Professional Documents

Culture Documents

1ammonium Nitrate Industrial

Uploaded by

Edenson Flores TrujilloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1ammonium Nitrate Industrial

Uploaded by

Edenson Flores TrujilloCopyright:

Available Formats

Technical

Information

Properties

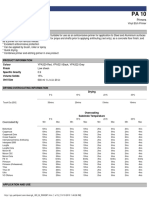

NLD-01-05-05-11

See Product Disclaimer on page 2

Hazardous Shipping Description

Ammonium Nitrate 5.1 UN1942 III or

Ammonium Nitrate Fertilizer 5.1 UN2067 III

AMMONIUM NITRATE

Industrial Grade

Product Description

DYNO NOBEL AMMONIUM NITRATE prills are industrial grade and specifcally

designed to be used as a solid oxidizer ingredient for explosive compositions such

as ANFO, WR ANFO, Heavy ANFO emulsion and watergels. They are small-sized

(average diameter range between 0.055 to 0.078 in (1.4 to 2.0 mm), low-moisture

content, non-setting, porous spheres (prills) which are a lower density than agricultural

grade ammonium nitrate used for fertilizer. The particle density of the prills is such

that, when liquid fuel is properly applied to and mixed with them, the prills absorb the

fuel uniformly which enhances reactivity. AMMONIUM NITRATE prills are infnitely

soluble in water and does not precipitate with any common chemical.

Application Recommendations

Low density AMMONIUM NITRATE is used extensively in the mining industry and

is intentionally made very porous to allow for the rapid uptake of liquid fuel oil. The

prill is coated with a paraffn which makes the AMMONIUM NITRATE diffcult to

dissolve and use for other applications. Consult your Dyno Nobel representative

for additional details.

AMMONIUM NITRATE will decompose into ammonia and nitric acid fume at

350

o

F.

MSDS

#1020

a

As manufactured. Screen analysis changes with with handling.

b

As manufactured. Bulk density as received may be higher [0.84 g/cc (52 lbs/cu ft)]

depending on types and amounts of handling prior to receipt.

U.S. Standard Mesh +8 +10 +12 +14 +16 +20 Fines

Average % retained 8 29 38 22 2 0.75 0.25

Typical Size Distribution

Ammonium Nitrate, % by weight 98.8

Moisture, % by weight <0.1

Screen Analysis

a

% by weight on 6 mesh

% by weight through 20 mesh

0

<1

Bulk Density, typical, pneumatic

g/cc

lbs/cuft

0.80

50

Donora, PA & Lomo, MO

Technical

Information

Product Disclaimer Dyno Nobel Inc. and its subsidiaries disclaim any warranties with respect to this product, the safety or suitability thereof, or the results to be obtained, whether express or

implied, INCLUDING WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND/OR OTHER WARRANTY. Buyers and users

assume all risk, responsibility and liability whatsoever from any and all injuries (including death), losses, or damages to persons or property arising from the use of this product. Under no circumstances

shall Dyno Nobel Inc. or any of its subsidiaries be liable for special, consequential or incidental damages or for anticipated loss of profts.

Dyno Nobel Inc.

2795 East Cottonwood Parkway, Suite 500, Salt Lake City, Utah 84121 USA

Phone 800-732-7534 Fax 801-328-6452 Web www.dynonobel.com

AMMONIUM NITRATE

product, see the Safety Library Publications of the Institute of Makers of Explosives

and/or consult the many publications that address transportation, storage and

handling of ammonium nitrate.

The Fertilizer Institute: AMMONIUM NITRATE Packaging, Handling,

Transportation, Storage and Use.

Bureau of Mines: I 28.23:6773 Explosive Hazards of Ammonium Nitrate Under

Fire Exposure.

International Fertilizer Industry Association: Handbook for the Safe Storage

of AMMONIUM NITRATE Based Fertilizers.

Institute of Makers of Explosives: Recommendations for the Transportation of

Explosives, Division 1.5 & AMMONIUM NITRATE Emulsions, Division 5.1 Bulk

Packaging.

Unauthorized access to industrial grade AMMONIUM NITRATE must be denied

at each step during transportation and storage.

ALWAYS rotate inventory by using the oldest product frst.

ALWAYS choose bins and tanks that are designed to keep the weight of the bulk

material from compacting into transfer augers that are located directly beneath

them.

ALWAYS empty and clean bulk tanks and bins routinely to prevent product build-up

on walls.

ALWAYS minimize inventory during warm weather and high humidity conditions.

Packaged product may harden with temperature cycling; bulk material may cake,

lump or break down (fnes).

ALWAYS keep prilled ammonium nitrate dry. Choose transportation, processing

and storage containers or equipment without openings though which water or

moisture can enter.

Dyno Nobel AMMONIUM NITRATE is available in bulk by railcar or truck.

ALWAYS wash vessels containing AMMONIUM NITRATE thoroughly before

attempting repairs requiring welding.

ALWAYS check with the bulk emulsion explosive or matrix manufacturer to ensure

compatibility before using ANFO containing Dyno Nobel prilled AMMONIUM

NITRATE in Heavy ANFO or repumpable emulsion/ ANFO blends.

ALWAYS keep doors, hatches and lids closed when not in use. Inspect all tanks and

bins regularly for cracks and leaks.

Industrial grade prilled ammonium nitrate is susceptible to breakage from moisture,

humidity, heat, temperature cycling, pressure and pneumatic or mechanical handling.

Fines can result producing possible caking or lumping as well as decreased product

fow characteristics / increased bulk density.

ALWAYS design storage and process facilities to minimize repeated pneumatic

and mechanical handling. Whenever possible, choose mechanical rather than

pneumatic methods to off-load or otherwise transfer ammonium nitrate prills.

ALWAYS use an air transfer pressure of 78 psig to maintain prill quality where bulk

deliveries are transferred to storage by pneumatic conveyance.

NEVER exceed 8-10 psig air pressure.

ALWAYS use equipment especially designed to blend and load ANFO, Heavy

ANFO or repumpable emulsion / ANFO blends. Bulk delivery equipment should be

calibrated periodically to ensure quality.

ALWAYS purge all hoses, piping, augers and especially bins or tanks that have

integral augers before discontinuing loading or mixing. AMMONIUM NITRATE prill

left in process equipment can make start up diffcult and even cause damage.

ALWAYS consider air vibrators for bins, bulk trucks and railcars to assist with the

fow of material.

Transportation, Storage and Handling

Oxidizers must be transported, stored, handled and used in conformity with all

applicable federal, state, provincial and local laws and regulations.

For recommended good practices in transporting, storing, handling and using this

Application Recommendations (continued)

You might also like

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- ANFO Explosives: Ammonium Nitrate (AN) As An Oxidizer - BackgroundDocument12 pagesANFO Explosives: Ammonium Nitrate (AN) As An Oxidizer - BackgroundmoolmanspitcontrolNo ratings yet

- AnfoDocument2 pagesAnfoSyahril Huda AndriyanNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Ammonium Nitrate v3Document2 pagesAmmonium Nitrate v3martinusteddy100% (1)

- Tds Bulk Systems Titan 5000 Heavy Anfo v6.0Document2 pagesTds Bulk Systems Titan 5000 Heavy Anfo v6.0jbravo999No ratings yet

- Vinnapas 8031 H (RI 551 Z)Document2 pagesVinnapas 8031 H (RI 551 Z)Shambhatia100% (1)

- Bitumen Brochure CUTBACK BPDocument2 pagesBitumen Brochure CUTBACK BPe110807No ratings yet

- IOCAENGRSMOMobilux EP 2Document2 pagesIOCAENGRSMOMobilux EP 2mh09No ratings yet

- RBA Training Bitumen HSE 20may2003Document33 pagesRBA Training Bitumen HSE 20may2003Pedro ValverdeNo ratings yet

- Ammonium Nitrate IndustrialDocument2 pagesAmmonium Nitrate IndustrialDina NovaliaNo ratings yet

- 1ammonium Nitrate Industrial PDFDocument2 pages1ammonium Nitrate Industrial PDFandreas gilangNo ratings yet

- Britannia LP Webinar Cargo Contamination on Chemical Tankers 03 2022Document71 pagesBritannia LP Webinar Cargo Contamination on Chemical Tankers 03 2022Manoj Kumar KalamegamNo ratings yet

- Oil SkimersDocument139 pagesOil SkimerszirimiaNo ratings yet

- 19 DuolineoilDocument2 pages19 Duolineoilstuart3962No ratings yet

- User Instructions Bull Wheel Liners 4-2010Document8 pagesUser Instructions Bull Wheel Liners 4-2010Alexander SladeNo ratings yet

- Nitoproof 100 PDFDocument2 pagesNitoproof 100 PDFmilanbrasinaNo ratings yet

- Axa Multimotive 1 (18.07.01)Document1 pageAxa Multimotive 1 (18.07.01)D Wahyu BawonoNo ratings yet

- Alufer N enDocument3 pagesAlufer N enStephen MalobaNo ratings yet

- Prevent Stress Cracking in Aluminum Can EndsDocument14 pagesPrevent Stress Cracking in Aluminum Can Endsmohd iqbalNo ratings yet

- Uses and Applications of AmmoniaDocument5 pagesUses and Applications of AmmoniaSohail Asghar100% (2)

- AnfoDocument2 pagesAnfoLuis Adrián ElguézabalNo ratings yet

- MSDS Foam Liquid AFFF Chemguard - STARVVO IndonesiaDocument10 pagesMSDS Foam Liquid AFFF Chemguard - STARVVO IndonesiaSaepul AnwarNo ratings yet

- PETRO Cube BrochureDocument13 pagesPETRO Cube Brochurepaulm3565No ratings yet

- Interlaced Braided Ptfe Packing: Operating ConditionsDocument2 pagesInterlaced Braided Ptfe Packing: Operating ConditionsPablo PasqualiniNo ratings yet

- Nalco 2000 Product Bulletin PDFDocument3 pagesNalco 2000 Product Bulletin PDFEragoncxz2No ratings yet

- Qerpodu01 Pctransfer Oxzeich 8file 890-000-000-000-014Document2 pagesQerpodu01 Pctransfer Oxzeich 8file 890-000-000-000-014dantopanNo ratings yet

- Safe Handling of BitumenDocument67 pagesSafe Handling of BitumenLamija LamyNo ratings yet

- Bombas NeumaticasDocument32 pagesBombas Neumaticasfawllyn guevaraNo ratings yet

- TDS 8034Document2 pagesTDS 8034Nguyễn Quốc Tiến0% (1)

- RINOL Surgical Medical Industrial Flooring Application and CatalogueDocument6 pagesRINOL Surgical Medical Industrial Flooring Application and CataloguedesignfNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Avalon 90ABDocument2 pagesAvalon 90ABborlixNo ratings yet

- Marthon Jotun Marine PaintDocument5 pagesMarthon Jotun Marine PaintNishanthNo ratings yet

- Carbothane 134 Series PDS Sept 2012Document2 pagesCarbothane 134 Series PDS Sept 2012salamrefighNo ratings yet

- Dion FR 9300Document6 pagesDion FR 9300Peñaloz GustavoNo ratings yet

- Marine Line 784 Protective CoatingsDocument6 pagesMarine Line 784 Protective CoatingsTushar SorteNo ratings yet

- Caltex HavolineXLIPremixedDocument2 pagesCaltex HavolineXLIPremixedsabujNo ratings yet

- Ultramax 68 Hydraulic Oil-PI SheetDocument2 pagesUltramax 68 Hydraulic Oil-PI SheetNgila João AndréNo ratings yet

- F013Document2 pagesF013Sai PrasathNo ratings yet

- Palmair Design ManualDocument37 pagesPalmair Design ManualAlfred Harvey ElacionNo ratings yet

- Castrol Optigear Synthetic A Serie - Pds - Eng. - Rev. 03.03.2010Document2 pagesCastrol Optigear Synthetic A Serie - Pds - Eng. - Rev. 03.03.2010MaxNo ratings yet

- Bentonite Trugel 100 2007-09Document1 pageBentonite Trugel 100 2007-09Tanadol PongsripachaNo ratings yet

- Ammonia SafetyDocument2 pagesAmmonia SafetydodolxNo ratings yet

- Rheomatrix 110: High-Performance Viscosity Modifying Agent (VMA) For Fluid ConcretesDocument2 pagesRheomatrix 110: High-Performance Viscosity Modifying Agent (VMA) For Fluid ConcretesAlexi ALfred H. TagoNo ratings yet

- Instructions For The Safe Use Of: Roundslings: Storing and Handling RoundslingsDocument2 pagesInstructions For The Safe Use Of: Roundslings: Storing and Handling Roundslingsreda mesbahNo ratings yet

- Safe Storage of Ammonium NitrateDocument16 pagesSafe Storage of Ammonium Nitratepartha das sharma100% (1)

- Rando MV PDFDocument3 pagesRando MV PDFHoang Minh HungNo ratings yet

- IndustrialDocument338 pagesIndustrialjjNo ratings yet

- Butonal NX1129Document4 pagesButonal NX1129Liz AfanadorNo ratings yet

- Fertilizer Chemical SafetyDocument3 pagesFertilizer Chemical Safetyahsani6No ratings yet

- Waterproofing Guide FountainsDocument2 pagesWaterproofing Guide FountainsBRVNo ratings yet

- Amsoil Antifreeze Coolant Antpc AnthdDocument2 pagesAmsoil Antifreeze Coolant Antpc AnthdamsoildealerNo ratings yet

- Vacuum Technology Catalogue FipaDocument794 pagesVacuum Technology Catalogue FipaJoão SilvaNo ratings yet

- Akros Multi FCT 10W-30 Transmission OilDocument10 pagesAkros Multi FCT 10W-30 Transmission OilFer EmilNo ratings yet

- Ammonium Nitrate CourseworkDocument8 pagesAmmonium Nitrate Courseworkbcnwhkha100% (2)

- Pinza 1Document88 pagesPinza 1Rio de MarioNo ratings yet

- OPW Fluid Transfer Group's Solutions for Ethanol Production, Loading, Transporting and UnloadingDocument10 pagesOPW Fluid Transfer Group's Solutions for Ethanol Production, Loading, Transporting and UnloadingNacho.pNo ratings yet

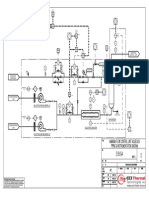

- Urea Infrastructure Project: Power Utility - North CarolinaDocument1 pageUrea Infrastructure Project: Power Utility - North CarolinaEdenson Flores TrujilloNo ratings yet

- HHO Hydrogen Generator GuideDocument35 pagesHHO Hydrogen Generator GuideANVNo ratings yet

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaNo ratings yet

- Diaz, ControlDocument179 pagesDiaz, ControlEdenson Flores TrujilloNo ratings yet

- Batch DistillationDocument197 pagesBatch DistillationKrishanu SahaNo ratings yet

- 4 FertilizerDocument12 pages4 FertilizerEnrique CastañedaNo ratings yet

- Inferential Control: Lack of MeasurementDocument11 pagesInferential Control: Lack of MeasurementEman El DsoukyNo ratings yet

- Inferential Control System of Distillation Compositions Using Dynamic Partial Least Squares RegressionDocument10 pagesInferential Control System of Distillation Compositions Using Dynamic Partial Least Squares RegressionEdenson Flores TrujilloNo ratings yet

- Ammonia Vaporization DrawingsDocument3 pagesAmmonia Vaporization DrawingsEdenson Flores TrujilloNo ratings yet

- MATLAB IntroDocument104 pagesMATLAB IntroCarlos Salas LatosNo ratings yet

- Ammonia Handling Manual PDFDocument14 pagesAmmonia Handling Manual PDFEdenson Flores TrujilloNo ratings yet

- Antennas - 2014 PDFDocument34 pagesAntennas - 2014 PDFEdenson Flores TrujilloNo ratings yet

- 04 Carbon Dioxide Absorption Into Aqueous Blends ofDocument15 pages04 Carbon Dioxide Absorption Into Aqueous Blends ofEdenson Flores TrujilloNo ratings yet

- 1ammonium Nitrate IndustrialDocument2 pages1ammonium Nitrate IndustrialEdenson Flores TrujilloNo ratings yet

- 04 Carbon Dioxide Absorption Into Aqueous Blends ofDocument15 pages04 Carbon Dioxide Absorption Into Aqueous Blends ofEdenson Flores TrujilloNo ratings yet

- Simulation of Sulfuric Acid Plant Using Aspen-HYSYSDocument3 pagesSimulation of Sulfuric Acid Plant Using Aspen-HYSYSacckypenrynNo ratings yet

- Divisor de Frecuencia de 50MHz A 1Hz para Parpadeo de LEDDocument2 pagesDivisor de Frecuencia de 50MHz A 1Hz para Parpadeo de LEDepievegaNo ratings yet

- Simzlab Eula - TXT 8/10/08 11:51 PMDocument6 pagesSimzlab Eula - TXT 8/10/08 11:51 PMpeteryu1028No ratings yet

- 91988v00 Modeling Industrial Chemical Processes With Matlab and Simulink 04 PPDocument4 pages91988v00 Modeling Industrial Chemical Processes With Matlab and Simulink 04 PPEdenson Flores TrujilloNo ratings yet

- journalTechV10N2 Aticle11Document9 pagesjournalTechV10N2 Aticle11dhavaleshNo ratings yet

- Termite ControlDocument8 pagesTermite ControlJoshua EdokpayiNo ratings yet

- Why Does Trend Following WorkDocument3 pagesWhy Does Trend Following Workapi-3701488No ratings yet

- Sound Generated AerodynamicallyDocument33 pagesSound Generated AerodynamicallyAbraham Benjamin Britto100% (1)

- Indo-European Lexicon: Pokorny Master PIE EtymaDocument44 pagesIndo-European Lexicon: Pokorny Master PIE EtymalamacarolineNo ratings yet

- Summer Trees AnalysisDocument5 pagesSummer Trees AnalysisseanNo ratings yet

- 2015 2nd-Term 5th-Primary English PDFDocument68 pages2015 2nd-Term 5th-Primary English PDFtootatootaNo ratings yet

- Agriculture Capsule For IBPS SO Agriculture Officer PDFDocument50 pagesAgriculture Capsule For IBPS SO Agriculture Officer PDFAravind AraNo ratings yet

- Enhanced Building Envelope Simulation with PCMsDocument10 pagesEnhanced Building Envelope Simulation with PCMsRam RamisettiNo ratings yet

- What Are Modal Verbs?: Examples: He Can Speak Chinese. She Should Be Here by 9:00Document26 pagesWhat Are Modal Verbs?: Examples: He Can Speak Chinese. She Should Be Here by 9:00Smita R. S.No ratings yet

- HVAC Guide: Controls, Operation, MaintenanceDocument11 pagesHVAC Guide: Controls, Operation, MaintenanceDaniel RgzNo ratings yet

- Clean Air ActDocument48 pagesClean Air ActEphraim Gieronymus Esteban80% (10)

- Optyma CU Leaflet - 46CDocument8 pagesOptyma CU Leaflet - 46CRahul PatilNo ratings yet

- 6th English Book Third TermDocument44 pages6th English Book Third TermTHERESA JNo ratings yet

- Home Flight Simulator Departure BriefingDocument20 pagesHome Flight Simulator Departure BriefinginstahNo ratings yet

- ARAB 102 Review This & Ism Wa SifaDocument1 pageARAB 102 Review This & Ism Wa Sifaresilient34No ratings yet

- Deepstar - Multiphase FlowDocument1,122 pagesDeepstar - Multiphase Flowfebrian100% (1)

- CEC 150 (K)Document4 pagesCEC 150 (K)I'am PhilNo ratings yet

- Guidance On Venting of Gas Systems Issue 1 Publication 9th Nov 2010Document26 pagesGuidance On Venting of Gas Systems Issue 1 Publication 9th Nov 2010elikruNo ratings yet

- CylianiDocument3 pagesCylianiCarlos MedinaNo ratings yet

- PPC Unit End QuestionsDocument5 pagesPPC Unit End QuestionsnaveenNo ratings yet

- How to Introduce Yourself and Make Small TalkDocument4 pagesHow to Introduce Yourself and Make Small TalksamagovaNo ratings yet

- DWDM Chapter 7 Decision TreeDocument33 pagesDWDM Chapter 7 Decision TreeAbhishek VkNo ratings yet

- ICAO Annex 3 XML RepresentationsDocument20 pagesICAO Annex 3 XML RepresentationsAmine SterNo ratings yet

- A3 Hima 1Document1 pageA3 Hima 1hima012No ratings yet

- Koba Fix 2Document3 pagesKoba Fix 2Linda Dwi ApecawatiNo ratings yet

- Aisi 340 Info PDFDocument3 pagesAisi 340 Info PDFAn DikaNo ratings yet

- 7Document3 pages7Faith InsoyNo ratings yet

- Sustainable Amsterdam 27-3-2015Document76 pagesSustainable Amsterdam 27-3-2015Aleks KoporgeNo ratings yet

- Mason's Borneo Hiking ExpeditionDocument3 pagesMason's Borneo Hiking ExpeditionMarta Romero62% (13)

- McQuiston HVAC Analysis Design 6th Solutions Parte1Document130 pagesMcQuiston HVAC Analysis Design 6th Solutions Parte1andreengmecNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Napoleon's Buttons: 17 Molecules That Changed HistoryFrom EverandNapoleon's Buttons: 17 Molecules That Changed HistoryRating: 4 out of 5 stars4/5 (25)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableFrom EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo ratings yet

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)