Professional Documents

Culture Documents

EN

Uploaded by

reacharunkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN

Uploaded by

reacharunkCopyright:

Available Formats

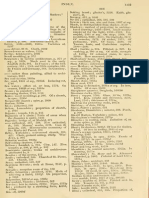

Chap. 1 1. GLASS.

5i5

Sect. XII

GLASS.

18()8. Glass is a combination of silex nitli fixed alkali, generally soda. Tlie mixture

when calcined receives the name of frit, which after the removal of all its impurities, is

conveyed to the furnace and melted in large pots or crucibles till the whole mass becon es

l>e;iutifiil]y clear, and the dross rises to the top. After being formed into the figures re-

quired, it is annealed or tempered by being placed in an appro])riate furnace. The /ineness

depends on the purity and proportion of tlie ingredients. An exiren.ely fine crystal glass

is ol)tained from 16 parts of (juartz, 8 of pure jjotash, 6 of calcined borax, 3 of fiake white,

and 1 of nitre. Tlie specific gravity of glass is about 26'()0

; of Frerxh plates, 28^0; of

English flint glass, 3:520. Glass is extremely elastic, and less dilatable by htat than

metallic substances.

18f)8rt. I'our pieces of the common sort of ulass being cut from one strip, each piece was

5 inches wide, 6 inches long, a.id 4 inches thick. In the trial of strenglh they were calcu-

lated out at a staniiard size, and gave 17.208 lbs., 15,435 lbs., 14,931 lbs , and 11,385 lbs.

;

the mean being H,931 lbs. This great didcMence is the more singu'ar irom the circum-

stance of all the pieces being cut from the same plate. The weight of the

j.

lass at a size

of 9-0 X 4-5 X 3, all in inches, would be 11-12 Ihs. Sheet glass is .stated to Ijc stronger than

folate or crown glass, but less flexible. The c niipressive strength of glass is about

12^ to;.s

per square inch. The resistance of g'a.ss to a crushing force is about 12 times its resistance

tj extension.

1869. Pliny gives the follovving accoimt of the discovery of manu'actui ing L-lass, which

was well known in Aristotle's time, 350 u. c. "A merchant ves.-,el. laden with nitre or

fossil alkali, being driven on the coast of Palestine, near tlie river Eelus, tiie crew acciden-

tiilly supported the kettles on which tliey dried their provisions on pieces of the fassil

alkali

;

the sand about it was vitrified by its union with the alkali, and ))roduced glass."

Th:uigh, according to Bede, artificers skilled in making glass were brought into England

in 674, glass windows "ere not generally used here till 1180, and were for a considerable

time esteemed marks of great magnifieence.

1870. The manufacture of window glass during the last thirty years has undergr.ne

entire alteration, es|'.ecially since the abolition of the excise duty in 18-1 5. There are now

three speci.d kinds of glass used for glazing purposes, and several varieties of them :

1870a. I. Crown glass, which is blown into large globes and opened out into circular

flat tables. 11. S'^.eii glass, which is blown into long cylinders or

////'_/f!,-;

then split down

and flattened. III. Piute glass, which is either cast on iron tables for large purpose, and

))olished; or for smaller squares, blown into a cylinder and polished

1871. Crown g!a-s, the commonest wiadow glass, difil'ers froui flint glass in its containiiig

no lead or any metallic oxide except manganese, and sometimes oxide of cobalt, in minute

portions, for correcting the col,<ur, and not as a flux. It is comi)oiu-.ded of sand, alkali,

either potash or soda, the ^egetable ashes that contain the alkali, and generally a small

I-ortion of lime. To facilitate fusion, a small dose of arse..ic is I'requmtly added. ZatlVe

or oxide of cobalt, in the proi)ortion of 1 ounce for lOCO pounds, is added to correct the

colour

; but when the sand, alkali, and lime are very fine, and no other ingredients are

used, zaffre is not required Its manufacture is conducted difierentlv fiom that of flint-

glass articles, the object being to pioduce a large flat thin jilate, which is afterwards

by the i;lazier's diamond cut into the requisite shape. It is blown in circular plates, \aiy-

i..g fom 3 feet 6 inches to 4 and 5 feet diameter: the process is as follows:The

workman, having a sufficient mass of melted metal on his blowpipe, rolls it on an iron

))hite, and then, swinging it backwards and lorwards, causes it liy its own gravity to

form into a globe, which is made and brought to the required thinness by blowing

witli a fan of breath, which persons accustomed to the work know how to manaire. Thj

iiollow globe is then opened by holding it to the fire, which expanding the air confined

within it (the hole of the blowpipe being stopped), bursts it al the weakest part, and while

still soft it is opened out into a flat jilate by centrifugal f irce ; and being disengaged from

the r. d. a thick knob is left in its centre. It is then jdaced in a furnace, or in a certain

part of the furnace to undergo the process of annealing. When the table is cut for use,

the centre part in which the knob remains is called Itnoh-ylass, and is used only for the

very commonest purposes. Tables are now made of such a size that squares may be pro-

cured 38 inches by 24 inches as extra sizes.

187ia. The qualities of crown glass in common use are called best, seconds, thirds, and

fourths or coarse

;

with two still coarser. The last is of a very green hue. and only used

lor inferior buildings. They were sold by the crute, at ti e same prlcj. tlie difference being

made up by varying the number of the tal)les contained in it. Thus a crate of best crown

plass contained twelve tables

; of seconds, a crate contained liftcen; and of thirds, eighteen

Ubics. They are now sold (by Messrs. Hartley) in crates of eighteen tables of the usml

N N

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Lab 2 - StoichiometryDocument4 pagesLab 2 - Stoichiometryapi-272470922100% (3)

- Zhang, Xiangwu - Fundamentals of Fiber Science-DeStech Publications (2014)Document431 pagesZhang, Xiangwu - Fundamentals of Fiber Science-DeStech Publications (2014)Fawad hameed100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Disinfection For PH 2Document73 pagesDisinfection For PH 2Boas WayneNo ratings yet

- Investigation of Failures of 230KV Copper Conductor BushingsDocument15 pagesInvestigation of Failures of 230KV Copper Conductor BushingscalripkenNo ratings yet

- Emergency Response Quick Guide MY: 2014Document2 pagesEmergency Response Quick Guide MY: 2014reacharunkNo ratings yet

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkNo ratings yet

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkNo ratings yet

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkNo ratings yet

- Prospekt BGF PDFDocument150 pagesProspekt BGF PDFreacharunkNo ratings yet

- NameDocument2 pagesNamereacharunkNo ratings yet

- Supplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesDocument65 pagesSupplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesreacharunkNo ratings yet

- PZU EDUKACJA INSURANCE TERMSDocument19 pagesPZU EDUKACJA INSURANCE TERMSreacharunkNo ratings yet

- Supplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesDocument65 pagesSupplement To The Prospectuses and Summary Prospectuses For Investor Shares and Admiral™SharesreacharunkNo ratings yet

- En (1457)Document1 pageEn (1457)reacharunkNo ratings yet

- En (1464)Document1 pageEn (1464)reacharunkNo ratings yet

- En (1463)Document1 pageEn (1463)reacharunkNo ratings yet

- En (1461)Document1 pageEn (1461)reacharunkNo ratings yet

- En (1462)Document1 pageEn (1462)reacharunkNo ratings yet

- En (1459)Document1 pageEn (1459)reacharunkNo ratings yet

- En (1460)Document1 pageEn (1460)reacharunkNo ratings yet

- En (1458)Document1 pageEn (1458)reacharunkNo ratings yet

- And Rome.: in Front of The Prostyle Existed atDocument1 pageAnd Rome.: in Front of The Prostyle Existed atreacharunkNo ratings yet

- En (1456)Document1 pageEn (1456)reacharunkNo ratings yet

- En (1454)Document1 pageEn (1454)reacharunkNo ratings yet

- En (1453)Document1 pageEn (1453)reacharunkNo ratings yet

- En (1455)Document1 pageEn (1455)reacharunkNo ratings yet

- En (1450)Document1 pageEn (1450)reacharunkNo ratings yet

- En (1452)Document1 pageEn (1452)reacharunkNo ratings yet

- Mate The: (Fig. - VrouldDocument1 pageMate The: (Fig. - VrouldreacharunkNo ratings yet

- En (1390)Document1 pageEn (1390)reacharunkNo ratings yet

- En (1451)Document1 pageEn (1451)reacharunkNo ratings yet

- En (1389)Document1 pageEn (1389)reacharunkNo ratings yet

- En (1387)Document1 pageEn (1387)reacharunkNo ratings yet

- En (1388)Document1 pageEn (1388)reacharunkNo ratings yet

- Course Outline For 125:355, Physiological Systems For Biomedical EngineersDocument2 pagesCourse Outline For 125:355, Physiological Systems For Biomedical EngineersbillNo ratings yet

- Micro 2000 - Deox 2000Document139 pagesMicro 2000 - Deox 2000Achr FFNo ratings yet

- 1229.1 Steam Sterilization by Direct ContactDocument3 pages1229.1 Steam Sterilization by Direct ContactWasimNo ratings yet

- Chapter 11 Physical and ChemicalDocument49 pagesChapter 11 Physical and ChemicalJJ Almagro100% (1)

- Tea Processing: How Leaves Become Black Tea in 4 StepsDocument27 pagesTea Processing: How Leaves Become Black Tea in 4 StepsSaidur Rahman KhanNo ratings yet

- Bioplastic ProjectDocument15 pagesBioplastic ProjectSarthak Verma100% (1)

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNo ratings yet

- (Re) Coating of Pylons With ZINGAENDocument5 pages(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateNo ratings yet

- Ceridust 5551 - For Lively Colors.: Exactly Your ChemistryDocument2 pagesCeridust 5551 - For Lively Colors.: Exactly Your ChemistryMaximiliano MackeviciusNo ratings yet

- EfflorescenceDocument5 pagesEfflorescenceOmkar BordeNo ratings yet

- Ultrasonic Gas Flowmeters For Permanent Installation in Hazardous AreasDocument31 pagesUltrasonic Gas Flowmeters For Permanent Installation in Hazardous AreasrudrakrNo ratings yet

- Vragen Fasediagrammen Zuivere Componenten PDFDocument3 pagesVragen Fasediagrammen Zuivere Componenten PDFbilberNo ratings yet

- Spelling Bee WordsDocument3 pagesSpelling Bee WordsDana GomezNo ratings yet

- Metallurgical Defects of Cast Steel: SeminarDocument26 pagesMetallurgical Defects of Cast Steel: SeminarFacebookNo ratings yet

- Question Paper Applied Physics, Sem-1, BS-105Document5 pagesQuestion Paper Applied Physics, Sem-1, BS-105Kartik AgrawalNo ratings yet

- Biotechnology Reviewer - Photosynthesis and Cellular RespirationDocument3 pagesBiotechnology Reviewer - Photosynthesis and Cellular RespirationMaribeth VillanuevaNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument70 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentAnonymous DxaBg8fUENo ratings yet

- Turton - Appb 30 37Document8 pagesTurton - Appb 30 37asadNo ratings yet

- Comenius - CodDocument13 pagesComenius - CodsridharancNo ratings yet

- Jazeera Deco Primer-MsdsDocument5 pagesJazeera Deco Primer-MsdsMahmoud FlefilNo ratings yet

- Mech-HT 15.0 WS05 SolenoidDocument16 pagesMech-HT 15.0 WS05 SolenoidAndres Felipe Salas VillalvaNo ratings yet

- Cyclones ExerciseDocument4 pagesCyclones ExerciseValeria cNo ratings yet

- Lobo and Evans PDFDocument6 pagesLobo and Evans PDFSong HoeNo ratings yet

- Effectiveness of Liquid Oxygen BleachDocument4 pagesEffectiveness of Liquid Oxygen BleachSingh GurleenNo ratings yet

- Msds Icr 122 LSFDocument12 pagesMsds Icr 122 LSFWisnu AbaraiNo ratings yet