Professional Documents

Culture Documents

CE470 - F07 - Ch3b Welding

Uploaded by

Astri NgentOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE470 - F07 - Ch3b Welding

Uploaded by

Astri NgentCopyright:

Available Formats

CE 405: Design of Steel Structures Prof. Dr. A.

Varma

CHAPTER 3b. WELDED CONNECTIONS

3b.1 INTRODUCTORY CONCEPTS

Structural welding is a process by which the parts that are to be connected are heated and

fused, with supplementary molten metal at the joint.

A relatively small depth of material will become molten, and upon cooling, the structural

steel and weld metal will act as one continuous part where they are joined.

Fillet weld

Fillet weld

Fillet weld Fillet weld

Fillet weld Fillet weld

1

CE 405: Design of Steel Structures Prof. Dr. A. Varma

The additional metal is deposited from a special electrode, which is part of the electric circuit

that includes the connected part.

In the shielded metal arc welding (SA!" process, current arcs across a gap between the

electrode and the base metal, heating the connected parts and depositing part of the

electrode into the molten base metal.

A special coating on the electrode vapori#es and forms a protective gaseous shield,

preventing the molten weld metal from o$idi#ing before it solidifies.

The electrode is moved across the joint, and a weld bead is deposited, its si#e depending

on the rate of travel of the electrode.

As the weld cools, impurities rise to the surface, forming a coating called slag that must

be removed before the member is painted or another pass is made with the electrode.

Shielded metal arc welding is usually done manually and is the process universally used

for field welds.

%or shop welding, an automatic or semi automatic process is usually used. %oremost among

these is the submerged arc welding (SA!",

In this process, the end of the electrode and the arc are submerged in a granular flu$ that

melts and forms a gaseous shield. There is more penetration into the base metal than with

shielded metal arc welding, and higher strength results.

&ther commonly used processes for shop welding are gas shielded metal arc, flux cored arc,

and electro-slag welding.

'uality control of welded connections is particularly difficult, because defects below the

surface, or even minor flaws at the surface, will escape visual detection. !elders must be

(

CE 405: Design of Steel Structures Prof. Dr. A. Varma

properly certified, and for critical wor), special inspection techni*ues such as radiography or

ultrasonic testing must be used.

The two most common types of welds are the fillet weld and the groove weld. %illet weld

e$amples+ lap joint , fillet welds placed in the corner formed by two plates

Tee joint , fillet welds placed at the intersection of two plates.

-roove welds , deposited in a gap or groove between two parts to be connected

e.g., butt, tee, and corner joints with beveled (prepared" edges

.artial penetration groove welds can be made from one or both sides with or without edge

preparation.

3b.2 Design of Welded Conne!ions

%illet welds are most common and used in all structures.

!eld si#es are specified in 1/10 in. increments

A fillet weld can be loaded in any direction in shear, compression, or tension. 1owever, it

always f"ils in shear.

2

CE 405: Design of Steel Structures Prof. Dr. A. Varma

The shear failure of the fillet weld occurs along a plane through the throat of the weld, as

shown in the %igure below.

a

a

Throat 3 a $ cos45

o

3 6.767 a

a

a

Throat 3 a $ cos45

o

3 6.767 a

%ailure .lane

8

Shear stress in fillet weld of length 8 subjected to load . 3 fv 3

w

8 a 767 . 6

.

If the ultimate shear strength of the weld 3 fw

9n 3

w w

8 a 767 . 6 f

9n 3

w w

8 a 767 . 6 f 75 . 6

i.e., factor 3 6.75

fw 3 shear strength of the weld metal is a function of the electrode used in the SA!

process.

The tensile strength of the weld electrode can be 06, 76, :6, ;6, 166, 116, or 1(6 )si.

The corresponding electrodes are specified using the nomenclature <06==, <76==,

<:6==, and so on. This is the standard terminology for weld electrodes.

The strength of the electrode should match the strength of the base metal.

If yield stress (y" of the base metal is 06 > 05 )si, use <76== electrode.

If yield stress (y" of the base metal is 06 > 05 )si, use <:6== electrode.

<76== is the most popular electrode used for fillet welds made by the SA! method.

T"ble #2.$ in the AIS? Specifications gives the weld design strength

4

CE 405: Design of Steel Structures Prof. Dr. A. Varma

fw 3 6.06 %<==

%or <76==, fw 3 6.75 $ 6.06 $ 76 3 21.5 )si

Additionally, the shear strength of the base metal must also be considered. The fillet weld is

connected to the base metal. The area of the base metal subjected to shear stresses by the

fillet weld shall be e*ual to (t@ $ 8w".

This base metal area can fail by shear yielding or rupture. The smaller of the two strengths

will govern. See AIS? specification A4.( on page 10.1>11( for the e*uations A4>2 and A4>4

that can be used to determine the shear strength of the base metal+

%or shear yieldingB 9n 3 1.6 $ 6.0 %y $ gross area of base metal subjected to shear

%or shear ruptureB 9n 3 6.75 $ 6.0 %u $ net area of base metal subjected to shear

where, %y and %u are the yield and tensile strength of the base metal.

%or e$ample+

T

<levation

.lan

T

<levation

.lan

Strength of weld in shear Strength of base metal

3 6.75 $ 6.767 $ a $ 8w $ fw 3 min C1.6 $ 6.0 $ %y $ t $ 8w

6.75 $ 6.0 $ %u $ a $ 8wD

Smaller governs the strength of the weld

Always chec) weld metal and base metal strength. Smaller value governs. In most cases, the

weld metal strength will govern.

In weld design problems it is advantageous to wor) with strength per unit length of the weld

or base metal.

5

CE 405: Design of Steel Structures Prof. Dr. A. Varma

3b.2.1 Li%i!"!ions on &eld di%ensions (See AIS? Spec. #2.2b on page 1'.1($) of manual"

*ini%+% si,e -"%in.

( function of the thic)ness of the thinnest connected plate

> given in Table A(.4 of the AIS? specifications

*"/i%+% si,e -"%"/.

( function of the thic)ness of the thic)est connected plate+

> Along edges of plates with thic)ness 6.(5 in., ama$ 3 t or 6.(5 in. whichever is smaller.

> Along edges of plates with thic)ness 6.(5 in., ama$ 3 t > 1/10 in.

*ini%+% leng!0 -L&.

( length (8w" 4 a otherwise, aeff 3 8w / 4

> 9ead #2.2 b

> Intermittent fillet welds+ 8w>min 3 4 a and 1.5 in.

*"/i%+% effe!i1e leng!0 ( 2e"d AISC #2.2b

If weld length 8w E 166 a, then effective weld length (8w>eff" 3 8w

If 8w E 266 a, then effective weld length (8w>eff" 3 8w (1.( , 6.66( 8w/a"

If 8w F 266 a, the effective weld length (8w>eff" 3 6.0 8w

Weld Te2%in"!ions ( 2e"d AISC #2.2b

8ap joint , fillet welds terminate at a distance F a from edge.

!eld returns around corners must be F ( a

0

CE 405: Design of Steel Structures Prof. Dr. A. Varma

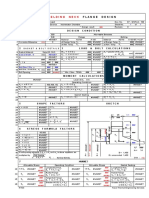

E/"%3le 3b.1. Getermine the design strength of the tension member and connection system

shown below. The tension member is a 4 in. $ 2/: in. thic) rectangular bar. It is welded to a 1/(

in. thic) gusset plate using <76== electrode. ?onsider the yielding and fracture of the tension

member. ?onsider the shear strength of the weld metal and the surrounding base metal.

5 in.

5 in.

6.5 in.

6.5 in.

4 in $ 2/ : in.

t 3 6.5 in.

a 3 6.(5 in.

5 in.

5 in.

6.5 in.

6.5 in.

4 in $ 2/ : in.

t 3 6.5 in.

a 3 6.(5 in.

Solution

S!e3 I. ?hec) for the limitations on the weld geometry

tmin 3 2/: in. (member"

tma$ 3 6.5 in. (gusset"

Therefore, amin 3 2/10 in. > AIS? T"ble #2.)

ama$ 3 2/: > 1/10 3 5/10 in. > AIS? #2.2b

%illet weld si#e 3 a 3 1/4 in. > Therefore, OK!

8w>min 3 1.6 in. > &H.

8w>min for each length of the weld 3 4.6 in. (transverse distance between welds, see #2.2b"

-iven length 3 5.6 in., which is F 8min. Therefore, OKI

8ength/weld si#e 3 5/6.(5 3 (6 > Therefore, maximum effective length #2.2 b satisfied.

<nd returns at the edge corner si#e > minimum 3 ( a 3 6.5 in. >Therefore, OK!

7

CE 405: Design of Steel Structures Prof. Dr. A. Varma

S!e3 II. Gesign strength of the weld

!eld strength 3 $ 6.767 $ a $ 6.06 $ %<== $ 8w

3 6.75 $ 6.767 $ 6.(5 $ 6.06 $ 76 $ 16 3 55.07 )ips

@ase etal strength 3 min C $ 6.0 $ %y $ 8w $ t B $ 6.0 $ %u $ 8w $ aD

3 min C1.6 $ 6.0 $ 56 $ 16 $ 2/: B 6.75 $ 6.0 $ 05 $ 16 $ 1/4D

3 min C11(.5 B 72.1(5 )ipsD

3 72.1(5 )ips

S!e3 III. Tension strength of the member

9n 3 6.; $ 56 $ 4 $ 2/: 3 07.5 )ips > tension yield

9n 3 6.75 $ Ae $ 05 > tension fracture

Ae 3 J A

A 3 Ag 3 4 $ 2/: 3 1.5 in

(

> See Table G2.1

J 3 6.75 , since connection length (8conn" E 1.5 w > See Table G2.1

Therefore, 9n 3 54.: )ips

The design strength of the member-connection system = !." #i$s. Tension fracture of the

member governs. The end returns at the corners were not included in the calculations.

:

CE 405: Design of Steel Structures Prof. Dr. A. Varma

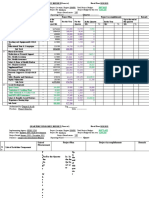

E/"%3le 3b.2 Gesign a double angle tension member and connection system to carry a factored

load of (56 )ips.

%olution

S!e3 I. Assume material properties

Assume 20 )si steel for designing the member and the gusset plates.

Assume <76== electrode for the fillet welds.

S!e3 II. Gesign the tension member

%rom Table 5>: on page 5>47 of the AIS? manual, select (& 5 $ 2K $ 1/( made from 20 )si

steel with yield strength 3 (06 )ips and fracture strength 3 (01 )ips.

S!e3 III. Gesign the welded connection

amin 3 2/10 in. > T"ble #2.)

ama$ 3 1/( > 1/10 in. 3 7/10 in. > #2.2b

'esign, a 3 2/: in. 3 6.275 in.

Shear strength of weld metal 3 9n 3 6.75 $ 6.06 $ %<== $ 6.767 $ a $ 8w

3 :.25 8w )ips

Strength of the base metal in shear 3 min C1.6 $ 6.0 $ %y $ t $ 8w B 6.75 $ 6.0 $ %u $ a $ 8wD

3 min C 16.: 8w B ;.7:75 8wD )ips

Shear strength of weld metal governs, 9n 3 :.25 8w )ips

9n F (56 )ips

:.25 8w F (56 )ips

8w F (;.;4 in.

Gesign, length of 1/( in. <76== fillet weld 3 26.6 in.

%hear strength of fillet weld = (). #i$s

;

CE 405: Design of Steel Structures Prof. Dr. A. Varma

S!e3 I4. 8ayout of ?onnection

!elding on both

sides of gusset.

8

1

a

8

(

(a

8

2

-".

-b.

-.

!elding on both

sides of gusset.

!elding on both

sides of gusset.

8

1

a

8

(

(a

8

2

8

1

a 8

1

a 8

1

a

8

(

(a

8

(

8

(

(a

8

2

8

2

8

2

-".

-b.

-.

8ength of weld re*uired 3 26 in.

Since there are two angles to be welded to the gusset plate, assume that total weld length for

each angle will be 15.6 in.

As shown in the %igure above, 15 in. of 1/( in. <76== fillet weld can be placed in three

ways (a", (b", and (c".

%or option (a", the AIS? Spec. #2.2b re*uires that the fillet weld terminate at a distance

greater than the si#e (1/( in." of the weld. %or this option, 81 will be e*ual to 7.5 in.

%or option (b", the fillet weld can be returned continuously around the corner for a

distance of at least ( a (1 in.". %or this option, 8( can be either 0.5 in. or 7.5 in. 1owever,

the value of 7.5 in. is preferred. The end returns are provided to ensure that the weld si#e

is maintained over the full length of the weld. These are not re*uired by AIS? Specs.

16

CE 405: Design of Steel Structures Prof. Dr. A. Varma

%or option (c", 82 will be e*ual to 5.75 in.

S!e3 4. %racture strength of the member

Ae 3 J Ag

%or the double angle section, use the value of $ from Table 1>7 on page 1>27 of manual.

Assume case (a". Therefore, J 36.::

9n 3 6.75 $ 6.:: $ :.66 $ 5: 3 260.(4 )ips F (56 )ips > fracture limit state is o#!

S!e3 4I. Gesign the gusset plate

9n F Tu > tension yielding limit state

Therefore, 6.; $ Ag $ 20 F (56 )ips

Ag F 7.71 in

(

9n F Tu > tension fracture limit state

Therefore, 6.75 $ An $ %u F (56 )ips

An 6.:5 Ag > Spec. #$

An F 5.747 in

(

Therefore, Ag F 0.70 in

(

Gesign gusset plate thic)ness

3 1.6 in. and width 3 :.6 in.

&ption

J 3

8

$

1

(a" 1>6.;61/7.5 3 6.:: 6.;

(b" 1>6.;61/0.5 36.:0 6.;

(c" 1>6.;61/5.75 3 6.:4 6.;

11

c.g.

$

c.g.

$

1/(

7.5 in.

-".

1/( 7.5 in.

1/( 7.5 in.

1/( 7.5 in.

-usset plate : $ K in.

Two 5 $ 2.5 $ 1/ ( in

1/(

7.5 in.

-".

1/( 7.5 in.

1/( 7.5 in.

1/( 7.5 in.

-usset plate : $ K in.

Two 5 $ 2.5 $ 1/ ( in

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- D Value CalcDocument5 pagesD Value CalcAstri NgentNo ratings yet

- Beam Desain1Document2 pagesBeam Desain1Astri NgentNo ratings yet

- Data Dial IndikatorDocument2 pagesData Dial IndikatorAstri NgentNo ratings yet

- Mud Barge Sea ChestDocument1 pageMud Barge Sea ChestAstri NgentNo ratings yet

- ZX 100 K-Truss Support PadDocument4 pagesZX 100 K-Truss Support PadAstri NgentNo ratings yet

- Weld Analysis-IC Method v1.1Document5 pagesWeld Analysis-IC Method v1.1jefersonpimentelNo ratings yet

- Flange Example CalcDocument14 pagesFlange Example CalcAstri NgentNo ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- Bearing Layout PDFDocument1 pageBearing Layout PDFAstri NgentNo ratings yet

- Over Head Water Tank DesignDocument5 pagesOver Head Water Tank DesignAstri Ngent100% (1)

- Spherical Roller Thrust Bearing PDFDocument16 pagesSpherical Roller Thrust Bearing PDFAstri NgentNo ratings yet

- Brake and Shaft Seal UnitDocument4 pagesBrake and Shaft Seal UnitAstri NgentNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lathe Operators Manual 96-8900 Rev A English January 2014Document458 pagesLathe Operators Manual 96-8900 Rev A English January 2014coyoteassasin0% (1)

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioDocument12 pagesAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasNo ratings yet

- CH 13 RNA and Protein SynthesisDocument12 pagesCH 13 RNA and Protein SynthesisHannah50% (2)

- The Benefits of RunningDocument1 pageThe Benefits of Runningefendi odidNo ratings yet

- 4th Summative Science 6Document2 pages4th Summative Science 6brian blase dumosdosNo ratings yet

- Liquid Enema ProcedureDocument3 pagesLiquid Enema Procedureapi-209728657No ratings yet

- 1 Nitanshi Singh Full WorkDocument9 pages1 Nitanshi Singh Full WorkNitanshi SinghNo ratings yet

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 pagesTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanNo ratings yet

- ODocument11 pagesOMihaela CherejiNo ratings yet

- Marine Advisory 03-22 LRITDocument2 pagesMarine Advisory 03-22 LRITNikos StratisNo ratings yet

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- Formulas Related Question, PebcDocument1 pageFormulas Related Question, PebcBhavesh NidhiNo ratings yet

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonDocument1 pageVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaNo ratings yet

- Capstone-ModDocument25 pagesCapstone-ModMohammad Ryyan PumbagulNo ratings yet

- 2017 LT4 Wiring DiagramDocument10 pages2017 LT4 Wiring DiagramThomasNo ratings yet

- Practice Problems Mat Bal With RXNDocument4 pagesPractice Problems Mat Bal With RXNRugi Vicente RubiNo ratings yet

- Waste Sector ProjectsDocument5 pagesWaste Sector ProjectsMrcoke SeieNo ratings yet

- Assignment Nutrition and HydrationDocument17 pagesAssignment Nutrition and Hydrationmelencio olivasNo ratings yet

- Installation Manual (DH84309201) - 07Document24 pagesInstallation Manual (DH84309201) - 07mquaiottiNo ratings yet

- MelatoninaDocument32 pagesMelatoninaCodrut GeorgescuNo ratings yet

- B65a RRH2x40-4R UHGC SPDocument71 pagesB65a RRH2x40-4R UHGC SPNicolás RuedaNo ratings yet

- Qi Gong & Meditation - Shaolin Temple UKDocument5 pagesQi Gong & Meditation - Shaolin Temple UKBhuvnesh TenguriaNo ratings yet

- CampingDocument25 pagesCampingChristine May SusanaNo ratings yet

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventDocument8 pagesEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumNo ratings yet

- S:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Document19 pagesS:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Lui TCC BariaNo ratings yet

- Corn Fact Book 2010Document28 pagesCorn Fact Book 2010National Corn Growers AssociationNo ratings yet

- Api 579-2 - 4.4Document22 pagesApi 579-2 - 4.4Robiansah Tri AchbarNo ratings yet

- Global Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirDocument24 pagesGlobal Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirinderpreetNo ratings yet

- Equine Anesthesia Course NotesDocument15 pagesEquine Anesthesia Course NotesSam Bot100% (1)