Professional Documents

Culture Documents

Basic Hydraulic System

Uploaded by

Alif Aizat Azman100%(1)100% found this document useful (1 vote)

425 views142 pagesnotes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnotes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

425 views142 pagesBasic Hydraulic System

Uploaded by

Alif Aizat Azmannotes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 142

1

Assembly & Maintenance of

Pneumatic & Hydraulic System

(SED 23103)

Basic Automation System

(SRD 23403)

Malaysian Spanish Institute

MSI Pneumatic System

v5

Assembly & Maintenance of Pneumatic & Hydraulic System

(SED 23103) - (Assessment)

1. Basic Pneumatic System

Technical Report 10%

Mini Project 10%

Test 10%

Exam Practical 20%

2. Basic Hydraulic System

Technical Report 10%

Mini Project 10%

Test 10%

Exam Practical 20%

Total Marks (SED 23103)

Technical Report 20%

Mini Project 20%

Test 20%

Exam Practical 40%

100%

2

MSI Electrical System

Assembly & Maintenance of Pneumatic & Hydraulic System

(SED 23103) - (Assessment)

1. Basic Pneumatic System

Pneumatic Power

Pneumatic Control

Pneumatic Actuator

2. Basic Hydraulic System

Hydraulic Power

Hydraulic Control

Hydraulic Actuator

End of Course

Comparison of Power System

Selection of Power System

3

MSI Electrical System

Assembly & Maintenance of Pneumatic & Hydraulic System

(SED 23103) (Study Planning)

1. Basic Pneumatic System

Week 1 6 (Study week)

Week 7 (Practical Test)

2. Basic Hydraulic System

Week 8 13 (Study Week)

Week 14 (Practical Test)

4

MSI Electrical System

Extra Assessment

Attitude marks

1. Attendant (per/minute = 0.019%)

2. Cheating (per/cheat = 1%)

3. Attire (per/day = 5%)

4. Behavior (per/hour = 5%)

Basic Automation System

(SRD 23403) - (Assessment)

1. Basic Pneumatic System

Technical Report 7%

Mini Project 7%

Test 7%

Exam Practical 14%

2. Basic Hydraulic System

Technical Report 7%

Mini Project 7%

Test 7%

Exam Practical 14%

3. Basic Electrical System

Technical Report 6%

Mini Project 6%

Test 6%

Exam Practical 12%

Total Marks (SRD 23403)

Technical Report 7+7+6%

Mini Project 7+7+6%

Test 7+7+6%

Exam Practical 14+14+12%

100%

5

MSI Electrical System

Basic Automation System

(SRD 23403) - (Content Summary)

1. Basic Electrical System

Electrical Power

Electrical Control

Electrical Actuator

2. Basic Pneumatic System

Pneumatic Power

Pneumatic Control

Pneumatic Actuator

3. Basic Hydraulic System

Hydraulic Power

Hydraulic Control

Hydraulic Actuator

End of Course

Comparison of Power System

Selection of Power System

6

MSI Electrical System

Basic Automation System (SRD 23403)

(Study Planning)

1. Basic Pneumatic System

Week 1 4 (Study week)

Week 5 (Practical Test)

2. Basic Hydraulic System

Week 6 9 (Study week)

Week 10 (Practical Test)

3. Basic Electrical System

Week 11 13 (Study Week)

Week 14 (Practical Test)

Extra Assessment

Attitude marks

Attendant (per/minute = 0.019%)

Cheating (per/cheat = 1%)

Attire (per/day = 5%)

Behavior (per/hour = 5%)

7

MSI Electrical System

8

MSI Hydraulic System

Basic Hydraulic System

9

Introduction to Didactic Unit

Objective of Module

Why hydraulic system?

Because: hydraulic system is amazing in its strength and agility. It is uses in medium

and heavy application. It is a basic control system. Uses liquid as its medium.

Uses in medium and heavy application.

Why learn hydraulic system?

Its a basic control system.

Why learn maintenance of hydraulic system?

To describe the methodology of preventive and corrective maintenance technique of

Hydraulic System.

MSI Hydraulic System

10

Basic Control System

MSI Hydraulic System

signal

processing

output

signal

input

pushbutton valve cylinder

11

MSI Hydraulic System

Control & Maintenance

signal

processing

output

signal

input

Assembly / Maintenance / Troubleshoot

12

Content of Module

CHAPTER X INTRODUCTION TO DIDACTIC UNIT

CHAPTER 0 SAFETY IN HYDRAULIC SYSTEM

CHAPTER 1 INTRODUCTION TO HYDRAULIC SYSTEM

CHAPTER 2 FUNDAMENTAL IN HYDRAULIC SYSTEM

CHAPTER 3 TANK PIPING AND COUPLINGS

CHAPTER 4 HYDRAULIC PUMPS

CHAPTER 5 HYDRAULIC ACTUATOR

CHAPTER 6 DISTRIBUTOR VALVES

CHAPTER 7 PRESSURE VALVES

CHAPTER 8 FLOW VALVES

CHAPTER 9 BLOCK VALVES

CHAPTER 10 ELECTRO HYDRAULIC SYSTEM

MSI Hydraulic System

13

Safety In Hydraulic System

chapter 0

General safety

High pressures, temperatures and forces occur in

Hydraulic System. Energy is also stored, sometimes in

large quantities. A whole series of safety measures is

necessary to rule out the possibility of danger to

personnel and equipment during the operation of

hydraulic systems. In particular, the valid safety

regulations for hydraulic systems are to be OBSERVED.

MSI Hydraulic System

14

Regulations and standards

The following safety regulations apply for the field of hydraulics:

1. Accident prevention regulations, directives, safety rules and the testing

guidelines,

2. Regulations on pressure vessels, pressurized gas vessels and filling

systems (pressure vessel regulations),

3. DIN standards, VDI directives, VDMA standard sheets and technical

rules for pressure vessels, containing in particular, notes and regulations

on dimensions, design, calculations, materials and permissible loads as

well as conditions on functions and requirements.

4. Electro-hydraulic systems must comply not only with the regulations on

hydraulic systems but also with the regulations on electrical systems and

components (e.g. DIN VDE 0100).

MSI Hydraulic System

15

Safety Recommendations

MSI Hydraulic System

Install the EMERGENCY STOP push-button in a place where it can be easily

reached.

Use standardized parts only.

Enter all alterations in the circuit diagram immediately.

The rated pressure must be clearly visible.

Check whether the installed equipment can be used at the maximum operating

pressure.

The design of suction lines should ensure that no air can be drawn in.

Check the oil temperature in the suction line to the pump. It must not exceed 60 C.

The piston rods of the cylinders must not be subjected to bending loads or lateral

forces. Protect piston rods from dirt and damage.

16

Start-up of Hydraulic System

MSI Hydraulic System

Do not operate systems or actuate switches if you are not totally sure what function they perform.

All setting values must be known.

Do not switch on the power supply until all lines are connected.

Important: check that all return lines (leakage lines) lead to the tank.

When starting up the system for the first time, open the system pressure relief valve almost

completely and gradually set the system to the operating pressure. Pressure relief valves must

be installed in such a way that they cannot become ineffective.

Carefully clean the system prior to start-up, then change the filter cartridge.

Vent system and cylinders.

In particular, the hydraulic lines to the reservoir are to be carefully vented. It is generally

possible to effect venting at the safety and shut-off block of the reservoir.

Special care is needed when handling hydraulic reservoirs.

Before the reservoirs are started up, the regulations determined by the manufacturer are to be

studied carefully.

17

Repair and Maintenance

MSI Hydraulic System

Repair work may not be effected on hydraulic systems

until the fluid pressure of the reservoir has been

release. If possible, separate the reservoir from the

system (using a valve). Never drain the reservoir un-

throttled.

When repairs are completed effect a new start-up in line

with the safety regulations listed above.

All hydraulic reservoirs are subject to the provisions of

the pressure vessel regulations and must be inspected

at regular intervals.

18

General Lab rules

MSI Hydraulic System

1. You are prohibited from entering

Hydraulic Lab without SAFETY

BOOT (all time), DUST COAT

(practical uses)

2. Do not be afraid to ask questions.

We are here to assist you.

3. Do not step on any signal or

actuator controller cable.

4. Never use your finger to align bolt-

holes.

5. You must keep your work area

clean and free of rubbish.

6. Never place any part of your body in

an area that is considered a crush

point.

7. If you break or notice any defects in

the equipment you are using,

immediately inform the TTO. This

ensures that you will not be held

responsible for repairing the

equipment.

8. Do not leave tools on load frames or

specimens, and at the end of the

day put all tools back where they

belong.

9. Work methodically and at a steady

pace, and do not be afraid to ask

your fellow students or Mr. FATHUL

to assist you.

10. USE COMMON SENSE.

19

Introduction to Hydraulic System

chapter1

Hydraulic means the generation of forces and motion using hydraulic

fluids. Hydraulic fluids represent the medium for power transmission.

MSI Hydraulic System

Advantage of hydraulic system

Great power intensity

Precise positioning

Start-up under heavy load

Independent of load

Smooth operation and reversal

Good control and regulation

Favorable heat dissipation

Disadvantage of hydraulic system

Pollution

Sensitivity to dirt

Danger resulting from excessive pressures

Temperature dependence

Unfavorable efficiency factor

20

Application Of Hydraulic System

Stationary Hydraulic

(Vise, clamp, stamping machine, injection moulding machine, and etc).

Mobile Hydraulic

(bulldozers, backhoes, shovels, loaders, fork lifts, cranes and etc).

MSI Hydraulic System

21

MSI Hydraulic System

Hydraulic System Overview

22

Hydraulic System vs. Pneumatic System

MSI Hydraulic System

Drive section

Control section

Power section

23

MSI Hydraulic System

Schematic Diagram Of A Hydraulic System

Single Acting Cylinder Double Acting Cylinder

24

The Basic Idea

The basic idea behind any hydraulic system is very simple: Force

that is applied at one point is transmitted to another point using

an incompressible fluid.

The picture below shows the simplest possible hydraulic system:

MSI Hydraulic System

25

Working Principle

Retract position Extend position

MSI Hydraulic System

26

Fundamental in Hydraulic System

Chapter 2

1. Pressure

2. Pressure Transmission

3. Power Transmission

4. Displacement

Transmission

5. Pressure Transfer

6. Flowrate

7. Pressure Measurement

8. Type of Flow

9. Friction, heat & pressure

drop

10. Energy & Power

11. Power

12. Cavitations & Throttle

point

13. Hydraulic Fluid

MSI Hydraulic System

27

1. Pressure

Pressure (symbol: p) is

the force per unit area

acting on a surface in a

direction perpendicular

to that surface.

Mathematically:

where:

MSI Hydraulic System

A

p

F

Area of double

acting cylinder

= (d/2)

28

example

MSI Hydraulic System

29

2. Pressure Transmission

If a force F1 acts at area A1 on an

enclosed liquid, a pressure p is

produced which extends

throughout the whole of the liquid

(Pascals Law).

This will cause a same pressure

acting at every point of the closed

system.

MSI Hydraulic System

30

example

MSI Hydraulic System

31

3. Power Transmission

If same pressure applies at every point in a closed

system, the shape of the container has no significance.

MSI Hydraulic System

32

example

MSI Hydraulic System

Therefore

33

4. Displacement Transmission

If load F2 is to be lifted to a distance s2, Piston 1 must be displace at

distance s1, at a specific quantity of liquid which lifts the Piston 2 by a

distance s2.

MSI Hydraulic System

34

example

MSI Hydraulic System

35

5. Pressure Transfer

The pressure P1 exerts F1 force on area A1 which is transferred thru piston rod onto

the small piston. Force F1 will acts on area A2 and produces pressure P2. Since

piston area A2 is smaller than piston area A1, the pressure P2 will be greater than

the pressure P1.

MSI Hydraulic System

36

example

MSI Hydraulic System

37

6. Flowrate

Flow rate is the term used to describe the volume of liquid flowing

through a pipe in a specific period of time.

For example, approximately one minute is required to fill a 10 liter

bucket from a tap. Thus, the flow rate amounts to 10 l/min.

MSI Hydraulic System

38

6. Flowrate

MSI Hydraulic System

Other derivation

Well have

39

MSI Hydraulic System

7. Pressure Measurement

To measure pressures in the lines or at the inputs and outputs of

components, a pressure gauge is installed in the line at the

appropriate point.

40

MSI Hydraulic System

1. Laminar flow

fluid moves through the

pipe in cylindrical layers

order.

8. Type of flow

2. Turbulence flow

when flow velocity of fluid

rises above a certain point

the fluid particles stop to

move in ordered layers.

41

MSI Hydraulic System

Reynolds number (Re).

A method of calculating the type of flow in

a smooth pipe is enabled by the Reynolds

number (Re). This is dependent on:

the flow velocity of the liquid v (m/s) (flowrate)

the pipe diameter d (m)

and the kinematics viscosity (m/s) (viscosity)

laminar flow: Re < 2300

turbulent flow: Re > 2300

42

MSI Hydraulic System

Reynolds number (Re).

The value 2300 is termed the critical Reynolds

number (Re

crit

) for smooth round pipes.

Turbulent flow does not immediately become laminar on

falling below (Re

crit

). The laminar range is not reached

until (Re

crit

).

To prevent turbulent flow causing considerable friction

losses in hydraulic systems, (Re

crit

) should not be

exceeded.

43

MSI Hydraulic System

Example:

1

2

3

4

1. Draw line from piping dia. to

liquid flow velocity(1-2)

2. From point (2) draw a line to

flowrate in the pipe, (2-3)

3. The Reynolds number are on

point (4)

44

MSI Hydraulic System

Guideline Hydraulic flowrate

45

MSI Hydraulic System

9. Friction, Heat & Pressure droop

Friction occurs in all devices and lines in a hydraulic system.

Mainly at the line walls (external friction and between the layers of

liquid (internal friction).

The friction causes heat. As heat generation, the pressure in the

system drops and reduces the actual pressure at the drive section.

The size of the pressure drop is based on the internal resistances in

a hydraulic system. These are dependent on:

Flow velocity (cross-sectional area, flow rate),

Type of flow (laminar, turbulent),

Type and number of cross-sectional reductions in the system of lines

(throttles, orifices),

Viscosity of the oil (temperature, pressure),

Line length and flow diversion,

Surface finish,

Line arrangement.

46

MSI Hydraulic System

The energy of a hydraulic system is made

up of several forms of energy.

Static

Potential energy

Pressure energy

Dynamic

Motion energy

Thermal energy

10. Energy & Power

47

MSI Hydraulic System

Type of Energy

Static

Potential energy: energy which a body (or a

liquid) has when it is lifted by a height h.

Pressure energy: pressurized volume

Dynamic

Motion energy: when a force F acting on the

body that moves at a certain speed. (also

known as kinetic energy)

Thermal energy: is the energy required to

heat a body (or a liquid) to a specific

temperature.

In hydraulic installations, part of the

energy is converted into thermal energy

as a result of friction. This leads to

heating of the hydraulic fluid and of the

components. Part of the heat is emitted

from the system, i.e. the remaining

energy is reduced. The consequence of

this is a decrease in pressure energy.

48

MSI Hydraulic System

11. Power

Power is usually defined as work or a change in

energy per unit of time.

Hydraulic power is calculated from the pressure

and the flow rate.

49

MSI Hydraulic System

Example

50

MSI Hydraulic System

Efficiency

The input power in a hydraulic system does not correspond to the output

power since line losses occur. The ratio of the output power to the input

power is designated as efficiency (h).

In practice, distinction is made between volumetric power loss caused by

leakage losses and hydro-mechanical power loss caused by friction. In the

same way, efficiency is divided into:

Volumetric efficiency (

vol

): This covers the losses resulting from internal and

external leakage losses in the pumps, motors, and valves.

Hydro-mechanical efficiency (

hm

): This covers the losses resulting from friction

in pumps, motors, and cylinders.

51

MSI Hydraulic System

Example

52

MSI Hydraulic System

12. Cavitations & Throttle point

Refers to the releasing of the

smallest particles from the surface of

the material.

Motion energy is required for an

increase in flow velocity of the oil at a

narrowing. This motion energy is

derived from the pressure energy.

Because of this, pressure drops at

narrow points may move into the

vacuum range.

From a vacuum of 0.3bar onwards,

dissolved air (Gas bubbles) are

formed. If the pressure now rises

again as a result of a reduction in

speed, the oil causes the gas

bubbles to collapse.

53

13. Hydraulic Fluid

Hydraulic fluids represent the medium for power

transmission.

Function

Pressure transfer

Lubrication for moving parts / devices

Cooling agent: - diversion of heat produced by energy

conversion

Cushioning of oscillations cause by pressure jerks.

Corrosion protection

Scuff removal

Signal transmission

MSI Hydraulic System

54

MSI Hydraulic System

Characteristic of hydraulic fluid

lowest possible density

minimal compressibility

viscosity not too low (lubricating film)

good viscosity-temperature characteristics

good viscosity-pressure characteristics

good ageing stability

low flammability

good material compatibility

example of hydraulic fluid

HLP 68

H:- hydraulic fluid,

L:- with additives to corrosion protection and/or ageing stability,

P:- with additives to reduce and/or increase load carrying ability

68:- viscosity code as defined in DIN 51517

55

MSI Hydraulic System

Viscosity

can be defined as resistance to flow. The viscosity of a

liquid indicates its internal friction.

Ball Viscometer

56

MSI Hydraulic System

Tank, Piping & Coupling

Chapter 3

Tank / Reservoir

acts as intake and storage reservoir for the hydraulic fluid required for operation of

the system;

dissipates heat;

separates air, water and solid materials;

supports a built-in or built-on pump and drive motor and other hydraulic

components, such as valves, accumulators, etc.

Reservoir size, dependent on:

pump delivery

the heat resulting from operation in connection with the maximum permissible

liquid temperature

the maximum possible difference in the volume of liquid which is produced when

supplying and relieving consuming devices (e.g. cylinders, hydraulic fluid

reservoirs)

the place of application

the circulation time.

57

MSI Hydraulic System

Tank / Reservoir

Reservoir shape

High reservoirs are good for heat dissipation,

wide ones for air separation.

Intake and return lines

These should be as far away from one another

as possible and should be located as far

beneath the lowest oil level as possible.

Baffle and separating plate

This is used to separate the intake and return

areas. In addition, it allows a longer settling

time for the oil and, therefore, makes possible

more effective separation of dirt, water and

air.

Base plate

The base of the tank should slope down to the

drain screw so that the deposited sediment and

water can be flushed out.

Ventilation and exhaust (air filter)

To balance the pressure in case of a

fluctuating oil level, the reservoir must be

ventilated and exhausted. For this purpose, a

ventilation filter is generally integrated into the

filler cap of the feed opening.

58

MSI Hydraulic System

Piping (Flexible Hoses)

These are flexible line connections which are used between mobile

hydraulic devices or in places where there is only limited space

(particularly in mobile hydraulics).

The inner tube (1) is made of synthetic rubber, Teflon, polyester-elastomer, perbunan or neoprene. The pressure carrier

is a woven intermediate layer of steel wire and/or polyester or rayon.

This woven section (2) may consist of one or more layers depending on the pressure range.

The top layer (3) is made of wear-resistant rubber, polyester, polyurethane elastomer or other materials. The pipelines

may be additionally protected against mechanical damage by external spirals or plaited material.

59

MSI Hydraulic System

Installation of Hose Lines

60

MSI Hydraulic System

Coupling

Hose lines may either be connected

to the various pieces of equipment or

else connected together by means of

screw fittings or quick connection

couplings.

Hose support connectors ensure that

connections do not affect operation:

61

MSI Hydraulic System

HYDRAULIC PUMP

Chapter 4

The pump in a hydraulic system, also known as a hydraulic pump, converts the

mechanical energy in a drive unit into hydraulic energy (pressure energy).

The pump draws in the hydraulic fluid and drives it out into a system of lines.

62

MSI Hydraulic System

The Basic Concept

Low pressure

High pressure

63

MSI Hydraulic System

Hydraulic pumps

Gear Pump Rotary Vane Pump Piston Pump

External Gear Pump

Internal Gear Pump

Single Chamber

Double Chamber

Radial Piston Pump

Axial Piston Pump

TYPE OF HYDRAULIC PUMP

64

MSI Hydraulic System

TYPE OF HYDRAULIC PUMP

External Gear Pump Internal Gear Pump Single Chamber

Double Chamber Radial Piston Pump Axial Piston Pump

65

MSI Hydraulic System

Gear Pump: Working Principle

Volume

increase

From tank

To hydraulic

system

Volume

increase

From

tank

To

hydraulic

system

Internal gear

External gear

Working Operation

(Gear Pump)

The suction area S is connected to the reservoir. The

gear pump operates according to the following

principle:

One gear is connected to the drive, the other is

turned by the meshing teeth. The increase in volume

which is produced when a tooth moves out of a mesh

causes a vacuum to be generated in the suction

area. The hydraulic fluid fills the tooth gaps and is

conveyed externally around the housing into

pressure area P. The hydraulic fluid is then forced

out of the tooth gaps by the meshing of teeth and

displaced into the lines.

Fluid is trapped in the gaps between the teeth

between suction and pressure area. This liquid is fed

to the pressure area via a groove since pressure

peaks may arise owing to compression of the trapped

oil, resulting in noise and damage.

66

MSI Hydraulic System

67

MSI Hydraulic System

Rotary Vane: Working Principle

Volume

increase

Volume

increase

From tank

To hydraulic

system

From tank

To hydraulic

system

Single chamber Double chamber

68

MSI Hydraulic System

Piston Pump: Working Principle

compression

From tank

To hydraulic

system

Radial chamber Axial chamber

From tank To hydraulic

system

compression

From tank Hyd sys

69

MSI Hydraulic System

Pump

Specification

Assignment 2

70

MSI Pneumatic System

Working operation for:

1. Internal Gear Pump,

2. Vane Pump and

3. Piston Pump

71

There are two basic types of hydraulic actuator:

Rotary actuator

(motor / rotary)

Linear actuator

(cylinder)

MSI Hydraulic System

Hydraulic Actuator

Chapter 5

72

MSI Hydraulic System

Hydraulic Motor (Rotary Movement)

Hydraulic motor comes various type same

as hydraulic pump. It working operation

are similar.

Gear motor

Vane motor

Piston motor

73

MSI Hydraulic System

Linear Actuator (Linear Movement)

Single Acting Cylinder

Double Acting Cylinder

There are two basic types of hydraulic cylinder

single-acting and

double-acting cylinders.

74

MSI Hydraulic System

Type of Linear Actuator

75

MSI Hydraulic System

Type of Linear Actuator

76

Distribution Valve

Chapter 6

Introduction

Directional control valves are components which change, open or close flow paths in

hydraulic systems. They are used to control the direction of motion of power

components and the manner in which these stop. Directional control valves are

shown as defined in DIN ISO 1219.

Type

2/2-way valve

3/2-way valve

4/2-way valve

5/2-way valve

4/3-way valve

MSI Hydraulic System

77

MSI Hydraulic System

Symbols for directional

control valves

The following rules apply to the representation of directional control valves:

Each different switching position is shown by a square.

Flow directions are indicated by arrows.

Blocked ports are shown by horizontal lines.

Ports are shown in the appropriate flow direction with line arrows.

Drain ports are drawn as a broken line and labeled (L) to distinguish them

from control ports.

78

MSI Hydraulic System

The switching position of a directional control valve can be changed by various

actuation methods, such as push button, pedal, lever with detent, a spring is always

necessary for resetting.

Methods of Actuation

79

MSI Hydraulic System

Port Designation

80

MSI Hydraulic System

Type of Distribution Valve (symbol)

81

MSI Hydraulic System

Working Principle

2/2 way valve, Normally close

Release position

Press position

82

MSI Hydraulic System

Circuit Example

Release 2/2 WV Cylinder Extend

Pressed 2/2 WV Cylinder Retract

83

MSI Hydraulic System

Basic Construction of 3/2 way valve

(3/2 way valve N.C)

84

MSI Hydraulic System

Basic Construction of 4/2 way valve

85

MSI Hydraulic System

Basic Construction of 4/3 way valve

(4/3 way valve, mid position pump re-circulating)

86

MSI Hydraulic System

Basic Construction of valve

(2/2 way valve N.C)

(3/2 way valve N.C)

(4/3 way valve, mid position pump

re-circulating)

87

MSI Hydraulic System

Conversion of Valve

88

MSI Hydraulic System

Pressure Valve

Chapter 7

Pressure valves have the task of controlling and regulating the pressure in a

hydraulic system.

Pressure relief valves

The pressure in a system is set and restricted

by these valves. The control pressure is

sensed at the input (P) of the valve.

Pressure regulator

These valves reduce the output pressure where there

is a varying higher input pressure. The control

pressure is sensed at the output of the valve.

Symbol

2 way pressure regulator 3 way pressure regulator Pressure relief valves

89

MSI Hydraulic System

Working Principle

(pressure relief valve)

90

MSI Hydraulic System

Working Principle

(2 way pressure regulator)

91

MSI Hydraulic System

Working Principle

(3 way pressure regulator)

92

MSI Hydraulic System

Basic Construction

Pressure Relief Valve

2 Way Pressure Regulator

3 Way Pressure Regulator

93

MSI Hydraulic System

Flow Valve

Chapter 8

Introduction

Flow control valves are used to reduce the speed of a cylinder or a motor.

Type of control valve:

2. Throttle Valve

(two way flow control valve)

- Restrict both direction of flow.

1. One Way Flow Control Valve

- Restrict one direction of flow only.

94

MSI Hydraulic System

Working Principle

One-way flow control valve

The one-way flow control valve where the restrictor is only effective in one direction is a

combination of a restrictor and a non-return valve. The restrictor controls the flow rate in a

single direction dependent on flow. In the opposite direction, the full cross-sectional flow is

released and the return flow is at full pump delivery. This enables the one-way flow control

valve to operate.

Control Not control

95

MSI Hydraulic System

Circuit Example

(One way flow control valve)

Fluid is block

by check valve

Fluid enter cylinder

with normal flow

Fluid have to flow

through throttle valve

Extend slow

96

MSI Hydraulic System

Circuit Example

(One way flow control valve)

Fluid is block

by check valve

Fluid enter cylinder

with normal flow

Fluid have to flow

through throttle valve

Retract slow

97

MSI Hydraulic System

Working Principle

Throttle Valve

Flow control valves

influence the

volumetric flow of the

fluid in both directions.

Control flow in both direction

98

MSI Hydraulic System

Circuit Example

(Throttle valve)

Extend & Retract

slow

99

MSI Hydraulic System

Block Valve (Non Return Valve)

Chapter 9

100

MSI Hydraulic System

Check Valve

Check valves can stop the flow completely

in one direction. In the opposite direction

the flow is free with a minimal pressure

drop due to the resistance of the valve.

Spring loaded

Spring un-loaded

101

MSI Hydraulic System

De-lockable Valve

In de-lockable valve, flow can be released in the closed position by pilot control of

the valve poppet. This takes place according to the following principle:

1. Flow is possible from A to B.

2. Flow is blocked from B to A.

3. In order permits flow from B to A,

signal X is produce.

102

MSI Hydraulic System

Circuit Example

(De-Lockable valve)

Signal x must

be connected to tank

In order to release

pressure at port x.

Uses when cylinder

is vertically install

103

MSI Hydraulic System

Circuit Example

(De-Lockable valve)

Change input

To suite

existing valve

with practical task

104

MSI Hydraulic System

Shuttle Valve

This shuttle valve has two inlets X and Y and one

outlet A. If Hydraulic fluid is applied to the first inlet X,

the valve seals the opposing inlet Y, the fluid flows

from X to A. Inlet X is closed, if fluid passes from Y to

A. A signal is generated at the outlet. When the Fluid

flow is reversed, i.e. a cylinder or valve is exhausted,

the seat remains in its previously assumed position

because of the pressure conditions. This valve is also

called an OR element.

X Y

A

X Y A

0 0 0

0 1 1

1 0 1

1 1 1

TRUTH TABLE

105

MSI Hydraulic System

De-lockable Double Non-Return Valve

The piloted double non-return valve operates according to the following principle:

Free flow is possible either in the flow direction from A1 to B1 or from A2 to B2, flow is

blocked either from B1 to A1 or from B2 to A2.

If flow passes through the valve from A1 to B1, the control piston is shifted to the

right and the valve poppet is lifted from its seat. By these means, flow is opened

from B2 to A2 (the valve operates in a corresponding manner where there is flow from

A2 to B2).

106

MSI Hydraulic System

Circuit example

107

Electro-Hydraulic System

Chapter 10

Malaysian Spanish Institute

MSI Electro-Hydraulic System

108

Schematic

Design Of An

Electro-Hydraulic

System

MSI Electro-Hydraulic System

109

MSI Electro-Hydraulic System

Hydraulic Pump

Pushbutton

Cylinder

Power

Supply

Pushbutton

Relay,

Timer,

Solenoid

Electro-Hydraulic Overview

From electro

110

MSI Electro-Hydraulic System

Electro Hydraulic Automatons

Switching

control

Manual

actuation

Electrical

actuation

111

Content of Electro-Hydraulic

Safety precaution

Introduction

Advantages

Comparison

Electrical Fundamental

Electrical Input Element

Sensor

Relay

Solenoid

Electrical Timer

Sequence Control

MSI Electro-Hydraulic System

112

Safety Precaution

MSI Electro-Hydraulic System

1. Pneumatic safety must be apply

2. DO NOT wear sandals, wear covered shoes

3. DO NOT wear excessive jewelry

4. DO NOT wear swing-loose-long hair style, neatly tie-up the long hair or

place under a proper head gear.

5. DO NOT wear shoes with heel higher than 1" (2.5 cm)

6. DO wear lab-coat all the time

7. DO NOT disturb people who are conducting experiments! (or any time)

8. NO eating or drinking inside the lab.

9. NO social gathering is allowed in the labs. The labs should not be

crowded for non-working purposes.

10. In case of spilling water on a lab bench near power points, first SWITCH

OFF the electrical power before cleaning.

11. TO INSPECT any electrical equipment, first turn the power off and ask for

the instruction/help from the lab officer in charge. Any faulty equipment

should be attended by trained personnel only. DO NOT do it on your

own.

113

Introduction

Electro-Hydraulic Systems are made up of

hydraulic and electrical components:

The movements and forces are generated by

Hydraulic means (e.g. by cylinders).

Signal input and signal processing, on the other hand,

are effected by Electrical and Electronic

components (e.g. electromechanical switching

elements or stored-program controls).

MSI Electro-Hydraulic System

114

Advantages

MSI Electro-Hydraulic System

Electrical signals can be transmitted via cables quickly and easily

and over great distances. Mechanical signal transmission (linkages,

cable-pulls) or hydraulic signal transmission (tubes, pipes) are far

more complex.

In the field of automation, signal processing is generally effected

by electrical means. This enhances the options for the use of

electro-hydraulic systems in automatic production operations (e.g.

in a fully automatic pressing line for the manufacture of car wings).

Many machines require complex control procedures (e.g. plastics

processing). In such cases, an electrical control is often less

complex and more economical than a mechanical or hydraulic

control system.

115

MSI Electro-Hydraulic System

Comparison

116

MSI Electro-Hydraulic System

Electrical Fundamental

The relationship between voltage, current strength and resistance is

described by Ohms law. Ohms law states that in a circuit with constant

resistance the current strength changes in proportion to the change in

voltage:

if the voltage increases, the current strength also increases.

if the voltage falls, the current strength also decreases.

117

MSI Electro-Hydraulic System

In the field of mechanical engineering, power can be defined in terms of the

work performed. The faster a task is performed, the greater the required

power. Power therefore means work per unit of time.

In the case of a consuming device in a circuit, electrical energy is converted

into kinetic energy (e.g. electrical motor), light radiation (e.g. electrical lamp)

or thermal energy (e.g. electrical heater, electrical lamp). The faster the

energy is converted, the greater the electrical power.

Electrical power

118

MSI Electro-Hydraulic System

A power supply unit consists of

the following modules:

the mains transformer which

transforms the alternating

voltage of the mains supply

(e.g. 220 V) into the output

voltage (mostly 24 V).

a smoothed direct voltage is

generated by the rectifier G and

the capacitor C.

the direct voltage is then

stabilized by the in-phase

regulator.

Power Supply

119

MSI Electro-Hydraulic System

Electrical controls are generally supplied with a direct current of 24V.

The alternating voltage from the power supply therefore has to be

stepped down to 24V and then rectified.

Conversion AC to DC

AC DC

120

MSI Electro-Hydraulic System

Electrical input elements

NORMALLY OPEN CONTACT

circuit is open when the push-button is in the normal position

121

MSI Electro-Hydraulic System

Electrical input elements

NORMALLY CLOSED CONTACT

circuit is closed when the push-button is in the normal position

122

MSI Electro-Hydraulic System

Electrical input elements

CHANGEOVER SWITCH

These contacts combine the

functions of normally closed and normally open contacts in one unit.

123

MSI Electro-Hydraulic System

Circuit example

Pressed S1, H will on

Pressed S1, H will off

Pressed S1, H will on,

Pressed S2, H will off.

124

MSI Electro-Hydraulic System

Practical

(Electrical Input Element)

And

Function

Or

Function

And

Function

Or

Function

Switching ON Command

Switching OFF Command

S1 AND S2 H1 on S1 OR S2 H1 on S1 AND S2 H1 off S1 OR S2 H1 off

125

MSI Electro-Hydraulic System

Sensor Limit switch

A mechanical limit switch is an

electrical switch which is activated

when a machine part or a workpiece

is in a certain position.

Normally open limit switch

1-4

Normally closed limit switch

1-2

126

MSI Electro-Hydraulic System

Sensor Pressure switch

requires a pressure to activated the sensor

the pressure acts on a cylinder surface (x).

If the pressure exerted exceeds the spring

force of the return spring, the piston moves

and operates the contact set.

Normally open limit switch

1-4

Normally closed limit switch

1-2

127

MSI Electro-Hydraulic System

Circuit Example

128

MSI Electro-Hydraulic System

Relay

Relays are electromagnetically

actuated switches.

They consist of a housing with

electromagnet and movable

contacts.

An electromagnetic field is created

when a voltage is applied to the coil

of the electromagnet.

This results in attraction of the

movable armature to the coil core.

The armature actuates the contact

assembly.

This contact assembly can open or

close a specific number of contacts

by mechanical means.

If the flow of current through the coil

is interrupted, a spring returns the

armature to its original position.

129

MSI Electro-Hydraulic System

Concept of a Relay

(Electromagnet)

An electromagnet is a type of magnet in which the

magnetic field is produced by the flow of an electric

current. The magnetic field disappears when the current

ceases.

130

MSI Electro-Hydraulic System

Working Principle

Relay

1 pole

Relay

2 pole

131

MSI Electro-Hydraulic System

Example

132

MSI Electro-Hydraulic System

Circuit Example

Direct Control

In-direct Control

133

MSI Electro-Hydraulic System

9. Solenoids

In electro-hydraulics, valves are actuated via solenoids. It has the

same concept of electromagnet.

solenoid

Directional control Valve

134

MSI Electro-Hydraulic System

Circuit Example

135

MSI Electro-Hydraulic System

Electromechanical Switching Element

(Symbol)

136

MSI Electro-Hydraulic System

Holding Element / Latching

S1 H1 ON

S2 H1 OFF

S1

S2

k1

K1

k1

137

MSI Electro-Hydraulic System

A timer is used to control the sequence

of an event or process.

Two type of timer

1. Delay-On Timer

2. Delay-Off Timer

Electrical Timer

138

MSI Electro-Hydraulic System

Electrical Timer

S1 5sec H1 ON

S2 H1 OFF

24V

0V

S1

S2

K1

K1

T1

K1

H1

T1

The Coil with ON delay activates its

associated contacts when current is

applied.

139

MSI Electro-Hydraulic System

Electrical Timer

S1 H1 ON

S2 5sec H1 OFF

The Coil with OFF delay deactivates

its associated contacts when current

is applied, but only after the preset

delay.

24V

0V

S1

S2

K1

K1

T1

K1

H1

T1

140

MSI Electro-Hydraulic System

Electrical Timer

24V

t

S1

0V

H1

Timer for Practical installation

Note:

For ON Delay:

Select selector to

DES.

For OFF Delay:

Select selector to

CON.

141

MSI Electro-Hydraulic System

Electro Hydraulic System

Hydraulic Circuit Diagram /

Power Circuit /

Schematic Diagram

Control Circuit Diagram /

Electrical Circuit Diagram

142

MSI Electro-Hydraulic System

You might also like

- Mine Canadian Royalties: Excavator TrainingDocument72 pagesMine Canadian Royalties: Excavator Trainingotak04No ratings yet

- Basic Vocational: HydraulicDocument33 pagesBasic Vocational: HydraulicIbnu Awalla100% (1)

- Gear Pump BucherDocument60 pagesGear Pump BucherDaniel EstradaNo ratings yet

- Hydraulic Schematic SymbolsDocument8 pagesHydraulic Schematic SymbolsJustice MachiwanaNo ratings yet

- VOLVO SD200DX SINGLE-DRUM ROLLER Service Repair Manual PDFDocument16 pagesVOLVO SD200DX SINGLE-DRUM ROLLER Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- Hydraulic Control SystemDocument22 pagesHydraulic Control SystemRahul DandugulaNo ratings yet

- OperationMaintenance950G Series II PDFDocument61 pagesOperationMaintenance950G Series II PDFFabian Ariza ArizaNo ratings yet

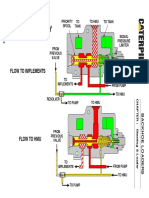

- Steering Priority Valve: Flow To ImplementsDocument19 pagesSteering Priority Valve: Flow To ImplementsAnonymous M28U3D100% (2)

- Hydraulic Pumps and MotorsDocument24 pagesHydraulic Pumps and MotorsMohammed Al-OdatNo ratings yet

- HDSD Ban Nap Lieu DONGHAIDocument28 pagesHDSD Ban Nap Lieu DONGHAITran Le100% (1)

- Design and Fabrication of Hydraulic Zig Zag Bending MachineDocument46 pagesDesign and Fabrication of Hydraulic Zig Zag Bending MachineAakash DindigulNo ratings yet

- D155AX-5 Chapter 6 Hydraulic Fan CircuitDocument12 pagesD155AX-5 Chapter 6 Hydraulic Fan Circuithaimay118No ratings yet

- 1.3 Basic Hydraulic Symbols and Major ComponentsDocument31 pages1.3 Basic Hydraulic Symbols and Major Componentsyared admassuNo ratings yet

- PC210LC-11 SEN06695-01 Swing & Travel SystemsDocument49 pagesPC210LC-11 SEN06695-01 Swing & Travel Systemsdatphuong100% (2)

- 320D PDT ComparisonDocument22 pages320D PDT Comparisonlalo11715No ratings yet

- Torque Conveter TA22-42E Training TextDocument8 pagesTorque Conveter TA22-42E Training TextPHÁT NGUYỄN THẾNo ratings yet

- Steering and Braking SystemDocument70 pagesSteering and Braking SystemPatrick MAZIMPAKANo ratings yet

- Torque Converter Stall-TestDocument3 pagesTorque Converter Stall-TestMiguel Angel Moreno67% (3)

- Hydraulic and Steering System PDFDocument8 pagesHydraulic and Steering System PDFPutra Jawa100% (1)

- View All Callouts: Function Isolation ToolsDocument11 pagesView All Callouts: Function Isolation ToolsEdwin GamarraNo ratings yet

- Hydraulic Fan SystemDocument4 pagesHydraulic Fan SystemEVER DAVID SAAVEDRA HUAYHUA100% (1)

- Training Courses For Hydraulic Control SystemsDocument11 pagesTraining Courses For Hydraulic Control SystemsMohamed Abdou100% (2)

- 953CDocument24 pages953CVictor M. Mejia Diaz0% (1)

- MTS Steering Brake Dozer - Grader KomatsuDocument6 pagesMTS Steering Brake Dozer - Grader KomatsuRizal MerahNo ratings yet

- Eaton 12 Service ManualDocument12 pagesEaton 12 Service ManualfowljimtNo ratings yet

- Material Schematic Hydraulic System Motor Grader 16h CaterpillarDocument2 pagesMaterial Schematic Hydraulic System Motor Grader 16h CaterpillarMuhammadRidhoHidayatNo ratings yet

- 320C Swing MotorDocument5 pages320C Swing Motormanu luvungaNo ratings yet

- Adjust Stand by PressDocument5 pagesAdjust Stand by PressKatarina KananiNo ratings yet

- Hydraulics Basic LevelDocument286 pagesHydraulics Basic LevelsmhosNo ratings yet

- Descripcion General Oht Cat 773Document3 pagesDescripcion General Oht Cat 773HU PINo ratings yet

- Wheel Loader Brake SystemDocument23 pagesWheel Loader Brake Systemsuwardjo100% (1)

- Troubleshooting Guide For The HydraulicDocument5 pagesTroubleshooting Guide For The Hydraulicweldsaidi100% (1)

- Torque Converter With The Impeller Clutch and The Lockup ClutchDocument10 pagesTorque Converter With The Impeller Clutch and The Lockup ClutchrickcyNo ratings yet

- Main Pump - Test - Measurement of Case Drain Oil: Shutdown SISDocument4 pagesMain Pump - Test - Measurement of Case Drain Oil: Shutdown SISR I SantosoNo ratings yet

- 773E Hydraulic SystemDocument2 pages773E Hydraulic SystemDipendra BhattacharyaNo ratings yet

- FLUID POWER SYSTEMS Theory and PracticeDocument37 pagesFLUID POWER SYSTEMS Theory and PracticeAchmad Ari Dwi P100% (2)

- 330CL Cooling System - Check - OverheatingDocument4 pages330CL Cooling System - Check - OverheatingOscar VargasNo ratings yet

- D6D Tractor Power TrainDocument17 pagesD6D Tractor Power Trainariel rubioNo ratings yet

- SSV Divider ValvesDocument28 pagesSSV Divider ValvesRock SayboltNo ratings yet

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 pagesSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezNo ratings yet

- Hydraulic Symbols: As Per DIN-ISO 1219 (1978) As Per ISO - 1219-1 (1991)Document35 pagesHydraulic Symbols: As Per DIN-ISO 1219 (1978) As Per ISO - 1219-1 (1991)saadNo ratings yet

- CAT 01 Hydraulic Fundamental Student GuideDocument30 pagesCAT 01 Hydraulic Fundamental Student GuideChristianSutanto100% (1)

- Sistem Kemudi & RemDocument171 pagesSistem Kemudi & RemAndikaNo ratings yet

- Hyd SymbolsDocument1 pageHyd SymbolsAdi Surya Herysusanto100% (2)

- Displacement Change ValveDocument5 pagesDisplacement Change ValveJuan Daniel Martinez Montoya100% (1)

- 600 SJDocument334 pages600 SJSERGALNo ratings yet

- 950F Frenos OperacionDocument19 pages950F Frenos OperacionChrissz Noxd50% (2)

- 140k Compliance FinalDocument29 pages140k Compliance FinalAGEGNEHU17100% (1)

- Caterpillar Speed Sensor Principles and OperationDocument31 pagesCaterpillar Speed Sensor Principles and OperationCharles HornNo ratings yet

- 856 Hydraulic Brake SystemDocument42 pages856 Hydraulic Brake Systemمهند احمد100% (1)

- Brochure BOMAG TELEMATIC EnglishDocument8 pagesBrochure BOMAG TELEMATIC Englishseba6487No ratings yet

- Hydraulics and PneumaticsDocument20 pagesHydraulics and Pneumaticsharishme028100% (2)

- En Maintenance and Repair Module 1Document55 pagesEn Maintenance and Repair Module 1ganesan 0011No ratings yet

- Rotary Kiln Hydraulic Oil Station User ManualDocument44 pagesRotary Kiln Hydraulic Oil Station User ManualDIAGNE100% (1)

- LVDT CalibrationDocument26 pagesLVDT Calibrationvasudeva yasasNo ratings yet

- BC-CR708 Operating ManualsDocument31 pagesBC-CR708 Operating ManualsCV. HAKA JAYANo ratings yet

- E21valve Remote Control SystemDocument13 pagesE21valve Remote Control System백승훈No ratings yet

- 7600 PM ProcedureDocument14 pages7600 PM ProceduremrscribdNo ratings yet

- Substation Maintenance Procedures R1Document76 pagesSubstation Maintenance Procedures R1Ansel Garvey II78% (9)

- 6ED10521HB080BA1 Datasheet enDocument2 pages6ED10521HB080BA1 Datasheet enalexNo ratings yet

- t8. Fault CodesDocument33 pagest8. Fault CodesjuanNo ratings yet

- HV Pressure Tests - 3 PDFDocument4 pagesHV Pressure Tests - 3 PDFssNo ratings yet

- SERVOPRO 4000 Series - Service ManualDocument190 pagesSERVOPRO 4000 Series - Service ManualGuillermo Zapata100% (1)

- Electrical Schematic With EMCP IIDocument4 pagesElectrical Schematic With EMCP IIAnonymous uEt1sNhU7l89% (19)

- BR 6000Document6 pagesBR 6000Klanac BrčkoNo ratings yet

- Document Title Form: I.D. Systems, IncDocument22 pagesDocument Title Form: I.D. Systems, IncAmc Forklift ElektrikNo ratings yet

- 2014 PricingDocument6 pages2014 PricingYun JungNo ratings yet

- Relay Module - PLC-RSC-24DC/21 - 2966171: Key Commercial DataDocument15 pagesRelay Module - PLC-RSC-24DC/21 - 2966171: Key Commercial Datasatheez3251No ratings yet

- Data Sheet: Trs 24Vdc 1coDocument14 pagesData Sheet: Trs 24Vdc 1coibrahim abd elhadyNo ratings yet

- Compact Single-Pole Relay For Switching 5 ADocument3 pagesCompact Single-Pole Relay For Switching 5 ASigit KurniawanNo ratings yet

- REF 601 RELAY ManualDocument53 pagesREF 601 RELAY Manualmaruf048100% (1)

- Commissioning Service Department Commissioning Standard Test Formats Description: ON LOAD TEST - MBC1Document1 pageCommissioning Service Department Commissioning Standard Test Formats Description: ON LOAD TEST - MBC1Googool YNo ratings yet

- Vasanth 1Document3 pagesVasanth 1Siva KrishnaNo ratings yet

- Relay Module RM10 To RM11Document3 pagesRelay Module RM10 To RM11EDDIN1960No ratings yet

- Exercise 3 Two-Way Traffic LightDocument3 pagesExercise 3 Two-Way Traffic LightJude Philip MaglasangNo ratings yet

- Olympian 21 Light Annunciator LEHF0040Document2 pagesOlympian 21 Light Annunciator LEHF0040gre294No ratings yet

- CCTV SpecDocument130 pagesCCTV SpecJeffrey TeoNo ratings yet

- C-2.4.2 Electrical Design PhilosophyDocument29 pagesC-2.4.2 Electrical Design Philosophyjhakg_169712275No ratings yet

- Guideline Bender RelaysDocument31 pagesGuideline Bender RelaysvijaiprasathNo ratings yet

- SIRIUS Dimensiones ContactoresDocument33 pagesSIRIUS Dimensiones ContactoresIRONWARNo ratings yet

- MR MESSKO - Digital Thermometer EPT202Document4 pagesMR MESSKO - Digital Thermometer EPT202OpscenarJMD100% (1)

- Micro-Speed: Operation ManualDocument44 pagesMicro-Speed: Operation Manualelectricidad industrialNo ratings yet

- T2500Document2 pagesT2500kylegazeNo ratings yet

- NanoRelay Operation ManualDocument21 pagesNanoRelay Operation ManualjimdigrizNo ratings yet

- R8285A-G, J, K Control CentersDocument8 pagesR8285A-G, J, K Control Centersdougbert13731No ratings yet

- Fault Code List For Rear Module (HM) Control UnitDocument5 pagesFault Code List For Rear Module (HM) Control Unitardi yanto100% (4)

- Electrical DocumentationDocument19 pagesElectrical DocumentationLuisNo ratings yet

- P40Agile VH EN 12Document14 pagesP40Agile VH EN 12Blake CislowskiNo ratings yet

- Catalog Rm6 2008Document56 pagesCatalog Rm6 2008Carmen Jureschi100% (1)