Professional Documents

Culture Documents

Xylanase Production

Uploaded by

rammohanroyal0 ratings0% found this document useful (0 votes)

130 views9 pagesProduction of xylanase by bacillus

Original Title

Xylanase production

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentProduction of xylanase by bacillus

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

130 views9 pagesXylanase Production

Uploaded by

rammohanroyalProduction of xylanase by bacillus

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Original Research Paper

Enhanced production of cellulase-free, thermo-alkali-solvent-stable

xylanase from Bacillus altitudinis DHN8, its characterization and

application in sorghum straw saccharication

Dharmesh N. Adhyaru

a

, Nikhil S. Bhatt

a,n

, H.A. Modi

b

a

P.G. Department of Microbiology, Gujarat Vidyapeeth, Sadra-382 320, Gujarat, India

b

Department of Life Sciences, School of Sciences, Gujarat University, Ahmadabad, Gujarat, India

a r t i c l e i n f o

Article history:

Received 16 September 2013

Received in revised form

7 October 2013

Accepted 11 October 2013

Available online 23 October 2013

Keywords:

Bacillus altitudinis DHN8

Cellulase-free xylanase

Submerged fermentation

Partial purication

Chemical pretreatments

Sorghum straw saccharication

a b s t r a c t

A newly isolated Bacillus altitudinis DHN8 was assessed for xylanase production by utilizing sorghum

straw. The highest xylanase production was recorded at sorghum straw 3% w/v, inoculum size 1% v/v,

inoculum age 18 h, incubation time 42 h, pH 7.0, temperature 35 1C and agitation speed 250 rpm.

Moreover, xylose 0.5%, gelatine 0.5% and KNO

3

0.3% (w/v) further enhanced the production. The detailed

optimization study resulted in a 3.74-fold increase in xylanase production as compared to that of

the initial conditions. The partially puried xylanase showed 70% pH stability after 18 h at pH range of

610. Thermostability study revealed more than 60% xylanase activity at temperature range 4565 1C

after 60 min. The presence of metal ions (10 mM CaCl

2

, MnCl

2

and FeCl

3

) and solvents (10% v/v

isopropanol, methanol, ethanol and acetone) were increased xylanase activities remarkably. During

saccharication study, 3% alkaline hydrogen peroxide treatment was found to be benecial for the

maximum enzymatic hydrolysis of sorghum straw (34.94 mg/g reducing sugar) after 36 h. As such, this

xylanase could be considered as a cellulase-free, thermo-alkali-solvent stable biocatalyst being important

tool for many biotechnological industries.

To the best of our knowledge, this is the rst report on the production of xylanase by this Bacillus

species.

& 2013 Elsevier Ltd. All rights reserved.

1. Introduction

Xylan is the principal hemicellulose which is the major compo-

nent of plant cell wall. It is the second plentiful polysaccharide after

cellulose, in both hard woods and annual plants (Qie et al., 2010;

Polizeli et al., 2005) and accounts for 2035% of the total dry weight

in tropical plant biomass. Endo-xylanases (EC 3.2.1.8) are an impor-

tant group of industrial enzymes responsible for complete hydrolysis

of xylan in to short xylooligosaccharides and xylose in synergism

with other accessory enzymes such as -xylosidase, -L-arabinofur-

anosidase and -glucuronidase (Chavez et al., 2006; Collins et al.,

2005). Xylanases have been reported from bacteria, fungi, actino-

mycetes and yeast (Qie et al., 2010; Sunna and Antranikian, 1997)

but bacteria due to their high metabolic diversity are widely used for

xylanase production. Several Bacillus sp. are known to secrete high

levels of extracellular xylanases which are either poor or free in

cellulase activity. In recent years, xylanases have attracted a great

deal of attention because of their biotechnological potential in the

various industrial processes such as, in food industry in order to

enhance the digestibility of animal feed, in textile industry and in

the paper and pulp industry for bleaching purpose resulting in a

decrease of chlorine utilization and consequently lowering environ-

mental impact (Chivero et al., 2001). Xylanases in synergism with

several enzymes can be used for the generation of biological fuels,

such as ethanol and xylitol from lignocellulosic biomass (Cormana

et al., 2005; Beg et al., 2001).

The major obstacle for wide range application of the xylanases

in industries is high cost of the production. Pure substrates being

highly expensive and thus it cannot be afforded at the industrial level

bulk production of enzymes. Therefore, it is necessary to explore

cheap substrates for cost-effective enzyme production. Agricultural

residues represent one such cheap raw material for industrial

production of enzymes. Furthermore, each bacterium has its own

special conditions for maximum enzyme production. Thus, the hyper

production of industrial enzymes by optimizing various physiological

and nutritional parameters is of prime importance because an

improper optimization of these growth parameters leads to a lower

enzyme production. In addition of the above problems, majority

of the reported xylanases do not withstand the robust industrial

Contents lists available at ScienceDirect

journal homepage: www.elsevier.com/locate/bab

Biocatalysis and Agricultural Biotechnology

1878-8181/$ - see front matter & 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.bcab.2013.10.003

n

Corresponding author. Tel.: 91 98794 83847/079 23274274;

fax: 079 232 74 272.

E-mail addresses: bhattnikhil2114@gmail.com, bhattnikhil_brc@yahoo.in

(N.S. Bhatt).

Biocatalysis and Agricultural Biotechnology 3 (2014) 182190

process conditions of high alkaline pH and high temperatures

(Sharma and Bajaj, 2005). Therefore, search for still better enzymes

which comply well with the industrial processes is in progress

(Kumar and Satyanarayana, 2011).

In view of the demand for novel xylanases with industrially

important properties, an attempt has been made to assess the

potentiality of newly isolated Bacillus species for the xylanase

production using low cost agricultural residue under submerged

fermentation. The partially puried enzyme was characterized

for few properties and further examined for its application in

the saccharication of sorghum straw.

2. Material and methods

2.1. Isolation, screening and identication of xylanase producing

strain

2.1.1. Primary screening

Different soil samples were collected from the active compost

pit (10 cm depth) during mid of the April 2011. Each sample was

mixed thoroughly and 1 g of that was suspended in 50 ml sterile

distilled water. Mixtures were allowed to settle down and then serial

dilutions were prepared. From each dilution, 0.1 ml was spread on

oat spelt xylan (1% w/v) agar plates and incubated at 37 1C for 48 h.

Those colonies showed a clear zone of xylan hydrolysis were isolated

and retained for further secondary screening.

2.1.2. Secondary screening

The isolates from the primary screening were cultured in basal

liquid media containing (g/l): Oat spelt xylan, 10.0; beef extract, 3.0;

NaCl, 5.0; KNO

3

, 2.0; K

2

HPO

4

, 1.0 and MgSO

4

7H

2

O, 0.5 at pH 7.0 in

100 ml Erlenmeyer asks and incubated at 37 1C under shaking

(150 rpm). After 48 h of incubation the fermented broth was

centrifuged at 10,000g for 10 min and the supernatant was used

for enzyme assay.

2.1.3. Bacterial identication

A total of 15 bacterial cultures were selected for the xylanase

production based on the secondary screening. The most promising

isolate DHN8 was identied on the basis of its morphological and

biochemical characterization. Further conrmation was done by

16S rRNA gene sequencing at Gujarat State Biotechnology Mission

(GSBTM), Gandhinagar, India. The gene sequence has been sub-

mitted to Gene Bank at NCBI (GenBank accession no. KF258832).

The sequence was compared with sequences available in NCBI

database and dendrogram was generated using Mega 5.2 software.

2.2. Selection of agro-residue for enhanced cellulase free xylanase

production

For enhanced xylanase production various agro-residues such

as caster shell, sugarcane bagasse, saw dust, rice straw, barley

straw, sorghum straw, wheat straw, groundnut shell and maize

straw were evaluated. Xylanase production was carried out using

2% (w/v) agro-residue in the 100 ml basal liquid medium (pH 7.0)

containing same medium components but without oat spelt

xylan. The asks were sterilized at 121 1C for 15 min, cooled and

inoculated with 1% (v/v) of bacterial culture. The contents were

incubated at 37 1C under shaking condition (150 rpm) for 48 h.

The fermented broth was centrifuged at 10,000g for 10 min at 4 1C

and the clear supernatant was analysed for enzyme assay.

2.3. Analytical methods

All the experiments were done in triplicates and the values

presented are mean values7SD.

Chemicals such as oat spelt xylan, carboxy methyl cellulose

(CMC), bovine serum albumin (BSA) and dinitrosalicylic acid

(DNSA) were purchased from Hi Media Laboratories Ltd. All the

other chemicals, media, salts and reagents used were of analytical

grade (Sigma- Aldrich, Hi Media, Qualigens and Merck).

The xylanase activity was measured according to Bailey et al.

(1992). The reaction mixture consisting 450 ml of 1% oat spelt xylan

in 50 mM sodium phosphate buffer (pH 7.0) and 50 ml of enzyme

was incubated for 10 min at 50 1C. The amount of reducing sugar

released was quantied using 3,5-dinitrosalicylic acid (DNS) method

as described by Miller (1959). The CMCase and FPase activities were

determined according to IUPAC recommendation (Ghose, 1987). One

unit of xylanase or cellulase activity was dened as the amount of

enzyme required to liberate 1 mmol of xylose or glucose equivalent

per min under the specied conditions.

The protein content was measured according to Lowry et al.

(1951) with BSA as the standard.

2.4. Assessment of process parameters for cellulase free xylanase

production

2.4.1. Optimization of physiological parameters

2.4.1.1. Inoculum size. To study the effect of inoculum size, produc-

tion media were inoculated at a level of 0.5, 1.0, 2.0, 3.0, 4.0 and

5.0% (v/v) from the 12 h old bacterial culture broth.

2.4.1.2. Inoculum age. To study the effect of inoculum age on

xylanase production, inoculum was prepared by inoculating 50 ml

of basal liquid medium with bacterium DHN8 and incubated at

37 1C under shaking condition (150 rpm). At regular interval of 6 h

incubation, 1% (v/v) of inoculum was transferred to 100 ml fresh

fermentation medium followed by incubation at 37 1C for 48 h

under shaking at 150 rpm. The culture ltrate was centrifuged and

nally used for enzyme assay.

2.4.1.3. Incubation time. In order to achieve maximum xylanase

production, incubation time was varied from 12 to 60 h. The crude

enzyme was extracted and assayed at regular interval of 6 h.

2.4.1.4. pH. Initial pH of the fermentation mediumwas varied from

3 to 10. The pH was adjusted by using 1 MHCl or NaOH prior to

autoclaving.

2.4.1.5. Temperature. Xylanase production was studied at different

temperatures ranging from 25 to 50 1C.

2.4.1.6. Agitation speed. The rate of agitation was studied at 0 to

300 rpm with a difference of 50 rpm.

2.4.2. Optimization of nutritional parameters

2.4.2.1. Inuence of carbon sources. Inuence of various carbon sources

on the xylanase production were assessed at a concentration of

0.5% (w/v).

2.4.2.2. Inuence of organic and inorganic nitrogen sources. Various

organic and inorganic nitrogen sources were evaluated for enhan-

ced xylanase production at concentration of 0.5 and 0.3% (w/v),

respectively.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 183

2.5. Partial purication and characterization of xylanase

Solid ammonium sulphate was slowly added to the culture

supernatant in an ice bath under constant stirring to achieve 70%

saturation. After centrifugation at 10,000g for 10 min at 4 1C,

the supernatant was removed and the precipitate was resus-

pended in 10 ml of 50 mM sodium phosphate buffer (pH 7.0).

The nal solution was dialysed against the same buffer overnight

at 4 1C with three intermittent changes of the buffer.

2.5.1. Effect of temperature on xylanase activity and stability

The optimum temperature was determined by incubating the

enzyme extract in 1% oat spelt xylan solution at various tempera-

tures (3575 1C). For thermostability assay, enzyme was incubated

at different temperatures in the absence of substrate for 120 min.

Aliquots were withdrawn at regular time intervals to test the

residual xylanase activity.

2.5.2. Effect of pH on xylanase activity and stability

The pH optima was determined by measuring relative activity at

various pH values using sodium citrate (pH 36), sodium phosphate

(pH 68) and glycine-NaOH (pH 810) buffers (50 mM). The stability

of xylanase was assessed by incubating enzyme samples for 24 h in

different buffers. At regular interval of 3 h samples were withdrawn

and residual enzyme activity was determined.

2.5.3. Effect of metal ions on xylanase activity

The effect of metal ions on enzyme activity was determined by

incubating the xylanase preparations in 10 mM metal solution for

30 min. Residual activity was measured by standard enzyme assay.

2.5.4. Effect of various solvents on xylanase activity

The enzyme was incubated with various alcoholic and non

alcoholic solvents at 10% (v/v) concentration for 30 min and residual

activity was measured by the standard assay procedure.

2.6. Chemical pretreatment of sorghum straw

Prior to the enzymatic hydrolysis, the sorghum straw was

given three separate chemical pretreatments. Ten grams of dried

and powdered sorghum straw was taken for each pretreatment

experiment. The biomass was mixed with 200 ml of 1 M NaOH (for

24 h), 1 M HCl (for 12 h) and 3% alkaline hydrogen peroxide, pH

11.0 (for 12 h) separately to obtain a solid:liquid ratio of 1:20. The

contents were kept under shaking (100 rpm) at 50 1C. The pre-

treated substrates were washed until neutrality and dried in oven

at 50 1C till constant weight was achieved.

2.7. Enzymatic hydrolysis

Enzymatic hydrolysis of sorghum straw was carried out in

50 ml Erlenmeyer ask with 2.5% (untreated and pre-treated)

substrate and 20 ml of appropriately diluted crude enzyme at

50 1C, 100 rpm for 48 h. Controls were kept in which active

enzyme was replaced with heat inactivated enzyme. The reaction

system was supplemented with 0.005% sodium azide to prevent

microbial growth. Aliquots were taken at regular intervals of 12 h,

centrifuged and the supernatant was assayed for total reducing

sugar by 3,5-dinitrosalysilic acid method (Miller, 1959).

2.8. Analysis of hydrolysed products by TLC

The products of enzymatic hydrolysis of sorghum straw were

examined by ascending thin-layer chromatography (TLC) on pre-

coated silica gel plates (60 F254, Merck) using acetone/ isopropyl

alcohol/water (6:3:1.5, v/v/v) as mobile phase. At dened times,

reaction mixtures were sampled, the enzyme activity was stopped

by boiling for 10 min and 3.0 ml samples were applied on TLC

plates. The separated products were detected by spraying the plate

with -naphthol (3.5% in ethanol and 10% sulphuric acid) followed

by heating at 100 1C.

3. Results and discussion

3.1. Isolation and identication of strain DHN8

The newly isolated DHN8 strain was Gram positive, strictly

aerobic, spore forming, rod shaped and peritrichous. It reacted

positively in the catalase and oxidase tests. According to these

results, it was clear that the bacterium belonged to the genus

Bacillus species. Based on the results of 16S rRNA gene sequencing

the bacterium was identied as Bacillus altitudinis (accession no.

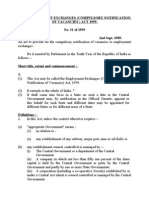

Fig. 1. The phylogenetic dendrogram of Bacillus altitudinis DHN8 was labelled with an aster and related species by the neighbour-joining approach. Bootstrap values obtained

with 1000 resamplings are indicated as percentages at all branches. The scale bars represent 0.05 substitutions per nucleotide position. Numbers following the names of the

strains are accession numbers of published sequences.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 184

KF258832) and designated as B. altitudinis DHN8. Through the

alignment of homologous sequences of known bacteria, phyloge-

netic position of the strain is shown in Fig. 1.

3.2. Effect of various agro-residues on xylanase production

Among tested agro residues, B. altitudinis DHN8 exhibited clear

preference towards sorghum straw for highest xylanase produc-

tion (65.4972.18 IU/ml) followed by wheat straw, sugarcane

bagasse, barley straw and rice straw (62.0071.91, 47.0071.68,

42.6871.16 and 34.7371.21 IU/ml, respectively). However, lower

xylanase activities were observed in presence of maize straw,

caster shell, groundnut shell and saw dust (Fig. 2). The higher

xylanase production in presence of sorghum straw might be due

to the nature of hemicellulose, the presence of some activators

in the carbon source, surface, pore size and favourable degrad-

ability of carbon source (Gomes et al., 1993). However, many

research groups used hemicellulosic substrates such as wheat

bran, rice straw, wheat straw, soybean akes, rice bran, sugarcane

bagasse and groundnut shells for xylanase production (Battan

et al., 2007; Sharma et al., 2007; Taneja et al., 2002; Gawande

and Kamat, 1999). These data suggested that the xylanase induc-

tion is a complex phenomenon and the level of response to

different inducers varies with the strains. This study highlighted

that choosing an appropriate agro-residue can improve enzyme

production markedly.

Further different concentrations of sorghum straw ranging

from 1.0 to 6.0% (w/v) were tested under submerged fermentation.

The maximum xylanase production (68.4972.37 IU/ml) was

achieved at 3% (w/v) sorghum straw (Fig. 3). The gradual decrease

in xylanase production was observed above 3% sorghum straw

concentration. The possible reason behind such xylanase produc-

tion behaviour could be formation of thick suspension in presence

of higher substrate concentration resulted in improper mixing of

the substrate under agitation condition.

3.3. Effect of inoculum size, inoculum age and incubation period

An optimum inoculum level is necessary for maintaining balance

between the proliferating biomass and available nutrients to produce

maximum enzyme level. The highest xylanase production (72.847

2.64 IU/ml) was achieved when the production medium was inocu-

lated with 1% (w/v) of 12 h old inoculum (Fig. 4). The enzyme titre

declined drastically with increase in inoculum size beyond the

optimum values could be due to faster nutrient consumption. In

earlier studies, Battan et al. (2007) and Nagar et al. (2010) also showed

the use of 1.05.0% (v/v) inoculum size for hyper xylanase production.

Higher concentration of inoculum is not preferable in industrial

fermentations (Lincon, 1960).

The effect of inoculum age was studied from 6 to 48 h old

culture of B. altitudinis DHN8. The maximum xylanase production

91.3872.68 IU/ml was obtained with 18 h old inoculum (Fig. 5)

but decreased thereafter. These results obtained might be due to

the fact that, the maximum enzyme titre is produced during early

to late exponential phase of the organism. It also suggests that the

partial association existed between growth of the organism and its

enzyme production pattern. Kumar et al. (2012) and Nagar et al.

(2010) also showed the use of 18 h old inoculum for xylanase

production.

The time of fermentation for maximum enzyme production

varies among different bacteria and is dependent upon the organism

0

0.5

1

1.5

2

2.5

0

10

20

30

40

50

60

70

80

CS SB SD RS BS SS WS GS MS

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

Agro-residues

Xylanase activity Protein

Fig. 2. Effect of various agro residues on xylanase production. CS: caster shell,

SB: sugarcane bagasse, SD: saw dust, RS: rice straw, BS: barley straw, SS: sorghum

straw, WS: wheat straw, GS: groundnut shell, MS: maize straw. The fermentation

medium containing 2% w/v agro residue, beef extract, 3.0; NaCl, 5.0; KNO

3

, 2.0;

K

2

HPO

4

, 1.0 and MgSO

4

7H

2

O, 0.5 at pH 7.0 was inoculated with 12 h old bacterial

culture at 1% v/v. The enzyme production was carried out at 37 1C under shaking

(150 rpm) for 48 h.

0

0.5

1

1.5

2

2.5

3

0

10

20

30

40

50

60

70

80

1 2 3 4 5 6

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

Sorghum straw concentration (%)

Xylanase activity Specific activity Protein

Fig. 3. Effect of sorghum straw concentration (16% w/v) on xylanase production.

The fermentation medium (pH 7.0) with varying concentration of sorghum straw

was inoculated with 12 h old bacterial culture at 1% v/v. The enzyme production

was carried out at 37 1C under shaking (150 rpm) for 48 h.

0

0.5

1

1.5

2

2.5

0

10

20

30

40

50

60

70

80

0.5 1 2 3 4 5

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

Inoculum size (% v/v)

Xylanase activity Specific activity Protein

Fig. 4. Effect of inoculum size on xylanase production. The 3% w/v sorghum straw

containing fermentation medium (pH 7.0) was inoculated with 12 h old bacterial

culture at 1 to 5% v/v. The enzyme production was carried out at 37 1C under

shaking (150 rpm) for 48 h.

0

0.5

1

1.5

2

2.5

3

0

10

20

30

40

50

60

70

80

90

100

6 12 18 24 30 36 42 48

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

Inoculum age (h)

Xylanase activity Specific activity Protein

Fig. 5. Effect of inoculum age on xylanase production. The fermentation medium

(pH 7.0) was inoculated at 1% v/v level with 12 to 60 h old bacterial culture. The

enzyme production was carried out at 37 1C under shaking (150 rpm) for 48 h.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 185

type, its enzyme production pattern, cultural conditions and genetic

makeup of the organism. During course of incubation period, high-

est xylanase production (81.5672.85 IU/ml) was obtained at 42 h

of incubation and thereafter it declined gradually (Fig. 6). The

reduction in xylanase yield could be due to nutrients depletion or

due to proteolysis (Flores et al., 1997). Xylanase produced by Bacillus

sp. was found to be growth-associated, reaching a maximum after

24 h and the enzyme production remained more or less constant

up to 48 h (Anuradha et al., 2007). On the other hand, Bacillus

halodurans PPKS-2 (Prakash et al., 2011) and Bacillus SSP-34

(Subramaniyan and Prema, 2000) produced maximum xylanase

after 48 and 96 h, respectively.

3.4. Effect of pH, temperature and agitation speed

The B. altitudinis DHN8 was cultivated in the production medium

adjusted at different pH (3.010.0). The bacterium did not produce

satisfactory xylanase yield at initial medium pH 3.0 to 5.0 but at pH

6.0 xylanase titre was increased and reached maximum at pH 7.0

(85.7372.23 IU/ml). Moreover, afterwards from pH 8.0 to 10.0

substantial xylanase production was observed (Fig. 7). Xylanase

production by various bacteria and fungi has been shown to be

markedly dependent on pH (Wong et al., 1982). Acidic pH (4.06.0)

generally favours fungal xylanases (Bajpai, 1997) while higher pH

favours bacterial xylanases (Bisaria and Ghose, 1991). In tuning with

this nding, Bacillus pumilus ASH (Battan et al., 2007) and Bacillus

subtilis ASH (Sanghi et al., 2008) showed elevated xylanase produc-

tion at pH 7.0. However, Bacillus mojavensis AG137 (Sepahy et al.,

2011) and Bacillus NT 9 (Han et al., 2004) showed maximum

xylanase production at medium pH 8.0 and 10, respectively.

The xylanase production was conducted at different temperatures

(2550 1C). The maximum xylanase production (91.1472.01 IU/ml)

was obtained at 35 1C (Fig. 8) and reduced sharply at higher

temperature range of 40 to 50 1C. Although the physiological changes

induced by high temperatures during enzyme production are not

completely understood, it has been suggested that at higher tem-

peratures microorganisms may synthesize only a reduced number

of proteins essential for growth and other physiological processes

(Gawande and Kamat, 1999). These results might also be corresponds

to the growth prole of the microorganism where as no other

temperature was suitable to such extant for growth and enzyme

secretion. Many researchers reported 37 1C temperature for max-

imum xylanase production from Bacillus sp. (Nagar et al., 2010;

Sanghi et al., 2008; Battan et al., 2007).

During submerged fermentation process, agitation and aeration

are two important parameters used for uniform mixing of the

nutrients and to meet the oxygen demand. The B. altitudinis DHN8

exhibited signicant amount of xylanase production in the range

of 150 to 300 rpm agitation speed with optimum xylanase yield

(103.8773.46 IU/ml) at 250 rpm. However, under static and lower

agitation (50 rpm) conditions only 10.21 and 45.31% of the maximum

xylanase activity was observed (Fig. 9). The lower xylanase produc-

tion under static to low agitation conditions may be attributed to the

dissolved oxygen (DO) limitation, improper mixing of media compo-

nents and cell clumping. Various researchers showed maximum

xylanase production at an agitation rate of 200250 rpm (Kumar

et al., 2012; Battan et al., 2007; Taneja et al., 2002; Beg et al., 2001;

Gawande and Kamat, 1999).

3.5. Inuence of carbon and nitrogen sources

Carbon source is one of the most important factors during

the growth and metabolic process of microorganisms. The presence

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

0

10

20

30

40

50

60

70

80

90

12 18 24 30 36 42 48 54 60

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

Incubation time (h)

Xylanase activity Specific activity Protein

Fig. 6. Effect of incubation time on xylanase production. The fermentation medium

(pH 7.0) was inoculated at 1% v/v level with 18 h old bacterial culture. The enzyme

production was carried out at 37 1C under shaking (150 rpm) and samples were

analysed at 6 h intervals.

0

0.5

1

1.5

2

2.5

0

10

20

30

40

50

60

70

80

90

100

3 4 5 6 7 8 9 10

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

pH

Xylanase activity Specific activity Protein

Fig. 7. Effect of pH on xylanase production. The fermentation medium containing

different pH from 3 to 10 was inoculated at 1% v/v level with 18 h old bacterial

culture. The enzyme production was carried out at 37 1C under shaking (150 rpm)

for 42 h.

0

0.5

1

1.5

2

2.5

3

0

10

20

30

40

50

60

70

80

90

100

25 30 35 40 45 50

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

Temperature ( C)

Xylanase activity Specific activity Protein

Fig. 8. Effect of temperature on xylanase production. The fermentation medium

(pH 7.0) was inoculated at 1% v/v level with 18 h old bacterial culture. The enzyme

production was carried out at different temperature range from 25 to 50 1C under

shaking (150 rpm) for 42 h.

0

0.5

1

1.5

2

2.5

3

0

20

40

60

80

100

120

0 50 100 150 200 250 300

P

r

o

t

e

i

n

c

o

n

c

e

n

t

r

a

t

i

o

n

(

m

g

/

m

l

)

X

y

l

a

n

a

s

e

a

c

t

i

v

i

t

y

(

I

U

/

m

l

)

;

S

p

e

c

i

f

i

c

a

c

t

i

v

i

t

y

(

I

U

/

m

g

)

Agitation speed (rpm)

Xylanase activity Specific activity Protein

Fig. 9. Effect of agitation speed on xylanase production. The fermentation medium

(pH 7.0) was inoculated at 1% v/v level with 18 h old bacterial culture. The enzyme

production was carried out at 35 1C under static and shaking (0 to 300 rpm)

conditions for 42 h.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 186

of carbon sources in the fermentation medium exerted profound

effect on the enzyme production behaviour of the bacterium. Among

various monosaccharide and disaccharides tested only xylose,

sucrose and starch (145.1373.85, 115.4173.66 and 111.073.91 IU/

ml, respectively) stimulated xylanase production. However, other

carbon sources failed to support high yield of xylanase production as

compared to control (Table 1). The most plausible explanation for

decrease in xylanase yield with other carbon sources is that these

sources exerted catabolite repression. Such carbon source dependent

enzyme production regulation has been noticed in different xylanase

producing microbial strains (Lakshmi et al., 2009; Oliveira et al.,

2006; Gassesse and MaMo, 1999).

To check the effect of nitrogen sources on xylanase production

different organic and inorganic nitrogen sources were added

individually to the fermentation medium (Table 2).

Amongst various organic nitrogen sources, maximum xylanase

production was obtained with gelatine (197.9476.00 IU/ml) followed

by urea, yeast extract, tryptone and beef extract. However, casein,

meat extract, malt extract and peptone did not showed stimulatory

effect on xylanase production. The enhanced production of xylanase

in presence of gelatine as organic nitrogen sources may be attributed

to organic nitrogen source mediated regulation of microbial growth

and metabolism (Gupta et al., 2000). Moreover, it has been also

observed that nitrogen can signicantly affect the pH of the medium

during the course of fermentation (Haapala et al., 1994) thereby

inuences the microbial metabolism. Bajaj and Manhas (2012)

reported 24.0% xylanase improvement in the presence of gelatine.

The most suitable organic nitrogen source for the xylanase production

by Geobacillus thermoleovorans (Sharma et al., 2007) and Bacillus

circulans AB16 (Dhillon and Khanna, 2000) was tryptone. B. moja-

vensis AG147 yielded maximum xylanase when tryptone and yeast

extract was used in combination (Sepahy et al., 2011).

During the evaluation of inorganic nitrogen sources KNO

3

showed

maximum xylanase production (245.0473.15 IU/ml). All other tested

inorganic nitrogen sources also showed increase in xylanase produc-

tion except (NH

4

)

2

H

2

PO

4

(103.7974.76 IU/ml) as compared to the

control set devoid of any nitrogen source. In accordance with these

results, Nagar et al. (2012) observed stimulatory effect of KNO

3

in

combination with peptone and yeast extract on xylanase production.

3.6. Partial characterization of xylanase produced by B. altitudinis

DHN8

3.6.1. Effect of temperature on activity and stability

The partially puried xylanase was active in the broad range

of temperatures 35 to 75 1C, with temperature optima at 50 1C.

The enzyme exhibited more than 60% of its activity in the range

from 45 to 65 1C. The xylanase activity was dropped at temperature

values above 70 1C and only 20% of relative xylanase activity was

detected at 75 1C (Fig. 10).

The enzyme thermostability depends upon molecular interac-

tions such as hydrogen bonds, electrostatic and hydrophobic inter-

actions, disulde bonds, and metal binding which can promote a

superior conformational structure for the enzyme with a higher

packing efciency, reduced entropy of unfolding, conformational

strain release and stability of -helices (Li et al., 2005). Thermo-

stability studies of B. altitudinis DHN8 xylanase showed residual

activity between 70 and 90% at 45 to 60 1C temperature after 60 min

of incubation. Even at 70 1C after 30 min of incubation 47% of the

residual activity was noticed. The obtained results clearly indicate

the nature of xylanase as thermostable. The suitable temperature

range for industrial application of present xylanase lies in 35 to 65 1C

(Fig. 11). Most of the bacterial xylanases showoptimumactivity at 50

to 60 1C (Bajaj and Singh, 2010). Identical temperature optima

at 50 1C were reported for the xylanases from Bacillus sp. (Nagar

et al., 2010; Polizeli et al., 2005). However, xylanase produced by

B. halodurans exhibited activity over 30100 1C, with an optimum at

Table 1

Inuence of carbon sources on cellulase-free xylanase production by Bacillus

altitudinis DHN8.

Carbon

sources

Xylanase activity

(IU/ml)

Protein

(mg/ml)

Specic activity

(IU/mg)

Control

a

103.1872.80 2.5470.09 40.5371.11

Glucose 62.0773.04 2.1070.06 29.6072.29

Maltose 83.9372.29 2.2870.07 36.7170.99

Starch 111.0073.91 2.2870.07 36.7172.30

Cellulose 68.3672.86 2.4470.09 27.9370.16

Sucrose 115.4173.66 2.9370.15 39.4170.80

Fructose 88.2972.66 2.2670.11 39.1171.69

Xylose 145.1373.85 3.1370.13 46.3172.02

Galactose 68.8773.70 2.3370.16 29.6672.72

Lactose 62.1271.71 2.3370.14 26.7272.36

Mannitol 85.3374.01 2.9370.06 29.1371.38

a

The control medium used was devoid of carbon source.

Table 2

Inuence of nitrogen sources on cellulase-free xylanase production by B.

altitudinis DHN8.

Nitrogen

source

Xylanase activity

(IU/ml)

Protein

(mg/ml)

Specic activity

(IU/mg)

Organic

Peptone 133.9673.13 3.0470.13 44.1071.40

Beef extract 144.2974.61 3.3370.07 43.3572.04

Yeast extract 173.6476.38 3.5470.08 48.9970.75

Casein 83.0372.66 2.5070.11 33.1470.54

Malt extract 101.0672.52 2.9070.10 34.8572.00

Trypton 154.7672.40 3.4970.14 44.3471.67

Gelatine 197.9476.00 3.8770.10 51.1772.12

Skim milk powder 144.8273.47 3.4270.09 42.2771.13

Meat extract 94.7873.94 2.3870.11 39.7971.21

Urea 183.8477.93 3.1870.08 57.6971.87

Inorganic

(NH

4

)

2

HPO

4

195.6578.69 3.8670.11 50.6770.79

(NH

4

)

2

H

2

PO

4

103.7974.76 3.2670.14 31.8470.93

KNO

3

245.0473.15 4.0070.17 61.3171.95

(NH

4

)

2

S

2

O

8

163.7372.49 3.6470.14 45.0071.10

NH

4

NO

3

213.8874.90 3.9170.16 54.6471.25

NH

4

Cl 177.3176.09 3.1070.09 57.1172.93

NaNO

3

198.1372.18 3.6670.15 54.0871.70

(NH

4

)

2

SO

4

207.0673.27 4.0870.19 50.8372.64

(NH

4

)

2

HPO

4

195.6578.69 3.8670.11 50.6770.79

Control

a

135.3973.87 3.1370.14 43.2371.08

a

The control medium used was devoid of nitrogen source.

0

20

40

60

80

100

120

35 40 45 50 55 60 65 70 75

R

e

l

a

t

i

v

e

a

c

t

i

v

i

t

y

(

%

)

Temperature ( C)

Fig. 10. Effect of temperature on the activity of partially puried xylanase. The

enzyme extract was incubated in 1% oat spelt xylan solution at different tempera-

tures (35 to 75 1C). The relative activity was measured using standard assay after

10 min.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 187

80 1C (Kumar and Satyanarayana, 2011). B. halodurans PPKS-2

xylanase showed optimum temperature of 70 1C (Prakash et al.,

2011). Thermostability of different Bacillus sp. xylanases varies

between 55 and 80 1C (Kumar and Satyanarayana, 2011).

3.6.2. Effect of pH on activity and stability

Enzyme activity is markedly affected by pH because substrate

binding and catalysis are often dependent on charge distribution

of both substrate and particularly enzyme molecules. The xylanase

of B. altitudinis DHN8 exhibited the highest xylanase activity at pH

7.0 and retained more than 60% relative activity over broad range

of pH 5 to 10 (Fig. 12).

pH stability study revealed that the present xylanase was stable

in pH range of 6 to 10 and showed 70% residual activity after

18 h of incubation (Fig. 13). The results indicated that the partially

puried xylanase was alkali stable in nature. In similar study,

xylanase from Bacillus sp. GRE7 showed pH stability over the pH

range of 511 for 30 min (Kiddinamoorthy et al., 2008). Bacillus

stearothermophilus T-6 xylanase had stability at pH 6.510.0 for

5 min (Khasin et al., 1993). The differences in pH and temperature

stability for extracellular xylanases might be due to the post

transcriptional modications in xylanase excretion process, such

as glycosylation, that improved stability in more extreme pH and

temperature conditions (Savitha et al., 2007).

Thus, B. altitudinis DHN8 xylanase possessed cellulase-free

nature, broad pH stability spectrum and stability at elevated

temperature, could be important tool for application in many

industrial processes.

3.6.3. Effect of metal ions and additives on xylanase activity

Metal ions can be involved in enzyme catalysis in a variety

of ways: they may accept or donate electrons; they may them-

selves act as electrophiles; they may mask nucleophiles to prevent

unwanted side reactions; they may bring together enzyme and

substrate by coordinate bonds; they may hold the reacting groups

in the required 3D orientation and they may simply stabilize

a catalytically active conrmation of the enzyme (Palmer, 2001).

As shown in Table 3, xylanase activity was assayed in the presence

of several metal solutions (10 mM). The xylanase activity was

markedly stimulated in the presence of metal ions such as CaCl

2

(168.00%), MnCl

2

(126.95%) and FeCl

3

(106.01%). However, signi-

cant inhibition in xylanase activity was found in the presence

of other metal compounds. HgCl

2

was acted as strong inhibitory

compound (64% inhibition), suggesting that there is an impor-

tant cystein residue in or close to the active site of the enzyme

(Khandeparkar and Bhosle, 2006). Kumar and Satyanarayana

(2011) reported that the activity of B. halodurans xylanase was

strongly inhibited by Sn

2

, Hg

2

, Cu

2

and Cd

2

. More than

a quarter of all known enzymes require the presence of metal

atoms for fully catalytic activity (Palmer, 2001). These effects

reveal which kind of ions should be precluded or included in

industrial processes.

The reports on the solvent stable xylanases are very rare.

The inuence of various alcoholic and non alcoholic solvent additives

on the activity of xylanase is shown in Table 3. The xylanase activity

was stimulated in the presence of isopropanol (126.07%), methanol

(117.81%), ethanol (108.69%) and acetone (102.96%). However, pre-

sence of 1-butanol, 2-butanol, benzene and toluene resulted in

reduced xylanase activity. Similar observations for xylanase stimula-

tion and suppression in presence of straight chain alcohols were

reported by Li et al. (2010). Biocatalysis in organic media offers several

0

20

40

60

80

100

120

0 30 60 90 120

R

e

s

i

d

u

a

l

a

c

t

i

v

i

t

y

(

%

)

Time (min)

35 C

40 C

45 C

50 C

55 C

60 C

65 C

70 C

75 C

Fig. 11. Effect of temperature on the stability of partially puried xylanase.

The enzyme extract was incubated at different temperatures (35 to 75 1C) for

120 min. The residual activity was measured after each 30 min intervals.

0

20

40

60

80

100

120

3 4 5 6 7 8 9 10

R

e

l

a

t

i

v

e

a

c

t

i

v

i

t

y

(

%

)

pH

pH 3-6 pH 6-8 pH 8-10

Fig. 12. Effect of pH on the activity of partially puried xylanase. The enzyme

extract was incubated in different buffers: sodium citrate (pH 36), sodium

phosphate (pH 68) and glycine-NaOH (pH 810) buffers (50 mM).

0

20

40

60

80

100

120

0 3 6 9 12 15 18 21 24

R

e

s

i

d

u

a

l

a

c

t

i

v

i

t

y

(

%

)

Time (h)

pH 3

pH 4

pH 5

pH 6

pH 7

pH 8

pH 9

pH 10

Fig. 13. Effect of pH on the stability of partially puried xylanase. The enzyme

extract was incubated for 24 h in different buffers (pH 3 to 10) for 24 h. At regular

interval of 3 h samples were withdrawn and residual enzyme activity was

determined.

Table 3

Effect of metal compounds and solvents on cellulase-free xylanase activity.

Metal compound

(10 mM)

Relative xylanase

activity (%)

Solvents

(10% v/v)

Relative xylanase

activity (%)

Control

a

100.0071.42 Control 100.0071.42

CoCl

2

72.7072.45 Methanol 117.817 5.04

FeCl

3

106.017 4.98 Ethanol 108.6972.56

MnCl

2

126.9573.21 Isopropanol 126.0774.90

CaCl

2

168.7278.66 1-Butanol 89.3472.47

HgCl

2

46.8772.03 2- Butanol 92.5673.83

ZnCl

2

62.3673.00 Acetone 102.9672.81

NiCl

2

32.3571.21 Toluene 67.2172.99

MgCl

2

62.9571.27 Benzene 76.1071.60

a

The control medium used was devoid of any modulator or solvent.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 188

advantages viz. higher solubility of hydrophobic substrate enabaling

their effective reactions, reduced microbial contamination and reusa-

bility (Sardessai and Bhosle, 2004). These results provide essential

data for the application of xylanase in an organic phase industrial

reactions.

3.7. Enzymatic hydrolysis of sorghum straw

The utilization of enzymatic hydrolysis to obtain sugars from

agricultural residues is of great interest in modern biotechnology

particularly for bio-solvent production. Fig. 13 depicts the effect of

enzymatic hydrolysis on reducing sugar production from differ-

ently pretreated sorghum straw. The 3% alkaline hydrogen per-

oxide pretreated sorghum straw yielded maximum reducing sugar

(34.94 mg/g) after 36 h of enzymatic hydrolysis. Whereas, alkali

pretreated, acid pretreated and untreated biomass yielded 29.56,

23.81 and 2.58 mg/g reducing sugar after 48 h. In 3% alkaline

hydrogen peroxide pretreated sorghum straw after an initial phase

of rapid sugar formation during 36 h the rate of hydrolysis

decreased which could be due to enzyme inactivation or depletion

of an easily hydrolysable fraction of hemicellulose. As compared to

alkali and acid pretreatments, alkaline hydrogen peroxide treat-

ment is more effective in lignin solubilisation (Chen et al., 2008)

and improving of crop residue digestibility (Talebnia et al., 2010)

(Fig. 14).

4. Conclusion

Due to the increasing economic relevance of xylanases present

study was designed and attempt was made to optimize different

process parameters. The detailed optimization study resulted in a

3.74-fold enhancement in xylanase production as compared to

that of the initial conditions. The cellulase-free and thermo-alkali-

solvent stable xylanase produced by the newly isolated B. altitu-

dinis DHN8 using least reported sorghum straw as substrate is one

of the rare xylanases because of its stability at extreme process

conditions prevailing in the paper industry. The xylanase was able

to release reducing sugars mainly xylose from alkaline hydrogen

peroxide treated sorghum straw biomass which could be further

fermented to biofuel.

Acknowledgement

Authors are greatly acknowledges the nancial assistance from

Department of Science and Technology (DST), Ministry of Science

and Technology, Govt. of India, for giving INSPIRE Fellowship to

Mr. Dharmesh N. Adhyaru, under INSPIRE Program.

References

Anuradha, P., Vijayalaxmi, K., Prasanna, N.D., Sridevi, K., 2007. Production and

properties of alkaline xylanases from Bacillus sp. isolated from sugarcane eld.

Curr. Sci. 90, 12831286.

Bailey, M.J., Biely, P., Poutanen, K., 1992. Laboratory testing of methods for assay of

xylanase activity. J. Biotechnol. 23, 257270.

Bajaj, B.K., Manhas, K., 2012. Production and characterization of xylanase from

Bacillus licheniformis P11(C) with potential for fruit juice and bakery industry.

Biocatal. Agric. Biotechnol. 1, 330337.

Bajaj, B.K., Singh, N.P., 2010. Production of xylanase from an alkalitolerant

Streptomyces sp. 7b under solid state fermentation, its purication and

characterization. Appl. Biochem. Biotechnol. 162, 18041818.

Bajpai, P., 1997. Microbial xylanolytic enzyme system properties and applications.

Appl. Environ. Microbiol. 43, 141189.

Battan, B., Sharma, J., Dhiman, S.S., Kuhad, R.C., 2007. Enhanced production of

cellulase-free thermostable xylanase by Bacillus pumilus ASH and its potential

application in paper industry. Enzyme Microb. Technol. 41, 733739.

Beg, Q.K., Kappor, M., Mahajan, L., Hondal, G.S., 2001. Microbial xylanases and their

industrial applications: a review. Appl. Microbiol. Biotechnol. 20, 325333.

Bisaria, V.S., Ghose, T.K., 1991. Biodegradation of cellulosic materials: substrates,

microorganisms, enzymes and products. Enzyme Microb. Technol. 3, 90104.

Chavez, R., Bull, P., Eyzaguirre, J., 2006. The xylanolytic enzyme system from the

genus Penicillium. J. Biotechnol. 123, 413433.

Chen, H., Han, Y., Xu, J., 2008. Simultaneous saccharication and fermentation of

steam exploded wheat straw pretreated with alkaline peroxide. Process

Biochem. 43, 14621466.

Chivero, E.T., Mutukumira, A.N., Zvauya, R., 2001. Partial purication and char-

acterization of a xylanase enzyme produced by a microorganism isolated from

selected indigenous fruits of Zimbabwe. Food Chem. 72, 179185.

Collins, T., Gerday, C., Feller, G., 2005. Xylanases, xylanase families and extremo-

philic xylanases. FEMS Microbiol. Rev. 29, 323.

Cormana, E.C., Fialho, M.B., Buchgnani, E.B., Coelho, G.D., Brocheto-Braga, M.R.,

Jorge, J.A., 2005. Production, purication and characterization of a minor form

of xylanase from Aspergillus versicolor. Process Biochem., 359364.

Dhillon, A., Khanna, S., 2000. Production of a thermostable alkali-tolerant xylanase

from Bacillus Circulans AB 16 grown on wheat straw. World J. Microbiol.

Biotechnol. 16, 325327.

Flores, M.E., Perez, R., Huitron, C., 1997. -xylosidase and xylanase characterization

and production by Streptomyces sp. CH-M-1035. Lett. Appl. Microbiol. 24,

410416.

Gassesse, A., MaMo, G., 1999. High- level xylanase production by an alkaliphilic

Bacillus sp. by using solid state fermentation. Enzyme Microb. Technol.. 25,

6872.

Gawande, P.V., Kamat, M.Y.J., 1999. Production of Aspergillus xylanase by lignocel-

lulosic waste fermentation and its application. J. Appl. Microbiol. 87, 511519.

Ghose, T.K., 1987. Measurements of cellulase activities. Pure Appl. Chem. 59,

257268.

Gomes, J., Purkarthofer, H., Hyan, M., Kapplmuler, M., Sinner, N., Steiner, W., 1993.

Production of high levels of cellulase-free xylanase by Thermomyces lanuginosus

in laboratory scale and pilot scale using lignocellulosic materials. Appl. Micro-

biol. Biotechnol. 39, 700707.

Gupta, S., Bhushan, B., Hoondal, G.S., 2000. Isolation, purication and characteriza-

tion of xylanase from Staphylococcus sp. SG-13 and its application in biobleach-

ing of kraft pulp. J. Appl. Microbiol. 88, 325334.

Haapala, R., Linko, S., Parkkinen, E., Sumimonen, P., 1994. Production of endo-1,4

glucanase and xylanase by Trichoderma reesei immobilized on polyurethane

foam. Biotechnol. Tech. 8, 401406.

Han, X., Zheng, Lian, S., Xie, Y., 2004. Study on screening and cultivation conditions

xylanase producing alkaliphilic bacteria. Wuhan Univ. J. Nat. Sci. 9, 125128.

Khandeparkar, R., Bhosle, N.B., 2006. Purication and characterization of thermo-

alkalophilic xylanase isolated from the Enterobacter sp. MTCC 5112. Res.

Microbiol. 157, 315325.

Khasin, A., Alchanati, I., Shoham, Y., 1993. Purication and characterization of a

thermostable xylanase from Bacillus stearothermophilus T-6. Appl. Environ.

Microbiol. 59, 17251730.

Kiddinamoorthy, J., Anceno, A.J., Haki, G.D., Rakshit, S.K., 2008. Production,

purication and characterization of Bacillus sp. GRE7 xylanase and its applica-

tion in eucalyptus kraft pulp biobleaching. World J. Microbiol. Biotechnol. 24,

605612.

Kumar, A., Gupta, R., Shrivastava, B., Khasa, Y.P., Kuhad, R.C., 2012. Xylanase

production from an alkaliphilic actinomycete isolate Streptomyces sp. RCK-

2010, its characterization and application in saccharication of second genera-

tion biomass. J. Mol. Catal. B: Enzym. 74, 170177.

Kumar, V., Satyanarayana, T., 2011. Applicability of thermo-alkali-stable and

cellulase-free xylanase from a novel thermo-halo-alkaliphilic Bacillus halodur-

ans in producing xylooligosaccharides. Biotechnol. Lett. 33, 22792285.

Lakshmi, G.S., Rao, C.S., Rao, R.S., Hobbs, P.J., Prakasham, R.S., 2009. Enhanced

production of xylanase by a newly isolated Aspergillus terreus under solid state

fermentation using palm industrial waste: a statistical optimization. Biochem.

Eng. J. 48, 5157.

0

5

10

15

20

25

30

35

40

0 12 24 36 48

R

e

d

u

c

i

n

g

s

u

g

a

r

(

m

g

/

g

)

Time (h)

Untreated Acid treated Alkali treated Alkaline peroxide treated

Fig. 14. Enzymatic hydrolysis of chemically pretreated sorghum straw using crude

xylanase from B. altitudinis DHN8. Saccharication was carried out at 50 1C,

100 rpm for 48 h. Aliquots were taken at regular interval of 12 h and analysed for

reducing sugar production.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 189

Li, W.F., Zhou, X.X., Lu, P., 2005. Structural features of thermozymes. Biotechnol.

Adv. 23, 271281.

Li, X., She, Y., Sun, B., Song, H., Zhu, Y., Lv, Y., Song, H., 2010. Purication and

characterization of cellulase-free, thermostable xylanase from Streptomyces

rameus L2001 and its biobleaching effect on wheat straw pulp. Biochem. Eng.

J. 52, 7178.

Lincon, R.D., 1960. Control of stock culture preservation and inoculum build up in

bacterial fermentation. Microbiol. Technol. Eng. 2, 481500.

Lowry, O.H., Rosebrough, N.J., Farr, A.L., Randall, R.J., 1951. Protein measurement

with the folin phenol reagent. J. Biol. Chem. 31, 426428.

Miller, L.G., 1959. Use of dinitrosalicylic acid reagent for determination of reducing

sugar. Anal. Chem. 31, 426428.

Nagar, S., Gupta, V.K., Kumar, L., Kuhad, R.C., 2010. Production and optimization of

cellulase-free, alkali-stable xylanase by Bacillus pumilus SV-85S in submerged

fermentation. J. Ind. Microbiol. Biotechnol. 37, 7183.

Nagar, S., Mittal, A., Kumar, D., Gupta, V.K., 2012. Production of alkalitolerant

cellulase free xylanase in high levels by Bacillus pumilus SV-205. Int. J. Biol.

Macromol. 50, 414420.

Oliveira, L.A., Porto, A.L.F., Tambourgi, E.B., 2006. Production of xylanase and

protease by Penicillium janthinellum CRC 87-M-115 from different agricultural

wastes. Bioresour. Technol. 97, 862867.

Palmer, T., 2001. The Chemical Nature of Enzyme Catalysis, Enzymes: Biochemistry,

Biotechnology and Clinical chemistry. Hardwood Publication Ltd, UK, pp.

191222. (Chapter 11).

Polizeli, M.L.T.M., Rizzatti, A.C.S., Monti, R., Terenzi, H.F., Jorge, J.A., Amori, D.S.,

2005. Xylanases from fungi: properties and applications. Appl. Microbiol.

Biotechnol. 67, 577591.

Prakash, P., Jayalakshmi, S.K., Prakash, B., Rubul, M., Sreeramulu, K., 2011. Produc-

tion of alkaliphilic, halotolerant, thermostable cellulase free xylanase by Bacillus

halodurans PPKS-2 using agrowaste: single step purication and characteriza-

tion. World J. Microbiol. Biotechnol. 82, 183192.

Qie, Z., Shi, P., Luo, H., Bai, Y., Yuan, T., Yang, P., Liu, S., Yao, B., 2010. A xylanase with

broad pH and temperature adaptability from Streptomyces megaspores DSM

41476, and its potential application in brewing industry. Enzyme Microb.

Technol. 46, 506512.

Sanghi, A., Garg, N., Sharma, J., Kumar, K., Kumar, R.C., Gupta, V.K., 2008.

Optimization of xylanase production using inexpensive agro-residues by

alkalophilic Bacillus subtilis ASH in solid state fermentation. World J. Microbiol.

Biotechnol. 24, 633640.

Sardessai, Y., Bhosle, S., 2004. Industrial potential of organic solvent tolerant

bacteria. Biotechnol. Progr. 20, 655660.

Savitha, S., Sadhasivam, S., Swaminathan, K., 2007. Application of Aspergillus

fumigatus xylanase for quality improvement of waste paper pulp. Bull. Environ.

Contam. Toxicol. 78, 217221.

Sepahy, A.A., Ghazi, S., Sepahy, M.A., 2011. Cost-effective production and optimiza-

tion of alkaline xylanase by indigenous Bacillus mojavensis AG 137 fermented

on agricultural waste. Enzyme Res. , http://dx.doi.org/10.4061/2011/593624.

Sharma, A., Adhikari, S., Satyanarayana, T., 2007. Alkali-thermostable and cellulase-

free xylanase production by an extreme thermophile Geobacillus thermoleovor-

ans. World J. Microbiol. Biotechnol. 23, 483490.

Sharma, P., Bajaj, B.K., 2005. Production and partial characterization of alkalitoler-

ant xylanase from an alkaliphilic Streptomyces sp. CD3. J. Sci. Ind. Res. 64,

688698.

Subramaniyan, S., Prema, P., 2000. Cellulase free xylanase from Bacillus and other

microorganisms. FEMS Microbiol. Lett. 183, 17.

Sunna, A., Antranikian, G., 1997. Xylanolytic enzymes from fungi and bacteria. Crit.

Rev. Biotechnol. 17, 3967.

Talebnia, F., Karakashev, D., Angelidaki, I., 2010. Production of bioethanol from

wheat straw: an overview on pretreatment, hydrolysis and fermentation.

Bioresour. Technol. 101, 47444753.

Taneja, K., Gupta, S., Kuhad, R.C., 2002. Properties and application of a partially

puried alkaline xylanase from an alkaliphilic fungus Aspergillus nidulans KK99.

Bioresour. Technol. 85, 3942.

Wong, K.K.Y., Tan, L.U.L., Saddler, J.N., 1982. Multiplicity of -1,4-xylanase in

microorganisms: functions and applications. Microbiol. Rev. 52, 305317.

D.N. Adhyaru et al. / Biocatalysis and Agricultural Biotechnology 3 (2014) 182190 190

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Perkin Elmer Gas Chromatography PDFDocument6 pagesPerkin Elmer Gas Chromatography PDFrammohanroyalNo ratings yet

- Cho 1Document8 pagesCho 1rammohanroyalNo ratings yet

- G. Ramanjaneyulu, Et Al PDFDocument6 pagesG. Ramanjaneyulu, Et Al PDFrammohanroyalNo ratings yet

- DocumentDocument5 pagesDocumentrammohanroyalNo ratings yet

- Dehydrogenase ActivityDocument10 pagesDehydrogenase ActivityrammohanroyalNo ratings yet

- Comparitive Pretreatment Studies On Wheat StrawDocument11 pagesComparitive Pretreatment Studies On Wheat StrawrammohanroyalNo ratings yet

- Basic Techniques The Do's and Don'ts of Cell CultureDocument2 pagesBasic Techniques The Do's and Don'ts of Cell Culturemakis_sigalas100% (1)

- Enzyme XylanaseDocument5 pagesEnzyme XylanaserammohanroyalNo ratings yet

- Recent Developments in Microbial Oils ProductionDocument18 pagesRecent Developments in Microbial Oils ProductionrammohanroyalNo ratings yet

- Adenini Complementory Test PDFDocument8 pagesAdenini Complementory Test PDFrammohanroyalNo ratings yet

- Ev1311-01 PHD Copenhagen 0Document2 pagesEv1311-01 PHD Copenhagen 0rammohanroyalNo ratings yet

- Carotenoid Based Yeast ScreeningDocument10 pagesCarotenoid Based Yeast ScreeningrammohanroyalNo ratings yet

- ColumnDocument10 pagesColumnrammohanroyalNo ratings yet

- Yeast GeneticsDocument86 pagesYeast Geneticsdiashx70% (1)

- FulltextDocument8 pagesFulltextrammohanroyalNo ratings yet

- Brazilian Journal of Chemical EngineeringDocument5 pagesBrazilian Journal of Chemical EngineeringrammohanroyalNo ratings yet

- International Food Research JournalDocument8 pagesInternational Food Research JournalrammohanroyalNo ratings yet

- Isolation and Identification of BacteriaDocument1 pageIsolation and Identification of BacteriarammohanroyalNo ratings yet

- Substrate Dependency and Effect of Xylanase Supplementation On Enzymatic Hydrolysis of Ammonia-Treated BiomassDocument12 pagesSubstrate Dependency and Effect of Xylanase Supplementation On Enzymatic Hydrolysis of Ammonia-Treated BiomassrammohanroyalNo ratings yet

- CaroteneDocument6 pagesCarotenerammohanroyalNo ratings yet

- FulltextDocument8 pagesFulltextrammohanroyalNo ratings yet

- OjokohDocument3 pagesOjokohMuhammad Edi SukmanaNo ratings yet

- 9 F 957375 B 361250 FB 704Document15 pages9 F 957375 B 361250 FB 704api-498018677No ratings yet

- Instructions For Assembling Your Owners ManualDocument8 pagesInstructions For Assembling Your Owners ManualJim PowersNo ratings yet

- Pulse Production in India: Major Constraints and Way ForwardDocument33 pagesPulse Production in India: Major Constraints and Way ForwardDeus EXNo ratings yet

- 8th Semester Mechanical Engineering Syllabus (MG University)Document17 pages8th Semester Mechanical Engineering Syllabus (MG University)Jinu MadhavanNo ratings yet

- Vision Medilink Product DetailsDocument4 pagesVision Medilink Product DetailsRaj SekarNo ratings yet

- Time ManagementDocument1 pageTime ManagementZaidi1No ratings yet

- Denon DHT-T100 Ver 3 PDFDocument34 pagesDenon DHT-T100 Ver 3 PDFboroda241083% (6)

- Start A Quick Budget Start A Budget by MonthDocument13 pagesStart A Quick Budget Start A Budget by MonthMichelle PadillaNo ratings yet

- 1402AHS Prac Manual - 2023 - FINALDocument200 pages1402AHS Prac Manual - 2023 - FINALRuan BritsNo ratings yet

- Water Quality Parameters A Case Study of Karnafully - Dr. A K MajumderDocument6 pagesWater Quality Parameters A Case Study of Karnafully - Dr. A K MajumderMd. Badrul IslamNo ratings yet

- Co JetDocument4 pagesCo JetJaime PaulNo ratings yet

- Desalting Opportunity CrudesDocument8 pagesDesalting Opportunity CrudesTheophile MegueptchieNo ratings yet

- Made in His ImageThe Amazing Design of The Human BodyDocument4 pagesMade in His ImageThe Amazing Design of The Human BodyAriam MariaNo ratings yet

- (AC-S07) Week 07 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (7573)Document5 pages(AC-S07) Week 07 - Pre-Task - Quiz - Weekly Quiz (PA) - INGLES IV (7573)Lucero JimenezNo ratings yet

- Employement ExchangeDocument22 pagesEmployement ExchangeNeelam ThakurNo ratings yet

- Black and Decker Vaporera Electrica RecetarioDocument17 pagesBlack and Decker Vaporera Electrica RecetarioFabio AtenógenesNo ratings yet

- A Guide To Patient Medication Review: September 2003Document33 pagesA Guide To Patient Medication Review: September 2003Muhamad GunturNo ratings yet

- Industrialisation by InvitationDocument10 pagesIndustrialisation by InvitationkimberlyNo ratings yet

- Chapter1-The Clinical LabDocument24 pagesChapter1-The Clinical LabNawra AhmadNo ratings yet

- Fdocuments - in From The Margins To The Mainstream Disaster Research at The CrossroadsDocument26 pagesFdocuments - in From The Margins To The Mainstream Disaster Research at The CrossroadsHanan M. HadidiNo ratings yet

- Developments in Injection Moulding 3Document331 pagesDevelopments in Injection Moulding 3Salah HammamiNo ratings yet

- ISO 9001: 2015 Certified Semen Freezing LaboratoryDocument43 pagesISO 9001: 2015 Certified Semen Freezing LaboratoryShubhamNo ratings yet

- Mapeh 10 1 Grading Examination: E. Modern NationalismDocument3 pagesMapeh 10 1 Grading Examination: E. Modern NationalismMildred Abad SarmientoNo ratings yet

- Aigen Zhao, PHD, Pe, Gse Environmental, LLC, Usa Mark Harris, Gse Environmental, LLC, UsaDocument41 pagesAigen Zhao, PHD, Pe, Gse Environmental, LLC, Usa Mark Harris, Gse Environmental, LLC, UsaCarlos Ttito TorresNo ratings yet

- HC-33 Maximum Moisture Hair Styling Gel PDFDocument2 pagesHC-33 Maximum Moisture Hair Styling Gel PDFdianaNo ratings yet

- Physical, Chemical and Biological HazardsDocument32 pagesPhysical, Chemical and Biological HazardsDaisy ObisoNo ratings yet

- Whisper 500 Spec SheetDocument1 pageWhisper 500 Spec Sheetfranco cuaylaNo ratings yet

- Safety Data Sheet: Rhodamine B (C.I.45170) For MicrosDocument9 pagesSafety Data Sheet: Rhodamine B (C.I.45170) For MicrosSeshagiri KalyanasundaramNo ratings yet

- 2023-24 SR - Super60 (Incoming) STERLING Batch CHEMISTRY Teaching & Test Schedule Code@03!04!2023Document16 pages2023-24 SR - Super60 (Incoming) STERLING Batch CHEMISTRY Teaching & Test Schedule Code@03!04!2023K R I S H100% (1)