Professional Documents

Culture Documents

Seminar S.G Iron

Uploaded by

ravikataria020 ratings0% found this document useful (0 votes)

404 views32 pagesThis document discusses the production of spheroidal graphite (SG) iron. SG iron, also known as ductile or nodular iron, has graphite present in the form of spheres rather than flakes, giving it improved ductility compared to grey cast iron. The key points are:

1. SG iron is produced by treating molten grey iron with magnesium or cerium to cause the graphite to form into spheres during solidification.

2. Proper chemical composition is important, with carbon content between 3-4% and silicon 1.8-2.8% promoting spheroid formation. Manganese should be below 0.5% to avoid carbides.

3. Properties of SG iron

Original Description:

sg iron

Original Title

Seminar s.g Iron

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the production of spheroidal graphite (SG) iron. SG iron, also known as ductile or nodular iron, has graphite present in the form of spheres rather than flakes, giving it improved ductility compared to grey cast iron. The key points are:

1. SG iron is produced by treating molten grey iron with magnesium or cerium to cause the graphite to form into spheres during solidification.

2. Proper chemical composition is important, with carbon content between 3-4% and silicon 1.8-2.8% promoting spheroid formation. Manganese should be below 0.5% to avoid carbides.

3. Properties of SG iron

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

404 views32 pagesSeminar S.G Iron

Uploaded by

ravikataria02This document discusses the production of spheroidal graphite (SG) iron. SG iron, also known as ductile or nodular iron, has graphite present in the form of spheres rather than flakes, giving it improved ductility compared to grey cast iron. The key points are:

1. SG iron is produced by treating molten grey iron with magnesium or cerium to cause the graphite to form into spheres during solidification.

2. Proper chemical composition is important, with carbon content between 3-4% and silicon 1.8-2.8% promoting spheroid formation. Manganese should be below 0.5% to avoid carbides.

3. Properties of SG iron

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 32

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

1

1. INTRODUCTION

Spheroidal Graphite (S.G) Iron is the name given to that cast iron, where the graphite is

present in the matrix in the form of spheroid or globules or nodules. Hence it is also called as

Nodular Iron and because of its exceptionally high ductility (with elongation some times as high

as 22%) is also referred to as ductile iron.

The rapid growth of S.G iron and its high consumption are testimonials to its outstanding

mechanical properties. Heat treatments such as austempering have further enhanced its

properties. S.G iron is hence finding extensive application in number of the fields. After having

basically replaced a number of gray iron and malleable iron casting they have made

penetrating in roads, the forging industry such as crank shafts and cam shafts originally made

by the forging technology are now being cast in iron. S.G iron is produced by the treatment of

gray-iron with either cerium or magnesium. The more commercial of the two is magnesium and

is now almost universally used for production of S.G iron. Use of cerium is restricted as it is a

carbide forming element beyond 0.01%.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

2

2. LITERATURE SURVEY

2.1 HISTORY OF S.G IRON

The first announcement of successful production of Spheroidal Graphite structures in grey cast

irons was made by H.Morragh of British cast iron Research Association in the year 1948 at the

American Foundrymens societys Annual convention in Phladelphia, U.S.A.The process

involved a treatment of low sulphur hyper- eutectic cast iron with cerium, which was added as

mish metal shortly before casting. In same convention, T.M Wickenden of the International

Nickel Company, U.S.A disclosed that their researchers had also found out a method of

production of Spheroidal Graphite structure in the as cast condition by the introduction in the

iron, either hyper- eutectic, of a small but effective amount of magnesium or a magnesium

containing addition such as a nickel-magnesium alloy. Since then the latter process has been

found to be a commercially viable process and is now universally used for the production of

Spheroidal cast-iron.

The mechanism of graphite nodule formation however is still a matter of great controversy.

Various theories have been put forward by various researchers but none of them have gained

universal acceptance.

Basically S.G iron is produced by noduliging grey iron. Thus a melt of grey-iron is first of all

desulphurised. Desulphurization has to be invariably carried out and recarburization has to be

done if necessary. Once the base iron of required composition is ready, it is suitably treated for

spheroidization. Post-inoculations are then carried out if required and the melt is poured in to

the moulds as early as possible to avoid fading effect.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

3

2.2 DIFFERENT BETWEEN GREY IRON AND S.G IRON

Engineering application of cast iron have been traditionally based upon gray (flake

graphite) irons providing a range of tensile strengths between about 150N/mm

2

and 400N/mm

2

with recommended design stress in tensile application.

In contrast ductile irons have tensile strengths ranging from 350 to 1500N/mm

2

with

good elongation and high toughness. They now account for about 25% of iron casting

production serving in safety critical applications where they have replaced steel casting,

forging.

In short we can say that the highest mechanical properties of grey iron are the starting

points for S.G iron castings.

Gray Iron Structure S.G. Iron Structure

2.3 PRORERTIES OF S.G IRON

The S.G. family iron has several interesting properties. These are given below

High strength (in some cases even greater than steel)

Adequate ductility.

Superior castability.

Excellent machinability.

Lower density then that of steel.

Superior surface lubrication properties.

Better damping characteristics.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

4

3. PRODUCTION OF S.G. IRON

3.1 SLECTION OF CHEMICAL COMPOSITION

The choice of chemical composition in alloys started with the aim of obtaining a carbon-free as-

cast structure. The other factors that are considered are the effect of the various elements on

the shape and distribution of graphite and the structure of the matrix. All factors are further

affected by cooling rate.

CARBON: - It strongly promoted carbide free as cast structure. The carbon content for the

commercial ductile iron is form 3.0 to 4.0%, although much narrower limits are usually desired.

Nodule counts are directly affected by the carbon content greater number of spheroids

formation at the higher carbon contents. Increasing the carbon content also increases

castability by improving fluidity and feeding. The carbon content level should be co-related

with the carbon equivalent formula:-

CE = %C + 1/3 %Si + 1/3 %P

Carbon equivalents greatly is excess 4.3 promote the development and growth of graphite

spheroids. Since graphite is far less dense than molten iron these spheroids may be become

buoyant and float toward the cope surface of casting, resulting in gross carbon segregation,

floating, as this phenomenon is called is prevent in analyses having carbon equivalents greater

than 4.60 and in section sizes greater than 1inch.

SILICON:- It is a very strong promoter of carbide free as-cast structure. Apart from promoting

graphite and refining its distribution, silicon is the most potent beneficial element in increasing

strength and up to 4% will also increase as-cast ductility. Silicon being ferrite stabilizer,

increases hardness, particularly in the annealed condition. Silicon also influences the

distribution of graphite spheroids. The higher the silicon content, the higher the nodule count

and the more the ferrite content. However, higher silicon content is known to promote chunky

type graphite resulting in deterioration in properties of heavy ductile iron castings other

potentially objectionable influences of increasing silicon content are reduced impact energy,

increasing impact transition temperature and decreased thermal conductivity. The general

range for commercial production is specified at around 1.8% to 2.8%.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

5

Typical carbon and silicon range of S.G.Iron Casting

MANGANESE: - The only single aim in selection of the manganese percentage is to avoid as-

cast carbide. It must be preferably kept below 0.5%. A side benefit of lowered manganese

content is the lowering of the tendency of hydrogen pick- up and there by minimization of the

danger of pin hole. It must be noted that the manganese content must never be chosen with

the aim of controlling the matrix structure.

SULPHUR: - The control of sulphur for the production of the S.G iron is highly essential. If base

metal contains higher than 0.015% S are used in production of S.G iron, uneconomical

amounts of magnesium or other nodulizing agents would be required and problems such as

dross defect control get magnified. The base iron in-mould process should have sulphur

contents within the 0.01% range.

PHOSPHORUS: - Phosphorus decreases ductility, toughness and weldability and it is

detrimental to casting soundness. For these reasons most specifications tolerate a maximum of

0.03% only. It is however, a good practice to keep phosphorus content below 0.04%. In certain

cases where reduced creep rate, increased thermal conductivity and abrasion resistance are

required, the phosphorus content should be much more.

MAGNESIUM: - Magnesium is added for nodularization generally in the alloyed form. It has

been extensively reported in literature that the residual magnesium content in the S.G iron

formed should be between 0.02% to 0.06% while calculating the amount of magnesium

alloyed, required factors such as temperature of treatment, the efficiency of the treatment

process and the percentage of the magnesium in the alloy will have to be taken in to

consideration.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

6

Relationship between S and Mg in ductile iron

CARBON EQUIVALENT: - Selection of proper carbon equivalent depend to the great extent on

the section thickness of the casting produced. As the casting section increases the carbon

equivalent decreases. It varies from 4.2 for a section thickness of 80 to 100m.m to as high as 5

for a 3m.m section thickness.

Recommended carbon equivalent values for ductile iron castings of various thickness

Optimum pouring temperatures for different minimum section thickness

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

7

3.2 ALLOYING ELEMENT AND THEIR EFFECTS

ELEMENT NORMAL

ADDITION

GENERAL EFFECTS OF ELEMENTS

COPPER 0.5 to 2.0 Strong pearlite promoter

Increases poof stress

Good tensile strength and hardness with no

embitterment

NICKEL 0.5 to 2.0 Mild pearlite promoter

Increases proof stress but little effect on

tensile strength

Danger of embitterment with larger addition

in excess of about 2 percent

TIN 0.05 to 0.1 Very strong pearlite promoter

Increases poof stress and hard ness but

danger of embitterment giving low tensile

strength elongation values

MOLYBDENUM 0.2 to 1.0 Mild pearlite promoter

Forms intercellular carbides especially in

heavy section

Increases poof stress and hardness

Danger of embitterment giving low tensile

strength and elongation

Improve elevated temperature properties

ARSENIC 0.05 to 0.1 Very strong pearlite promoter but not used

commercial possible , risk of embitterment

ANTIMONY 0.01 to 0.05 Very strong pearlite promoter but not used

commercial in S.G iron

CHROMIUM <0.1 Very strong carbide former. Should not be

employed if carbide-free structure is

required.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

8

3.3 SUBVERSIBLE ELEMENT AND ITS NEUTRALIZATION

The aim when production good quality ductile iron is to produce an iron having a fine

distribution of well formed nodules in the structure. The process of nodular graphite may reduce

mechanical properties, the reduction depending of nonnodular or flake graphite which may

present ISO 945 and ASTM 247 standard classify graphite according to a schematic

presentation of the observed structure and the ASTM standard contains enable control

personnel to assess graphite nodule number and size rapidly.

Small amount of element such as lead, bismuth, antimony and titanium singly or in combination

prevent magnesium having the desired modularizing effect and hence are often referred to as

subversive or interfering elements. The effects of subversive elements are cumulative. Small

amounts of two or more subversive elements present in amounts which individually have no

signification effect, together may adversely affected the formation of nodular graphite. The

subversive effect of some elements:-

Particularly titanium, lead and bismuth increasing as the size of the cast section increases. For

this reason acceptable levels can not be quoted and the effects of using furnace charge

materials controlling subversive elements can be evaluated by determination of the effect on

graphite structures in test bar or casting. When the elements are present individually,

subversive effects are likely to occur if the following levels are acceded lead 0.0005%, bismuth

0.002%, antimony 0.004 and titanium 0.1%.

The effect of subversible elements can be neutralized by the adding of a small amount of

cerium (0.002 to 0.005%) in addition to the magnesium.

Cerium contents above about 0.01% will results in a reduce nodule number and increasing risk

of carbide formation, so it is important not to add too much

3.4 MELTING PRACTICES

The relationship of melting practice to the type and amount of spheroiding alloy used is of

importance to casting and its physical properties

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

9

Cupola melting is the most common methods of melting for melting for ductile iron, moreover

electrical induction furnace are in use in a number of foundries.

ACID CUPOLA MELTING:-Using acid cupolas necessitates close control over charge

materials and coke since the acid slag produced are not capable of reducing the sulpher

content of the iron. This result in sulpher contents of 0.06 to 0.12 present, which, if not lowered,

necessitates, the use of increasing amounts of spheroidizing alloy. Acid cupola melting,

however, is capable of controlling the readily oxidizable elements in the charge, such as

chromium and manganese. Since it is a more oxidizable process than the basic cupola

operation. Because of the moderate carbon pick up in acid base cupola melting and the desired

base iron chemistry , the use of pig iron of return is some what limited close composition

control and high metal temperatures, however can be produce without the need of a hot blast.

BASIC CUPOLA MELTING:- Basic cupola melting is characterized by the definite advantage

of sulpher control. Average sulpher content of the basic melt before spheradizing ranges from

0.025 to 0.035%. this decreased sulpher level in the melt is obtained at the expense of higher

operating cost , higher silicon losses during melting , less effective temperature and

composition control and a greater carbon pickup during melting.

ELECTRICAL MELTING:- Electrical melting has provided to be a clean and reliable melt. It

has also offered the greatest flexibility for melting irons of different grades.

Electrical arc furnaces have been found to be less popular than induction heated ones. Their

batch type operation and noise pollution have been the contributing factors. The facts that it

has found some application both as a primary melter and as a duplexer is mainly due to its time

prove reliability.

Electrical induction furnace have been the most common melting units for the production of S.G

iron , both in simplex operation in small foundries and as duplexing units. The coreless type is

being used for primary melting and a channel furnace is being used for duplexing .High

frequency units have been found to be good form the metallurgical point of view but are

associated with high costs. However, where furnace capacities under one tone are desirable

and speed of melting is a consideration, than the high frequency is to be preferable. The

coreless line frequency induction furnace has been found to be the best possible furnace for

melting of base iron for S.G. iron production. The low frequency ensures better stirring thus

resulting in homogenization melting.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

10

3.5 CHARGE MATERIALS

The average metallic charge for ductile base iron consists of pig iron, steel scrap, foundry

returns, ferrosilicon and other ferro alloys if necessary and carburizes if added with the charge.

Pig- iron has been found to be a significant contributor to the control of chemical composition.

The pig-iron for S.G iron production must be of a selective grade in view of very small amount

of sulpher and phosphorus present in sponge iron. There is trend to use sponge iron in place of

pig iron in S.G iron production.

3.6 POURING TEMPERATURE

Pouring temperature depends on the casting section. As the section thickness increasing, the

pouring temperature required decreases. For minimum section thickness up to 20 mm the

pouring temperature can be vary from 1350

0

c to 1480

0

c.

3.7 DESULPHURIHATION

Economical production of quality S.G iron can be take place only with consistently low sulphur

contents, with high sulphur content problem of dross defects gets magnified. The iron therefore,

must be thoroughly desulphurization before spheroidization treatment is carried out .Some of

the practical desulphurization agents are

Soda ash

Caustic soda

Burnt lime

Lime stone

Calcium carbide

A fine grained calcium carbide is desirable so as to present the greatest possible surface area

and the highest possible temperature has been found to be favorable for desulphurization .It

has also been known that the carbide must be kept in motion to present unreaceted carbide

surface to the dissolve sulfides. An addition of 1.5 to 2% calcium carbide has been reported to

have reduced a base sulphur content of 0.12% to 0.01%.

Soda ash has been used to bring down sulphur from 0.06% to 0.08% range. Further reduction

has not been possible by this compound. It was also found to cause environmental problems.

Various techniques have been evolved with the sole aim of effecting mixing and causing the

reaction between the molten metal and the desulphurization agents.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

11

3.8 NODULARIZING MATERIAL AND NODULARIZATION TECHNIQUES

With commercial and technical growth of S.G. Iron, there has been an evolutioan in the ranges

and character of nodularizing materials and methods unlike in the past the newer nodularizers

and processes lend to better control over process variables.

Nodularizing Materials.

Magnesium and the rare earths have been integral parts of S.G. iron production from its

earliest stages. As mentioned earlier, magnesium has, since than been found to be a

commercially viable nudularizer. However, to utilize the ability of cerium in neutralizing the

deleterious effects of subversive elements. Some alloys of magnesium used for nodularization

also contain small amounts of cerium.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

12

Basically two classes of nodularizers have evolved

(i) Elemental nodulizers where the magnesium is in unalloyed form.

(ii) Alloyed nudulizers in which the magnesium is alloyed with either silicon or nickel

with or without rare earths.

The magnesium content in the alloy in these alloys is an important factor. Numerous

investigators have demonstrated that as the magnesium content of the alloy decreases, the

magnesium recovery associated with in use increases. In Indian conditions, the 9% Mg-Fe-Si

alloy is reported to give good results. The magnesium recovery is also dependent on the

treatment temperature. Higher the treatment temperature, lesser will the magnesium recovery.

0.76 x (S% in base metal S% residual) + residual Mg%

Mg Recovery % =

Mg% added.

The amount of nodulizer required is given by the formula :

% nudulizer alloy =

E Mga

Mgs Mgr

% * %

% %

Where Mgr = residual magnesium

Mgs = The amount of magnesium that will reacts with sulpher

(% Mgs = 075 x % of sulphur in base Iron)

Mga = Magnesium in the alloy

E = Efficiency of the processes.

Problems associated with the addition of magnesium :

There are a number of inherent problems with the addition of magnesium and much of the

investigative work resulting to the production of ductile iron has been associated with ways and

means of over coming these problems.

1. Low Boiling Point Magnesium has a boiling point of about 1107

o

C which is lower than

the temperature of the molten cast iron being reacted. This pressure of magnesium at

the treatment temperature, prevent easy solution of magnesium and result in

considerable agitation and even violence during the reaction.

2. Low solubility - magnesium is only sparingly soluble in molten and solid cast iron, so

the use of alloys based on iron and magnesium is not possible.

3. Lower specific gravity The specific gravity of magnesium only 174 in comparison with

a value above 7 for cast iron. When added to cast iron, magnesium or its low density

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

13

alloys tend to float giving rise to excessive losses caused by local boiling and

oxidation.

4. Fume As well as the fume and agitation associated with the addition of magnesium

or its alloys, excessive magnesium oxide fume is also formed. Although this is not toxic

it does result in a deterioration of working conditions in the found and is potential

problem unless adequate fume collection equipment is installed.

5. Dross formation During the treatment sulphides and oxides of magnesium are

formed which may remain suspended in the metal and subsequently lead to the

formulation of dross type defects in the casting. In addition, a magnesium oxides rich

skin is constantly being formed on the treated metal surface and this, in combination

with other oxides, results in the formation of refractory type complexes which can also

cause dross defect in castings.

Basic methods of overcoming the problem:

All the work carried out on improving the efficiency of the Mg treatment has been carried out

along with following lines:

1. To alloy the magnesium in order to increase the specific gravity and reduce the

tendency for the addition to float on the molten iron and control the rate of the action of

the Mg thereby reducing the reactions of violence and increasing recovery. Alloy

includes the classical nickel magnesium alloy containing 15% Mg, a range of Cu-Mg

alloys and also the ferrosilicon magnesium range which, are the most commonly used

materials for productions.

2. The magnesium alloy may be submerged, below the metal surface thereby eliminating

the floating effect. This enables alloys of high magnesium content to be employed

typical examples being Mg/Si containing 30-40% mg, magnesium impregnated coke

(42% Mg) and Mg sponge-Iron briquettes (15% Mg). Further advantages of this

practice may be achieved by increasing the depth of metal in the ladle. This gives

grater metal head which increases the time of passage through the molten Iron,

resulting in an increased Mg recovery.

3. Mg or Mg rich alloys may be impacted or dispersed into the molten Iron, which reduces

the reactions violence and provides an extended passage time for the Mg to react with

molten metal, pure Mg can be employed in this named

4. The pressure above the metal in the ladle can be in increased to a level exceeding the

vapour pressure of a magnesium at the temperature of treatment. This eliminates the

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

14

boiling effect of magnesium and results on a quite reaction and good magnesium

recovery. Pure Mg is as used in such application.

5. Other methods have been devised where by the reaction rate and hence violence

associated with the addition of Mg is controlled, either in the mould itself or in a

specially designed vessel.

Techniques of Adding Magnesium to Molten Metal

In general the simple treatment methods can be satisfactory used with the more costly low

magnesium content alloys. Special purpose equipment enable cheaper, higher magnesium

content materials to be employed, but often introduces additional metal handling, maintenance

and control cost.

In Direct Pour On Technique :

This is the simplest technique of adding magnesium where by the metal is poured directly on

the weighed magnesium alloy. It requires no special equipment and conventional foundry

ladles can be used satisfactory. Temperature loss during treatment is also at a minimum, but

the technique can only be employed with the higher density alloys such as nickel magnesium,

copper magnesium and magnesium ferrosilicon to produce a magnesium recovery of about 25-

30%.

Since conventional foundry ladles are employed the technique can be readily applied to any

metal weight which can be of advantages in jobbing work where it is often impossible to

programme metal production to give a consistent metal demand.

IN DIRECT POUR ON TECHNIQUE

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

15

SAND WHICH PROCESS:

The aim of this technique, which is basically an extension of the pour on methods is to produce

a higher magnesium recovery by holding down the magnesium alloy for a period of time and

also producing a localized low temperature area. The technique consists of building a pocket

into the bottom the Mg alloys and a cover of steel scrap (2-3%) of metal weight or a steel or

ductile iron plate. The metal stream from the furnace must be directed a way from the pocket to

obtain the maximum benefit the pocket should be deep enough to contain all of the alloy and

steel scrap and latter should be of small size in order to produce a high packing density. The

main disadvantages of metal temperature resulting from the scrap. The loss of about 0.1%

carbon due to the dilution effect of the steel scrap should also be borne in mind. The depth and

surface area of the formed cavity must be sufficient to contain the Mg alloy and steel scrap.

The metal stream is directed into the empty half of the ladle which then produces a smooth flow

of metal across the steel scrap, thereby precuenting premature reaction.

SAND WHICH PROCESS

COVER TRIGGER PROCESS :

This is a modification of the sandwich process, but instead of a steel cover a layer of an inert

materials such as calcium carbide is placed over the magnesium alloy. The ensure a uniform

layer of alloy it is advisable to employ the magnesium-ferrosilicon in the form of graded fines. It

is found that when metal is poured into the empty half of the ladle and subsequently flows over

the refractory bridge, the inert layer is not dislodge and reaction of magnesium does not

commences using this technique the ladle can be completely filled and if necessary transported

to suitable casting station before reaction is initiated. This has been carried out by

dislodgements of the calcium carbide or inert-cover crust and is accomplished by pricking with

a long diameter steel bar or alternatively, by the insertion of a graphite rod into the treatment

chamber before addition of the inert cover. In this instance, when the reaction is required to be

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

16

started the graphite bar is nearly, twisted and removed from the chamber when reaction

commences.

If the correct of alloy fines and inert cover are employed a relatively quiet reaction results and

magnesium recoveries of the order of 50% can be achieved, even with the conventional

foundry ladle having a low height to diameter ratio. These benefits have to be offset by the

extra core required in adding the materials to the ladle, and the removal of the calcium carbide

rich slag, which is produced during treatment.

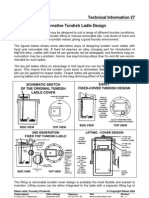

THE TUNDISH COVER :

Significant improvement in the treatment efficiency of the saved which process can be

achieved by the use of a suitably designed cover to the ladle, component with the simple open

laddle design, the tundish ever system offer greater consistency and increased magnesium

recovery together with significant reductions in fume and glare. The differences between

conventional ladle and tundish ladle operation are.

The tundish cover operates on the simple principle limiting the amount of air available for west

full combination with magnesium. Magnesium recovery is increased to between 60% and 65%

with accompanying cost savings.

Iron enters the ladle through a suitably sized hole in the tundish which forms an integral part of

the ladle cover. The entry hole is so positioned as to ensure that the first iron entering the ladle

is directed away from the treatment alloy. The diameter of the entry hole is designed to regulate

the iron flow and ensure that the tandish remains full throughout most of the magnesium

reaction there by limiting the in grass of air. Good sealing of the cover with the ladle and the

use of an overlapping opron are design features which improve the efficiency of the system.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

17

PLUNGING OR SUBMERGING TECHNIQUES

They are used with alloys of higher magnesium content (15 to 50%) which have low densities.

There are a number of operational factors to consider with these techniques especially position

of the holes in the plunger bell, and the ladle. Many variations in design of equipment are

possible but always the aim must be to maintain the alloy in the submerged position during the

entire treatment operation disadvantage of the techniques compared with the use of the simple

pour on methods are :

The higher metal temperature loss the need to treat a minimum of about 1 tonne of metal if

excessive temperature loss and low magnesium recoveries are to be avoided and the capital

plunger or other components of the system and more complex metal handling requirements.

The principal advantage is the ability to use the cheaper, higher magnesium content alloys

which may be silicon and aluminium free, to give magnesium recoveries typically of 40-60%.

G.F. CONVERTER PROCESS

The Gerge Fisher process has been the most successful of the treatment methods using pure

magnesium. The design of vessel is on the converter style and the metal is added when it is in

the horizontal position. After charging the metal the magnesium the hole formed in the side of

the ladle. This hole is than sealed and the converter is moved to the vertical position when

metal flows into the reaction chamber by using the correct number and diameter of the holes in

there factory partition plate the reaction is controlled and very high magnesium recoveries of

the order of 50-60% are readily achieved. The advantages of the techniques are the high

magnesium content the production irrespective of the base metal sulphur content and the use

of a silicon aluminum free treatment materials. The disadvantages are the capital of the

equipment and the need to treat a minimum of about 6 tons of the metal per hour.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

18

TREATMENT IN THE MOULD :

The technique of adding magnesium ferro-silicon in the mould cavity, now well known as the in

mould process. In this process not suitable for longer and relatively higher volume production of

ductile, the runner system for each casting contains a suitably designed chamber in which is

placed a weighed amount of magnesium alloy but development work is required to ensure that

consistency of structure can be assured on a production scale especially where multi-

impression cavities are involved. The metal flowing at a known rate over the treatment alloy,

produces a consistent pick-up of magnesium throughout the pouring period.

No smoke or fume comes out from the mould during the reaction period whilst excellent

magnesium recovery levels (usually >75%) are obtained. In addition there is no longer from

fading and the nucleating effect of the treatment alloy aviated the need for additional

inoculation.

Further more since no handling at magnesium containing iron is involved, problem with build

up of magnesium containing slags on ladle or furnace walls is eliminated.

Nevertheless, the technique requires low base iron sulpher levels (<0.015%), properly

designed running reaction system as a outlined above and also close control over the

treatment alloy if satisfactory structures and freedom form inclusions are to be achieved.

Adequate supervision or suitable monitoring systems are necessary to ensure that the addition

of the alloy has been made to each mould since each mould is in effect a separator treatment

the quality control systems adopted mg reflect this situation with possibly 100% checking being

required.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

19

Nodularing Alloy and Treatment Process

Treatment Process

1. Nickel Magnesium (5-15%Mg)

2. Copper Magnesium (10-15%Mg)

Pour on technique

1. Nickel silicon magnesium (15% Mg)

2. Copper silicon magnesium (12% Mg)

Sandwich technique

1. Magnesium Ferrosilicon (9%Mg)

2. Magnesium Ferrosilicon (5%Mg)

Sandwich and cover technique

1. Magnesium Ferrosilicon (5% Mg or 9%

Mg)

Tundish Cover

1. Magnesium Ferrosilicon (5% Mg ) In mould

1. Magnesium Ferrosilicon (3-6+%Mg) Flow through technique

1. Magnesium Silicon (20-35% Mg)

2. Magnesium impregnated coke (42%Mg)

3. Iron Magnesium briquettes (5-15% Mg)

Plunging or submerged

method technique

Magnesium bar (>99% Mg)

Magnesium powder (>99% Mg)

Pressure vessel, converter,

injection method

3.9 INOCULATION OF DUCTILE IRONS

PURPOSE:-The inoculation of cast iron involves the addition of small amounts of materials

(inoculant) to molten metal either just before or during pouring. Inoculation increases number of

points viable for the precipitation and subsequent growth of graphite. This effect of high level of

nucleation is demonstrated. High level of nucleation promoted graphite structure whilst low

levels can result in the formation of either mottled structure or white irons. The need for a high

level of nucleation increases as cooling rate increases i.e. section size decreases.

In addition to its effects on graphite morphology, magnesium is powerful carbide promoter;

there is a tendency for ductile irons to solidify with white or mottled structures. The primary

purpose of inoculating ductile irons, therefore is to suppress formation of chill and mottle. In

addition, inoculation is important in maintaining good nodule shape and also high nodule

numbers.

INOCULANTS USED:-Graphite is not an effective inoculant for ductile iron and all effective

inoculants are based on silicon. The most widely used is foundry grade ferrosilicon, contenting

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

20

about 75% silicon. This alloy must contain small amount of aluminum and calcium, in order to

be fully effective the amounts required are about 1.5 to 2.05% aluminum and about 0.3 to 1.0%

calcium.

ADDITION OF INOCULANTS: In general, much larger of inoculants are used for ductile iron

than for grey irons with as much as 0.75% of silicon to be added as ferrosilicon. In practice, for

ladle inoculation a 0.5% silicon addition should be adequate for most purposes.

FADING: The effect of an inoculation addition is not permanent and starts to decreases (fade)

immediately after the addition of Mg is made. As fading occur the number of nodules

decreases, and the tendency to produce chill and mottle increases. In many cases half of the

inoculating effect is lost within the first five minutes and nearly all after 10 minutes. As fading

occurs graphite nodule shape deteriorates and quasi-flake or exploded nodules can be to occur

Different technique of inoculation

They are various technique of inoculation are

1. Ladle inoculation The selected grade of inoculant for ladle inoculation should

always be added to thermal stream when tapping from furnace to ladle, or ladle to

ladle. Additions should begin when the ladle is one-quarter full and be completed when

the ladle is three-quarters full, so that the last metal merely mixes.

It is therefore difficult to give an accurate estimate of the amount of inoculant which is

requiredfor every situation. In general inoculant addition of 0.3 to 1% by weight of

metal will be satisfactorily for S.G. Iron. Care must be taken not to over inoculate of

S.G. Iron there is problem arise with shrinkage porosity due to high nucleation level.

2. MOULD INOCULATION:-The starting point was the placing of a small amount of fine

ferrosilicon at the base of the sprue. However, results obtain tend to be erratic owing to

the tendency for the inoculants to be washed away by the initial stage of metal .as

development progressed the used of a bonded pellet or pre-cast.

Slug of inoculants was placed either in a chamber in the running system, or

top of the strainer are which was positioned at the bottom of the sprue. In either case it

was customary to provide a small mixing chamber before the metal entered the

casting.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

21

The weight of the inoculants placed in the mould varied in accordance with

weight of the casting and usually in the range 0.1 to 0.5% by weight of metal poured.

This means that the running system and feeder system to be taken in to account. it is

important that the inoculation is completely and uniformly distributed so that the effect

is uniformly through out the casting. How these are achieved will depend on the design

of the casting running and gating system. Mould inoculation can be used as the sole

method of inoculation but because of problem in ensure complete and uniformly

solution of the inoculation. It is more frequently used as a bake up to ladle inoculation.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

22

METAL STREM INOCULATION:- Most other forms of inoculation are based on the addition of

the powdered inoculants to the metal stream just above the pouring basin or bush. The

powdered inoculants (0.1 to 0.5 mm) are introduced via a tube to the metal stream. The

dispenser can be activated by means of a photoelectric cell or alternatively by the control

system fitted to an automatic pouring furnace. The delivery rate is set or the control box and

does not change significantly. The principle requirement is that the inoculants used should be

correctly sized and free from impurities which could give rise to slag inclusion.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

23

4. HEAT TREATMENT OF DUCTILE IRON

It is obviously desirable to achieve the required properties in the as-cast form, but this is not

always possible because of variations of section thickness etc. Heat treatment of the castings will

eliminate carbides in thin sections, produce more consistent matrix structures and for a given

structure, the mechanical properties are often improved by heat treatment, especially by

normalising. Where tempered martensite structures are needed, heat treatment is essential.

Stress relief

Heat at 50-100C/h to 600C (taking care not to exceed 610C), soak for one hour plus an hour for

every 25 mm of section thickness in the thickest section. Cool at 50-100C/h to 200C or less.

Ensure that the castings are adequately supported in the furnace so that they are not subjected

to stress.

Breakdown of carbides

Thin section castings may contain carbides in the as-cast structure, these can be eliminated by

soaking the castings at 900-925C for 3 to 5 hours.

Annealing to produce a ferritic matrix

Castings should be soaked at 900-925C for 3-5 hours, followed by slow cooling at around 20-

35C/h through the critical temperature (about 800-710C), then furnace cooled at, say 50-

100C/h to 200C

Normalising to produce a pearlitic matrix

Soak the castings above the critical temperature then air cool. Again a soaking temperature of 900-

925C is usually used, to ensure that carbides are broken down, then use forced air cooling to form

pearlite. The type of heat treatment "unace available and the size of the load determines the cycle

that is possible. it may be necessary to adjust the metal composition with tin or copper to help

the formation of fully pearlitic structures.

Hardened and tempered structures

Austenirise at 900-920C then oil quench. Tempering is usually carried out 600-650C.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

24

Austempered ductile iron (ADI)

Austempering is an isothermal heat treatment for producing 'bainitic' structures. It can double the

strength of ductile iron while retaining good ductility and toughness. Wear resistance and fatigue

properties are excellent so that ADI is comparable with wrought steel.

The ADI heat treatment is a two-stage process, shown in the graph. Austenitising is carried out at

815-930C to fully transform the matrix to austenite. This is done either in a non-oxidising

atmosphere furnace or in a high temperature salt bath, temperatures and times are determined

by chemical composition, section size and grade of ADI required. 1 to 1.5 hours is usually adequate.

Slow initial heating of the casting is desirable to avoid the danger of cracking of complex shapes.

The castings are then quenched to the required isothermal heat treatment temperature, usually

between 210 and 400C This is usually done in a salt bath. The castings are held at temperature for

1-2 hours to complete the transformation of austenite to bainite. The lower temperatures give high

hardness, strength and wear resistance, while the higher heat treatment temperatures result in

higher ductility and toughness. After the isothermal treatment, the castings are cooled to

ambient temperature

Typical austempering heat-treatment stages.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

25

5. MECHANICAL PROPERTIES & MICROSTRUCTURE OF S.G. IRON

5.1 MECHANICAL PROPERTIES

BS-2789:1985 GRADES OF S.G IRON AND THEIR MECHANICAL PROPERTIES:

Propery

Grade Produce to BS-2789:1985

350/

22

400/

18

420/

12

450/

10

500/

7

600/

3

As-cast or

normalized

Quenched and

tempered martensite

700/2 800/2 900/2 700/2 800/2 900/2

Tensile strength

N/mm

2

350 400 420 450 500 600 700 800 900 700 800 900

Elongation%

(minimum and

range)

22

to

29

18

to

27

12

to

20

10

To

18

7

To

15

3

To

7

2

To

5

2

To

5

2

To

5

2

To

5

2

To

5

2

To

5

0.1% Poof strength(N/mm

2

)

1.Tension 203 248 266 293 323 346 385 440 495 525 600 675

2.Compression 226 271 289 316 340 360 397 452 507 537 612 687

3.Torosion 157 192 206 227 241 247 270 308 347 368 420 473

1.Typical impact

properties un-notch

fully ductile

108

To

149

108

To

149

108

To

149

95

To

140

85

To

120

40

To

75

27

To

40

25

To

35

25

To

35

108

To

149

108

To

149

108

To

149

2. Notched fully

dutile (J)

18

to

21

16

to

19

16

to

19

9

to

16

7

to

16

7

to

11

6

to

8

6

to

8

6

to

8

6

to

8

6

to

8

6

to

8

Ductile to Brittle

Transition

o

C

(Mean notch

values)

-50

to

-10

-50

to

-10

-50

to

-10

0

to

20

20

to

60

40

to

80

60

to

80

60

to

80

60

to

80

0

to

40

0

to

40

0

to

40

Hardness HB

10/3000 Range

107

to

130

130

to

140

140

to

155

155

to

172

172

to

216

216

to

247

247

to

265

265

to

282

282

to

299

232

to

259

259

to

286

286

to

313

Recommended design Stress

Tensile (Static)

N/mm

2

114 139 140 154 155 161 173 138 223 236 270 304

Corpression (Static)

N/mm

2

136 163 173 190 204 216 239 272 305 323 368 413

Alternative fatigue

Un notched 60 65 67 70 75 83 93 101 106 93 101 106

Notched 38 40 41 43 45 50 56 61 63 56 61 63

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

26

Mechanical properties and their chemical composition of some casting

(produced by L&T)

1. Mechanical Properties

Yield strength. 302.39MPa

U.T.S. 420.77MPa

% Of elongation. 20.57

Impact strength. 8 J

The impact strength is measured at 20

o

C.

Microstructure as-cast condition

100X

The metal composition of this casting:-

Composition Percentage

C 3.63

Si 2.15

Mn 0.17

S 0.008

P 0.029

Cr 0.3

Ni 0.36

Cu 0.02

Mg 0.043

2. Mechanical properties

0.2% Proof stress. 261MPa

U.T.S. 369MPa

% Of elongation. 22.28

Impact strength. 14,13,16 J

Microstructure of as-cast conditions

100X

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

27

The metal composition of this casting:-

Composition Percentage

C 3.6

Si 2.67

Mn 0.19

S 0.01

P 0.031

Cr 0.03

Ni 0.39

Cu 0.007

Mg 0.067

COMPOSITIONS some SG Iron casting (Produced by L&T)

SL.NO. C Si Mn S P Cr Ni Mo Cu Mg

1 3.63 2.15 0.17 0.008 .029 0.03 0.36 0.002 0.02 0.043

2 3.68 2.55 0.15 0.01 0.03 0.039 0.33 0.005 0.028 0.038

3 3.55 2.19 0.18 0.01 0.026 0.02 0.36 0.001 0.011 0.045

4 3.58 2.05 0.2 0.011 0.036 0.02 0.42 0.002 0.002 0.037

5 3.54 1.8 0.2 0.01 0.031 0.03 0.31 0.00 0.009 0.04

Mechanical Properties of the ITEMS:-

SL.NO Test

condition

0.2%proof

stress (Mpa)

U.T.S.

(Mpa)

% Of

elongation

Impact (J)

At 20

o

C

1 Not heat treated * 420.77 20.57 8 8 8

2 Not heat treated 270.56 382.00 23.14 16 17 17

3 Not heat treated 238.97 382.00 22.28 17 16 17

4 Not heat treated 302.07 481.08 17.28 6 6 5

5 Not heat treated 270.56 391.47 23.14 17 15 15

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

28

5.2 MICROSTRUCTURE OF SG IRON

Microstructure of nodular iron with 4.13% silicon content

Microstructure of nodular iron with 0.50%

phosphorus content

Microstructure of nodular iron with 2.92% Mn content

Nodular iron prepared from Swedish charcoal iron

with no special addition other than magnesium and

inoculant

Small amount of flake form of graphite due to 0.009%

lead.

0.13% cerium. Graphite nodules in a matrix of

pearlite.

Flake from of graphite in iron No. 4 with 0.013% lead

0.003% basimuth.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

29

0.004% antimony.

0.022% antimony and 0.15% cerium.

0.022% antimony and 0.028% cerium.

0.016% tin.

0.13% aluminum

Iron no. 53 with 0.34% aluminum.

0.02% titanium.

0.03% titanium.

1.2 in. diameter bar with 0.075% magnesium.

1.2 in. diameter bar with 0.117% magnesium

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

30

6. APPLICATION OF S.G IRON

The application of the S.G iron have increased tremendously in recent times as can be seen

from the list of the components which are being made.

Engine crank shaft

Brake caliper, disc brake anchor, brake anchor plate.

Machine- tool bed

Electrical insulator post and cap.

Steering Knuckle

Rack and pinion of steering assembly

Piston for impact drills.

Rolling mill rolls.

Moulding boxes and mould box clamps

Brake shoe for heavy duty brakes.

Glass moulds.

Spacer cage for rolling bearing.

Piston rings.

Wind mill items.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

31

7. CONCLUSIONS

The ductile iron finds wide engineering application because of its excellent combination of

castability and mechanical property. It has also very good machaniability, corrosion resistance,

wear resistance and thermal shock resistance. It finds application in gears, dies, valve and

pump bodies, pinion, crank shaft etc. It is a widely acceptable cast iron because of high

strength and good ductility. The problems faced due to lower melting and boiling point of Mg

have been encounter by using various magnesium treatment practices.

Seminar Report on Production of S.G. Iron Page No.

National Institute of Foundry & Forge Technology

32

REFERENCES

1. Source book on Ductile Iron, ASM Publication, June 1977.

2. AFS Production of S.G. Iron Practice, 1976.

3. Fosico-ferrous Foundrymen, Handbook by R. Brown, 2000.

4. Principles of Metal Casting by Philip C. Rosenthal, 2003

5. ASM Hand Book, vol.15 (Casting), Ninth Edition, September, 1988.

6. Ductile Iron Production practice by BRCA, 1995.

7. Foundry Technology Paul J. Mikelonis ASM and AFS, 1985.

8. Typical Microstructures of cast metal, by G. Lambert, 1966

You might also like

- S.G IronDocument6 pagesS.G IronQasim BarkatNo ratings yet

- SG Iron ProductionDocument20 pagesSG Iron ProductionShreyashri Nayak100% (1)

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocument23 pages1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Grey Iron A Unique MaterialDocument13 pagesGrey Iron A Unique MaterialmetkarthikNo ratings yet

- MagnesiumDocument3 pagesMagnesiumIsidoro LópezNo ratings yet

- Cerium in Ductile IronDocument2 pagesCerium in Ductile Ironvivek1312100% (2)

- ELMAGDocument2 pagesELMAGthomazfabricioNo ratings yet

- Home About Us Products Quality Control Representation Useful Links Contact UsDocument5 pagesHome About Us Products Quality Control Representation Useful Links Contact Ustushak mNo ratings yet

- Elkem 05 Inoculation MechanismsDocument2 pagesElkem 05 Inoculation Mechanismsmarcotulio123No ratings yet

- Elkem 13 Compacted Graphite IronDocument2 pagesElkem 13 Compacted Graphite Ironmarcotulio123No ratings yet

- Selection of Inoculants For Grey Cast IronDocument2 pagesSelection of Inoculants For Grey Cast Ironarnaldorcr8646No ratings yet

- Shrinkage in Ductile IronDocument5 pagesShrinkage in Ductile Ironkarthikkanda100% (1)

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocument2 pagesPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646No ratings yet

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646No ratings yet

- Common Metallurgical Defects in Grey Cast IronDocument9 pagesCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Chunky GraphiteDocument16 pagesChunky GraphitesachinguptachdNo ratings yet

- Analysis of Quality and Cost of FeSiMg Treatment Master Alloy vs. Cored Wire in Production of Ductile Cast IronDocument4 pagesAnalysis of Quality and Cost of FeSiMg Treatment Master Alloy vs. Cored Wire in Production of Ductile Cast IronAdams GodoyNo ratings yet

- Effect of Bismuth in Ductile IronDocument4 pagesEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Elkem 10 Tundish Cover Ladle NodularizationDocument2 pagesElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123No ratings yet

- Late Metal Stream InoculationDocument2 pagesLate Metal Stream Inoculationarnaldorcr8646No ratings yet

- S.G.Iron GuidelinesDocument28 pagesS.G.Iron GuidelinesTarun Chakraborty100% (3)

- Foundry DefectsDocument12 pagesFoundry DefectsVirendra Gupta100% (1)

- O HC HCDocument101 pagesO HC HCIndustrial Infra Jobs100% (1)

- AFS Thermal Analysis of CupsDocument12 pagesAFS Thermal Analysis of Cupsyash_ganatraNo ratings yet

- Elkem 07 Magnesiun Contents in Ductile IronDocument2 pagesElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123No ratings yet

- Niobium in Cast IronDocument13 pagesNiobium in Cast IronTayyab HussainNo ratings yet

- Sampling of Liquid Cast IronDocument2 pagesSampling of Liquid Cast Ironarnaldorcr8646No ratings yet

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocument8 pagesCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdNo ratings yet

- Cast Iron SolidificationDocument12 pagesCast Iron Solidificationkatchani123100% (1)

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 pagesRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazNo ratings yet

- Ductile Dross Formation MonitoringDocument27 pagesDuctile Dross Formation MonitoringsachinguptachdNo ratings yet

- ATAS Metstar Kovis FoundryDocument18 pagesATAS Metstar Kovis FoundryslagmercuryNo ratings yet

- Surface Graphite Degeneration in Ductile Iron CastDocument8 pagesSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarNo ratings yet

- Cast Iron DampingDocument5 pagesCast Iron Dampinggabs88No ratings yet

- Manganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronDocument30 pagesManganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronNetoNo ratings yet

- Colour MetallographyDocument12 pagesColour MetallographystefaneduardNo ratings yet

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 pagesFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646No ratings yet

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Magnesium Contents in Ductile IronDocument2 pagesMagnesium Contents in Ductile Ironarnaldorcr8646No ratings yet

- A Model For The Graphite Formation in Ductile Cast Iron Part I Inoculation MechanismsDocument25 pagesA Model For The Graphite Formation in Ductile Cast Iron Part I Inoculation MechanismsAdams GodoyNo ratings yet

- Ferroalloy Storage Bin DesignDocument2 pagesFerroalloy Storage Bin Designarnaldorcr8646No ratings yet

- S.G. Iron : MouldingDocument11 pagesS.G. Iron : MouldingsureshbabuamalaNo ratings yet

- Common Metallurgical Defects in Ductile Iron EnglishDocument1 pageCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessNo ratings yet

- Technical InformationDocument78 pagesTechnical InformationCarlos Barrachina Martínez100% (2)

- Offsetting Macro-Shrinkage in Ductile IronDocument13 pagesOffsetting Macro-Shrinkage in Ductile IronmetkarthikNo ratings yet

- Oxidation of Ferrosilicon Alloys During StorageDocument1 pageOxidation of Ferrosilicon Alloys During Storagearnaldorcr8646No ratings yet

- 26-ELKEM Poster-Graphite Structures in Cast IronsDocument1 page26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENNo ratings yet

- Effects of MN Content and Heat TreatmentDocument5 pagesEffects of MN Content and Heat TreatmentTrần Xuân VịnhNo ratings yet

- AntiSegregation HopperDocument5 pagesAntiSegregation Hoppermecaunidos7771No ratings yet

- 2005 AFS - Nucleations Mechanisms in Ductile IronDocument18 pages2005 AFS - Nucleations Mechanisms in Ductile IronDouglas Vidal100% (1)

- Feeding Steel and Ductile Iron CastingDocument22 pagesFeeding Steel and Ductile Iron Castingjosemiguelzu100% (1)

- Shrinkage in Iron CastingsDocument10 pagesShrinkage in Iron CastingskarthikkandaNo ratings yet

- Cold Mounting EnglishpdfDocument6 pagesCold Mounting EnglishpdfJorge BonillaNo ratings yet

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet

- Heat Conservation in Liquid IronDocument2 pagesHeat Conservation in Liquid Ironarnaldorcr8646No ratings yet

- Ductile Iron Data - Section 12Document17 pagesDuctile Iron Data - Section 12ante_zivkovic1No ratings yet

- 1999 Ductile Iron Production - A Comparison of Alternative Treatment Methods PDFDocument19 pages1999 Ductile Iron Production - A Comparison of Alternative Treatment Methods PDFDouglas VidalNo ratings yet

- IBPS PO Model Paper - Bank of Maharashtra Probationary Officer 2009 Solved Question PaperDocument34 pagesIBPS PO Model Paper - Bank of Maharashtra Probationary Officer 2009 Solved Question Paperravikataria02No ratings yet

- Casting DefectDocument25 pagesCasting Defectravikataria02No ratings yet

- QuestionjjDocument6 pagesQuestionjjravikataria02No ratings yet

- Hbi Use in FoundryDocument3 pagesHbi Use in Foundryravikataria02No ratings yet

- Uses of HBIDocument11 pagesUses of HBIravikataria02No ratings yet

- March 2014Document27 pagesMarch 2014ravikataria02No ratings yet

- SmsDocument3 pagesSmsravikataria02No ratings yet

- 26ASregistration 06092011Document20 pages26ASregistration 06092011pmnitsNo ratings yet

- Welding Consumables-Cast IronDocument9 pagesWelding Consumables-Cast IronKuldeep RatnuNo ratings yet

- EPW, Vol.58, Issue No.44, 04 Nov 2023Document66 pagesEPW, Vol.58, Issue No.44, 04 Nov 2023akashupscmadeeaseNo ratings yet

- Probation Period ReportDocument17 pagesProbation Period ReportMiranti Puspitasari0% (1)

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Accessoryd-2020-07-31-185359.ips 2Document20 pagesAccessoryd-2020-07-31-185359.ips 2Richard GarciaNo ratings yet

- Aditya Academy Syllabus-II 2020Document7 pagesAditya Academy Syllabus-II 2020Tarun MajumdarNo ratings yet

- Topic One ProcurementDocument35 pagesTopic One ProcurementSaid Sabri KibwanaNo ratings yet

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Document7 pagesMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimNo ratings yet

- Rsi r2 Super Rsi FaqDocument14 pagesRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- Configuration Guide - Interface Management (V300R007C00 - 02)Document117 pagesConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiNo ratings yet

- Waves and Ocean Structures Journal of Marine Science and EngineeringDocument292 pagesWaves and Ocean Structures Journal of Marine Science and Engineeringheinz billNo ratings yet

- Amity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorDocument23 pagesAmity School of Business:, Semester IV Research Methodology and Report Preparation Dr. Deepa KapoorMayank TayalNo ratings yet

- Chakir Sara 2019Document25 pagesChakir Sara 2019hiba toubaliNo ratings yet

- Building Material Supplier in GurgaonDocument12 pagesBuilding Material Supplier in GurgaonRodidustNo ratings yet

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainNo ratings yet

- Board of Technical Education (Student Marksheet)Document2 pagesBoard of Technical Education (Student Marksheet)Manoj SainiNo ratings yet

- Press Statement - Book Launching Shariah Forensic 27 Oct 2023Document4 pagesPress Statement - Book Launching Shariah Forensic 27 Oct 2023aNo ratings yet

- Quality Standards For ECCE INDIA PDFDocument41 pagesQuality Standards For ECCE INDIA PDFMaryam Ben100% (4)

- Church and Community Mobilization (CCM)Document15 pagesChurch and Community Mobilization (CCM)FreethinkerTianNo ratings yet

- Uniform Motion WorksheetDocument8 pagesUniform Motion Worksheetnikhil patro100% (1)

- Six Sigma PresentationDocument17 pagesSix Sigma PresentationDhular HassanNo ratings yet

- DLP English 10 AIRADocument8 pagesDLP English 10 AIRAMae Mallapre100% (1)

- Determinant of Nurses' Response Time in Emergency Department When Taking Care of A PatientDocument9 pagesDeterminant of Nurses' Response Time in Emergency Department When Taking Care of A PatientRuly AryaNo ratings yet

- English For Academic and Professional Purposes - ExamDocument3 pagesEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoNo ratings yet

- SM EFATEX Rev D2 3 1 2018 PDFDocument20 pagesSM EFATEX Rev D2 3 1 2018 PDFGuilhermePlacidoNo ratings yet

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComDocument4 pages147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenNo ratings yet

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocument3 pagesKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineDocument8 pages7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkeNo ratings yet

- AYUMJADocument1 pageAYUMJASoumet Das SoumetNo ratings yet

- BSS Troubleshooting Manual PDFDocument220 pagesBSS Troubleshooting Manual PDFleonardomarinNo ratings yet

- Homework 9Document1 pageHomework 9Nat Dabuét0% (1)