V 3.9mV/C thermis-

tor generated reference. Its output becomes the current

command signal and is summed with the current sense

amplifier output. A 5.0V voltage error amplifier upper

clamp limits maximum load current. During the trickle

charge state, the voltage amplifier output is opened (high

impedance output) by the charge enable comparator. A

trickle bias current is summed into the CA input which

sets the maximum trickle charge current.

The VEA, V

OH

= 5V clamp saturates the voltage loop

and consequently limits the charge current as stated in

Equation 1.

During the trickle bias state the maximum allowable

charge current (ITC) is similarly determined:

(2)

ITC

I RG

RS

TRICK CONTROL

=

_

1

5

I

TRCK_CONTROL

is the fixed control current into CA.

I

TRCK_CONTROL

is 10A when R

SET

= 11.5k. See RSET

pin description for equation.

Current Error Amplifier

The current error amplifier (CA) compares the output of

the current sense amplifier to the output of the voltage

error amplifier. The output of the CA forces a PWM duty

cycle which results in the correct average battery current.

With integral compensation, the CA will have a very high

DC current gain, resulting in effectively no average DC

current error. For stability purposes, the high frequency

gain of the CA must be designed such that the magni-

tude of the down slope of the CA output signal is less

than or equal to the magnitude of the up slope of the

PWM ramp.

CHARGE ALGORITHM

Refer to Figure 3 in UC3906 Data Sheet in the data

book.

A) Trickle Charge State

STAT0 = STAT1 = STATLV = logic 0

When CHGNB is less than VREF (2.3V 3.9mV/C),

STATLV is forced low. This decreases the sense voltage

divider ratio, forcing the battery to overcharge (VOC).

(3)

( )

VOC VREF

RS RS RS RS

RS RS

=

+ +

( )

( )

||

1 2 3 4

3 4

| |

During the trickle charge state, the output of the voltage

error amplifier is high impedance. The trickle control cur-

rent is directed into the CA pin setting the maximum

trickle charge current. The trickle charge current is de-

fined in Equation 2.

B) Bulk Charge State

STAT1 = STATLV = logic 0, STAT0 = logic 1

As the battery charges, the UC3909 will transition from

trickle to bulk charge when CHGENB becomes greater

than 2.3V. The transition equation is

(4)

VT VREF

RS RS RS RS

RS RS RS

=

+ +

+

( || )

( || )

1 2 3 4

2 3 4

STATLV is still driven low.

7

UC2909

UC3909

UDG-95008-1

APPLICATION INFORMATION (cont.)

Figure 2. Typical application circuit

P

i

n

n

u

m

b

e

r

s

r

e

f

e

r

t

o

J

,

N

,

D

W

p

a

c

k

a

g

e

s

.

8

UC2909

UC3909

During the bulk charge state, the voltage error amplifier

is now operational and is commanding maximum charge

current (I

BULK

) set by Equation 1. The voltage loop at-

tempts to force the battery to VOC.

C) Overcharge State

STAT0 = STATLV = logic 0, STAT1 = logic 1

The battery voltage surpasses 95% of VOC indicating

the UC3909 is in its overcharge state.

During the overcharge charge state, the voltage loop be-

comes stable and the charge current begins to taper off.

As the charge current tapers off, the voltage at CSO in-

creases toward its null point of 2.3V. The center connec-

tion of the two resistors between CSO and VLOGIC sets

the overcurrent taper threshold (OVCTAP). Knowing the

desired overcharge terminate current (I

OCT

), the resistors

R

OVC1

and R

OVC2

can be calculated by choosing a value

of R

OVC2

and using the following equation:

(5)

( )

R I RS R

OVC OCT OVC 1 2

18518 = .

D) Float State

STAT0 = STAT1 = STATLV = logic 1

The battery charge current tapers below its OVCTAP

threshold, and forces STATLV high increasing the volt-

age sense divider ratio. The voltage loop now forces the

battery charger to regulate at its float state voltage (V

F

).

(6)

( )

( )

V V

RS RS RS

RS

F REF

=

+ + 1 2 3

3

If the load drains the battery to less than 90% of V

F

, the

charger goes back to the bulk charge state, STATE 1.

OFF LINE APPLICATIONS

For off line charge applications, either Figure 3 or Figure

4 can be used as a baseline. Figure 3 has the advan-

tage of high frequency operation resulting in a small iso-

lation transformer. Figure 4 is a simpler design, but at

the expense of larger magnetics.

APPLICATION INFORMATION (cont.)

Figure 3. Off line charger with primary side PWM

UDG-95009

9

UC2909

UC3909

Figure 4. Isolated off line charger

APPLICATION INFORMATION (cont.)

UNITRODE CORPORATION

7 CONTINENTAL BLVD. MERRIMACK, NH 03054

TEL. (603) 424-2410 FAX (603) 424-3460

UDG-95010

PACKAGE OPTION ADDENDUM

www.ti.com 10-Jun-2014

Addendum-Page 1

PACKAGING INFORMATION

Orderable Device Status

(1)

Package Type Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish

(6)

MSL Peak Temp

(3)

Op Temp (C) Device Marking

(4/5)

Samples

UC2909DW LIFEBUY SOIC DW 20 25 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 UC2909DW

UC2909DWG4 LIFEBUY SOIC DW 20 25 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 UC2909DW

UC2909DWTR OBSOLETE SOIC DW 20 TBD Call TI Call TI -40 to 85 UC2909DW

UC2909DWTRG4 OBSOLETE SOIC DW 20 TBD Call TI Call TI -40 to 85

UC2909N ACTIVE PDIP N 20 20 Green (RoHS

& no Sb/Br)

SN N / A for Pkg Type -40 to 85 UC2909N

UC3909DW LIFEBUY SOIC DW 20 25 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -20 to 70 UC3909DW

UC3909DWG4 LIFEBUY SOIC DW 20 25 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -20 to 70 UC3909DW

UC3909DWTR LIFEBUY SOIC DW 20 2000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -20 to 70 UC3909DW

UC3909N LIFEBUY PDIP N 20 20 Green (RoHS

& no Sb/Br)

N / A for Pkg Type -20 to 70 UC3909N

UC3909NG4 LIFEBUY PDIP N 20 20 Green (RoHS

& no Sb/Br)

N / A for Pkg Type -20 to 70 UC3909N

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

PACKAGE OPTION ADDENDUM

www.ti.com 10-Jun-2014

Addendum-Page 2

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

OTHER QUALIFIED VERSIONS OF UC2909 :

Enhanced Product: UC2909-EP

NOTE: Qualified Version Definitions:

Enhanced Product - Supports Defense, Aerospace and Medical Applications

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)

B0

(mm)

K0

(mm)

P1

(mm)

W

(mm)

Pin1

Quadrant

UC3909DWTR SOIC DW 20 2000 330.0 24.4 10.8 13.0 2.7 12.0 24.0 Q1

PACKAGE MATERIALS INFORMATION

www.ti.com 17-Aug-2012

Pack Materials-Page 1

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

UC3909DWTR SOIC DW 20 2000 367.0 367.0 45.0

PACKAGE MATERIALS INFORMATION

www.ti.com 17-Aug-2012

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per J ESD46, latest issue, and to discontinue any product or service per J ESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as components) are sold subject to TIs terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TIs terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license froma third party under the patents or other intellectual property of the

third party, or a license fromTI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different fromor beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harmand take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TIs goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or enhanced plasticare designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLPProducts www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright 2014, Texas Instruments Incorporated

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- NE555Document6 pagesNE555Sebastian DavidNo ratings yet

- Lm555 555c TimerDocument12 pagesLm555 555c TimerAlexis Orellana VediaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Uc 2906Document8 pagesUc 2906skipina74No ratings yet

- Mc1455-d Timer IcDocument11 pagesMc1455-d Timer IcDecker JamesNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Uc 3906Document9 pagesUc 3906ป๊ะป๋า ณัฐNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- LM555 Timer: General Description FeaturesDocument12 pagesLM555 Timer: General Description FeaturesMark J A. OkyoNo ratings yet

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- LM555 Timer: Literature Number: SNAS548BDocument14 pagesLM555 Timer: Literature Number: SNAS548BKenly WallNo ratings yet

- MC1455Document13 pagesMC1455eduardolsNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Fan 7314Document14 pagesFan 7314Kamal NonekNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Data Sheet: IC Timers 555 and 556Document8 pagesData Sheet: IC Timers 555 and 556Adenilson MatiasNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Uc 3909Document14 pagesUc 3909kumar_yogesh223881No ratings yet

- Transition-Mode PFC Controller: 1 FeaturesDocument17 pagesTransition-Mode PFC Controller: 1 Featuresadriancho66No ratings yet

- CS2841BD14Document10 pagesCS2841BD14giapy0000No ratings yet

- L7250 (Smooth) - HA13627 - Hitachi Motor DriverDocument46 pagesL7250 (Smooth) - HA13627 - Hitachi Motor Drivertrandito100% (5)

- Datasheet Smooth L7250Document46 pagesDatasheet Smooth L7250tosti77No ratings yet

- Obsolete Product(s) - Obsolete Product(s) : Control Circuit For Switch Mode Power Supplies Using Mos TransistorsDocument7 pagesObsolete Product(s) - Obsolete Product(s) : Control Circuit For Switch Mode Power Supplies Using Mos Transistorsbookreader1968No ratings yet

- S Feature D Escriptio: LTC1261 Switched Capacitor Regulated Voltage InverterDocument16 pagesS Feature D Escriptio: LTC1261 Switched Capacitor Regulated Voltage InverterFer CurtinoNo ratings yet

- Tda 4601Document8 pagesTda 4601Mirko AleksicNo ratings yet

- L 6565Document17 pagesL 6565tatatabuchoNo ratings yet

- MW Inverter IC RM6203Document7 pagesMW Inverter IC RM6203KybernetikumNo ratings yet

- MC34063AMDocument16 pagesMC34063AMSajjad4434No ratings yet

- Uc2577 AdjDocument14 pagesUc2577 AdjChandranoola RajuNo ratings yet

- MC34063A, MC33063A, NCV33063A 1.5 A, Step Up/Down/ Inverting Switching RegulatorsDocument14 pagesMC34063A, MC33063A, NCV33063A 1.5 A, Step Up/Down/ Inverting Switching RegulatorsVũ TưởngNo ratings yet

- Uc 3854Document12 pagesUc 3854Leandro CoradiNo ratings yet

- LM393 DDocument10 pagesLM393 DPardeep KumarNo ratings yet

- 28V 2A Step-Down Switching Regulator: Power Management Features DescriptionDocument19 pages28V 2A Step-Down Switching Regulator: Power Management Features DescriptionLuis Espino PérezNo ratings yet

- Green-Mode PWM Controller Saves Power with High-Voltage StartupDocument17 pagesGreen-Mode PWM Controller Saves Power with High-Voltage StartupSelagea IoanNo ratings yet

- LM293Document10 pagesLM293Bruno NascimentoNo ratings yet

- NCP 3063Document20 pagesNCP 3063Roozbeh BahmanyarNo ratings yet

- LM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903 Low Offset Voltage Dual ComparatorsDocument10 pagesLM393, LM393E, LM293, LM2903, LM2903E, LM2903V, NCV2903 Low Offset Voltage Dual Comparatorssam2No ratings yet

- LMC555 CMOS Timer: General Description FeaturesDocument12 pagesLMC555 CMOS Timer: General Description FeaturesNicolas FontanaNo ratings yet

- CM6800GIPDocument18 pagesCM6800GIPAndré Frota PaivaNo ratings yet

- NCP1337 PWM Current Mode Controller For Free Running Quasi Resonant OperationDocument14 pagesNCP1337 PWM Current Mode Controller For Free Running Quasi Resonant Operationcorrales_86No ratings yet

- LMC555 CMOS Timer: General Description FeaturesDocument10 pagesLMC555 CMOS Timer: General Description FeaturesJeremy ObriotNo ratings yet

- Uc 3872 DWDocument8 pagesUc 3872 DWCarlos CuebasNo ratings yet

- TSM 101Document15 pagesTSM 101thiemncNo ratings yet

- LM393Document6 pagesLM393Joao EfremNo ratings yet

- Motor Driver - Full-Bridge PWM - A3953-N5Document14 pagesMotor Driver - Full-Bridge PWM - A3953-N5Ludwig Schmidt100% (1)

- Datasheet Fairchild UC3843Document7 pagesDatasheet Fairchild UC3843Tina JohnsonNo ratings yet

- LM3622Document9 pagesLM3622kloppigNo ratings yet

- A3941 DatasheetDocument21 pagesA3941 Datasheetsoft4gsmNo ratings yet

- lm555 DatasheetDocument11 pageslm555 DatasheetKhu GhingNo ratings yet

- Dap006 Dap6a DataDocument15 pagesDap006 Dap6a DataluisfeipezzNo ratings yet

- MC34067 PDFDocument16 pagesMC34067 PDFwj18868908No ratings yet

- 12V DC To 40V DC Converter Circuit DiagramDocument10 pages12V DC To 40V DC Converter Circuit DiagramAhdiat Darmawan LubisNo ratings yet

- NE/SE5560 Switched-Mode Power Supply Control Circuit: Description Pin ConfigurationDocument16 pagesNE/SE5560 Switched-Mode Power Supply Control Circuit: Description Pin ConfigurationkokiskoNo ratings yet

- Parallelable, Clamped Two-Switch Power-Supply Controller IC: General Description FeaturesDocument21 pagesParallelable, Clamped Two-Switch Power-Supply Controller IC: General Description Featurescatsoithahuong84No ratings yet

- LM25005 42V, 2.5A Step-Down Switching Regulator: Literature Number: SNVS411BDocument24 pagesLM25005 42V, 2.5A Step-Down Switching Regulator: Literature Number: SNVS411BPravin MevadaNo ratings yet

- 3-Phase MOSFET Driver: Description Features and BenefitsDocument17 pages3-Phase MOSFET Driver: Description Features and BenefitsRyan DelaneyNo ratings yet

- ECG Peak DetectionDocument7 pagesECG Peak DetectionAmarnath M DamodaranNo ratings yet

- CAN Bus ESD Protection Diode (PESD2CAN)Document13 pagesCAN Bus ESD Protection Diode (PESD2CAN)Amarnath M Damodaran100% (1)

- CPR (Cardio Pulmonary Resuscitation)Document3 pagesCPR (Cardio Pulmonary Resuscitation)Amarnath M DamodaranNo ratings yet

- Decap PaperDocument4 pagesDecap PaperTanmoy RoyNo ratings yet

- Unidirectional and Bidirectional TVS DevicesDocument2 pagesUnidirectional and Bidirectional TVS DevicesAmarnath M Damodaran100% (2)

- Phantom GravityDocument41 pagesPhantom GravityAmarnath M DamodaranNo ratings yet

- AVR415: RC5 IR Remote Control Transmitter: 8-Bit Microcontroller Application NoteDocument8 pagesAVR415: RC5 IR Remote Control Transmitter: 8-Bit Microcontroller Application NoteØrova RaihanNo ratings yet

- System Level ESD Protection FAQDocument7 pagesSystem Level ESD Protection FAQAmarnath M DamodaranNo ratings yet

- AVR Hardware Design ConsiderationsDocument14 pagesAVR Hardware Design ConsiderationsAmarnath M Damodaran100% (1)

- Digital Sensor I/O DriverDocument12 pagesDigital Sensor I/O DriverAmarnath M DamodaranNo ratings yet

- Interfacing DDR SDRAM With Cyclone DevicesDocument42 pagesInterfacing DDR SDRAM With Cyclone DevicesAmarnath M DamodaranNo ratings yet

- Technical Note: TN-46-07 Ddr333 Design Guide For Two-Dimm SystemsDocument21 pagesTechnical Note: TN-46-07 Ddr333 Design Guide For Two-Dimm SystemsAmarnath M DamodaranNo ratings yet

- Manual Sharkv3.94Document86 pagesManual Sharkv3.94Amarnath M DamodaranNo ratings yet

- Photoelectric SensorDocument3 pagesPhotoelectric SensorAmarnath M DamodaranNo ratings yet

- VFD Fundamentals & TroubleshootingDocument28 pagesVFD Fundamentals & TroubleshootingPrashanthi Balamurugan67% (3)

- Shark2 Operators Manual GenDocument88 pagesShark2 Operators Manual GenAmarnath M DamodaranNo ratings yet

- Phantom GravityDocument41 pagesPhantom GravityAmarnath M DamodaranNo ratings yet

- Chapter 2, Traffic Detector Handbook - Third Edition-Volume I - FHWA-HRT-06-108Document45 pagesChapter 2, Traffic Detector Handbook - Third Edition-Volume I - FHWA-HRT-06-108Amarnath M Damodaran100% (1)

- Red GuideDocument33 pagesRed GuideAmarnath M DamodaranNo ratings yet

- 17 99 1 PBDocument5 pages17 99 1 PBAmarnath M DamodaranNo ratings yet

- Ilb Ilbb EnoteDocument5 pagesIlb Ilbb EnoteAmarnath M DamodaranNo ratings yet

- LMH 6611Document42 pagesLMH 6611Amarnath M DamodaranNo ratings yet

- MSP 430 F 2011Document93 pagesMSP 430 F 2011Amarnath M DamodaranNo ratings yet

- 185Document4 pages185Amarnath M DamodaranNo ratings yet

- ADP1614Document20 pagesADP1614Amarnath M DamodaranNo ratings yet

- Subsection 15 6 5 PDFDocument4 pagesSubsection 15 6 5 PDFAmarnath M DamodaranNo ratings yet

- MT 222Document3 pagesMT 222Amarnath M DamodaranNo ratings yet

- PanavisionSVI ELIS 1024A Datasheet PDS0004RevJDocument13 pagesPanavisionSVI ELIS 1024A Datasheet PDS0004RevJAmarnath M DamodaranNo ratings yet

- Single Ended Primary Inductor ConverterDocument4 pagesSingle Ended Primary Inductor ConverterAmarnath M DamodaranNo ratings yet

- 4709 Outline f15Document2 pages4709 Outline f15ricedragonNo ratings yet

- Nanonics Imaging LTDDocument9 pagesNanonics Imaging LTDNanonicsNo ratings yet

- WP Sierra Capillary Thermal Users GuideDocument29 pagesWP Sierra Capillary Thermal Users Guidegermantoledo244596No ratings yet

- 1Document40 pages1Vladimir BecejacNo ratings yet

- Kvas 100Document98 pagesKvas 100Vikash Kumar PrasadNo ratings yet

- Chapter 13: Analog To Digital Conversion, Data Acquisition and ControlDocument11 pagesChapter 13: Analog To Digital Conversion, Data Acquisition and ControlAnonymous GQjHHSX9yNo ratings yet

- Antenna ViolationDocument14 pagesAntenna Violationramsampath78No ratings yet

- Mcs 012 PDFDocument397 pagesMcs 012 PDFIshan TiwariNo ratings yet

- Atrato Instruction ManualDocument8 pagesAtrato Instruction ManualRoyAlvaNo ratings yet

- Thyristors CH 7Document23 pagesThyristors CH 7Harris AnchesNo ratings yet

- Project Report On Safety BoatDocument36 pagesProject Report On Safety BoatNikil.A HadiNo ratings yet

- File:Circuit Diagram - Pictorial and Schematic - PNGDocument4 pagesFile:Circuit Diagram - Pictorial and Schematic - PNGBhel_Mortel_6465No ratings yet

- (D. A. Bradley, D. Dawson, N. C. Burd, A. J. Loade (B-Ok - CC) PDFDocument518 pages(D. A. Bradley, D. Dawson, N. C. Burd, A. J. Loade (B-Ok - CC) PDFchinnapparaj.sNo ratings yet

- MOS and CMOS Process OverviewDocument36 pagesMOS and CMOS Process OverviewashishNo ratings yet

- 5 MCE Test Data PDFDocument60 pages5 MCE Test Data PDFLuis GonzalezNo ratings yet

- Magnetic Balance and Magnetising (Excitation) Current Test - A Effective Diagnostic ToolDocument13 pagesMagnetic Balance and Magnetising (Excitation) Current Test - A Effective Diagnostic ToolVishal Mahire80% (10)

- Electric Circuits McqsDocument6 pagesElectric Circuits McqsSharaz AliNo ratings yet

- RW748U 700W 48V DC Wall Mount RectifierDocument2 pagesRW748U 700W 48V DC Wall Mount RectifierGuillermo OvelarNo ratings yet

- Maximizing Solar Energy Collection Through TrackingDocument3 pagesMaximizing Solar Energy Collection Through Trackingtakethebow runNo ratings yet

- How To Measure Duty Cycle With A Digital MultimeterDocument2 pagesHow To Measure Duty Cycle With A Digital MultimeterCiprian AndreescuNo ratings yet

- Java RingDocument12 pagesJava RingMegha OmshreeNo ratings yet

- Datasheet Led 3MMDocument5 pagesDatasheet Led 3MMVictor Chavez torresNo ratings yet

- Special Forming ProcessDocument11 pagesSpecial Forming Processvelavansu0% (2)

- Standards List For ElectricalDocument46 pagesStandards List For ElectricalSunil PurohitNo ratings yet

- And NeetsDocument10 pagesAnd NeetsKier Jexter BagunuNo ratings yet

- Pvpsiddhartha Institute of Technology Kanuru Vijayawada-7. Dept - of Ece. Edc Lab, Budget Proposal For A.Y.2020-21Document1 pagePvpsiddhartha Institute of Technology Kanuru Vijayawada-7. Dept - of Ece. Edc Lab, Budget Proposal For A.Y.2020-21Sri ChandanaNo ratings yet

- Infineon-ApplicationNote EVAL 2.5KW CCM 4PIN-ApplicationNotes-v01 00-ENDocument31 pagesInfineon-ApplicationNote EVAL 2.5KW CCM 4PIN-ApplicationNotes-v01 00-ENАлексей АндрияшNo ratings yet

- 3 s2.0 B9781895198843500168 MainDocument18 pages3 s2.0 B9781895198843500168 MainYiğit IlgazNo ratings yet

- ED Lesson PlanDocument5 pagesED Lesson PlanGeetha MNo ratings yet

- BC547 PDFDocument7 pagesBC547 PDFToño ParodNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)