Professional Documents

Culture Documents

Mathematics at Work Brochure: Manufacturing

Uploaded by

Achieve, Inc.Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathematics at Work Brochure: Manufacturing

Uploaded by

Achieve, Inc.Copyright:

Available Formats

mathematics

Manufacturing

at work

Manufacturing

The manufacturing industry has changed dramatically over

the last two decades. The sophistication and skills needed

for success in the workplace today mean that employers

place a premium on the ability to apply mathematical

knowledge to solve problems. An education system that

provides students with the quantitative knowledge and

skills for translating information represented in different

formats coupled with the ability to engage in critical

inquiry and problem solving will be what keeps the

skilled manufacturing industry in the United States on

the cutting edge.

Available Manufacturing Jobs

Within the advanced manufacturing industry, there are

a variety of entry-level jobs that pay well and provide

opportunities for advancement jobs for high school

graduates with postsecondary training or education but

less than a four-year college degree. Individuals who

participate in some form of postsecondary training

be it on the job, in a training center or at a community

college are often even better positioned to succeed in

the manufacturing sector. Some employers and industries

may require specialized training or education beyond a

high school diploma. In addition to motor vehicle produc-

tion, other leading manufacturing industries with good

job opportunities include semiconductor and electronic

components, aerospace products and parts, and

architectural and structural metals.

Core Mathematics Knowledge

in Todays Manufacturing Jobs

Developed by secondary, postsecondary, business, industry

and government leaders, the national Career Cluster Pathway

Plans of Study for Production and Manufacturing Production

Process Development recommend a set of rigorous mathe-

matics courses for students to take at both the secondary

and postsecondary levels in traditional or vocational settings

to pursue a career track in manufacturing. These Plans of

Study show in detail how the foundation provided by courses

such as Algebra I, Geometry, Algebra II, Trigonometry or

Statistics, Computer Applications, and Applied Manufactur-

ing Technology equips high school graduates with the

mathematical knowledge and skills needed for success on

the job. Until high school graduates understand the advanced

mathematical skills used in the manufacturing sector, they

will remain unable to meet the demands of this high-growth

industry. For more information on the Career Clusters Initia-

tive, see www.careerclusters.org/resources/web/pos.cfm.

at work

Mathematics in the Manufacturing Sector

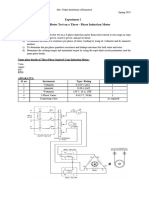

Jobs

Median yearly

salary

Percentage of total jobs by

education/training (ages 2544)

Number of total jobs

High school

Some college/

associate

2010 2020 % change

Electrical and electronics

engineering technicians

$56,900 23% 56% 151,100 154,000 2%

Mechanical engineering

technicians

$51,400 23% 56% 44,900 46,700 4%

Installation, maintenance and

repair mechanics

$36,700 40% 34% 143,600 160,300 12%

Engine assemblers $36,400 53% 31% 33,700 35,500 5%

Source: Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook Handbook, 201213 Edition.

83%

Employers experiencing

serious/moderate difculty

hiring qualied workers

A Growing Skills Gap of Qualied Workers

Source: Manufacturing Institute, 2011 Skills Gap Report.

Mathematics at Work Series

First developed in 2008, using the American Diploma Project benchmarks as the foundation, Achieve

produced a series of Mathematics at Work brochures to examine how higher-level mathematics is used in

todays workplaces. Updated in 2013 to reect the expectations set by the Common Core State Standards in

mathematics, the brochures present case studies drawn from leading industries nationwide to illustrate the

advanced mathematics knowledge and skills embedded in jobs that offer opportunities for advancement and

are accessible to graduates with some education and training beyond high school but less than a four-year

degree.

The series underscores the value of a rigorous high school curriculum in mathematics. All high school graduates

regardless of whether they enroll in college, join the workforce or enter the military benet from acquiring

a college- and career-ready foundation in mathematics.

To view or download the full set of Mathematics at Work brochures,

go to www.achieve.org/math-works-brochures.

The Common Core State Standards (CCSS) are K12

mathematics and English language arts/literacy standards

that identify the academic knowledge and skills all

students need when they graduate high school to be

ready for their next step, be it college, the workplace or

the military. The CCSS were developed through a process

managed by the National Governors Association and

Council of Chief State School Ofcers and led by states.

To date, more than 40 states have chosen to adopt and

implement the CCSS.

In mathematics, the CCSS include focused content

standards as well as Standards for Mathematical Prac-

tice, which articulate the ways students should apply

mathematics both in school and on the job to solve

problems, reason abstractly and quantitatively, critique

arguments, model, exercise precision, and look for

repeated reasoning. In English language arts/literacy, the

CCSS include expectations for reading, writing, language,

and speaking and listening, including students ability to

work in teams and communicate effectively in a range of

settings.

The CCSS are anchored in college- and career-ready

expectations, which start in grade 12 and are back

mapped to the earliest grades. Students who graduate

from high school having mastered the CCSS will be aca-

demically prepared for college-level courses and rigorous

career training programs. Importantly, the CCSS represent

the oor, not the ceiling, and students should engage in

additional coursework and work-based experiences to

help chart their career pathway.

The CCSS can be found at www.corestandards.org.

The Common Core State Standards:

Ensuring College and Career Readiness

Manufacturing companies like Toyota recognize that the

most effective and productive line employees are multi-

skilled workers who have a sophisticated understanding

of electrical and mechanical design as well as uid power

and fabrication applications. Toyota, in fact, has found

that the single most important asset possessed by their

most talented multiskilled employees many of whom

have only a high school education and some additional

training is a strong foundation in mathematics that

is applicable across all manufacturing elds.

Over the years, Toyota has streamlined its training

program to maximize its effectiveness so that new

hires work through a rigorous sequence of job training

courses in only those areas where they lack sufcient

background. Many of the courses teach concepts covered

by the Common Core State Standards in mathematics.

Key courses include:

n Math Refresher (e.g., computing with rational

and real numbers, basic operations with alge-

braic expressions, modeling, right-triangle

trigonometry)

n Electronics (e.g., manipulating linear equations,

advanced physics, amplitude and phase shift

for sine and cosine)

n Machine Structure (e.g., output-input power,

graphical representations of data)

n Fluid Power (e.g., Pascals law)

n Metric System (e.g., units and measurements: length,

mass, time, temperature, pressure and torque)

n Blueprint Reading (e.g., Cartesian and polar coordinates)

The capstone course for manufacturing trainees is

Troubleshooting. In this course, technicians must be able

to draw on all of the mathematics, physics and engineer-

ing concepts they have learned to solve real problems

drawn from the factory oor.

Solid mathematics is not the only skill needed to be suc-

cessful at companies like Toyota. Although the specics of

the technical work may vary from team to team, all skilled

line employees are expected to be able to articulate and

communicate the complexity of a project, translate their

understanding into the language of mathematics, and

work together as a team to arrive at the most practical

and effective solution to the task at hand.

Integrating their understanding and putting it to work is

just the beginning, as employers know that change is just

around the corner. Hiring knowledgeable employees and

equipping them with the training they need means that

companies in the manufacturing sector will be able to

compete today and adapt to the technological needs

of tomorrow.

Mathematics drives success at Toyota

Good math skills will improve your chances of getting a job

with Toyota, improve your chances of getting a higher-paying

job, improve your chances of being successful on the job and

improve your chances of moving up in the company.

Bob Tribble, Team Leader

Toyota Paint Operations

Career Preparation for Multiskilled Employees

on the Toyota Production Line

Cobalt blue, cherry red, midnight black Toyotas

cars come in these and 26 other colors. Transforming

the steel frame into the sleek car of tomorrow requires

among other tasks opening the hood during painting.

Creating a machine that automates the process and can

be adapted to future car designs was the challenge

but would the design team made up of line workers be

up to the task?

The goal was to build a hood opener with a lift arm to hold

the hood in place while a technician installs a stabilizing

monster jig the device that keeps the hood in the

correct position prior to painting. The hood opener

needed to follow along with the car, complete its task

and return to home position in less than a minute. And

it needed to operate safely more than a thousand times a

day and last for at least 10 years a long time frame

that would allow the hood opener to be adaptable

to subsequent model changes and

new car designs.

Designing from the Ground Up

Mathematical Reasoning,

Problem Solving and Teamwork

The hood opener design team consisted of a group

of skilled employees who had expertise in welding,

machining and electronics but were not engineers.

During the initial design phase, they needed to outline

the function the hood opener would perform and

determine how it would be powered.

They determined that the hood opener would be

suspended from a track above the production line

and follow the car as it neared completion. The lift arm

would extend and contract to grab and raise the hood,

and then it would release the hood once the monster

jig was in place. The team compared the advantages

and disadvantages of using

electricity, hydraulics or

pneumatics to propel the

hood opener. They

decided against

using an electric motor

because it would be heavy

and cumbersome and could emit

sparks. They eliminated hydraulics

due to the potential mess and danger if

a leak developed. Pneumatics the choice

of the team are explosion proof and, provided

the pressurized air is kept clean and

proper lubrication is added,

they have a long

service life.

Mathematics drives success at Toyota

Painting by Numbers: Mathematics in

Action on the Toyota Production Line

Putting the Pieces in the Right

Place at the Right Time

Geometry, Algebra and Data Analysis

Coordinating the actions of the pneumatic arms required

the design team to refer back to the formula for the

proportionality of theoretical torque. By determining the

torque that corresponds to motor displacement and

knowing the uid density and gravitational acceleration

the design team determined the difference in hydrostatic

pressure due to the weight of the uid and built a motor

for a smoothly operating yet durable lift arm.

After working through the mechanics of pneumatic arms,

the design team next wanted to ensure that the hood

opener would have the latest safety controls installed.

Electrical circuitry would guarantee the well-being of

technicians on the production line if the switches used

were both efcient and fully operational. Together, the

team checked the control circuits employed in the design

of the lift arm using truth tables based on Boolean algebra

to analyze their logical behavior and ensure that power

would be delivered accurately and efciently to specic

parts of the circuit.

After running through the electronics, the team turned

to measurements. How long was the hood? Where was

the lip of the hood relative to the hinge? If the lift arm did

not extend far enough, it would not connect to the hood

properly. If the hood was raised too high, it could cause

a premature release. If the hood was not raised high

enough, team members would not be able to perform

their job properly, and the hood could be damaged

when released.

Basic right-triangle trigonometry was essential to the

task of designing the lift arm, but the calculations were

complicated by the fact that car hoods are not perfectly

straight like the side of a triangle and different hoods

open to different angles. By considering several different

locations for the hood opener, the team determined where

to anchor the lift arm relative to a car as it traveled down

the production line. The team created an all-purpose

schematic so that, once the size of the hood was known,

the length of the lift arm could be calculated. Its length

depends on the initial and nal angle of the hood as well

as the position of the lift arm in the ceiling mount and

is designed to allow the hood opener to work with any

type of car.

20 Years and 6 Million Operations

It has been more than two decades since the design

team armed with a diverse array of high school

mathematics skills built and installed the hood

opener. But through numerous new car designs and

more than 6 million operations, the lift arm is still

working safely and effectively. That is mathematics at

work for business.

Mathematics drives success at Toyota

Any improvement in personal math

skills is equivalent to a company

improvement at Toyota.

Cheryl Berkley, Team Member

Toyota Assembly Operations

Companies like Toyota expect all of their technicians to

have a strong foundation in mathematical knowledge

because the most productive and skilled workers are

those who can apply mathematics in a wide variety of

situations. The application of such mathematical skills is

evident in the successful design of the lift arm at Toyota.

The team consisted of line workers high school

graduates with some postsecondary training and

relied on their understanding of many mathematical

applications, including calculating proportions and scale

factors; modeling and solving linear equations such as

Boyles Law for ideal gases; measuring using various

units in different systems; calculating with integers,

fractions and decimals; and reading and presenting

data in charts, tables and other graphic displays.

The team also relied on coordinate geometry and

trigonometry to be able to describe the location of the

point of support of the hood and how to position the lift

arm for different types of vehicles. In addition, the control

circuits employed in the design of the lift arm required

knowledge of Boolean algebra and propositional logic

to understand the truth tables involved.

Although the design of the lift arm relied on the mathe-

matical knowledge of the team members, it also relied on

their ability to work together. Indeed, research by Achieve

and others shows that both in the college classroom

and in the workplace, professors and employers identify

collaboration and communication as important factors for

success.

At Toyota, teamwork and communication skills have

always been at the core of its business but as the

global marketplace increases competition, today

more than ever Toyota relies on employees who can

collaborate and work together to keep the company on

the cutting edge. Regularly, Toyota expects its employees

to provide ideas and solve problems to improve the

manufacturing process. The company actively seeks out

workers with foundational mathematical knowledge and

provides training to build or reinforce their ability to share

information and cooperate on projects.

The focus of leaders in the manufacturing sector reinforces

the importance of ensuring that students graduate from

high school with the academic knowledge and skills they

need to succeed in jobs that pay well and offer opportunities

for advancement. For employees to succeed at Toyota

or elsewhere in the manufacturing industry they need

higher-level mathematics knowledge and skills as well as

the ability to communicate and problem solve skills that

also are included in the college- and career-ready Common

Core State Standards in mathematics and English language

arts/literacy.

Mathematics + Teamwork = Success

At Toyota, math is so

foundational to all of our work

in machine maintenance,

on the production oor, in the

ofce that its inseparable

from that work. Without

effective math skills, one

cannot be an effective

Toyota worker.

Dennis Dio Parker

Toyota North American

Production Support Center

E

d

i

t

o

r

i

a

l

a

s

s

i

s

t

a

n

c

e

a

n

d

d

e

s

i

g

n

:

K

S

A

-

P

l

u

s

C

o

m

m

u

n

i

c

a

t

i

o

n

s

Achieve

n

1400 16th Street NW, Suite 510

n

Washington, DC 20036

n

www.achieve.org

Copyright March 2013 Achieve, Inc. All rights reserved.

About Achieve

Achieve, created by the nations governors and business leaders, is a bipartisan, non-prot organization that helps

states raise academic standards, improve assessments and strengthen accountability to prepare all young people for

postsecondary education, careers and citizenship.

About the American Diploma Project (ADP) Network

In 2005, Achieve launched the ADP Network a collaboration of states working together to improve their academic

standards and provide all students with a high school education that meets the needs of todays workplaces and

universities. The ADP Network members responsible for educating nearly 85 percent of all our nations public

high school students are committed to taking four college and career readiness action steps:

1. Align high school academic content standards with the demands of college and careers;

2. Establish graduation requirements that require all students to complete a college- and career-ready curriculum;

3. Develop statewide high school assessment systems anchored to college- and career-ready expectations; and

4. Create comprehensive accountability and reporting systems that promote college and career readiness for all

students.

The world has changed, and high schools must change with it. The ADP Network is leading the charge in

ensuring that all high school students graduate with a degree that works.

For more information about Achieve and the ADP Network, visit www.achieve.org. To view additional

Mathematics at Work brochures, visit www.achieve.org/math-works-brochures.

You might also like

- Does Your District Need Training To Identify Quality NGSS Materials?Document3 pagesDoes Your District Need Training To Identify Quality NGSS Materials?Achieve, Inc.No ratings yet

- What Gets Tested Gets TaughtDocument6 pagesWhat Gets Tested Gets TaughtAchieve, Inc.No ratings yet

- Independent Analysis of The Alignment of The ACT To The Common Core State StandardsDocument61 pagesIndependent Analysis of The Alignment of The ACT To The Common Core State StandardsAchieve, Inc.No ratings yet

- Achieve Insights: College-Readiness Assessments Special EditionDocument3 pagesAchieve Insights: College-Readiness Assessments Special EditionAchieve, Inc.No ratings yet

- February 2018 NGSS NOW NewsletterDocument3 pagesFebruary 2018 NGSS NOW NewsletterAchieve, Inc.No ratings yet

- Thinking Longterm Graduation Rate Goals Under ESSADocument14 pagesThinking Longterm Graduation Rate Goals Under ESSAAchieve, Inc.No ratings yet

- States Leading: Progress and Best Practices: Graduation Rates Are Up - But Is Student Readiness Increasing Too?Document3 pagesStates Leading: Progress and Best Practices: Graduation Rates Are Up - But Is Student Readiness Increasing Too?Achieve, Inc.No ratings yet

- Strong Standards: A Review of Changes To State Standards Since The Common CoreDocument3 pagesStrong Standards: A Review of Changes To State Standards Since The Common CoreAchieve, Inc.No ratings yet

- October 2017 InsightsDocument3 pagesOctober 2017 InsightsAchieve, Inc.No ratings yet

- On Track or Falling Behind? How States Include Measures of 9th Grade Performance in Their ESSA PlansDocument8 pagesOn Track or Falling Behind? How States Include Measures of 9th Grade Performance in Their ESSA PlansAchieve, Inc.No ratings yet

- 2017 Achieve Annual ReportDocument20 pages2017 Achieve Annual ReportAchieve, Inc.No ratings yet

- NEW: Three Briefs Exploring State Accountability Plans Under ESSADocument4 pagesNEW: Three Briefs Exploring State Accountability Plans Under ESSAAchieve, Inc.No ratings yet

- Thinking Long Term: State Academic Achievement Goals Under ESSADocument14 pagesThinking Long Term: State Academic Achievement Goals Under ESSAAchieve, Inc.No ratings yet

- ICYMI: ESSA Tracker For State Accountability Plans: Show Me The Data 2017: States Can Improve Report Cards This YearDocument2 pagesICYMI: ESSA Tracker For State Accountability Plans: Show Me The Data 2017: States Can Improve Report Cards This YearAchieve, Inc.No ratings yet

- All Standards, All Students: Things To Know About Quality K-12 Science Education in January 2018Document4 pagesAll Standards, All Students: Things To Know About Quality K-12 Science Education in January 2018Achieve, Inc.No ratings yet

- EQuIP Summit OverviewDocument1 pageEQuIP Summit OverviewAchieve, Inc.No ratings yet

- Quality Examples of Science Lessons and Units: Things To Know About Quality K-12 Science Education in December 2017Document4 pagesQuality Examples of Science Lessons and Units: Things To Know About Quality K-12 Science Education in December 2017Achieve, Inc.No ratings yet

- Upcoming Webinar: Building A Science Strategy For Your School or DistrictDocument6 pagesUpcoming Webinar: Building A Science Strategy For Your School or DistrictAchieve, Inc.No ratings yet

- November 2017 InsightsDocument3 pagesNovember 2017 InsightsAchieve, Inc.No ratings yet

- Education Data Legislation: DQC's 2017 Review: OPINION: No Federal Interference in Indiana's High School Diplomas, PleaseDocument3 pagesEducation Data Legislation: DQC's 2017 Review: OPINION: No Federal Interference in Indiana's High School Diplomas, PleaseAchieve, Inc.No ratings yet

- November 2017 Perspective NewsletterDocument4 pagesNovember 2017 Perspective NewsletterAchieve, Inc.No ratings yet

- Strong Standards: A Review of Changes To State Standards Since The Common CoreDocument54 pagesStrong Standards: A Review of Changes To State Standards Since The Common CoreAchieve, Inc.No ratings yet

- NGSS Website Redesign Makes It Easier To Search The Standards and Find ResourcesDocument6 pagesNGSS Website Redesign Makes It Easier To Search The Standards and Find ResourcesAchieve, Inc.No ratings yet

- Achieve's September 2017 InsightsDocument3 pagesAchieve's September 2017 InsightsAchieve, Inc.No ratings yet

- State Science Education Standards Comparison ToolDocument36 pagesState Science Education Standards Comparison ToolAchieve, Inc.No ratings yet

- NGSS District Implementation WorkbookDocument55 pagesNGSS District Implementation WorkbookAchieve, Inc.No ratings yet

- NGSS Messaging CardDocument2 pagesNGSS Messaging CardAchieve, Inc.No ratings yet

- How To Read The Standards FigureDocument1 pageHow To Read The Standards FigureAchieve, Inc.No ratings yet

- Instructional Materials Collaboratives: Brief On Rhode Island & DelawareDocument3 pagesInstructional Materials Collaboratives: Brief On Rhode Island & DelawareAchieve, Inc.No ratings yet

- Why K-12 Science Standards MatterDocument2 pagesWhy K-12 Science Standards MatterAchieve, Inc.No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DB and DBM: Sound Pressure, Sound Level and Db. Sound Is Usually Measured With Microphones andDocument5 pagesDB and DBM: Sound Pressure, Sound Level and Db. Sound Is Usually Measured With Microphones andpathmakerpkNo ratings yet

- Characterization of Coconut Shell Ash For PotentiaDocument9 pagesCharacterization of Coconut Shell Ash For PotentiaLuisNo ratings yet

- Preservation of Indigenous Culture of Bataan Through An Ayta Magbukon School of Living Tradition (SLT) ProgramDocument11 pagesPreservation of Indigenous Culture of Bataan Through An Ayta Magbukon School of Living Tradition (SLT) ProgramEuniz ReyesNo ratings yet

- 10.1.1.658.8175.ready Mix - 7 QCDocument8 pages10.1.1.658.8175.ready Mix - 7 QCsyamsu dhuhaNo ratings yet

- Steel Design 5 May 2022Document3 pagesSteel Design 5 May 2022tous les joursNo ratings yet

- MOSFET - Working, Types, Operation, Advantages & ApplicationsDocument28 pagesMOSFET - Working, Types, Operation, Advantages & ApplicationsgezahegnNo ratings yet

- Scan 02 Mar 2021Document10 pagesScan 02 Mar 2021ARPITA DUTTANo ratings yet

- 32681-UET4 ITECBRAND v1 LowresDocument26 pages32681-UET4 ITECBRAND v1 LowreshassanNo ratings yet

- The Rectangular Coordinate SystemDocument57 pagesThe Rectangular Coordinate SystemSAS Math-RoboticsNo ratings yet

- Cultural Center RRL ForeignDocument4 pagesCultural Center RRL ForeignJoedel CapillanNo ratings yet

- P299 Reynaldo - Final Research ProposalDocument12 pagesP299 Reynaldo - Final Research ProposalShamah ReynaldoNo ratings yet

- Ball Mill Dynamics: GRINDING I - Training SessionDocument45 pagesBall Mill Dynamics: GRINDING I - Training SessionFran jimenezNo ratings yet

- Determining The Location of The Sustainable Fishing Industry With Center of Gravity Method, Case Study Northeast Coast of JavaDocument6 pagesDetermining The Location of The Sustainable Fishing Industry With Center of Gravity Method, Case Study Northeast Coast of JavaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Lesson Plan Grade 7 3rd QuarterDocument3 pagesLesson Plan Grade 7 3rd QuarterDanny EspañolaNo ratings yet

- Project ReportDocument16 pagesProject Reportshaqib71% (7)

- Current Trends On Deep Learning Models For Brain Tumor Segmentation and Detection - A ReviewDocument5 pagesCurrent Trends On Deep Learning Models For Brain Tumor Segmentation and Detection - A ReviewPadmavathy VelayudhamNo ratings yet

- Global Demography: SubtitleDocument32 pagesGlobal Demography: SubtitleEneb De OcampoNo ratings yet

- WWW Samsung Com - TranslateDocument5 pagesWWW Samsung Com - TranslateÇAĞATAY ÇALIŞKANNo ratings yet

- Optimal Recovery of Operator Sequences: V. F. Babenko, N. V. Parfinovych, D. S. Skorokhodov October 19, 2021Document21 pagesOptimal Recovery of Operator Sequences: V. F. Babenko, N. V. Parfinovych, D. S. Skorokhodov October 19, 2021Bart MaxNo ratings yet

- Ingles Intermedio 2Document12 pagesIngles Intermedio 2Julieta FHNo ratings yet

- Three-Dimensional Topographic Scanning Electron Microscope and Raman Spectroscopic Analyses of The Irradiation Effect On Teeth by ND, YAG, Er, YAG, and CO2 LasersDocument9 pagesThree-Dimensional Topographic Scanning Electron Microscope and Raman Spectroscopic Analyses of The Irradiation Effect On Teeth by ND, YAG, Er, YAG, and CO2 Laserszubair ahmedNo ratings yet

- Equipment List For Resection and IntersectionDocument6 pagesEquipment List For Resection and IntersectionDiegoNo ratings yet

- PTD25 Series Pressure Transmitters: Features ApplicationsDocument3 pagesPTD25 Series Pressure Transmitters: Features Applicationsjim bobNo ratings yet

- Department of Education: Learning Activities PlanDocument2 pagesDepartment of Education: Learning Activities PlanSamantha FernandezNo ratings yet

- Lit21st 1 Semester (1 Quarter) Social Innovation Fundamental: Global Issues I. The Universe Some Terminologies & Points To PonderDocument13 pagesLit21st 1 Semester (1 Quarter) Social Innovation Fundamental: Global Issues I. The Universe Some Terminologies & Points To PonderRoie Andrae ArayonNo ratings yet

- Tps 22967Document29 pagesTps 22967Thanh LeeNo ratings yet

- Exp-2 - Blocked-Rotor Test On A Three-Phase IMDocument3 pagesExp-2 - Blocked-Rotor Test On A Three-Phase IMMudit BhatiaNo ratings yet

- Distance Learning Challenges On The Use of Self-Learning ModuleDocument14 pagesDistance Learning Challenges On The Use of Self-Learning ModuleAngelica PioquidNo ratings yet

- Say It With Charts - McKinsey-32Document4 pagesSay It With Charts - McKinsey-32YONGXING CHENNo ratings yet

- Percentage Composition: Juliusleo M. Martin Teacher IIIDocument26 pagesPercentage Composition: Juliusleo M. Martin Teacher IIIjuliusleo martin100% (1)