Professional Documents

Culture Documents

50B4KG

Uploaded by

onin007Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50B4KG

Uploaded by

onin007Copyright:

Available Formats

F

i

r

e

P

r

o

d

u

c

t

s

U.L. Listed

Factory Mutual Approved

Fast Opening to Maintain Steady Line Pressure

Accommodates Wide Range of Flow Rates.

Closes Gradually for Surge-Free Operation.

Adjustable Pressure Settings, Not Affected by

Pressure At Valve Discharge.

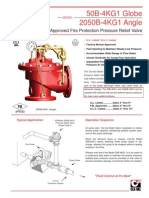

The Cla-Val Model 50B-4KG-1 Globe/2050B-4KG Angle

Pressure Rel i ef Val ve i s desi gned speci fi cal l y to

automatically relieve excess pressure in fire protection

pumping systems. Pilot controlled, it maintains constant

system pressure at the pump discharge within very close

limits as demands change.

At pump start, Cla-Val Relief Valve modulates to relieve

excess pump capacity, maintaining positive system

pressure at the pump discharge.

When fire demand slows or ceases, Cla-Val Model

50B-4KG-1 opens, di verti ng enti re pump output to

discharge, allowing fire pump to be stopped without

causing surging in the lines.

(Please note that if the Model 50B-4KG-1 is to be used on

a continuous duty basis to maintain fire-system pressure,

suitable back pressure must be provided on the valve to

prevent cavitation damage. Consult the factory for

details.)

Operation Sequence Typical Application Model 2050B-4KG-1

Pressure Relief Valve

(Angle Pattern)

Fire Pump

Check Valve

"Fluid Control at It's Best"

2050B-4KG1 (Angle)

F

i

r

e

P

r

o

d

u

c

t

s

Fire Protection Pressure Relief Valve

50B-4KG-1

MODEL

To Fire

Protection System

Model 2050B-4KG-1 Angle Model 50B-4KG-1 Globe

We recommend providing adequate space around valve for maintenance work.

Specifications

Globe: 2" - 12" flanged

Angle: 2" - 12" flanged

150 and 300 ANSI B 16.42

class - 175 psi Max.

class - 300 psi Max

Water, to 180F Max.

Main Valve Body & Cover

Ductile Iron ASTM A-536

Naval Bronze ASTM B61

Other Material Available

Standard Main Valve Trim:

Bronze Seat, Teflon Coated

Stainless Steel Stem, Delrin Sleeved

Standard Pilot Control System:

Cast Bronze with

Stainless Steel trim

Available in the following relief

pressure ranges:

20-200 psi (150 Class)

100-300 psi (300 Class)

Protective epoxy resin coating

of wetted surfaces of main

valve cast iron components

(UL listed HNFX EX2855)

50B-4KG-1 (R-7/98)

Represented By

Dimensions (in Inches)

B

G

H E

C

F

A

C

D

The Fire Pump Pressure Relief Valve shall modulate to relieve excess

pressure in a fire protection system. It shall maintain constant pressure in

the system regardless of demand changes. It shall be pilot controlled and

back pressure shall not affect its set point. It shall be actuated by line

pressure through a pilot control system and open fast in order to maintain

steady system pressure as system demand decreases. It shall close

gradually to control surges and shall re-seat drip-tight within 5% of its

pressure setting. The main valve shall be of the hydraulically-operated,

pilot-controlled, diaphragm-type, globe or angle valve. It shall have a

single, removable, teflon-coated seat, a delrin-sleeved stem guided at both

ends, and a resilient disc with a rectangular cross section, being contained

on 3 1/2 sides. No external packing glands shall be permitted and the

diaphragm shall not be used as a seating surface. The pilot control shall

be a direct-acting, adjustable, spring-loaded, diaphragm-type valve

designed for modulating service to permit flow when controlling pressure

exceeds spring setting. This valve shall be UL Listed and Factory Mutual

approved. It shall be the MODEL 50B-4KG-1 (globe) or Model 2050B-

4KG-1 (angle) Pressure Relief Valve as manufactured by Cla-Val.

Newport Beach, California.

*Special Note:

The Model 50B-4KG-1 Pressure Relief Valve is available with 300# ANSI

inlet flange and 100# ANSI outlet flange. This Valve is used on higher

pressure systems where 300# flange connections are required, and allows

for adapting of a discharge cone (generally supplied with 150# flange) to

accommodate "atmospheric break" at relief valve discharge. This Relief

Valve, with 300# X 150# flanges is available on special order, and is

UNDERWRITERS LABORATORIES LISTED AND FACTORY MUTUAL

APPROVED.

Purchase Specifications

U.L. Listed...............Sizes 3" thru 6"

F.M. Approved.........Sizes 4" thru 8"

U.L.C. Listed............Sizes 2 thru 8

Specifications Seawater Service Option

Sizes Globe: 2" - 8" flanged

Angle: 2" - 8" flanged

Consult factory for materials and flange ratings.

Valve Sizes in Inches: 2" 2 1/2" 3" 4" 6"

NFPA 20 Maximum

Recommended GPM 208 300 500 1000 2500

8"

5000

Valve Capacity

Valve Size 2" 4" 6" 8"

G & H 6.00 7.88 8.50

Screwed Ends 9.38 -- -- --

9.75

A 150 Flanged 9.38 15.00 20.00 25.38

300 Flanged 10.00 15.62 21.00 26.38

300 x 150 15.31 20.56 26.382

C 12.00 13.00 14.31 16.31

D 1.50 3.19 4.31 5.31

Screwed Ends 4.75 -- -- --

E 150 Flanged 4.75 7.50 10.00 12.75

300 Flanged 5.00 7.88 10.50 13.25

Screwed Ends 3.25 -- -- --

F 150 Flanged 3.25 5.00 6.00 8.00

300 Flanged 3.50 5.31 6.50 8.50

10"

--

13.25

29.75

31.72

30.44

18.00

9.25

--

14.88

15.56

--

8.62

9.31

12"

--

14.25

34.00

35.50

34.75

20.56

10.75

--

17.00

17.75

--

13.75

14.50

11.87 B 3.37 5.81 8.00 10.12 14.06

CLA-VAL

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL CANADA, LTD. CLA-VAL SA

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin des Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

COPYRIGHT CLA-VAL 1998 Printed in USA

Specifications subject to change without notice. www.cla-val.com

F

i

r

e

P

r

o

d

u

c

t

s

3"

7.75

12.50

12.00

13.25

12.88

12.50

2.19

4.62

6.25

6.00

6.38

4.50

4.00

4.38

Sizes

End Details

Pressure Ratings

Materials

Adjustment Range

OPTIONAL

2 1/2"

6.69

11.00

11.00

11.62

12.25

1.69

4.06

5.50

5.50

5.88

4.00

4.00

4.31

You might also like

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Main Relief ValveDocument2 pagesMain Relief ValveJesseNo ratings yet

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Fire Pump Relief Valve Model 108FC/108FCA Sizes Features SpecificationsDocument2 pagesFire Pump Relief Valve Model 108FC/108FCA Sizes Features SpecificationsAdil AzizNo ratings yet

- PLL 2144Document80 pagesPLL 2144Amit TandelNo ratings yet

- E 55L 60Document2 pagesE 55L 60Gustavo Acosta MorenoNo ratings yet

- E 50 49 - FireDocument2 pagesE 50 49 - FireJulio C. Sivira CallejaNo ratings yet

- 501 007Document4 pages501 007burckhardt83No ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- Hydraulic Valves & AccessoriesDocument1 pageHydraulic Valves & AccessoriesAledinho10No ratings yet

- Regulador 1253 B - American M.Document8 pagesRegulador 1253 B - American M.Jheysson FloresNo ratings yet

- E 90 21 - FireDocument2 pagesE 90 21 - Firepequenita34No ratings yet

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocument7 pagesMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- INBAL GeralDocument10 pagesINBAL GeralAlisson Gustavo KalilNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Hi Flow Control Valves.iDocument3 pagesHi Flow Control Valves.iGilberto Meneses NavarroNo ratings yet

- Hydr Valve 60554Document7 pagesHydr Valve 60554errenmayNo ratings yet

- Modulating Float ValvesDocument4 pagesModulating Float ValvesJayakrishnan RadhakrishnanNo ratings yet

- Pressure Vacuum BleedersDocument4 pagesPressure Vacuum BleedersGustavo AlcaNo ratings yet

- Valvula de Alivio SCIDocument2 pagesValvula de Alivio SCIDj-Jhon En La PistaNo ratings yet

- Series 51/52 Flanged Ball Valves: Standard and Anti-Static Valves in ANSI Class 150 and 300Document8 pagesSeries 51/52 Flanged Ball Valves: Standard and Anti-Static Valves in ANSI Class 150 and 300Hafizuddin RazaliNo ratings yet

- 100G - 2100G ClavalDocument2 pages100G - 2100G Clavale1901bNo ratings yet

- M110-14, M1110-14 Specification SheetDocument6 pagesM110-14, M1110-14 Specification SheetWattsNo ratings yet

- CKEI enDocument2 pagesCKEI enSergio MasinNo ratings yet

- BFV TechDocument120 pagesBFV TechSatyamEngNo ratings yet

- 43 430 UF Final PDFDocument4 pages43 430 UF Final PDFCarlos TarquinoNo ratings yet

- PRH04-300 FLG PDFDocument5 pagesPRH04-300 FLG PDFengp3077No ratings yet

- CLAVAL Pressure Reducing ValveDocument4 pagesCLAVAL Pressure Reducing ValvermgatocNo ratings yet

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephNo ratings yet

- 1190 TANK BLANQUETING REGULATOR Bulletin PDFDocument12 pages1190 TANK BLANQUETING REGULATOR Bulletin PDFM Betzabe MoraNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Ste/Surfacetest Tree: HalliburtonDocument2 pagesSte/Surfacetest Tree: Halliburtonsaeed65No ratings yet

- Air Release Valve E-34 Series FireDocument5 pagesAir Release Valve E-34 Series FireUghojor ElohoNo ratings yet

- PRV SizingDocument4 pagesPRV SizingTiffany CombsNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Pump Start Relief Valve 50-20Document2 pagesPump Start Relief Valve 50-20nastyn-1No ratings yet

- Inbal - Deluge Valve Pressure Control 03-13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03-13 CR01pvalverdea2014No ratings yet

- 61fSTO PStopperDocument2 pages61fSTO PStopperBenjamin BrownNo ratings yet

- Type 1805P Pilot-Operated Relief ValveDocument8 pagesType 1805P Pilot-Operated Relief ValveJOMAGUESNo ratings yet

- Velan Ball Valve 1 PDFDocument9 pagesVelan Ball Valve 1 PDFMilena Lemus FonsecaNo ratings yet

- FunctionalSafety V7666Document12 pagesFunctionalSafety V7666rufino.perea.2No ratings yet

- Mustang Series M115 (Globe), M1115 (Angle) Specification SheetDocument7 pagesMustang Series M115 (Globe), M1115 (Angle) Specification SheetWattsNo ratings yet

- Pressure Relief Valve 55LDocument2 pagesPressure Relief Valve 55Ljhoger20120% (1)

- 3105 B 26Document3 pages3105 B 26ParIs MoRanNo ratings yet

- 90-01 Reductora de Presion Cla-ValDocument4 pages90-01 Reductora de Presion Cla-ValPablo SolisNo ratings yet

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocument4 pagesModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinNo ratings yet

- Inbal - Deluge Valve Pressure Control 03 - 13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03 - 13 CR01gustavosalvatoNo ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- 198 Pressure Regulators - Aperflux 851 - Eng - Nov2010Document12 pages198 Pressure Regulators - Aperflux 851 - Eng - Nov2010Mohammad Abdelhady0% (1)

- OpGL Globe ValveDocument20 pagesOpGL Globe Valvemanmohansingh1999No ratings yet

- Pfeiffer Br26d EngDocument4 pagesPfeiffer Br26d EngAleksandr KrigerNo ratings yet

- Catálogo Master FloDocument12 pagesCatálogo Master FloclaudioandrevalverdeNo ratings yet

- 417 Model E Alarm Check ValvesDocument4 pages417 Model E Alarm Check ValvesM Kumar MarimuthuNo ratings yet

- A Pilotair ValvesDocument33 pagesA Pilotair ValvesZMCONTROL100% (1)

- E 90 48Document4 pagesE 90 48Agus Qupink Luph AriaNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- CFCM2Document1 pageCFCM2onin007No ratings yet

- CVS1Document1 pageCVS1onin007No ratings yet

- SanDrgNo3-10 - Waste Sump (For Sullage Water Drainage)Document1 pageSanDrgNo3-10 - Waste Sump (For Sullage Water Drainage)onin007No ratings yet

- GG 04Document2 pagesGG 04onin007No ratings yet

- 6102Document3 pages6102onin007No ratings yet

- Bsen 50081 2Document14 pagesBsen 50081 2Dumitru Cristina100% (1)

- 4901Document3 pages4901onin007No ratings yet

- S6102Document2 pagesS6102onin007No ratings yet

- Underground pipe stress analysisDocument5 pagesUnderground pipe stress analysiskumaran__k100% (3)

- Seismic Design of Buried PipeDocument105 pagesSeismic Design of Buried Pipetnvish100% (4)

- 6102Document3 pages6102onin007No ratings yet

- 13603Document3 pages13603onin007No ratings yet

- 20031100-Behaviour of Various Support Systems For Deep Excavations Changi Airport Underground MRT StationDocument12 pages20031100-Behaviour of Various Support Systems For Deep Excavations Changi Airport Underground MRT Stationonin007No ratings yet

- 13646Document3 pages13646onin007No ratings yet

- S6102Document2 pagesS6102onin007No ratings yet

- 10031Document2 pages10031onin007No ratings yet

- CFR 2010 Title49 Vol3 Part192Document115 pagesCFR 2010 Title49 Vol3 Part192onin007No ratings yet

- 6073Document3 pages6073onin007No ratings yet

- CFR 2010 Title49 Vol3 Part195Document68 pagesCFR 2010 Title49 Vol3 Part195onin007No ratings yet

- STAAD Pro Getting Started 2007 Complete PDFDocument540 pagesSTAAD Pro Getting Started 2007 Complete PDFbryan94No ratings yet

- StaadPro Knowledge BaseDocument251 pagesStaadPro Knowledge Baseingsabrina100% (1)

- R3 DReferDocument335 pagesR3 DReferbenness11No ratings yet

- Getting Started STAAD 2005 PDFDocument570 pagesGetting Started STAAD 2005 PDFbryan94No ratings yet

- Staadpro 2007 International Codes 2007 CompleteDocument690 pagesStaadpro 2007 International Codes 2007 Completewesprit23100% (1)

- Purchase Specification: Model No. 16-4 Double Check Detector AssemblyDocument3 pagesPurchase Specification: Model No. 16-4 Double Check Detector Assemblyonin007No ratings yet

- 501ADocument2 pages501Aonin007No ratings yet

- 55L pg1Document1 page55L pg1onin007No ratings yet

- 37Document5 pages37onin007No ratings yet

- Sketch of 2 Step Platform (Revised 13 Jan 14)Document1 pageSketch of 2 Step Platform (Revised 13 Jan 14)onin007No ratings yet

- List of Intel MicroprocessorsDocument46 pagesList of Intel MicroprocessorsnirajbluelotusNo ratings yet

- Mike-Rose - The-Language-of-Exclusion (Edited)Document20 pagesMike-Rose - The-Language-of-Exclusion (Edited)abankiNo ratings yet

- George Novack's - Understanding HistoryDocument272 pagesGeorge Novack's - Understanding HistoryagustibravoNo ratings yet

- Zaporojets - Sobre A Natureza Da Percepção Visual de Um ObjetoDocument10 pagesZaporojets - Sobre A Natureza Da Percepção Visual de Um ObjetoCarol VasconcelosNo ratings yet

- Latifa's Thesis PDFDocument182 pagesLatifa's Thesis PDFنذير امحمديNo ratings yet

- WAE ParaphrasingAndPlagiarism Pp127 136Document37 pagesWAE ParaphrasingAndPlagiarism Pp127 136คิคะปู้ นะจ๊ะNo ratings yet

- Circuits 4 Name & SetDocument2 pagesCircuits 4 Name & SetMUhammad Saqib Naveed ShahNo ratings yet

- Convention of Film Blocking Day 2Document6 pagesConvention of Film Blocking Day 2GENELYN GAWARANNo ratings yet

- Brochure DRYVIEW 5700 201504 PDFDocument4 pagesBrochure DRYVIEW 5700 201504 PDFRolando Vargas PalacioNo ratings yet

- W3 Deep FoundationDocument42 pagesW3 Deep FoundationTeoh Zhi TongNo ratings yet

- Algorithmic Composer: Openmusic and Chaos - Omchaos LibraryDocument11 pagesAlgorithmic Composer: Openmusic and Chaos - Omchaos LibrarysophochaNo ratings yet

- Ds Esprimo c910 LDocument9 pagesDs Esprimo c910 Lconmar5mNo ratings yet

- 4340 Fracture Toughness PDFDocument22 pages4340 Fracture Toughness PDFGrafton Montgomery0% (1)

- Lattice SeminarDocument48 pagesLattice SeminarNaina JabbarNo ratings yet

- 130nm Techbrief01Document3 pages130nm Techbrief01Gilang Mardian KNo ratings yet

- Tad 1641 GeDocument2 pagesTad 1641 GeGiangDoNo ratings yet

- Macro To Roll Exalted 3e Die in Foundry VTTDocument5 pagesMacro To Roll Exalted 3e Die in Foundry VTTtcherban100% (1)

- Sustainable Urban Transport Index for Bhopal, IndiaDocument43 pagesSustainable Urban Transport Index for Bhopal, IndiaSayani MandalNo ratings yet

- (JPP-1) - (Indefinite Integration) - 11th SepDocument52 pages(JPP-1) - (Indefinite Integration) - 11th Sepfunnyvideos. comNo ratings yet

- Study of the Courier Industry at BookMyPacketDocument34 pagesStudy of the Courier Industry at BookMyPacketPiyush MittalNo ratings yet

- TTLA0649-Monitor ZX-3Document23 pagesTTLA0649-Monitor ZX-3saufanNo ratings yet

- Job AnalysisDocument19 pagesJob AnalysisdookudumanNo ratings yet

- Advanced View of Projects Raspberry Pi List - Raspberry PI ProjectsDocument186 pagesAdvanced View of Projects Raspberry Pi List - Raspberry PI ProjectsBilal AfzalNo ratings yet

- IEEE STD 1193™-2003 Guide For Measurement of Environmental SensitivitiesDocument81 pagesIEEE STD 1193™-2003 Guide For Measurement of Environmental SensitivitiesVitalyNo ratings yet

- Irene Muliawan: Tarumanagara University - Bachelor of Accountancy - Aug 2016 - Jan 2020Document1 pageIrene Muliawan: Tarumanagara University - Bachelor of Accountancy - Aug 2016 - Jan 2020naboyaNo ratings yet

- What Is Crash Manoeuvring of Ship in Emergency SitDocument8 pagesWhat Is Crash Manoeuvring of Ship in Emergency SitstamatisNo ratings yet

- Materi TOEFL ListeningDocument29 pagesMateri TOEFL Listeningputra fajarNo ratings yet

- G 20 Summit in Indian Presidency PDFDocument3 pagesG 20 Summit in Indian Presidency PDFSynergy BhavaniNo ratings yet

- 5S PDFDocument41 pages5S PDFpranayrulzNo ratings yet

- Pipelining VerilogDocument26 pagesPipelining VerilogThineshNo ratings yet