Professional Documents

Culture Documents

RFQ - ATM (20110323) Tanks Manual

Uploaded by

Almario SagunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RFQ - ATM (20110323) Tanks Manual

Uploaded by

Almario SagunCopyright:

Available Formats

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

REQUISITION (CONSTRUCTION)

for

STORAGE TANKS

of

JG Summit Naphtha Cracker Project

in

Batangas, Philippines

Client : JG Summit Petro. Corp.

STE Proposal No. : STE-PROP-10-080-002 (Rev.0)

June 18, 2010 (Rev.0)

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : June 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

CONTENTS

1. Tank Item List

2. Scope of Supply and Work

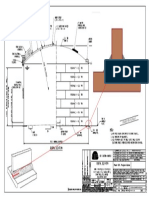

3. General Assembly Drawings

4. Project Schedule

5. Painting Specification

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

1. Tank Item List

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

1. Tank Item List

No Item Product Type

Qt'y

(Set)

Capacity

(/1-Tank)

Size

Main

Material

Dia(mm)

HT (mm)

(G.L to CL)

1 D-0407

Flux Oil

CRT 1 154 5,500 6,500 A283-C

2 D-0516

Wash Oil

CRT 1 411 8,300 7,600 A283-C

3 D-3001A/B

FRN

SDFRT 2 46,770 55,120 19,900

4 D-3021

Raw

Pyrolysis

Gasoline

CIFRT 1 10,615 26,160 19,750

A573-70

A283-C

5 D-3022

Pyrolysis

Gasoline

CRT 1 15,884 32,000 19,750 A283-C

6 D-3031

Pyrolysis

Fuel Oil

CRT 1 471 9,000 7,400 A283-C

7 D-3051

Fresh

Caustic

CRT 1 199 5,850 7,400 A516-60

8 D-3052

Caustic

Day

CIFRT 1 33 2,950 4,900 A283-C

9 D-3141

Desalinated

water

CRT 1 5,360 20,000 17,060 A283-C

10 D-3151

Demi. Water

CRT 1 2,940 16,000 14,620 A283-C

11 D-3201

Spent

Caustic

CRT 1 735 9,750 9,850 A516-60

Total 12

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2. Scope of Supply and Work

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2. Scope of Supply and Work

[ Classification ] :

( S ) Mark means STEs scope

( V ) Mark means Vendors scope

( X ) Mark means out of STEs scope

2.1 Scope of Supply

( S ) Equipment proper

( S ) Internal and external accessories indicated on Inquiry

( S ) Clips for platform/ladder/pipe support directly welded on equipment

( S ) Internal support

( S ) Bolts/nuts, clamps, gaskets for internal

( S ) Blind flanges together with bolts/nuts and gaskets for blinded nozzles & manholes

( S ) Davits and/or hinge for manholes

( S ) Vortex breaker (if required)

( S ) Insulation support rings (required Tank)

( S ) Anchor bolts, nuts and washers (if required)

( S ) Platforms, stairs, ladders & handrails, roof handrail (without roof platform)

( S ) Water spray pipe (1.5m from G.L) with spray nozzles on tank

( S ) Foam pipe (1.0m from G.L) with support

( S ) Emergency vent cover, gauge hatches (required tanks)

( S ) Breather valve with flame arrester (if required)

( S ) Vent with bird screen (if required)

( S ) Name plates (A240-304) with bracket

( S ) Earth lugs

( S ) Settlement check lugs (if required)

( V ) Heavy equipment for construction

( V ) Welding rods for construction

( V ) Tools and jigs for construction

( V ) Consumable material for erection

( V ) Blind flanges together with bolts/nuts and proper gaskets for hydrostatic test

( V ) Corrosion inhibitor for hydrostatic test (if required)

( V ) Painting material for equipment proper

( V ) Sealing between tank bottom and foundation

( V ) Test plate for PQT and WPQT

( S ) Spare parts of gasket and B/N for construction and commissioning

( S ) Spare parts of gasket and B/N for 2-years operation (by option)

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2.2 Scope of Work

( S ) Mechanical design (strength calculation, stress analysis and detail design)

( S ) Documentations and manufacturing drawings

( S ) Provision of as-built documents and drawings

( S ) Loading data for tank foundation

( S ) Material procurement

( S ) Mechanical guarantee

( S ) Shop fabrication

( V ) Site construction

( V ) PWHTC-3051,C-3052 only

( V ) Inspection & test at shop and test

( V ) Touch-up painting and site as per painting specification

( V ) Dimensional check and acceptance of foundation including minor adjustment work

( V ) WPS with PQR and WPQT

( V ) Hydro-test and water drainage as broom clean condition after hydro-test and drying

( V ) Settlement checking during hydrostatic test

( V ) Rust prevention

( V ) Third party inspection excluded its inspectors fee

( S ) Packing list (packing volume, size & weight, etc.)

( S ) Packing and inland transportation in Korea

( X ) Ocean transportation and inland transportation in Philippine

( V ) Unloading of materials at site

( V ) Temporary work of utility for construction and test

( S ) Documentation for government approval

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

2.3 Out of Scope

( X ) Tank foundation and civil

( X ) Electrical and Instrument

( X ) Process Piping

( X ) Cabling and wiring materials

( X ) Cathodic protection system

( X ) All kinds of valves including shut-off valves for draw-off sumps and external piping

( X ) Companion flanges with bolts/nuts

( X ) Insulation material and work

( X ) Fire protection material and work (if required)

( X ) Grouting for tank bottom

( X ) Utility for construction

( X ) Foam chamber with deflector

( X ) Electricity for construction (will be supplied to the first panel within 100m by Owner)

( X ) Water (will be supplied to the first block valve by Owner)

( X ) Customs clearance and taxes & duties for importation in Thailand

( X ) Government permit and approval (for local regulation)

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

3. General Assembly Drawings

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : J une 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

4. Project Schedule

Project Name : Storage Tank for JG Summit NCC Project Date : Dec. 20. 2010

1. MILESTONES

2. ENGINEERING

-

-

-

3. PROCUREMENT

-

-

-

4. PRE-FABRICATION

-

-

-

5. OCEAN FREIGHT

-

-

-

-

6. CONSTRUCTION

Preparation

- Material and Tool-Consumable Prepare of on site

- Temporary Facillties & shop welder test

Q'ty Weight

I.D(m) H(m) Set Ton

- D-3001A SDFRT 55.12 19.60 1 922 Aug.15

- D-3001B SDFRT 55.12 19.60 1 922 Aug.15

- D-3021 CRT 26.16 19.75 1 264 Jul.14

- D-3022 CIFRT 32.00 19.75 1 354 Jul.14

- D-3031 CRT 9.00 7.40 1 30 Jul.14

- D-3051 CRT 5.85 7.40 1 16 Jul.14

- D-3052 CRT 2.95 4.90 1 8 Jul.14

- D-3141 CRT 20.00 17.06 1 124 Jul.29

- D-3151 CRT 16.00 14.62 1 73 Oct.15

- D-3201 DRT 9.75 9.85 1 34 Jun.15

- D-0407 CRT 5.50 6.50 1 15 May.16

- D-0516 CRT 8.30 7.60 1 24 May.16

5

278Ton

2010 2011 2012

63Ton

1,000Ton

1,000Ton

All Item

S-Tank Engineering Co.,Ltd.

1 7 8

2,652Ton

2,368Ton

362Ton

4

56Ton

Body Detail Drawing

Accessory Detail Drawing

Steel Plate

Steel Shape 405Ton

All Item

All Item

Others Material

Others Material

Steel Plate

3rd Shipment

1st Shipment

2nd Shipment

Steel Shape

3

DESCRIPTION

9 10

Strength Calculation

Gr.

Remarks

12 3 4 6 5 2 11 12

G

r

.

1

G

r

.

2

G

r

.

3

PROJECT MASTER SCHEDULE

Item No Type

Tank Size

6 1 2

ERECTION START FABRICATION START 1ST SHIPMENT HYDRO TEST START MECHANICAL COMPLETE

TECHNICAL PROPOSAL

FOR

STORAGE TANKS

DATE : June 18, 10

REV.0

S-Tank Engineering Co., Ltd.

S-TANK ENGINEERING

5. Painting Specification

PROJ ECT : Storage Tanks for J G Summit NCC Project in Batangas, Philippines

P R I C E F O R M

'11. 01. 26 (Rev.0)

S-TANK ENGINEERING CO., LTD.

Net

Capacity

per Tank

Design

Pressure

C.A (S/B/R)

Shell

Thick.

Internal

Coating

&

Lining

Q'TY W/T Construction

Field

PWHT

Test

and

Inspection

(Excluding

H.T Water)

Site

Painting

&

Epoxy

Coating

Insulation

(Work)

Tank

Calibratio

n

Sub

Total

( C )

Total

D H () (mmH20) (mm) (mm) (Yes/No) SET (TON) (USD) (USD) (USD) (USD) (USD) (USD) (USD) (USD)

1 D-0407 FluxOil Tank CRT API 650 SA283-C 5.50 6.50 154 150/-50 0.950 3.0/3.0/1.5

6.0

9.0/9.0

7.0

No 1 15

2 D-0516

Wash Oil Storage

Tank

CRT API 650 SA283-C 8.30 7.60 411 150/-50 0.950 3.0/3.0/1.5

6.0

9.0/9.0

7.0

No 1 24

3 D-3001A/B FRN Storage Tank SDFRT API 650

SA573-70

SA283-C

55.12 19.60 46,770 F.W 0.720 3.0/3.0/3.0

8.0~26.0

9.0/9.0

8.0

No 2 1,844

4 D-3021

RawPyrolysis

GassolineStorageTank

CRT API 650 SA283-C 26.16 19.75 10,615 F.W+150/-25 0.771 3.0/3.0/1.5

6.0~17.0

9.0/9.0

7.0

No 1 264

5 D-3022

Pyrolysis Gasoline

Storage Tank

CIFRT API 650 SA283-C 32.00 19.75 15,884 F.W+150/-25 0.813 1.5/1.5/1.5

6.0~20.0

8.0/8.0

7.0

No 1 354

6 D-3031

Pyrolysis Fuel Oil

Storage Tank

CRT API 650 SA283-C 9.00 7.40 471 F.W+150/-25 1.011 3.0/3.0/1.5

6.0

9.0/9.0

7.0

No 1 30

7 D-3051

Fresh Caustic

Storage Tank

CRT API 650 SA283-C 5.85 7.40 199 150/-25 1.530 3.0/3.0/1.5

6.0

9.0/9.0

7.0

No 1 16

8 D-3052

Caustic Day

Storage Tank

CRT API 650 SA283-C 2.95 4.90 33 150/-25 1.205 3.0/3.0/1.5

6.0

9.0/9.0

7.0

No 1 8

9 D-3141

Desalinated Water

Tank

CRT API 650 SA283-C 20.00 17.06 5,360 F.W 0.995 0/0/0

6.0~12.0

6.0/6.0

6.0

Epoxy

Coating

1 124

10 D-3151

Demi. Water

Storage Tank

CRT API 650 SA283-C 16.00 14.62 2,940 F.W 1.000 0/0/0

6.0~9.0

6.0/6.0

6.0

Epoxy

Coating

1 73

11 D-3201

Spent Caustic

Tank

CRT API 650 SA283-C 9.75 9.85 735 150/-25 1.089 3.0/3.0/1.5

6.0~7.0

9.0/9.0

7.0

No 1 34

12 2,786

S.G

Total

Remarks NO ITEM NO. Product

Applied

CODE

Main

Material

Tank Size

(m)

Type

You might also like

- Spherical Tank Technical SpecificationDocument21 pagesSpherical Tank Technical SpecificationAlmario Sagun100% (1)

- Drawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013Document4 pagesDrawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013chompink6900No ratings yet

- Large Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalDocument2 pagesLarge Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalBarmar SbahiNo ratings yet

- Field Erected Tanks - API Cantoni System (Innovative Method) - Above Ground Storage Tank API 650 - YouTubeDocument2 pagesField Erected Tanks - API Cantoni System (Innovative Method) - Above Ground Storage Tank API 650 - YouTubeSlim Kanoun100% (1)

- Cryogenic Tank Erection ProcedureDocument5 pagesCryogenic Tank Erection Proceduretaparia_piyushNo ratings yet

- Tank GADocument1 pageTank GASubramanianNo ratings yet

- Tank Schedule 18.10Document1 pageTank Schedule 18.10Muhammad WaseemNo ratings yet

- LPG Storage Tanks LPG Tank 100 M Ton Qty LPG Tank 100 M Ton QtyDocument69 pagesLPG Storage Tanks LPG Tank 100 M Ton Qty LPG Tank 100 M Ton QtyIqra AngelsNo ratings yet

- Name Designation JOB Job Description Crew NoDocument52 pagesName Designation JOB Job Description Crew NoattaullaNo ratings yet

- Ferrofab's State-of-the-Art Heavy Engineering and Manufacturing FacilityDocument20 pagesFerrofab's State-of-the-Art Heavy Engineering and Manufacturing Facilitysd.ehtesham100% (1)

- Erection Tank Settlement Check Schedule 103 110 165Document8 pagesErection Tank Settlement Check Schedule 103 110 165hrdsby100% (1)

- Format From EIL 5 2744 0212 F1 - REV2Document27 pagesFormat From EIL 5 2744 0212 F1 - REV2sshastrimechNo ratings yet

- FIRENZE FPSO Preservation Maintenance Project EstimationDocument1 pageFIRENZE FPSO Preservation Maintenance Project EstimationSriNo ratings yet

- PROJECT STANDARD and SPECIFICATIONS Oil Storage Recommended Practices Rev01webDocument5 pagesPROJECT STANDARD and SPECIFICATIONS Oil Storage Recommended Practices Rev01webKaren Isabel Ambiado RivasNo ratings yet

- Description SLP Number Date Location Project Client Prepared by REF Attachments Machine: ConfigurationDocument1 pageDescription SLP Number Date Location Project Client Prepared by REF Attachments Machine: ConfigurationozchrisNo ratings yet

- Gangway Tower Preservation Procedure On SiteDocument4 pagesGangway Tower Preservation Procedure On SiteSalim Mohd RazNo ratings yet

- EilDocument33 pagesEilparasshuram0% (2)

- (Package-2-Mech Works) : Clean Fuels ProjectDocument17 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNo ratings yet

- Quotation For Industrial Pipling MaterialsDocument6 pagesQuotation For Industrial Pipling MaterialsKingsley MNo ratings yet

- B2020-TDC-SR-006 Shell Rolling R0Document2 pagesB2020-TDC-SR-006 Shell Rolling R0Ramalingam PrabhakaranNo ratings yet

- Calculation of Maximum Discharge RateDocument1 pageCalculation of Maximum Discharge Ratech3g44No ratings yet

- TBE Master-Y3 - R-2154-101H - R0 (Storage Tank) - 20091022Document4 pagesTBE Master-Y3 - R-2154-101H - R0 (Storage Tank) - 20091022meshahan100% (1)

- Plate Sheet Cutting PlansDocument1 pagePlate Sheet Cutting PlansAlbet MulyonoNo ratings yet

- Tank Design and DetailingDocument17 pagesTank Design and DetailingFuatNo ratings yet

- 130 - S-HZL Storage tankBOQ - 20.12.19Document4 pages130 - S-HZL Storage tankBOQ - 20.12.19ananthu.uNo ratings yet

- Fabrication Daily ReportDocument2 pagesFabrication Daily ReportlangcvNo ratings yet

- Cons Tank enDocument27 pagesCons Tank enSujesh Beherain VasudevaNo ratings yet

- CCK VNT DuplexDocument4 pagesCCK VNT DuplexNikki RobertsNo ratings yet

- Eil Tender List: S.No Project Name Bidding/Document NoDocument2 pagesEil Tender List: S.No Project Name Bidding/Document NoarshadbayaNo ratings yet

- AFS, KanpurDocument5 pagesAFS, Kanpurdipmoip2210No ratings yet

- NPM40 Hn8239 W (20080902)Document21 pagesNPM40 Hn8239 W (20080902)Bui Duy ThanhNo ratings yet

- Dung Quat Refinery Project WBS StructureDocument18 pagesDung Quat Refinery Project WBS Structurethanhvutn@yahoo.comNo ratings yet

- Khadimally RT011215Document33 pagesKhadimally RT011215jkj_13874No ratings yet

- DSP Phase I Structural Works StatusDocument1 pageDSP Phase I Structural Works Statuspata nahi hai mujeNo ratings yet

- KfloatDocument24 pagesKfloatBTE100% (1)

- External Floating RoofDocument14 pagesExternal Floating RoofAjeetKumarNo ratings yet

- Pertamina (Persero) 080221 - Spherical Tank Terminal LPG Reff Jatim 1 - TubanDocument1 pagePertamina (Persero) 080221 - Spherical Tank Terminal LPG Reff Jatim 1 - TubanMochamad TaufikNo ratings yet

- Engineering Design Guide For Storage TanksDocument107 pagesEngineering Design Guide For Storage Tankssonng.engNo ratings yet

- Format SOW TankiDocument8 pagesFormat SOW TankiprtamaekaputraNo ratings yet

- Oisd STD 141Document31 pagesOisd STD 141Amritesh PandeyNo ratings yet

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocument20 pagesITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriNo ratings yet

- Daily Progress UpdateDocument20 pagesDaily Progress UpdateMathias OnosemuodeNo ratings yet

- Fabrication Daily ReportDocument898 pagesFabrication Daily ReportlangcvNo ratings yet

- Mechanical Engineer CV for Oil & Gas rolesDocument4 pagesMechanical Engineer CV for Oil & Gas rolesKarthik AnandanNo ratings yet

- CTS-TANK Gert Van MeijerenDocument38 pagesCTS-TANK Gert Van MeijerenA87_navjNo ratings yet

- Ramel Ornales Construction SuperintendentDocument6 pagesRamel Ornales Construction SuperintendentIndustrial WeldersNo ratings yet

- BTE Dome Brochure Jun 10Document2 pagesBTE Dome Brochure Jun 10م.ذكى فضل ذكىNo ratings yet

- API Standard 650 Storage Tank Data SheetDocument3 pagesAPI Standard 650 Storage Tank Data SheetLuis JaraNo ratings yet

- Annual Report HELLENIC PETROLEUM 2010Document77 pagesAnnual Report HELLENIC PETROLEUM 2010AbdelmotelbElbannaNo ratings yet

- Monitor Piping Construction Progress with WCS and ITPDocument8 pagesMonitor Piping Construction Progress with WCS and ITPAsraf Ali100% (1)

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- 50kl Cost Estimation of Storage TankDocument1 page50kl Cost Estimation of Storage TankRafeek ShaikhNo ratings yet

- Aviation Fuel System - WEC Engineers & Constructors Pte LTDDocument3 pagesAviation Fuel System - WEC Engineers & Constructors Pte LTDsipteckNo ratings yet

- API 650 Storage Tank Design ReportDocument69 pagesAPI 650 Storage Tank Design Reportshahroze mustafaNo ratings yet

- Withdrawn NACE Technical ReportsDocument11 pagesWithdrawn NACE Technical ReportspabloNo ratings yet

- Ssec Profile 2010Document47 pagesSsec Profile 2010Syaiful AzliNo ratings yet

- Oil Tank 750 m3Document15 pagesOil Tank 750 m3Lutfi AndreansyahNo ratings yet

- MM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With InternalDocument9 pagesMM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With Internalpragatheesk100% (1)

- P445 - Technical Proposal Rev.0Document37 pagesP445 - Technical Proposal Rev.0ArtG.EnziNo ratings yet

- TBDP A M DS 0007 2Document7 pagesTBDP A M DS 0007 2Bùi Văn HợpNo ratings yet

- WAIR Employer's Work-Accident-Illness ReportDocument2 pagesWAIR Employer's Work-Accident-Illness ReportAlmario Sagun80% (5)

- Annual medical report form insightsDocument5 pagesAnnual medical report form insightsGemarie Adarlo CastilloNo ratings yet

- AEDR Annual Work Accident-Illness Exposure Data ReportDocument4 pagesAEDR Annual Work Accident-Illness Exposure Data ReportAlmario Sagun100% (1)

- Petron Bataan Refinery Power Center Plans and ElevationsDocument1 pagePetron Bataan Refinery Power Center Plans and ElevationsAlmario SagunNo ratings yet

- Structural S 01 Petcoke BuildingDocument1 pageStructural S 01 Petcoke BuildingAlmario SagunNo ratings yet

- Work Contract SampleDocument1 pageWork Contract SampleAlmario SagunNo ratings yet

- Power Center CoverpageDocument1 pagePower Center CoverpageAlmario SagunNo ratings yet

- Petcoke Doors ScheduleDocument6 pagesPetcoke Doors ScheduleAlmario SagunNo ratings yet

- Typical Concrete Slab and Beam DetailsDocument1 pageTypical Concrete Slab and Beam DetailsAlmario SagunNo ratings yet

- Typical Concrete Slab and Beam DetailsDocument1 pageTypical Concrete Slab and Beam DetailsAlmario SagunNo ratings yet

- Approved For Construction: Etron Bataan RefineryDocument1 pageApproved For Construction: Etron Bataan RefineryAlmario SagunNo ratings yet

- Roof Plan, Reflected Ceiling, Detail PlanDocument1 pageRoof Plan, Reflected Ceiling, Detail PlanAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-02Document1 pagePower Center Building Electrical System-E-02Almario SagunNo ratings yet

- Sanitary P 01 Petcoke BuildingDocument1 pageSanitary P 01 Petcoke BuildingAlmario SagunNo ratings yet

- Structural S 02 Petcoke BuildingDocument1 pageStructural S 02 Petcoke BuildingAlmario SagunNo ratings yet

- Perspective - Petcoke BuildingDocument1 pagePerspective - Petcoke BuildingAlmario SagunNo ratings yet

- Sanitary P 02 Petcoke BuildingDocument1 pageSanitary P 02 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-05Document1 pagePower Center Building Electrical System-E-05Almario SagunNo ratings yet

- Mechanical DWNG - M02 Petcoke BuildingDocument1 pageMechanical DWNG - M02 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-03Document1 pagePower Center Building Electrical System-E-03Almario SagunNo ratings yet

- Power Center Building Electrical System-E-02Document1 pagePower Center Building Electrical System-E-02Almario SagunNo ratings yet

- Power Center Building Electrical System-E-04Document1 pagePower Center Building Electrical System-E-04Almario SagunNo ratings yet

- Power Center Building Electrical System-E-01Document1 pagePower Center Building Electrical System-E-01Almario SagunNo ratings yet

- Mechanical DWNG M-01 Petcoke BuildingDocument1 pageMechanical DWNG M-01 Petcoke BuildingAlmario SagunNo ratings yet

- Petcoke Transformer Plan & Elevation.p2Document1 pagePetcoke Transformer Plan & Elevation.p2Almario SagunNo ratings yet

- Architectural 01 - Petcoke BuildingDocument1 pageArchitectural 01 - Petcoke BuildingAlmario SagunNo ratings yet

- Petcoke Transformer Plan & Elevation-01Document1 pagePetcoke Transformer Plan & Elevation-01Almario SagunNo ratings yet

- Fire Rated Stainless Steel Double Panel DoorDocument2 pagesFire Rated Stainless Steel Double Panel DoorAlmario SagunNo ratings yet

- Architectural Drawing 01 - Petcoke BuildingDocument1 pageArchitectural Drawing 01 - Petcoke BuildingAlmario SagunNo ratings yet

- Proposed Man Ladder DesignDocument1 pageProposed Man Ladder DesignAlmario SagunNo ratings yet

- Datasheet Sigraflex MF - en 2010Document6 pagesDatasheet Sigraflex MF - en 2010m bNo ratings yet

- 2e-Aruana 40 Efi 2017Document57 pages2e-Aruana 40 Efi 2017costinbalca46No ratings yet

- Doosan Engine Dl08c Maintenance ManualDocument10 pagesDoosan Engine Dl08c Maintenance Manualkathleen100% (50)

- Remove Final Drive Pinions and FlangesDocument7 pagesRemove Final Drive Pinions and Flangesrapha raphaNo ratings yet

- CB506 - EN High Performance Decanter WestfaliaDocument2 pagesCB506 - EN High Performance Decanter WestfaliaLTE002No ratings yet

- Pw100-098R5 PW127 Fuel Nozzle Flexible Manifold InstallationDocument7 pagesPw100-098R5 PW127 Fuel Nozzle Flexible Manifold InstallationadzrocNo ratings yet

- Section 5 GposDocument21 pagesSection 5 GposDangolNo ratings yet

- DEP 31.38.01.11-Gen. (Piping General Requirements) - InformativeDocument24 pagesDEP 31.38.01.11-Gen. (Piping General Requirements) - InformativeDarrel Espino AranasNo ratings yet

- c90 - Manual de PartesDocument49 pagesc90 - Manual de Partesjorge mezaNo ratings yet

- Equipment Data Sheet: Saudi Arabian Oil CompanyDocument5 pagesEquipment Data Sheet: Saudi Arabian Oil CompanyzhangNo ratings yet

- Donaldson Replacement Filters & Spare Parts Catalog: Part Number Lists Conversions, Modifications & UpgradesDocument48 pagesDonaldson Replacement Filters & Spare Parts Catalog: Part Number Lists Conversions, Modifications & UpgradesSulaimanjeffNo ratings yet

- Complete AMERICAN Ductile Iron Pipe and Fittings Manual (12!14!15)Document366 pagesComplete AMERICAN Ductile Iron Pipe and Fittings Manual (12!14!15)Tan Nguyen CongNo ratings yet

- Register of StockDocument1,222 pagesRegister of StockAnonymous Of0C4dNo ratings yet

- Mack Reducing ValvesDocument11 pagesMack Reducing ValvesJOHNNo ratings yet

- Gate, Globe & Check Valves Technical SpecificationsDocument12 pagesGate, Globe & Check Valves Technical SpecificationsKrunal MahidadiaNo ratings yet

- SB2013E02 Diesel Engine ManualDocument78 pagesSB2013E02 Diesel Engine ManualTaufan Arif100% (4)

- Fire Pumps 9100 SeriesDocument2 pagesFire Pumps 9100 SeriesBiggie ColdAngelNo ratings yet

- Submittal Data SheetDocument8 pagesSubmittal Data SheetErickNo ratings yet

- Matchless MotorcyclesDocument44 pagesMatchless Motorcyclesisland14No ratings yet

- BWTS 2014 Performance Turbo Catalog PDFDocument68 pagesBWTS 2014 Performance Turbo Catalog PDFАндрей СтрилецNo ratings yet

- ADS Corrugated Heavy Duty Pipe Data SheetDocument4 pagesADS Corrugated Heavy Duty Pipe Data Sheetiask5275No ratings yet

- Opw Emea Product Catalog 2014 EnglishDocument64 pagesOpw Emea Product Catalog 2014 EnglishSergio MorenoNo ratings yet

- Triple Effect Evaporator PlantDocument28 pagesTriple Effect Evaporator PlantArjun KrishnakumarNo ratings yet

- CASE CX460 Crawler Excavator Parts Catalogue Manual PDFDocument31 pagesCASE CX460 Crawler Excavator Parts Catalogue Manual PDFfjjsekfksemm100% (1)

- Piping QuestionsDocument8 pagesPiping Questionsjijimon85No ratings yet

- Catalog: Trailer PartsDocument12 pagesCatalog: Trailer Partsseeralan_1986No ratings yet

- Service Instructions: DMX and DMHDocument14 pagesService Instructions: DMX and DMHataoulalimtNo ratings yet

- UntitledDocument2,174 pagesUntitledsukarno wijayaNo ratings yet

- 755Document19 pages755JOHNNo ratings yet

- Engine (WL, WL Turbo, WL-3, WLT-3) : Drive BeltDocument16 pagesEngine (WL, WL Turbo, WL-3, WLT-3) : Drive Beltpavel35No ratings yet