Professional Documents

Culture Documents

TI - GB2715-2005 Hygienic Standard For Grains

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TI - GB2715-2005 Hygienic Standard For Grains

Copyright:

Available Formats

Regional Economic Cooperation and Integration in Asia

Technical Inputs

National Standard of Peoples Republic of China

GB 2715-2005

Hygienic standard for grains

Imprint

Published by the

Deutsche Gesellschaft fr

Internationale Zusammenarbeit (GIZ) GmbH

Registered offices

Bonn and Eschborn, Germany

Regional Economic Cooperation and Integration in Asia

China Office

TaYuan Diplomatic Office

14 Liangmahe South Street, Chaoyang District

10600 Beijing, PR China

T +86-10-8532-5344

F +86-10-8532-5744

Office Mongolia

Naiman Zovkhi Building

Seoul Street 21

Ulaanbaatar 14251, Mongolia

rci-asia@giz.de

www.giz.de

As at

September 2014

Photo credits

Copyrights for all pictures: GIZ

Copyright for cover picture: GIZ/ Ursula Meissner

Text

Shenzhen Institute of Standards and Technology (SIST), Shenzhen, PR China

The findings and conclusions expressed in this documentation are entirely those of the authors. They do not necessarily repre-

sent the view of the Deutsche Gesellschaft fr Internationale Zusammenarbeit (GIZ) or further organising parties. The informa-

tion provided is without warranty of any kind.

On behalf of the German Federal Ministry for Economic Cooperation and Development (BMZ)

1

ICS 67.020

C 53

Nat|ona| Standard of the eop|es kepub||c of Ch|na

GB 2715 2005

Replaces GB 2715 1981

Hygienic standard for grains

Issue date: January 25, 2005 Implementation date: October 1, 2005

Issued by the M|n|stry of the nea|th of the eop|es kepub||c of China

2

Foreword

This standard is mandatory in full text.

This standard will replace GB 2715 -- 1981: Hygienic standard for grains, which was

revoked.

The main changes in this standard compared with GB 2715 -- 1981 are as follows:

- Adding the scope of this stadard as This standard is applicable to raw grain and

processed grain for human consumption including cereal, Legumes and tuber

crops. This standard is not applicable to raw materials for edible oil processing;

- Adding the hygiene requirements of packaging, marking, transportation and

storage;

- Adding the indexes of heat-damaged kernels and moldy kernels;

- Adding the index limits of ergot, lolium temulentum and stramonium seeds and

other seeds of poison plant;

- Adding the limits of deoxynivalenol, zearalenone and ochratoxin A;

- Adding the maximum residue limits of methyl bromide, malathion,

chlorpyrifos-methyl, pirimiphos-methyl, deltamethrin, lindane. Changing the

indexes of total arsenic into inorganic arsenic. Deleting the indexes of cyanide

and carbon disulfide.

This standard shall be effective on 1st October 2005; Transition period will be one

year. Those products manufactured before 1st October 2005 but meeting the

requirements of relevant standards are allowed to sell until 30th September, 2006.

Annex A of this standard is normative.

This stadard is proposed ad adiistered by the Miistry of Health of the Peoples

Republic of China.

The main organizations that participated in the drafting of this standard are Jiangsu

Provincial Center for Disease Prevention and Control, National Center for Health

Inspection and Supervision, Standards &Quality Center of the State Administration of

Grain, National Institute of Nutrition and Food Safety of Chinese Center for Disease

Prevention and Control, Grain Monitoring Center of the Ministry of Agriculture,

3

Liaoning Inspection and Quarantine Bureau, or Liaoning Entry-Exit Inspection and

Quarantine Bureau of Peoples Republic of China in full (LNCIQ), Shanghai Entry-Exit

Inspection and Quarantine Bureau.

Main drafters of this standard are Baojun Yuan, Yunyan Zheng, Huamin Xie, Xiahui Li,

Tianliang Hou, Yuliang Guan, Ying Zhang, and Xuqing Wang.

The previous edition(s) replaced by this standard is (are) as follows:

- GB n1-1977

- GB 2715-1981

4

Hygienic Standard for Grains

1. Scope

This standard defines the hygiene indexes of grains, testing methods and hygiene

requirements of packaging, marking, transportation and storage.

This standard is applicable to raw grains and processed grains for human

consumption including cereals, legumes and tuber crops. This standard is not

applicable to raw materials for edible oil processing.

2. Normative References

The terms of the following documents are by reference as the provisions of this

standard. All subsequent modification lists (excluding corrigendum content) or

revised editions of reference documents with date notes are not applicable to

this standard. However, all parties entering into an agreement based on this

standard are suggested to study whether the latest editions of these reference

documents are applicable. The latest editions of all reference documents without

date notes are applicable to this standard.

- GB 2760 Hygienic standard for uses of food additives

- GB 2763 Maximum residue limits for pesticides in Food

- GB/T 5009.11 Determination of total arsenic and abio-arsenic in foods

- GB/T 5009.12 Determination of lead in foods

- GB/T 5009.15 Determination of cadmium in foods

- GB/T 5009.17 Determination of total mercury and organic mercury in

foods

- GB/T 5009.19 Determination of HCH and DDT residues in foods

- GB/T 5009.20 Method for determination of organophosphorus pesticide

residues in foods

- GB/T 5009.22 Method for determination of aflatoxin B1 in foods

- GB/T 5009.36 Method for analysis of hygienic standard of grains

- GB/T 5009.96 Determination of ochratoxin A in cereals and soybeans

- GB/T 5009.110 Determination of cypermethrin,fenvalerate and

5

deltamethrin residues in vegetable foods

- GB/T 5009.111 Determination of deoxynivalenol in cereal and cereal

products

- GB/T 5009.145 Determination of organophosphorus and carbamate

pesticide multiresidues in vegetable foods

- GB/T 5494 Inspection of grain and oilseeds; Methods for

determination of foreign matter and unsound kernels

- GB 7718 General standard for the labeling of prepackaged foods

- GB 13122 Hygienic specifications of flour milling factory

- SN 0649 Method for the determination of methyl bromide residues

in cereals for export

- SN/T 0080.7 Cereals and feedstuffs for import and export--Method for

the inspection of imperfect grains

3. Terms and definitions

The following terms and definitions are applicable to this standard.

3.1 Heat damaged kernel

Kernel whose color is changed into an abnormal one due to heat produced by

microorganism or other reasons

3.2 Ergot

Sclerotium grown from fungi parasitizing in the ovary of gramineous plants

3.3 Lolium temulentum

Caryopsis of gramineae herb

3.4 Moldy kernel

Kernel with no edible value whose surface is clearly moldy and embryo and

endosperm (or cotyledon) are damaged

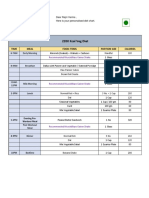

4.Requirements on indexes

4.1 Sensory requirements

The color, smell and hygiene requirements for grains should reach the ordinary levels

6

and meet the requirements in Table 1.

Table 1 Sensory requirement for grains

Item Index

Heat damaged kernel/(%)

Wheat

0.5

Moldy kernel/(%) 2.0

4.2 Indexes of poisoned and harmful fungus and plant seeds

It should meet the requirements in Table 2.

Table 2 Indexes of poisoned and harmful fungus and plant seeds

Item Index

Ergot/(%)

Rice, corns and beans

Wheat, Barley

Not allowed to be

detected

0.01

Darnel/(seed/kg)

Wheat and barley

1

Mandala seeds and other

seeds of poisoned plants

(seed/kg)

Beans

1

4.3 Physicochemical indexes

4.3.1 Index of fungaltoxin limit

It should meet the requirements in Table 3.

Table 3 Index of fungaltoxin limit

Item L|m|t](g]kg)

Aflatoxin B

1

Corn

20

7

Rice

Other

10

5

Deoxynivalenol (DON)

Wheat, barley, corn and

processed grains

1000

Zearalenone

Wheat and corns

60

Ochratoxin A

Cereals and beans

5

4.3.2 Index of pollutant limit

It should meet the requirements in Table 4.

Table 4 Index of pollutant limit

Item Limit/(mg/kg)

Lead (Pb) 0.2

Cadmium (Cd)

Paddy (including rice)

and beans

Wheat (including

wheatmeal), corns and

others

0.2

0.1

Mercury (Hg) 0.02

Inorganic arsenic (As)

Rice

Wheatmeal

Others

0.15

0.1

0.2

4.3.3 Maximum residue limit of pesticide

8

It should meet the requirements in Table 5.

Table 5 Maximum residue limit of pesticide

Item Maximum residue limit

/(mg/kg)

Phosphide (PH

3

) 0.05

Methyl bromide 5

Malathion

Rice

0.1

Chlorpyrifos-methyl 5

Pirimiphos-methyl

Wheat and grains

5

Deltamethrin 0.5

Benzex 0.05

Lindane

Wheat

0.05

DDT 0.05

Nitrochloromethane (raw

grains)

2

Heptachlor 0.02

Aldrin 0.02

Dieldrin 0.02

Other pesticides

See the requirements of

GB 2763

5. Food additives

5.1 The quality of food additives should meet the requirements of relevant standards

or certain regulations.

5.2 The kinds and usage amount of food additives should meet the requirements of

GB 2760.

9

6 Testing methods

6.1 Sensory testing

Follow the testing method in GB/T 5009.36.

6.2 Heat damaged kernel

Follow the testing method in SN/T 0080.7.

6.3 Moldy kernel

Follow the testing method in GB/T 5494.

6.4 Ergot, darnel, mandala seed and other seeds of poisoned plants

Follow the testing method in GB/T 5009.36.

6.5 Aflatoxin B1

Follow the testing method in GB/T 5009.22.

6.6 Deoxynivalenol

Follow the testing method in GB/T 5009.111.

6.7 Zearalenone

Follow the testing method in Annex A.

6.8 Ochratoxin A

Follow the testing method in GB/T 5009.96.

6.9 Inorganic arsenic

Follow the testing method in GB/T 5009.11.

6.10 Lead

Follow the testing method in GB/T 5009.12.

6.11 Cadmium

Follow the testing method in GB/T 5009.15.

6.12 Mercury

Follow the testing method in GB/T 5009.17.

6.13 Phosphide, heptachlor, aldrin, dieldrin and nitrochloroform

Follow the testing method in GB/T 5009.36.

6.14 Methyl bromide

Follow the testing method in SN 0649.

6.15 Malathion

10

Follow the testing method in GB/T 5009.110.

6.16 Chlorpyrifos-methyl and pirimiphos-methyl

Follow the testing method in GB/T 5009.145.

6.17 Deltamethrin

Follow the testing method in GB/T 5009.110.

6.18 Benzex, DDT and Lindane

Follow the testing method in GB/T 5009.19.

7 Processing procedure of processed grains

Follow the testing method in GB 13122.

8 Packaging

Packaging of grains shall use materials or containers which meet certain hygiene

requirements. Packaging should be intact, undamaged and unpolluted.

9. Labelling

Labels of packaged grains should meet the requirements of GB 7718. Labels of

genetically modified food (GMF) should meet the relevant national rules and

regulations.

10. Transportation and Storage

Grain should be stored in a clean and dry environment to prevent moisture, rain and

pollution. There should be no mingling with poisoned, harmful, smelly substances or

substances with high moisture.

The tools and containers for transportation should meet certain hygiene

requirements. They should prevent from raining and pollution during the

transportation.

11

Annex A

(Normative)

Determination of Zearalenone-Thin Layer

Chromatography (TLC)

A.1 Scope

This standard defines the zearalenone determined by TLC method.

This standard is applicable to the determination of zearalenone in grains.

The detection limit of this standard is 0.03 g.

A.2 Principle

After being extracted, cleansed, concentrated, thin-layer chromatography of silica-gel

G, zearalenone in the sample will allow the visualization of blue-fluorescence spots

under 254 nm UV-light. Determine the amount of zearalenone according to the

fluorescence amount on the thin layer, compared with the standard.

A.3 Reagents

Unless otherwise noted, only analytical reagents, distilled water or water with a

certain pure level are applied in analysis.

A 3.1 Absolute ethyl alcohol

A 3.2 Ethyl acetate and cool

A 3.3 Trichloromethane

A 3.4 1 mol /L sodium hydroxide

A 3.5 Phosphoric acid

A 3.6 Acetone

A 3.7 Silica-gel G

A 3.8 Anhydrous sodium sulfate

A 3.9 Zearalenone standard solution

Preparation of zearalenone standard solution: Dissolve 3 mg zearalenone in 100 ml

absolute ethyl alcohol to make standard solution of 0.03 g/L zearalenone. Extract 1

ml standard solution and dilute it with absolute ethyl alcohol to 10 ml to make

12

stadard solutio of 3 g/ml zearalenone. Reserve this solution in a refrigerator of

4C.

A 4 Apparatus

A 4.1 Micromill

A 4.2 Electric agitator

A 4.3 Ultraviolet lamp

A 4.4 Glass plate: 5 cm 20 cm

A 4.5 Thin layer spreader

A 4.6 Microsyringe

A 5 Analysis procedure

A 5.1 Extracting and purifying

Weigh 20 g sample in powder and put the powder into 250 ml flask with stopper. Add

6 ml water and 100 ml ethyl acetate. Vibrate the flask for 1 hour. Filter the solution

with folded filter paper. Weigh 25 ml filtrate into 75 ml evaporating dish and place

the dish on a container with hot water to make it concentrate into dryness. Dissolve

the residue with 25 ml trichloromethane in three times and transfer the solution into

separating funnel of 100ml. Add 10 ml 1 mol/l sodium hydroxide solution in the

previous evaporating dish, drop 1 mol/l sodium hydroxide solution along the funnel

wall 1cm-2cm from the surface of trichloromethane layer, and rotate five times

slightly incase emulsification. Still the funnel until the solution is separated into layers.

Transfer the trichloromethane layer into second separating funnel of 100ml and add

10 ml 1 mol/l sodium hydroxide solution slowly, rotate five times slightly, remove

trichloromethane layer, blend the sodium hydroxide solution in second

separating funnel into the first funnel and cleanse the second funnel with few

distilled water. Then transfer the cleansing liquid into the first funnel, add 5 ml

trichloromethane, rotate and vibrate slightly, remove trichloromethane layer, add 5

ml trichloromethane and rotate for layer separation again, remove trichloromethane

layer. Add 6ml 1.33 mol/l phosphoric acid into sodium hydroxide solution in first

13

funnel, neutralize the PH value of sodium hydroxide solution to 9.5 with 0.67 mol/l

phosphoric acid, add 15 ml trichloromethane, rotate 20-30 times, filter the

trichloromethane layer through quantitative filter paper at a slow speed with 5 g

anhydrous sodium sulfate into 75 ml evaporating dish. Cleanse the funnel with few

trichloromethane and blend cleansing liquid into evaporating dish. Evaporate the

dish on a container with hot water into dryness, put the dish on a container with icy

water and dissolve the residue with 1 ml acetone. Transfer the solution with dropper

to flask with stopper as sample solution for TLC spotting.

A 5.2 Thin-layer chromatography (TLC)

A 5.2.1 Preparation of thin layer plate: Grind 3 g silica gel G with 78 ml distilled

water to thick slurry. Move the slurry into a thin layer spreader and spread the slurry

on three glass plates of 5 cm 20 cm. Still the plates at room temperature into

dryness and activate it by heating in an oven for 60 minutes at 105C. Reserve the

plates in the dryer for next steps.

A 5.2.2 Developing agent: Choose 15 ml mixture of chloroform and

methanol (95:5) or 15 ml mixture of toluene, acetic acid, formic acid (6:3:1) as

developing agent.

A 5.2.3 Spotting: Drop three spots of sample liquid on the baseline 2.5 cm up from

botto edge of plate with g microsyringe: 1 spot of 10 l zearalenone standard

solution, 1 spot of 30 l of extraction solution for sample and 1 spot of 30 l of

extraction solution for sample and 10 l zearalenone standard solution. When

dropping, a cold air blower can be used to speed up the drying of plate. Drop a new

spot after the previous spot is dried.

A 5.2.4 Developing: Add developing agent into a developing tank and dip the plate in

agent. Remove the plate from the tank and dry when it is developed to 10 cm.

A 5.2.5 Observation and determination: Observe the plate under UVC 254 nm. If

there are no blue green fluorescence spots on the spot of sample solution at the

same location of spot of standard solution, the amount of zearalenone in sample

determined at the method of sensibility is below 50 g/kg; if the intensity of

fluorescence spots in spot of sample solution is the same with the minimum

14

detectable quantity of fluorescence intensity in spot of standard solution and the

locations of two fluorescence spots overlap, the amount of zearalenone in sample

determined at the method of sensibility equals to 50 g/kg; if the intensity of

fluorescence spots in spot of sample solution is higher than the minimum detectable

quantity of fluorescence intensity in spot of standard solution, based on the

fluorescence intensity, reduce the amount of solution or add different amount of

sample solution after being diluted, until the intensity of fluorescence spots in spot

of sample solution is the same with the one of minimum detectable quantity.

A 6 Calculations of results

Calculate the amount of zearalenone according to the following formula (A.1):

= 0.03

(A.1)

Where,

: amount of zearalenone, in the unit of g/kg;

0.03: minimum detectable quantity of zearalenone, in the unit of g;

V

1

: volume of acetone, in the unit of ml;

V

2

: volume of sample solution to drop when minimum quantity of fluorescence spots

appears, in the unit of ml;

D: total dilution ratio of sample solution;

m: weight of sample when residue of acetone solution is added, in the unit of g.

Registered offices

Bonn and Eschborn, Germany

T +49 228 44 60-0 (Bonn)

T +49 61 96 79-0 (Eschborn)

Dag-Hammarskjld-Weg 1-5

65760 Eschborn, Germany

T +49 61 96 79-0

F +49 61 96 79-11 15

E info@giz.de

I www.giz.de

Regional Economic Cooperation and Integration in Asia

Office China

Ta Yuan Diplomatic Office

14 Liangmahe South Street, Chaoyang District

100600 Beijing, PR China

Office Mongolia

Naiman Zovkhis Building

Seoul Street 21,

Ulaanbaatar 14251, Mongoli

E rci-asia@giz.de

You might also like

- Regional Infrastructure Investment Initiatives: Zero-Sum Game or Win-Win Collaboration? Proceedings of The Roundtable Meeting On 11-12 September 2015 in Hangzhou, PR ChinaDocument71 pagesRegional Infrastructure Investment Initiatives: Zero-Sum Game or Win-Win Collaboration? Proceedings of The Roundtable Meeting On 11-12 September 2015 in Hangzhou, PR ChinaRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Study Tour and Workshop: Building Capacities For Labour Migration Management in Cambodia and Lao PDRDocument24 pagesStudy Tour and Workshop: Building Capacities For Labour Migration Management in Cambodia and Lao PDRRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB5749-2006 Standards For Drinking Water QualityDocument16 pagesTI - GB5749-2006 Standards For Drinking Water QualityRegional Economic Cooperation and Integration (RCI) in Asia67% (3)

- TI - GB5503-2009 Inspection of Grain and Oils - Determination of Broken KernelsDocument9 pagesTI - GB5503-2009 Inspection of Grain and Oils - Determination of Broken KernelsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Potential For Development and Cooperation in The ACPBG Region: A Study On Ports and LogisticsDocument96 pagesPotential For Development and Cooperation in The ACPBG Region: A Study On Ports and LogisticsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB7718-2011 National Standard of Food Safety - General Standard For The Labelling of Prepackaged FoodDocument21 pagesTI - GB7718-2011 National Standard of Food Safety - General Standard For The Labelling of Prepackaged FoodRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Study Tour and Technical Training On Single Window ImplementationDocument34 pagesStudy Tour and Technical Training On Single Window ImplementationRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Expert Hearing: Special Economic Zones in A Regional and Global Context - Economic Significance and ImpactDocument89 pagesExpert Hearing: Special Economic Zones in A Regional and Global Context - Economic Significance and ImpactRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Connect Asia Newsletter, No. 04Document6 pagesConnect Asia Newsletter, No. 04Regional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB5490-2010 Inspection of Grain and Oils - General RulesDocument18 pagesTI - GB5490-2010 Inspection of Grain and Oils - General RulesRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB1350-2009 PaddyDocument10 pagesTI - GB1350-2009 PaddyRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB1354-2009 RiceDocument13 pagesTI - GB1354-2009 RiceRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB5497-1985 Inspection of Grain and Oilseeds - Methods For Determination of Moisture ContentDocument8 pagesTI - GB5497-1985 Inspection of Grain and Oilseeds - Methods For Determination of Moisture ContentRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB5502-2008 Inspection of Grain and Oils - Determination of Processing Degree of Rice and Other Grain KernelsDocument11 pagesTI - GB5502-2008 Inspection of Grain and Oils - Determination of Processing Degree of Rice and Other Grain KernelsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB-T5496-1985 Inspection of Grain and Oilseeds - Methods For Determination of Yellow-Colored Rice and Cracked KernelsDocument6 pagesTI - GB-T5496-1985 Inspection of Grain and Oilseeds - Methods For Determination of Yellow-Colored Rice and Cracked KernelsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB5491-1985 Inspection of Grain, Oilseeds and Vegetable OilsDocument10 pagesTI - GB5491-1985 Inspection of Grain, Oilseeds and Vegetable OilsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB15682-2008 Inspection of Grain and Oils - Method For Sensory Evaluation of Paddy or Rice Cooking and Eating QualityDocument18 pagesTI - GB15682-2008 Inspection of Grain and Oils - Method For Sensory Evaluation of Paddy or Rice Cooking and Eating QualityRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB14881-1994 General Hygienic Regulation For Food EnterprisesDocument20 pagesTI - GB14881-1994 General Hygienic Regulation For Food EnterprisesRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB17109-2008 Package of Grain SellsDocument9 pagesTI - GB17109-2008 Package of Grain SellsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB17891-1999 High Quality PaddyDocument16 pagesTI - GB17891-1999 High Quality PaddyRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Input and Materials: Development of Ferry Boat Routes in Northeast Asia - Utilizing European Examples of Regional ConnectivityDocument16 pagesInput and Materials: Development of Ferry Boat Routes in Northeast Asia - Utilizing European Examples of Regional ConnectivityRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB5494-2008 Inspection of Grain and Oils - Determination of Foreign Matter and Unsound Kernels of Grain and OilseedsDocument14 pagesTI - GB5494-2008 Inspection of Grain and Oils - Determination of Foreign Matter and Unsound Kernels of Grain and OilseedsRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Inputs and Materials: Second Expert Hearing On Cross-Border Cooperation and Trade Facilitation in AsiaDocument43 pagesInputs and Materials: Second Expert Hearing On Cross-Border Cooperation and Trade Facilitation in AsiaRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- TI - GB15683-2008 Rice - Determination of Amylose ContentDocument20 pagesTI - GB15683-2008 Rice - Determination of Amylose ContentRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Inputs and Materials - Guideline On How To Successfully Implement Special Economic Zones in Lao PDRDocument76 pagesInputs and Materials - Guideline On How To Successfully Implement Special Economic Zones in Lao PDRRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Inputs and Materials: Background Paper China (Shanghai) Free Trade ZoneDocument18 pagesInputs and Materials: Background Paper China (Shanghai) Free Trade ZoneRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Inputs and Materials: Mapping Workshop & Trade Capacity Building - ASEAN-China Free Trade AgreementDocument40 pagesInputs and Materials: Mapping Workshop & Trade Capacity Building - ASEAN-China Free Trade AgreementRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Inputs and Materials: Potentials For Port Cooperation in The Pan-Beibu Gulf RegionDocument23 pagesInputs and Materials: Potentials For Port Cooperation in The Pan-Beibu Gulf RegionRegional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- Connect Asia, No 03Document6 pagesConnect Asia, No 03Regional Economic Cooperation and Integration (RCI) in AsiaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Coco Cola SWOT Analysis: StrengthsDocument17 pagesCoco Cola SWOT Analysis: StrengthsDeepNo ratings yet

- English Grammar: Syntax and Semantics of ThanksgivingDocument1 pageEnglish Grammar: Syntax and Semantics of ThanksgivingGalo2142No ratings yet

- BN Commander S Letter PDFDocument6 pagesBN Commander S Letter PDFEchoEagles100% (1)

- Course Name: Strategic Management Title: Submitted To:: Case Study On "Pepsico"Document13 pagesCourse Name: Strategic Management Title: Submitted To:: Case Study On "Pepsico"ashabNo ratings yet

- The Abington Journal 09-12-2012Document16 pagesThe Abington Journal 09-12-2012The Times LeaderNo ratings yet

- Thermoregulation and Human PerformanceDocument22 pagesThermoregulation and Human PerformanceHyperHodgeyNo ratings yet

- Salted Caramel Chocolate Vegan CupcakesDocument5 pagesSalted Caramel Chocolate Vegan CupcakesShieldon Vic Senajon PinoonNo ratings yet

- CBL Daily Nutrition Plans1 PDFDocument3 pagesCBL Daily Nutrition Plans1 PDFJunior CaputoNo ratings yet

- FTT eDocument2 pagesFTT eSyarifah Lubbna YahyaNo ratings yet

- AG 201 Properties Biological Materials Food QualityDocument2 pagesAG 201 Properties Biological Materials Food QualitySonu Lokprakash ChandraNo ratings yet

- 3.1 Description of The Home - Angol Szóbeli Témakör B2Document2 pages3.1 Description of The Home - Angol Szóbeli Témakör B2Nagyné KingaNo ratings yet

- Practice Test: Responda Las Preguntas 1 A 5 de Acuerdo Con El EjemploDocument8 pagesPractice Test: Responda Las Preguntas 1 A 5 de Acuerdo Con El Ejemplocarlos puche ojedaNo ratings yet

- Easy Vegan Holiday Recipes by Amy KatzDocument14 pagesEasy Vegan Holiday Recipes by Amy KatzharleyNo ratings yet

- The World Is An AppleDocument5 pagesThe World Is An AppleWayne Jonlie De ClaroNo ratings yet

- Benjamín Flores Castro (Triptico)Document2 pagesBenjamín Flores Castro (Triptico)Sergio Illimani FloresNo ratings yet

- BritanniaDocument5 pagesBritanniaakanksha1314No ratings yet

- BANYUWANGI PRICELIST (Periode 15-20 Mar 2021) SKU Code Nama Barang Harga JualDocument6 pagesBANYUWANGI PRICELIST (Periode 15-20 Mar 2021) SKU Code Nama Barang Harga JualMas FiNo ratings yet

- Soal Uts 1 B.inggris Kelas 5Document1 pageSoal Uts 1 B.inggris Kelas 5Gomgom Parlindungan SinuratNo ratings yet

- Rajni Verma's Diet PlanDocument2 pagesRajni Verma's Diet PlanPiyushNo ratings yet

- Department of Animal Husbandry and Dairying Institute of Agricultural Sciences Banaras Hindu University Varanasi - 221005Document2 pagesDepartment of Animal Husbandry and Dairying Institute of Agricultural Sciences Banaras Hindu University Varanasi - 221005Yamini GowdaNo ratings yet

- Improving Meatball Quality Using Different Varieties of Rice Bran As Natural AntioxidantDocument7 pagesImproving Meatball Quality Using Different Varieties of Rice Bran As Natural AntioxidantHari PurnomoNo ratings yet

- Genchem KJDocument3 pagesGenchem KJKheren D. PenidesNo ratings yet

- The Luncheon Is A Satirical Story That The Writer Uses Humor and Irony To Depict TheDocument5 pagesThe Luncheon Is A Satirical Story That The Writer Uses Humor and Irony To Depict TheDard TongNo ratings yet

- EO LA Cocktail MenuDocument2 pagesEO LA Cocktail MenuMatthewKangNo ratings yet

- Complete The Chart: Present Perfect Infinitive Past Simple Past ParticipleDocument10 pagesComplete The Chart: Present Perfect Infinitive Past Simple Past ParticipleYamilaPMNo ratings yet

- Book Extension Activity - Chocolate Milk Por FavorDocument2 pagesBook Extension Activity - Chocolate Milk Por Favorapi-534305086No ratings yet

- 1 - 3 September 2016: Hall 101-102 Bangkok International Trade and Exhibition Center (BITEC)Document60 pages1 - 3 September 2016: Hall 101-102 Bangkok International Trade and Exhibition Center (BITEC)TBS Máy Phát ĐiệnNo ratings yet

- Indian Monthly Grocery List (For Two People) : Item QuantityDocument6 pagesIndian Monthly Grocery List (For Two People) : Item Quantitysurya1293No ratings yet

- Design AOPDocument11 pagesDesign AOPP.sekaran P.sekaranNo ratings yet

- Riga Travel Guide (2007) by RyanairDocument10 pagesRiga Travel Guide (2007) by RyanairisrgffNo ratings yet