Professional Documents

Culture Documents

2009-07-24 Musculoskeletal Simulation Webinar

Uploaded by

Mounesh7Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2009-07-24 Musculoskeletal Simulation Webinar

Uploaded by

Mounesh7Copyright:

Available Formats

1

Musculoskeletal Webinar

Musculoskeletal Simulation Webinar

David Wagner, PhD

Ozen Engineering

July 24, 2009

Please visit:

http://www.ozeninc.com/default.asp?ii=273

for upcoming webinars

Welcome to the Webinar

Welcome to the Webinar. Please make sure

your audio is working

Feel free to use

computer speakers

or telephone

Type any questions

you have here

2

Summary

Coupling musculoskeletal modeling and finite element analysis

Extracting and incorporating 3D geometry and material properties

from tomographic medical image data

A Proposed workflow for incorporating musculoskeletal modeling

Modeling the human body Musculoskeletal simulation of activities

of daily living

Prevalent uses of simulation in the orthopedic industry

Uses of Simulation in the Orthopedic Industry

Replicating Physical Test Research (Internal/University)

Kim et al. 2008,

SBC2008-193023

Li et al. 2008, SBC2008-192776

Design of Orthopedic Devices and Prosthetics

ASME Summer Bioengineering Conference (2008)

Finding out what went wrong

Finite-element

analysis of

failure of the

Capital Hip

designs

Janssen et al.

2005

3

Benets of Simulation

The use of computational simulation can be beneficial if it:

accurately represents and replicates the physics of the system

increases the number of possible design iterations (within a fixed

time)

decreases the cost associated with each design iteration

improves the fidelity of analysis as related to making design

decisions

is integrated in the design process

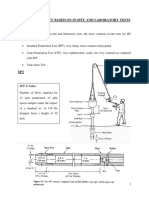

Replicating Standardized Physical Tests

For example

ASTM F384 -06 Standard Specifications and Test Methods for Metallic Angled Orthopedic

Fracture Fixation Devices (no associated ISO standard)

Methods for bending fatigue testing

Fatigue life over a range of maximum bending moment levels

Estimate the fatigue strength for a specified number of fatigue cycles

Not intended to define levels of performance of case-specific

ASTM F1264 Standard Specification and Test Methods for Intramedullary Fixation Devices

performance definitions

test methods and characteristics determined to be important to in-vivo performance

of the device (bending fatigue test, static torsion test, static four-point bend test)

It is not the intention of this specification to define levels of performance or case-

specific clinical performance of these devices, as insufficient knowledge to predict

the consequences of the use of any of these devices in individual patients for

specific activities of daily living is available

4

From Kojic 2008

Comparison of Fracture Fixation Devices

Fixed Plate

Internal compression

resulting from screw +

fixation plate geometry

Intramedullary nail

Bending stiffness:

K

b

= ExI

E, Youngs Modulus of Elasticity

I, the second moment of inertia

for bending of the nail cross

section

Torsional stiffness:

K

t

= ExI

t

G, Shear Modulus

I

t

, the second moment of inertia

for torsion

From Kojic 2008

Example Analysis - Fixed Plate Boundary Conditions

Fixed

Constraint

~ approximating

of axial load

during human

walking (single

stance phase of

70 kg

individual)

5

From Kojic 2008

Example Analysis Results - Effective Stresses

No slip

condition

modeled

between

screws, plate,

and bone =>

i.e. bonded

contacts

MPa

From Kojic 2008

Example Analysis Results - Fixed Plate Stresses

Stainless steel

used for plate

and screws

E = 2.1x10

5

Mpa

Poissons ratio = 0.3

Maximum effective stress

less than critical values for

stainless steel. However,

cyclic loading leading to

material fatigue must also

be considered

6

From Kojic 2008

Example Analysis - Intramedullary Nail

Same bone geometry,

material properties, and

boundary conditions as in

the neutralization plate

analysis

From Kojic 2008

Example Analysis - Intramedullary Nail Stresses

Effective stress concentrations in the nail near the screw regions => However, stress values

are significantly lower than the corresponding neutralization plate regions (~80 MPa).

Implication is that risk of intramedullary nail failure is significantly lower when compared to

neutralization plate.

7

From Kojic 2008

Example Analysis - Intracapsular Fractures

Parallel Screws Dynamic Hip Implant

Comparison of implant designs for internal fixation of intracapsular fractures of the

femoral neck

From Kojic 2008

Example Analysis - Parallel Screws BCs

Positive correlation

between

intraoperative

stability and

femoral neck

fractures that have

healed (versus did

not heal),

Rehnberg et al.

1989

Fixed Boundary

Condition

F

R

: Pelvis to femur head reaction force, 199 daN

F

A

: Force generated by gluteal muscles, 137 daN

Body weight: 70 daN

8

Can we use

simulation in a

more pro-active

way to develop

better products?

Doing More with Simulation (one idea)

Summary

Coupling musculoskeletal modeling and finite element analysis

Extracting and incorporating 3D geometry and material properties

from tomographic medical image data

A Proposed workflow for incorporating musculoskeletal modeling

Modeling the human body Musculoskeletal simulation of activities

of daily living

Prevalent uses of simulation in the orthopedic industry

9

Help understand what is going on inside the human body

We use simulation for many other engineering analyses,

why not for the human body as well

Design/redesign safe working environments

Teaching

Functional assessments (neuromusculoskeletal system)

Create/Mimic realistic movement

Sometimes the only way to understand and learn more

about complex systems (like people!)

Simulation for !Biomechanics" - Why?

Musculoskeletal Analysis

AnyBody

LifeMod

Opensim/SIMM/SimTK

Madymo (TNO)

ESI Group

Marlbrook

Motek

Digital Manikins

RAMSIS (Human

Solutions)

Jack (UGS/Siemens)

HumanBuilder/Delmia

(Dassault)

HumanCAD (NexGen)

SANTOS (U. Iowa)

Some others

Motion Capture

BodyBuilder (Vicon)

Simi

Qualisys

SIMM (Motion Analysis)

XSENS

Many others

CAE tools (FE/CAD)

ANSYS

LS-DYNA (ANSYS)

Abacus (Dassault)

AutoCAD (AutoDesk)

NASTRAN & ADAMS (MSC)

COMSOL

Other tools

Matlab (Mathworks)

Mathematica

Simulation Software for !Biomechanics"

10

The Holy Grail

Task + Environment + Population

Unique

Simulation

from Parkinson and Reed (2008)

Working Within the Connes of the Current Technology

Library of activities

Cant rely (yet) on the musculoskeletal models to adapt to new

task/environment conditions => particularly for novel (~non-cyclic)

tasks

Global Assessments vs. Better Products/Designs

Models that match measured results are great, but models that

exhibit realistic trends may be sufficient (and as useful)

Better incorporation/understanding of variability

E.g. Within subject variability as indicator of model performance

Will we ever be able to use Musculoskeletal Simulation

without a corresponding validation study

Cant ALWAYS be expected to conduct a validation study for a new activity

Must have confidence in the tools (e.g. Finite Element Models)

11

Expanding the Use of Activities of Daily Living with a

Library of Musculoskeletal Simulations

Long-term stability of hip-

implants have been

evaluated using normal

walking, sit to stand, stair

climbing, and combinations

of those activities.

Traditionally used as

pass/fail tests to identify

whether a particular design

performs to a set of

minimum specifications

Significantly Underutilized

Musculoskeletal Models Used Here

80

14.6

35

5.2

549

121

709

782

804

17

121

121

(b)

Popular class of musculoskeletal

models based on rigid body

dynamics:

Bones and objects from the

environment are rigid

Muscles and ligaments are

mass-less actuators

Soft tissue wobbly

masses are not taken into

account (mass is

concentrated in bones)

Phenomenological muscle

models

Easily scalable

Suited for simulating internal body forces (muscle,

joint, ligament) for prescribed activities

Static 2D

Dynamic 3D (AnyBody

Modeling System)

12

} ,.., 1 { , 0

] , [ where ,

) ( ) (

) ( ) (

M M

i

n i f ! "

= =

M R

f f f d Cf

Muscle

forces

Joint

reactions

Internal

forces

Applied

forces

The matrix C is rectangular. This means that there are

infinitely many solutions to the system of equations.

How to pick the right one?

Formulating Dynamic Equilibrium

Using Optimization to Get a Solution

!

Minimize

G(f

(M)

)

Subject to

Cf = d

f

i

(M )

" 0, i #{1,.., n

(M )

}

Objective function. Different

choices give different muscle

recruitment patterns.

What should be used for ?

!

G(f

(M)

)

13

Musculoskeletal Models for Commercial Use

No gold-standard, just like with other pieces of engineering

software

Commercially available (including open source) software

packages demand a knowledgeable user

Not traditionally incorporated in current design/engineering

methodologies

Always room for improvement (I.e. improved validation, better

accuracy, scaling to populations or patient specific, etc.)

Still must demonstrate where/how this arena of modeling can

improve specific processes (I.e. $$$)

Summary

Coupling musculoskeletal modeling and finite element analysis

Extracting and incorporating 3D geometry and material properties

from tomographic medical image data

A Proposed workflow for incorporating musculoskeletal modeling

Modeling the human body Musculoskeletal simulation of activities

of daily living

Prevalent uses of simulation in the orthopedic industry

14

Bridging the Gap with Simulation

Physical Testing

Simulated

Physical Testing

Simulated In-

Vivo Performance

All the necessary pieces:

Geometry

Mesh

Material Properties

Boundary Conditions

Solve

Post-Processing

Setting up an FE Simulation Using Boundary Conditions Derived from a

Musculoskeletal Model

15

Selected Arenas of Simulation (by Device)

The use of computational simulation can be beneficial if it:

accurately represents and replicates the physics of the system

increases the number of possible design iterations (within a fixed

time)

decreases the cost associated with each design iteration

improves the fidelity of analysis as related to making design

decisions

Starting with Geometry

16

Incorporating Musculoskeletal Modeling

Implant Evaluation

17

Implant Optimization

Associated Software

18

Summary

Coupling musculoskeletal modeling and finite element analysis

Extracting and incorporating 3D geometry and material properties

from tomographic medical image data

A Proposed workflow for incorporating musculoskeletal modeling

Modeling the human body Musculoskeletal simulation of activities

of daily living

Prevalent uses of simulation in the orthopedic industry

Geometry, Mesh, and Material Properties

Realistic geometries and material properties are practical ways to

improve the accuracy of the simulations

A NIH (National Institute of

Health) Project

Goal is anatomically detailed,

3D representation of the

human body

CT, MRI, Cryosection taken of

cadavers

Male specimen released 1994

Female specimen in 1995

Publicly available with an

application to National Library

of Medicine

CT

MRI

Cryosection

19

Tool for working with segmented

medical data

Provides a GUI environment to

apply various segmentation

methods

Creates and exports advanced 3D

geometries

Can be used to export Finite

Element Mesh (if desired)

Can be used to dene iso-tropic

material denitions from apparent

density relationships

Using Medical Data as Simulation Input

Deriving Material Properties From Scan Data

In Ansys, the mesh can be changed by a number of

operations, such as applying different boundary conditions or

for purposes of convergence

Deferring the material property assignment until the simulation

is fully set up ensures versatility

Bonemat is a public domain program originally written by

Cinzia Zannoni et al. at The Rizzoli Institute*

Uses a voxel data integration algorithm to determine material

properties for nte elements regardless of relative voxel size

*Zannoni C, Mantovani R, Viceconti M. Material properties

assignment to nite element models of bone structures: a new

method. Med Eng Phys 1998;20(10):73540.

20

Bonemat Workow

Bonemat takes 2 inputs:

A mesh in patran neutral le format (*.ntr)

Volumetric CT data in a vtk le format(rectilinear grid or point cloud)

Bonemat outputs:

An identical patran neutral mesh le with material properties assigned

An informational frequency le on material property distribution

Solution

Geometry Mimics

Commercially available software packages with

tomographic reconstruction capabilities

(Mimics, Analyze, Osiris) can also be used to

define material properties (isotropic) suitable for

FEA => using Hounsfield Units relationships

The material property of each

tetrahedral element was defined

using a procedure similar to that

used by Peng et al. (2006).

HU =

HU are normalized units associated with CT image

scans

- based on the linear attenuation coefficient ()

- based on scale -1000 (air) : + 1000 (bone), 0 (water)

Material properties from imaging data

21

Material properties from imaging data

The Hounsfield Units (HU) of each voxel in the CT scan indicates the radiodensity of the

material, distinguishing the different bone tissue types. There exist an approximate linear

relationship between apparent bone density and HU (Rho et al. 1995).

The maximum HU of the CT

scan, 1575, was defined to be

the hardest cortical bone of

density (2000 kg/m

3

) and the

HU value of 100 was defined to

be the minimum density of

cortical bone (100 kg/m

3

).

Density

100 kg/m

3

2000 kg/m

3

Material properties from imaging data

Elements were assigned elastic

moduli calculated from apparent

densities using axial loading

equations developed by Lotz et al.

(1991):

There exist an approximate power relationship between bone material properties and apparent

densities (Wirtz et al. 2000).

Elastic Moduli

A Poisson's ratio of 0.30 was

used for all materials.

HU >= 801, cortical bone (E = 2065!

3.09

MPa)

HU <= 800, cancellous bone (E = 1904!

1.64

MPa)

HU < 100, intramedullar tissue (E = 20 MPa)

22

Summary

Coupling musculoskeletal modeling and finite element analysis

Extracting and incorporating 3D geometry and material properties

from tomographic medical image data

A Proposed workflow for incorporating musculoskeletal modeling

Modeling the human body Musculoskeletal simulation of activities

of daily living

Prevalent uses of simulation in the orthopedic industry

All the necessary pieces:

Geometry

Mesh

Material Properties

Boundary Conditions

Solve

Post-Processing

Setting up the FE Simulation

23

Cycling Data

Cyclist Data

24

Musculoskeletal Simulation

Single Revolution

Observed Cadence of 62 rpm

5 points of support (pelvis, feet,

hands)

Anthropometry Matched to

Subject

Simulated Crank Torque =>

MechOutput = 170 (avg.

mechanical output over a

cycle in Watts)

Musculoskeletal Simulation

Force and Moment ! Free Body Diagram"

1 revolution = 0.97 seconds

Cut Plane (vector

lengths correspond to

force magnitudes)

25

Muscle Force Boundary Conditions at a Single Time Step

FE Model in Dynamic Equilibrium

- Matched mass and inertia

properties between rigid and

flexible body simulations

- Matched points of force

application

- No arbitrary constraints (i.e.

nodal position fixed in space)

- Inertia loads applied

- Model supported by weak springs

(~1e-3 Newtons), to prevent rigid

body motion

- Assumption of small deflections

26

Tested Fracture Fixation Plate (Distal Femur)

Geometry with 3 plate

thicknesses

3.25mm

4.0mm

4.75mm

Fatigue Life Results

Fatigue Life Minimum Cycles:

3.25 mm => 178,000 cycles

4.0 mm => 335,000 cycles

4.75 mm => 14.7 million cycles

Plots are depicted at

97% of cycle (t = 0.9704)

4.75 mm

3.25 mm

4.00 mm

Stress Life

Fully Reversed

t= 0.9409

Stress Life

Fully Reversed

t= 0.9409

Stress Life

Fully Reversed

t= 0.9409

27

Stress Contour Plots

Maximum Stress:

3.25 mm => 855 MPa

4.0 mm => 692 MPa

4.75 mm => 584 MPa

Plots are depicted at

97% of cycle (t = 0.9704)

4.75 mm

3.25 mm

4.00 mm

Yield Stress of Titanium Alloy => 930 MPa

Deformation Mode

Deformation from musculoskeletal forces @ 0.02 s, 18x scale

28

Equivalent Stresses for Three Plate Thicknesses

3.25mm

4.00mm

4.75mm

Summary of Simulation Capabilities

1. Replicating physical tests using

simulation

2. Compare performance of new

implant design to current on the

market device

3. Replicate implant failure

conditions associated

with clinical and/or case-specific

performance criteria

4. Evaluate implant performance

criteria (i.e. total deformation,

maximum stress, maximum

strain, and/or fatigue life)

for physiologically realistic

boundary conditions associated

with a single or library of

activities of daily living

29

Summary of Simulation Capabilities

5. Evaluate implant performance criteria

(i.e. total deformation, maximum

stress, maximum strain, and/or fatigue

life) for different populations (i.e. bone

size/geometry, bone quality/strength)

performing relevant activities of daily

living

6. Perform shape optimization of

parametrically defined implant to

maximize or satisfy

one/multiple performance objectives or

criteria

7. Perform sensitivity analysis on screw

placement and/or implant variations

with respect to performance criteria

8. Evaluate internal bone stresses

at/around implant-bone and bone-

bone interfaces for laboratory and

activity of daily living criteria

Thank you for your attention

Thank You For Your Attention

lor furLher lnformauon, please conLacL:

CZLn LnClnLL8lnC, lnC.

1210 L. A8CuLS AvL. Sul1L: 207

Sunn?vALL, CA 94083

(408) 732-4663

lnfo[ozenlnc.com

www.ozenlnc.com

lease leL us know lf you have any quesuons on speclc Loplcs presenLed here

(musculoskeleLal[ozenlnc.com)

Weblnars relaLed Lo musculoskeleLal slmulauon every monLh

(hup://www.ozenlnc.com/defaulL.asp?ll=273)

Cur 8uslness:

Collaborauon (l.e. granLs, Lralnlng)

Consulung

Soware

Some 8ecenL news (!uly 23, 2009)

hup://www.clemson.edu/newsroom/arucles/2009/[uly/Czen_gl_res.php3

30

You might also like

- LM50 23B12R2Document5 pagesLM50 23B12R2Mounesh7No ratings yet

- Kitab Ul-AquaidDocument32 pagesKitab Ul-AquaidMounesh7No ratings yet

- Updated On Board Team LoginDocument20 pagesUpdated On Board Team LoginMounesh7No ratings yet

- PLM - Indishtech PVT Ltd-Corporate ProfileDocument16 pagesPLM - Indishtech PVT Ltd-Corporate ProfileMounesh7No ratings yet

- Hayat e AlaHazratDocument138 pagesHayat e AlaHazratMounesh7No ratings yet

- The Real Reasons You Procrastinate PDFDocument15 pagesThe Real Reasons You Procrastinate PDFMounesh7No ratings yet

- M Tech Design EngineeringDocument22 pagesM Tech Design EngineeringMounesh7No ratings yet

- Madina Book1 Arabic TextDocument120 pagesMadina Book1 Arabic TextTewhid-islamNo ratings yet

- 1150 1Document58 pages1150 1Mounesh7No ratings yet

- Product Design 01Document6 pagesProduct Design 01Mounesh7No ratings yet

- Product Design 01Document6 pagesProduct Design 01Mounesh7No ratings yet

- Product Design 01Document6 pagesProduct Design 01Mounesh7No ratings yet

- HIFZDocument3 pagesHIFZMounesh7No ratings yet

- Gear Tooth DesignDocument18 pagesGear Tooth DesignMounesh7100% (1)

- Learn UrduDocument56 pagesLearn UrduSunilkumar Dubey86% (7)

- DisDocument1 pageDisMounesh7No ratings yet

- Learn UrduDocument56 pagesLearn UrduSunilkumar Dubey86% (7)

- Learn Urdu and English at HomeDocument39 pagesLearn Urdu and English at Homeapi-27152512100% (2)

- Urdu Ka Muallim Level1Document55 pagesUrdu Ka Muallim Level1Mounesh7No ratings yet

- LoadDocument1 pageLoadMounesh7No ratings yet

- ZakathDocument1 pageZakathMounesh7No ratings yet

- ThesisDocument1 pageThesisMounesh7No ratings yet

- Seven Qirats of The QurDocument11 pagesSeven Qirats of The Qurslavequadir1No ratings yet

- Book of SarfDocument263 pagesBook of SarfNasrin AktherNo ratings yet

- UrduDocument1 pageUrduMounesh7No ratings yet

- Models NewDocument2 pagesModels NewMounesh7No ratings yet

- Ishariya Fatwa Razviya Nusra Thul Haq, Rahmathe Kuha VandiDocument1 pageIshariya Fatwa Razviya Nusra Thul Haq, Rahmathe Kuha VandiMounesh7No ratings yet

- Kufic: Nabataean ScriptDocument11 pagesKufic: Nabataean ScriptMounesh7No ratings yet

- Urdu Ka Muallim Level1Document55 pagesUrdu Ka Muallim Level1Mounesh7No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 6 4rate of Plate MovementDocument5 pages6 4rate of Plate Movementapi-245872444No ratings yet

- Identifying VariablesDocument25 pagesIdentifying Variablesapi-236248022No ratings yet

- 15IPST024Document217 pages15IPST024Roland BagiNo ratings yet

- Gears and How Their World Is ChangingDocument69 pagesGears and How Their World Is Changingjohn doeNo ratings yet

- AP 101 SyllabusDocument3 pagesAP 101 SyllabusTamandeep SinghNo ratings yet

- Beginner Ansys TutorialDocument114 pagesBeginner Ansys TutorialNGUYEN92% (12)

- Product Safety Commission (Afps) : Management: Federal Institute For Occupational Safety and HealthDocument12 pagesProduct Safety Commission (Afps) : Management: Federal Institute For Occupational Safety and HealthFabricio AmorimNo ratings yet

- Determination of The Electron Specific MassDocument2 pagesDetermination of The Electron Specific MassAdina BlazeNo ratings yet

- Nonlinear AnalysisDocument8 pagesNonlinear Analysisstrawberry8320No ratings yet

- Trig EssayDocument4 pagesTrig Essayapi-265366548No ratings yet

- Investigating The Effect of Light Intensity On The Rate of PhotosynthesisDocument2 pagesInvestigating The Effect of Light Intensity On The Rate of PhotosynthesisIzwahaneIbrahim83% (12)

- Separation of Plant Pigments by Paper Chromatography PDFDocument3 pagesSeparation of Plant Pigments by Paper Chromatography PDFJade EncarnacionNo ratings yet

- Awdaw Aw Da Wda WDDocument6 pagesAwdaw Aw Da Wda WDebrown7No ratings yet

- Galata CFA Properties GuideDocument12 pagesGalata CFA Properties GuideToniHospitalerNo ratings yet

- Problems and Solutions To The MIChO Selection Camp 2015: Third PhaseDocument38 pagesProblems and Solutions To The MIChO Selection Camp 2015: Third PhaseYau Ching Koon100% (1)

- API GravityDocument1 pageAPI Gravityscribd_thakurNo ratings yet

- MTM Metro Expt1 ManualDocument10 pagesMTM Metro Expt1 ManualBhargav DindukurthiNo ratings yet

- Gypsum Moisture LossDocument3 pagesGypsum Moisture LossbyronvaughanNo ratings yet

- Determination of Synthesis Route of 1 - 3 4-Methylenedioxyphenyl - 2-Propanone Mdp-2-p Based On Impurity Profiles of MdmaDocument12 pagesDetermination of Synthesis Route of 1 - 3 4-Methylenedioxyphenyl - 2-Propanone Mdp-2-p Based On Impurity Profiles of Mdmagluebom69No ratings yet

- CP504Lecture - 06 - OK (Enzyme Reactor Design)Document12 pagesCP504Lecture - 06 - OK (Enzyme Reactor Design)Yurri Hutami ZarraNo ratings yet

- Molecular Energy Levels NotesDocument5 pagesMolecular Energy Levels Notesskrim2No ratings yet

- Heat Transfer Excel Calculations 1Document39 pagesHeat Transfer Excel Calculations 1Sharon LambertNo ratings yet

- Design of Concrete Airport PavementDocument64 pagesDesign of Concrete Airport Pavementaeroalan100% (4)

- Sediment Transport in Mountain Rivers: Christophe Ancey, Patricio Bohorquez, and Eric BardouDocument16 pagesSediment Transport in Mountain Rivers: Christophe Ancey, Patricio Bohorquez, and Eric BardouomeaveNo ratings yet

- 02 Mirski Czudak-Fem Used For Strength-Related Calculations of Adhesive Joints in The Making of Rail Vehicles PDFDocument9 pages02 Mirski Czudak-Fem Used For Strength-Related Calculations of Adhesive Joints in The Making of Rail Vehicles PDFAbhey DograNo ratings yet

- HeyWhatsThat Path ProfilerDocument2 pagesHeyWhatsThat Path ProfilerCharles VolkoffNo ratings yet

- Benzil SynthesisDocument2 pagesBenzil SynthesisVineeth GopalNo ratings yet

- Bearing Capacity From Other Methods-KFCDocument14 pagesBearing Capacity From Other Methods-KFCmazharNo ratings yet