Professional Documents

Culture Documents

AMRI ISORIA Broad Market Type Series Booklet Data

Uploaded by

rudiskw456Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AMRI ISORIA Broad Market Type Series Booklet Data

Uploaded by

rudiskw456Copyright:

Available Formats

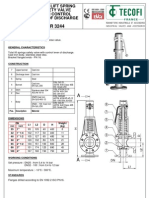

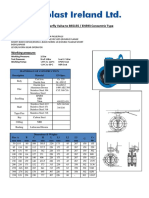

Type series booklet

8448.1/2-EN--US

ISORIA

Centered disc butterfly valves

with AMRING elastomer liner

240 PSI:

1 to 8

150 PSI :

10 to 24

Design in accordance with ISO 10631

Manual, electrical, pneumatical control

Applications

General circuits: water, fuel, oil, gas.

O.E.M.

Flow shut--off or regulation functions in the sectors including

water supply, treatment, distribution, sewage, irrigation.

Working conditions

Temperature: from 14 F (--10 C) minimum up to 230 F

(+110 C) maximum.

Allowable pressure (PS) at ambient temperature:

-- 240 psig (16 bar): NPS 1 (DN 40) to 8 (DN 200),

-- 150 psig (10 bar): NPS 10 (DN 250) to 24 (DN 600).

Materials

See page 2.

Design

Semi lug type body (Type 2): NPS1 (DN40) to 12 (DN300)

(NPS 1 to 12 may be installed as a wafer valve)

Full--lug type body with raised faces (Type 4): NPS1 (DN40)

to 24 (DN 600)

Possible downstream dismantling and end of line for bodies

Type 2 and 4.

Elastomer liner design includes an extra volume of rubber at

the shaft passage areas. This provides additional compression

to the disc and shafts for perfect shaft sealing.

Spherical machined disc ensures perfect upstream/

downstream sealing.

Face--to--face dimensions in accordance with ISO 5752 series

20, EN 558--1 series 20, API--609 Category A standards.

Connection standard defined on page 7.

Marking in accordance with EN 19.

Valves provide tight shut--off (no visible leakage) in either flow

direction, in accordance with EN 12266--1 leak level A and

ISO 5208 category A standards.

Design in accordance with ISO 10631.

Contains no asbestos, PCB and substances impairing paint

wetting.

Body coated with polyurethane paint, thickness 3 mils (80 m),

color blue ref. RAL 5012 conforming with the water

specifications.

The valves meet the safety requirements of the Pressure

Equipments Directive 97/23/EC (PED) appendix I for liquids

of the group 1 and fluids of the group 2.

A remote valve can be considered as a partly completed

machine in compliance with the requirements of the

machinery directive 2006/42/EC.

The valves comply with the requirements of the REACH

regulation.

Standard Operators + Accessories

CR handles

MG or MR gears

C series pneumatic double acting or spring return actuators

NAMUR VDI/VDE 3845 mount limit switches

NAMUR VDI/VDE 3845 mount positioners

NAMUR mount solenoid valves

Remarks

Operating instructions 8411.801/.-90

Data to be supplied when ordering

ISORIA valve in accordance with type leaflet

8448.1/2--EN--US.

Size.

Working conditions: nature of fluid, pressure, flow, temperature.

Flange connection.

Actuation.

ISORIA

2

Materials

Body KSB code

Type 2: Ductile iron JS 1030 NPS 1 to 12

Type 4: Ductile iron JS 1030 NPS 1 to 24

3g

3g

Shafts KSB code

Stainless steel 1.4029 (13 % Cr) NPS 1 to 24 6k

Disc KSB code

Aluminium--bronze CC333G/C95800 NPS 1 to 24

Ductile iron JS 1030 NPS 1 to 24

Stainless steel 1.4401 / AISI 316 SS NPS 1 to 8

Stainless steel 1.4408 / ASTM A351 gr. CF8M (316 SS) NPS 10 to 24

2

3g

6

6

AMRING liner KSB code

E.P.D.M drinking water approved

Temperature: from 14 F (--10 C) minimum up to 230 F (+110 C) maximum

-- ACS (French rules) approved

-- WRAS (English rules) approved

-- DVGW (German rules) approved

XC

High content nitrile

Temperature: from 23 F (--5 C) minimum up to 194 F (+90 C) maximum

K

Vacuum limits

NPS DN Minimum pressure Maximum temperature

inch mm psia

1 to 12 40 to 300 0.0002 (10

--2

torr) 194 F (90 C)

14 to 24 350 to 600 4.35 194 F (90 C)

ISORIA

3

Construction

100

412

310.1

970.1

310.2

213

550

310.3

413

210

100

412

310.1

900.1

970.1

310.2

213

550

310.3

413

210

916

310.4

900.2

NPS 14 to 24 NPS 8 to 12 NPS 1 to 6

100

970.1

213

550

413

210

412

Spare parts included in the liner kit Spare parts included in the disc kit Spare parts in the shaft kit

Item Designation NPS Materials

100 Body 1 to 24 Refer to materials paragraph page 2

210 Shaft 1 to 24 Stainless steel

213 Operating shaft 1 to 24 Stainless steel

310.1 Plain bearing 8 to 24 PTFE filled on steel casing

310.2 Plain bearing 8 to 24 PTFE filled on steel casing

310.3 Plain bearing 8 to 24 PTFE filled on steel casing

310.4 Plain bearing 14 to 24 PTFE filled on steel casing

412 O--ring 1 to 24 Nitrile

413 Liner 1 to 24 Refer to materials paragraph page 2

550 Disc 1 to 24 Refer to materials paragraph page 2

900.1 Anti blow--out screw 14 to 24 Stainless steel

900.2 Anti blow--out screw 14 to 24 Stainless steel

916 Plug 14 to 24 Polyethylene

970.1 Identity plate 1 to 24 Polyester + adhesive

To order spare parts in the kit, it is necessary to have the valve code from the identity plate.

ISORIA

4

Dimensions

e1

e2

h2

h1

h4

h3

Flat end s machined in z or

l1

s

NPS DN Face

to face

Mounting plate

ISO 5211

Flat shaft end Square shaft

end

Disc

clearance

inch mm l1 h1 h2 n h4 s z h3 s h3 e1 e2

1 40 33 105 51 F05 10 11 14 24 32 4

2 50 43 109 55 F05 10 11 14 24 33 4

2 65 46 136 67 F05 10 11 14 24 55 11

3 80 46 142 73 F05 10 11 14 24 71 17

4 100 52 163 92 F05 10 14 18 24 90 23

5 125 56 176 105 F05 10 14 18 30 119 35

6 150 56 194 120 F07 12 14 18 30 144 46

8 200 60 222 150 F07 12 19 25 35 196 69

10 250 68 255 194 F10 15 19 25 35 249 92

12 300 78 282 226 F12 18 22 28 40 297 111

14 350 78 335 269 F12 23 25 45 326 127

16 400 102 380 298 F14 23 36 55 370 140

18 450 114 410 329 F14 23 36 55 422 160

20 500 127 440 359 F14 27 36 55 470 178

24 600 154 495 439 F16 27 50 65 566 215

ISORIA

5

Hydraulic characteristics

NPS DN Valve flow coefficient in fully open position

inch mm Cvo

1 40 75

2 50 151

2 65 319

3 80 580

4 100 870

5 125 1,914

6 150 3,016

8 200 4,756

10 250 7,598

12 300 9,918

14 350 12,876

16 400 16,936

18 450 21,112

20 500 25,636

24 600 35,032

Operating torques*

NPS DN Operating torques* (in--lbs)

inch mm

150 psig (10 bar)

lubricated

150 psig (10 bar)

non lubricated

240 psig (16 bar)

lubricated

1 40 89 177 177

2 50 177 265 265

2 65 265 354 354

3 80 354 443 443

4 100 531 620 620

5 125 708 885 885

6 150 1,150 1,239 1,239

8 200 1,504 1,858 1,858

10 250 1,947 2,921

12 300 3,360 4,602

14 350 4,425 6,372

16 400 5,752 8,673

18 450 7,080 10,620

20 500 8,850 13,275

24 600 12,390 18,585

* The safety factor for actuator sizing is included in the torque value.

ISORIA

6

Manual control

Operator sizing is based on a maximumvelocity of 10 FT/sec liquid and 165 FT/sec gas. Higher velocities are possible through the

valve but may require a longer handle. Please consult AMRI for longer handle, gear, or other actuator recommendations.

Manual control -- CR handle -- NPS 1 to 12

d1

h5

l2

l1

NPS DN

Control by CR handle

NPS DN

Weight* (lbs)

inch mm l1 d1 l2 h5

Semi--lug type body

(T2)

Full--lug type body

(T4)

1 40 33 108 157 3.3 5.0

2 50 43 118

CR 165

162 3.9 6.1

2 65 46 132

CR 165

188 5.5 7.2

3 80 46 138 194 6.8 10.5

4 100 52 150 215 10.3 12.7

5 125 56 234 CR 300 249 13.4 20.9

6 150 56 260 266 18.3 25.3

8 200 60 322 305 29.7 59.5

10 250 68 394 CR 510** 338 42.7 92.5

12 300 78 462 365 72.7 107.9

* The indicated weights are those of the assembled valve + handle.

** Only for lubricated application

ISORIA

7

Connections

The ISORIA valves can be fitted between the connections EN 1092 PN 10, EN 1092 PN 16, ASME B16.5 cl.150 and ASME B16.1 cl.125 .

Other connections on request.

Semi--lug type body -- Type 2 -- NPS 1 to 12 (NPS 1 to 12 can be installed as a wafer valve)

NPS DN

Connection

inch mm EN 1092 PN 10 EN 1092 PN 16 ASME B16.1 cl.125 ASME B16.5 cl.150

1 40

2 50

2 65

3 80

4 100

5 125

6 150

8 200

10 250

12 300

Fitting allowed

When used as a semi--lug valve,

insert a washer between the nut and the rib of the valve

Full--lug body with raised faces -- Type 4 -- NPS 1 to 24

NPS DN Connection

inch mm ASME B16.1 cl.125 ASME B16.5 cl.150

1 40

2 50

2 65

3 80

4 100

5 125

6 150

8 200

10 250

12 300

14 350

16 400

18 450

20 500

24 600

Fitting allowed

ISORIA

8

d1

d1

These are representative drawings only and may not reflect the actual number of threaded and plain bolt holes

Bolting and weight for semi--lug type body -- Type 2

NOTE: Bolting to be supplied by customer

L : Min. length of stud bolts

l1 : Face to face of the valve

e : Flange thickness

(customer specification)

f : Nut thickness

+ in addition to the stud bolt

L = l1 + 2e + 2f

f l1 e e f

L

M

NPS DN

d1 l1

EN 1092 PN 10 EN 1092 PN 16

ASME B16.5 cl.150

ASME B16.1 cl.125

Weight NPS DN

d1 l1

Stud bolt * Stud bolt * Stud bolt *

Weight

inch mm M f Qty M f Qty UNC f Qty lbs

1 40 108 33 M16 20 4 M16 20 4 1/2 17 4 2.4

2 50 118 43 M16 20 4 M16 20 4 5/8 20 4 2.8

2 65 132 46 M16 20 4 M16 20 4 5/8 20 4 4.2

3 80 138 46 M16 20 8 M16 20 8 5/8 20 4 5.5

4 100 150 52 M16 20 8 M16 20 8 5/8 20 8 8.6

5 125 234 56 M16 20 8 M16 20 8 3/4 24 8 10.3

6 150 260 56 M20 24 8 M20 24 8 3/4 24 8 15.2

8 200 322 60 M20 24 8 M20 24 12 3/4 24 8 23.1

10 250 394 68 M20 24 12 M24 29 12 7/8 29 12 36.1

12 300 462 78 M20 24 12 M24 29 12 7/8 29 12 660

* Quantity of nuts = quantity of stud bolts x 2

ISORIA

9

Bolting and weight for lug type body with raised faces -- Type 4

d1 d1

A

B

e

X

A = e + X

l1

A : Mini length of screws

X : Maxi implantation of screws

B : Threaded length > A--e

e : Flange thickness

(customer specification)

These are representative drawings only and may not reflect the actual number of threaded and plain bolt holes

NOTE: Bolting to be supplied by customer

NPS DN

d1 l1

ASME B16.5 cl.150

ASME B16.1 cl.125

Weight

NPS DN

d1 l1

Screw

inch mm UNC X Qty * lbs

1 40 108 33 1/2 14 4 4.4

2 50 120 43 5/8 18 4 5.5

2 65 134 46 5/8 20 4 6.6

3 80 140 46 5/8 20 4 8.8

4 100 210 52 5/8 22 8 12.1

5 125 236 56 3/4 23 8 19.8

6 150 260 56 3/4 26 8 24,0

8 200 312 60 3/4 26 8 53 0

10 250 396 68 7/8 28 12 86,0

12 300 466 78 7/8 28 12 101,0

14 350 510 78 1 30 12 137,0

16 400 598 102 1 34 16 223,0

18 450 622 114 11/8 37 16 269,0

20 500 708 127 11/8 37 20 395,0

24 600 822 154 11/4 42 20 564,0

* Quantity of screws by face

ISORIA

10

Flange Dimensions

ISORIA valves are designed for assembly between any type of flange and connection standard currently used.

The liner is directly compressed by the flanges, so it is necessary to verify that proper liner compression and disc clearance will be

provided. The recommended flange dimensions in this table are the same for all body types.

2a 1

3

5

4

6 10

20

2a and 3: diameter on the supporting area of the flange face.

NPS DN

Optimum

dia.

Max. dia

tolerated

Min. dia.

tolerated

face of flange

Min. dia. 10 mm

from face of

flange

Min. dia. 20 mm

from face of

flange

Min. dia.

tolerated of shoulder of

raised face flange

inch mm 1 2a 3 4 5 6

1 40 40

54,0

32 ------ ------ 77

2 50 49

63,0

33 ------ ------ 86

2 65 65

80,0

55 13 ------ 107

3 80 77

93,0

71 50 ------ 121

4 100 96

116,0

90 74 40 141

5 125 123

141.5

119 107 87 171

6 150 146

170.5 *

144 134 120 196

8 200 196

222,0 *

196 189 178 250

10 250 249

276.5 *

249 243 234 306

12 300 298

327.5 *

297 291 283 358

14 350 330

361,0

326 321 314 399

16 400 380

412,0

370 366 358 452

18 450 430

463,0

422 416 409 505

20 500 480

515,0

470 464 457 558

24 600 580

617,0

566 560 554 664

* Verify that the valve body is centered in the pipeline flanges.

NB:

Direct fitting on rubber coated flange or

rubber expansion joint is not recommended.

Please, consult us.

Rubber expansion joint Rubber coated flange

ISORIA

11

Notes

AMRI, INC.

2045 Silber Road HOUSTON, TX 77055

Phone: 713--682--0000 Fax: 713--682--0080 email: INFO@AMRIVALVES.com Web: www.AMRIVALVES.com

ISORIA

AMRING liner drinking water approved by:

-- ACS (French rules)

-- WRAS according to BS 6920 standard

(Water Council)

-- United Kingdom approval)-- DVGW

(KTW German rules)

Disc position index

Mounting plate according to ISO 5211 standard

Maintained shaft seal when the actuator is removed

Bearing in reinforced PTFE on steel support

Shaft passage tightness

Perfect tightness at shaft passage obtained

by the compression of the liner collar on the

spherical disc

Downstream/upstream tightness

Disc machined spherical for ensuring a

perfect tightness downstream/upstream

Driving shaft/disc without

contact with the fluid, by splines or keys

Flange tightness

Special design to obtain a total tightness at

flanges by compression

Face to face of the body according to ISO 5752

series 20 and EN 558 series 20 standards

Anti blow--out screw of the shaft (14 and larger)

Press fit shafts (12 and smaller)

Bearing in reinforced PTFE on steel support

Anti blow--out screw of the shaft(14 and larger)

Press fit shafts (12 and smaller)

Product features -- to our customers benefit

ISORIA

Valve design shown: NPS 14 and larger

2

0

1

4

.

0

1

.

0

7

T

h

i

s

l

e

a

f

l

e

t

i

s

n

o

t

c

o

n

t

r

a

c

t

u

a

l

a

n

d

m

a

y

b

e

a

m

e

n

d

e

d

w

i

t

h

o

u

t

n

o

t

i

c

e

.

8

4

4

8

.

1

/

2

-

-

E

N

-

-

U

S

You might also like

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- NAF Unex Butterfly 4141 GB PDFDocument8 pagesNAF Unex Butterfly 4141 GB PDFganeshanNo ratings yet

- 100 SeriesDocument5 pages100 Seriesfathur2107No ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- KSB Valvula Diafragma SISTO10Document4 pagesKSB Valvula Diafragma SISTO10Sarah PerezNo ratings yet

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCONo ratings yet

- Butterfly Valve Technical Data SheetDocument6 pagesButterfly Valve Technical Data SheetMr. ANo ratings yet

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanNo ratings yet

- Series LF860 Specification SheetDocument2 pagesSeries LF860 Specification SheetFEBCONo ratings yet

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocument24 pagesDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymNo ratings yet

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- Van An Toan 300b0d01Document1 pageVan An Toan 300b0d01tmh_hacid07No ratings yet

- Butterfly Valve TorqueDocument8 pagesButterfly Valve TorqueShyam KrishnanNo ratings yet

- Wafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ADocument4 pagesWafer Type Butterfly Valve Z 611-A Wafer Type Butterfly Valve Z 611-ARadu GanciuNo ratings yet

- KWP Non-Clogging Centrifugal Pump: Automation Products AvailableDocument16 pagesKWP Non-Clogging Centrifugal Pump: Automation Products Availablefedeparamos5030100% (1)

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FDocument0 pagesProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctNo ratings yet

- Series LF850 Specification SheetDocument2 pagesSeries LF850 Specification SheetFEBCONo ratings yet

- MasterSeries 880V Specification SheetDocument4 pagesMasterSeries 880V Specification SheetFEBCONo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- Valvula Borboleta Lug z614 ADocument6 pagesValvula Borboleta Lug z614 AWellington S. FrançaNo ratings yet

- Datasheet Sisto-Kbs Valve - KSBDocument4 pagesDatasheet Sisto-Kbs Valve - KSBSarah PerezNo ratings yet

- TS Apollo 50Document8 pagesTS Apollo 50Carlos GonzalezNo ratings yet

- Butterfly ValveDocument20 pagesButterfly Valvenazar750No ratings yet

- AAP S18 Butterfly Valves E2 SDocument9 pagesAAP S18 Butterfly Valves E2 SPete KardumNo ratings yet

- Gate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")Document3 pagesGate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")MOHAMMAD ASIFNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- Butterfly ValveDocument10 pagesButterfly ValvevtpsNo ratings yet

- Series TDV Specification SheetDocument2 pagesSeries TDV Specification SheetWattsNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Document16 pages3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasNo ratings yet

- Ball Valve Flange TypeDocument7 pagesBall Valve Flange TypeperoooNo ratings yet

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNo ratings yet

- RedvalvE 90 01Document4 pagesRedvalvE 90 01Rizal FalevyNo ratings yet

- Hydrotec SKM DDocument8 pagesHydrotec SKM DAmalNo ratings yet

- Centred disc butterfly valves guideDocument20 pagesCentred disc butterfly valves guideswcciqbalNo ratings yet

- Pin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting FlangeDocument4 pagesPin Through Shaft Concentric Butterfly Valve Series: Weather Seal Mounting Flangeshashikanth79No ratings yet

- TFP950 10 2010Document6 pagesTFP950 10 2010elpelaracingNo ratings yet

- Catalogo Regulador Watts Mod 152-ADocument2 pagesCatalogo Regulador Watts Mod 152-AGuatemalan1979No ratings yet

- 650 SchematicDocument4 pages650 Schematicab5951No ratings yet

- Pump STDRDocument7 pagesPump STDRsopian320No ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- Gate Valves ManualDocument3 pagesGate Valves ManualMOHAMMAD ASIFNo ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- VALVULA CHECK OSCILANTE HakohavDocument1 pageVALVULA CHECK OSCILANTE HakohavDanny VenturaNo ratings yet

- Uniworld: Series Pneumatic ValvesDocument2 pagesUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- Moto Case 845 PDFDocument693 pagesMoto Case 845 PDFjose villegas100% (6)

- EJ Series Butterfly ValvesDocument12 pagesEJ Series Butterfly ValvesGia Minh Tieu TuNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- Butterfly ValveDocument14 pagesButterfly ValveSingSareblakKanaManahNo ratings yet

- Nori 500 High Pressure Globe ValveDocument6 pagesNori 500 High Pressure Globe ValveFallo SusiloNo ratings yet

- Marine Valves Product GuideDocument236 pagesMarine Valves Product GuideGilbert MejulioNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ElectromagnetismDocument10 pagesElectromagnetismrudiskw456No ratings yet

- Enviranmental Impact AssessmentDocument17 pagesEnviranmental Impact AssessmentSrinath BonakurthiNo ratings yet

- Electrical Energy and PowerDocument8 pagesElectrical Energy and Powerrudiskw456No ratings yet

- Refurbishment Example 2Document6 pagesRefurbishment Example 2rudiskw456No ratings yet

- DC FsfsrcalcDocument120 pagesDC Fsfsrcalcrudiskw456No ratings yet

- Birkett and Stein 2008Document21 pagesBirkett and Stein 2008rudiskw456No ratings yet

- Mumias EIADocument35 pagesMumias EIArudiskw456No ratings yet

- Meridian Hotel: Net Charges VAT Receivable Amount Decscription CT Levy Tax 3 TotalDocument2 pagesMeridian Hotel: Net Charges VAT Receivable Amount Decscription CT Levy Tax 3 Totalrudiskw456No ratings yet

- IBAN Number:-GB73 BARC 2029 2310 4994 12: Barcgb22Document1 pageIBAN Number:-GB73 BARC 2029 2310 4994 12: Barcgb22rudiskw456No ratings yet

- Expenses Cameroon Trip Jan 2015 PDFDocument2 pagesExpenses Cameroon Trip Jan 2015 PDFrudiskw456No ratings yet

- Mumias EIADocument35 pagesMumias EIArudiskw456No ratings yet

- Flysaa Mauritius Island: Booking Reservation NumberDocument2 pagesFlysaa Mauritius Island: Booking Reservation Numberrudiskw456No ratings yet

- Existing ParametersDocument3 pagesExisting Parametersrudiskw456No ratings yet

- DC FsfsrcalcDocument120 pagesDC Fsfsrcalcrudiskw456No ratings yet

- A Theory of Sugar DryingDocument9 pagesA Theory of Sugar DryingjairojasNo ratings yet

- MailDocument10 pagesMailrudiskw456No ratings yet

- FK BookingDocument4 pagesFK Bookingrudiskw456No ratings yet

- Delivery and transport of construction materialsDocument13 pagesDelivery and transport of construction materialsrudiskw456No ratings yet

- Midlands Dam Project EiaDocument7 pagesMidlands Dam Project Eiarudiskw456No ratings yet

- The Impact Matrix: Construction Operation DecommissioningDocument1 pageThe Impact Matrix: Construction Operation Decommissioningrudiskw456No ratings yet

- Hi BillDocument1 pageHi Billrudiskw456No ratings yet

- PF136A 2014 (Editable)Document2 pagesPF136A 2014 (Editable)rudiskw456No ratings yet

- Conv4 StructureDocument1 pageConv4 Structurerudiskw456No ratings yet

- Estimate of Recoveries and Losses For Various Molasses PuritiesDocument2 pagesEstimate of Recoveries and Losses For Various Molasses Puritiesrudiskw456No ratings yet

- Conv4 StructureDocument1 pageConv4 Structurerudiskw456No ratings yet

- Conv4 StructureDocument1 pageConv4 Structurerudiskw456No ratings yet

- 1.9 Environment Impact AssessmentDocument56 pages1.9 Environment Impact Assessment996432No ratings yet

- Nuclear Energy & The Kyoto ProtocolDocument53 pagesNuclear Energy & The Kyoto Protocolrudiskw456No ratings yet

- Catalog Chptech Fuel CellsDocument25 pagesCatalog Chptech Fuel Cellsrudiskw456No ratings yet

- Centre Well & Ext DowntakeDocument2 pagesCentre Well & Ext Downtakerudiskw456No ratings yet

- CHAPTER 2 SPONGE AND MICROCELLULAR RUBBER LecturerDocument41 pagesCHAPTER 2 SPONGE AND MICROCELLULAR RUBBER LecturerMuhd BazliNo ratings yet

- ÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSDocument3 pagesÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSGiancarloNo ratings yet

- Venderbilt Rubber HandbookDocument987 pagesVenderbilt Rubber HandbookDaikinllc100% (3)

- Pericyclic Reaction ChemistryDocument18 pagesPericyclic Reaction ChemistrychemistNo ratings yet

- SEMINAR ON LIPOSOMESDocument77 pagesSEMINAR ON LIPOSOMESdianNo ratings yet

- BIOPLASTICDocument5 pagesBIOPLASTICRomer John SantosNo ratings yet

- Technical Data Sheet: Foam ControlDocument1 pageTechnical Data Sheet: Foam ControlSatish ChipkarNo ratings yet

- Carboxylic Acids:: R-Cooh, R-Co HDocument43 pagesCarboxylic Acids:: R-Cooh, R-Co HmacybnzNo ratings yet

- Engineered Elastomer - E-A-r Engineering Design GuideDocument20 pagesEngineered Elastomer - E-A-r Engineering Design GuidebNo ratings yet

- Experimental Study On Hybrid Fiber Concrete With Banana and Sugarcane FiberDocument10 pagesExperimental Study On Hybrid Fiber Concrete With Banana and Sugarcane FiberInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Astm d1752Document2 pagesAstm d1752Whitebeard RagnarokNo ratings yet

- Nptel: Introduction To Composites - Web CourseDocument3 pagesNptel: Introduction To Composites - Web CourseAnu PriyaNo ratings yet

- Microneedles: A Promising Approach for Transdermal Drug DeliveryDocument8 pagesMicroneedles: A Promising Approach for Transdermal Drug Deliveryapt Muthia Fadhila MFarmNo ratings yet

- White Nights Color Chart Watercolor AcuarelaDocument2 pagesWhite Nights Color Chart Watercolor Acuarelaana sal0% (1)

- Tamilnadu 12 Chemistry Shortcuts EMDocument18 pagesTamilnadu 12 Chemistry Shortcuts EMthom_atjNo ratings yet

- Electrochemical Degradation of Remazol Red RB 133 Using Sacrificial ElectrodesDocument23 pagesElectrochemical Degradation of Remazol Red RB 133 Using Sacrificial ElectrodesGlobal Research and Development ServicesNo ratings yet

- Organic Chemistry 3Document2 pagesOrganic Chemistry 3api-659209201No ratings yet

- Ketones and Carboxylic Acids GuideDocument5 pagesKetones and Carboxylic Acids GuideAnindya AcharyaNo ratings yet

- Epdm & FKM Chemical Resistance GuideDocument42 pagesEpdm & FKM Chemical Resistance GuideMauro MascheroniNo ratings yet

- DOWSIL™ 3074 Intermediate: Features & BenefitsDocument3 pagesDOWSIL™ 3074 Intermediate: Features & BenefitsZhan FangNo ratings yet

- 1 s2.0 S096014811200626X MainDocument7 pages1 s2.0 S096014811200626X MainAlex Martinez AlarconNo ratings yet

- Design For Production of PropyleneDocument168 pagesDesign For Production of PropyleneEmiliano Rohwein100% (1)

- SpacersDocument53 pagesSpacersAngelica Escobar MorenoNo ratings yet

- Imagine A Healthy, Beautiful Smile: Oral Care Product GuideDocument16 pagesImagine A Healthy, Beautiful Smile: Oral Care Product Guidecontentdrive4 drive4No ratings yet

- Formulas FarmaceuticasDocument544 pagesFormulas FarmaceuticasUrsula Hille75% (4)

- 321 e Lesson 22Document13 pages321 e Lesson 22mahmudtexNo ratings yet

- Forensics Chapter 4Document35 pagesForensics Chapter 4cjclark921No ratings yet

- Industrial Metal Catalysts 26072010Document53 pagesIndustrial Metal Catalysts 26072010gb130853100% (1)

- Manual For Certificate Course On PP&PMDocument406 pagesManual For Certificate Course On PP&PManjith kumar100% (1)

- EPR and Silicon CatalogueDocument6 pagesEPR and Silicon CatalogueHarshad ChauhanNo ratings yet