Professional Documents

Culture Documents

Opening in 2 Way Slab

Uploaded by

Gautam PaulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Opening in 2 Way Slab

Uploaded by

Gautam PaulCopyright:

Available Formats

Concrete international / JULY 2006 33

I

f you took an advanced concrete design course, you

probably had a good introduction to the design of two-

way slabs. Although all multistory buildings require

multiple small slab penetrations for routing of plumbing,

fire protection piping, and ductwork between floors and

larger openings for stairwells and elevator shafts, your

course probably covered the topic of slab openings only

briefly (if at all).

For newly constructed slabs, the locations and sizes of

the required openings are usually determined in the early

stages of design and can be easily accommodated in the

majority of instances. However, you may also be asked to

modify an existing structure, where the analysis and

strengthening (if required) are typically more involved

than for similar openings in a new slab.

In this article, well give you some guidance on selecting

locations and sizes for openings in two-way slabs for

both new and existing structures. By carefully selecting

their locations, small openings can often be accommodated

without requiring strengthening. Youll probably run

across situations, however, where the opening requires

strengthening or the location of these openings is

dictated by concerns other than the strength of the

structure. For these cases, well also introduce some

methods for strengthening existing structures.

TYPES OF TWO-WAY SLABS

Although there are several different variations of two-

way slabs, they can be generally described as one or a

combination of three two-way systems: flat plates, flat

slabs, and two-way beam-supported slabs. The selection

of the most advantageous location for a floor opening

depends on the type of two-way slab youre designing

or evaluating.

The simplest type of two-way slab to construct is

known as a flat plate. These slabs are supported directly

by the columns and have a completely flat soffit. For live

loads of about 50 psf (2.5 kPa), column spacing typically

ranges from 15 to 25 ft (4.5 to 7.5 m) with minimum slab

thicknesses of 6 to 10 in. (150 to 250 mm).

1

For longer

spans, drop panels (thickened portions of the slab) are

added at the columns. This system is referred to as a

flat slab and has an economical span range of 25 to 30 ft

(7.5 to 9 m) with minimum slab thicknesses of 8.5 to 10 in.

(200 to 250 mm). Two-way beam-supported slabs have

beams spanning between columns in both directions that

act with the slab to support gravity loads.

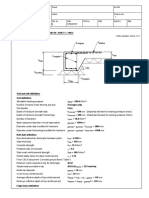

OPENINGS IN NEW SLABS

For the purposes of design, two-way slab systems are

divided into column and middle strips in two perpendicular

directions. The column strip width on each side of the

column centerline is equal to 1/4 of the length of the

shorter span in the two perpendicular directions. The

middle strip is bounded by two column strips.

Section 13.4.1 of ACI 318-05

2

permits openings of any

size in any new slab system, provided you perform an

analysis that demonstrates both strength and serviceability

requirements are satisfied. As an alternative to detailed

analysis for slabs with openings, ACI 318-05 gives the

NOTE: The information presented in this article is NOT

applicable to prestressed OR post-tensioned slabs.

BY MICHAEL C. MOTA AND MAHMOUD KAMARA

Floor Openings in

Two-Way Slabs

34 JULY 2006 / Concrete international

following guidelines for opening size

in different locations for flat plates

and flat slabs. These guidelines are

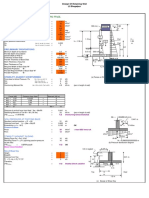

illustrated in Fig. 1 for slabs with l

2

l

l

:

n In the area common to intersecting

middle strips, openings of any size

are permitted (Section 13.4.2.1);

n In the area common to intersecting

column strips, the maximum

permitted opening size is 1/8 the

width of the column strip in either

span (Section 13.4.2.2); and

n In the area common to one column

strip and one middle strip, the

maximum permitted opening size

is limited such that only a maximum

of 1/4 of the slab reinforcement in

either strip may be interrupted

(Section 13.4.2.3).

To apply this simplified approach,

ACI 318-05 requires that the total

amount of reinforcement calculated

for the panel without openings, in

both directions, must be maintained;

thus, half of the reinforcement

interrupted must be replaced on

each side of the opening.

In addition to flexural requirements,

the reduction in slab shear strength

must also be considered when the

opening is located anywhere within a

column strip of a flat slab or within

10 times the slab thickness from a

concentrated load or reaction area.

The effect of the slab opening is

evaluated by reducing the perimeter

of the critical section b

o

by a length

equal to the projection of the opening

enclosed by two lines extending from

the centroid of the column and

tangent to the opening, as shown in

Fig 2(a). For slabs with shearheads to

assist in transferring slab shear to

the column, the effect of the opening

is reduced, and b

o

is reduced by only

half the length enclosed by the

tangential lines, as shown in Fig. 2(b).

OPENINGS IN

EXISTING SLABS

Small openings in existing slabs are

usually core-drilled to the required

diameter. Larger openings are cut

with a circular saw or a concrete

chain saw with plunge cutting

capabilities. Because a circular saw

makes a longer cut on the top of the

slab than on the bottom, small cores

drilled at the corners can be used to

help avoid over-cutting the opening

when a circular saw is used.

Cutting openings in existing slabs

should be approached with caution

and avoided if possible.

4

When

cutting an opening in an existing slab,

the effect on the structural integrity

of the slab must be analyzed. Its

advisable to analyze the slab for

excess capacity and possible moment

redistribution before making the final

decision on the sizes and locations of

the openings, but the following

guidelines taken from Reference 4

can assist you in making preliminary

decisions with the best chance to

avoid having to reinforce the slab.

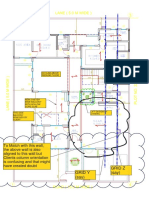

Openings in existing flat

plates and flat slabs

Because the punching shear

capacity of the slab around the

columns typically governs the

thickness of flat plates, any openings

at the intersection of column strips

(Area 3 in Fig. 3) should be avoided

as much as possible. This is especially

critical near corner and edge columns

where the shear in the slab is

typically highest. If openings must be

made in Area 3, to install a drainage

pipe for example, the size of the

opening should be no larger than

12 in. (300 mm). Because they reduce

the critical section for resisting

punching shear (as explained in

Section 11.12.5 of ACI 318-05),

openings cut in this area should be

evaluated carefully. One possible

exception to this guideline is when

column capitals, commonly seen in

older structures, are present to

reduce shear stresses in the slab.

Openings in Area 2, located at the

intersection of column and middle

strips, are less critical than in Area 3,

and small openings having a width

less than 15% of the span length can

often be made in this area. The most

Fig. 1: Suggested opening sizes and locations in flat plates with l

2

l

1

(from Reference 3)

Concrete international / JULY 2006 35

favorable location for openings from a structural point of

view is often the intersection of two middle strips (Area 1).

This is also often the least favorable location from an

architectural point of view, however, because its the

most disruptive to the function of the space.

The guidelines for openings in flat slabs generally

follow the recommendations for flat plates, but the

chances of accommodating larger openings in Area 3 are

increased due to the lower shear stresses in the region

of the drop panels.

Openings in existing two-way

beam-supported slabs

For openings in two-way beam-supported slabs, the

situation is reversed because much of the shear is

transferred to the column through the beams. The total

width of openings in Area 3 (intersection of two column

strips) can often be up to 1/4 of the span, as long as the

beams are left intact. Openings in Area 2 can be more

problematic because they may intersect the portion of

the slab used as a T-beam. Although Area 1 is the least

desirable location, openings with maximum dimensions up

to 1/8 of the span can often be located at the intersection

of two middle strips.

When removing an entire panel of slab between beams,

its often an advantage to leave enough of an overhang to

allow development of reinforcing bars from adjacent

spans. In this case, the beams should be checked for

torsion because the balancing moments from the portion

of the slab that was removed will no longer be present.

STRENGTHENING METHODS

Openings in new structures can often be accommodated

by the proper detailing of additional reinforcing steel in

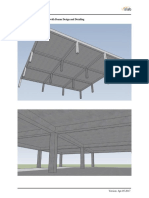

Fig. 2: Reduction to perimeter of critical section b

0

for a flat plate or flat slab with openings in column strips or within a distance of

10 times the thickness of the slab from a column: (a) no shearheads; and (b) with shearheads (from Reference 3)

Fig. 3: Areas for slab openings (after Reference 4)

36 JULY 2006 / Concrete international

the slab or beams, beams spanning between columns

or other beams, or thickening of portions of the slab

around openings. When you determine that an existing

structure cant accommodate new openings without

strengthening, the situation becomes more complex;

however, there are several common strengthening

methods you can consider.

5

The selection of the most

appropriate method to use will depend on several

factors, such as the amount of strengthening required,

the location where strengthening is required, and

architectural requirements.

One of the most common methods for increasing

moment capacity is to add steel plates to the surface of a

slab, using either through-bolts or post-installed anchors.

The installation is fairly simple, but because plates and

through-bolts would interfere with flooring surfaces,

plates are normally installed on the bottom of the slab

using post-installed anchors. Also, because overlapping

of the plates is difficult, this method works best when

strengthening is required in only one direction.

A similar method is to use fiber-reinforced polymer or

steel-reinforced polymer strips to strengthen the slab.

The strips can be overlapped at the corners of the

opening, making strengthening in two directions simpler,

and does not interfere with the floor surface as much as

anchored steel plates. Their installation, however, requires

more highly skilled labor.

When there are existing concrete beams, steel beams

can be installed that span between the concrete beams.

Shims or nonshrink grout should be installed between the

top flange of the steel beam and the bottom of the slab to

ensure uniform bearing.

When shear strengthening is required around columns,

a common solution is to install steel or concrete collars

around the columns to increase the perimeter of the

critical section for punching shear.

Its important to remember that exposed reinforcing

systems may require fire protection. Systems that

incorporate epoxy adhesives must be carefully evaluated,

as they can lose strength rapidly at elevated temperatures.

For low levels of strengthening, the contribution of the

exposed reinforcing system to the strength of the slab

can be neglected, and the strength checked using

factored loads for fire conditions that are lower than

under normal temperatures. For higher levels of

strengthening, special coatings may be required to

achieve a specific fire rating.

6

SEEK ADVICE

Experience is one of the most valuable tools when

selecting opening locations and strengthening methods.

Your first few projects would be an excellent opportunity

to seek the advice of more experienced engineers in your

company. They may be able to show you what theyve

done on previous projects, provide you with typical

details, and give their thoughts on which locations and

strengthening methods would work best for your

particular situation.

References

1. An Engineers Guide to: Economical Concrete Floor Systems,

Portland Cement Association, Skokie, IL, 2005, 6 pp.

2. ACI Committee 318, Building Code Requirements for Structural

Concrete (ACI 318-05) and Commentary (318R-05), American

Concrete Institute, Farmington Hills, MI, 2005, 430 pp.

3. Notes on ACI 318-05 Building Code Requirements for Structural

Concrete with Design Applications, M.E. Kamara and B.G. Rabbat, eds.,

Portland Cement Association, Skokie, IL, 2005, 1008 pp.

4. Newman, A., Structural Renovation of BuildingsMethods,

Details, and Design Examples, McGraw-Hill, New York, NY, 2001,

pp. 239-246.

5. Alkhrdaji, T., and Thomas, J., Keys to Success: Structural

Repair and Strengthening Techniques for Concrete Facilities,

Structural Engineer, V. 5, No. 4, May 2004, pp. 24-27.

6. Alkhrdaji, T., Concrete Q&A: Design Considerations for Fire

Resistance of Structural Strengthening System, Structural Engineer,

July 2004, available at www.gostructural.com.

Selected for reader interest by the editors.

ACI member Michael C. Mota is a Regional

Engineering Manager for the Portland

Cement Association (PCA), providing

technical assistance in all areas of building

design throughout the eastern U.S. He

received an MS in structural engineering

from the New Jersey Institute of Technology,

Newark, NJ, and practiced structural

engineering and construction management

for more than 5 years prior to joining PCA. He is a member of ACI

Committees 314, Simplified Design of Concrete Buildings; 375,

Performance-Based Design of Concrete Buildings for Wind Loads;

and 435, Deflection of Concrete Building Structures.

ACI member Mahmoud Kamara is a Senior

Structural Engineer at PCA. He is involved in

developing technical publications, coordinating

and conducting seminars, and assisting in

developing structural engineering software.

He serves on several ACI technical committees

and is a member of the American Society of

Civil Engineers. In 1992, he received the ACI

Structural Research Award.

You might also like

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pages(LECT-21,22) Prestressed Concrete SlabsSushil MundelNo ratings yet

- Opening in Slab and BeamDocument13 pagesOpening in Slab and BeamYohan LimNo ratings yet

- RCC Design TipsDocument9 pagesRCC Design Tipssatoni12No ratings yet

- Shear in SlabsDocument8 pagesShear in SlabsBehairy AhmedNo ratings yet

- v375 Ebook Ebook Download Reinforced Concrete Structures Analysis and Design by David FanellaDocument7 pagesv375 Ebook Ebook Download Reinforced Concrete Structures Analysis and Design by David FanellaGandhi HammoudNo ratings yet

- Two Way SlabDocument80 pagesTwo Way SlabD SRINIVAS100% (1)

- Sesmic Structural Design StepsDocument16 pagesSesmic Structural Design StepsGeorge GeorgianNo ratings yet

- Good Flat Slab Example Acc To EC2 (The Concrete Centre)Document14 pagesGood Flat Slab Example Acc To EC2 (The Concrete Centre)Nitish Ramdawor100% (4)

- 7 Mat FoundationsDocument34 pages7 Mat FoundationsRajesh Khadka100% (1)

- 2a - Design of Spread Footing-Usd MethodDocument27 pages2a - Design of Spread Footing-Usd MethodLouise LuyNo ratings yet

- Design of Cantilever SlabDocument1 pageDesign of Cantilever SlabHuzaifa NakhwaNo ratings yet

- International Codes-Is456 - Beam Design in STAAD Pro - V8iDocument5 pagesInternational Codes-Is456 - Beam Design in STAAD Pro - V8iUmesh ChikhlikarNo ratings yet

- Learn Flat Slab-Flat Slab Analysis Design and Drawing SoftwareDocument137 pagesLearn Flat Slab-Flat Slab Analysis Design and Drawing SoftwareWanda BeasleyNo ratings yet

- Seismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineerDocument16 pagesSeismic Design Steps: Er.T.Rangarajan, B.E, M.SC (Struct - Engg), Consulting Structural EngineercivilsadiqNo ratings yet

- Prepared BY Dr. Mohammed Kadhum FekheraldinDocument55 pagesPrepared BY Dr. Mohammed Kadhum Fekheraldinhemantkle2uNo ratings yet

- Voided Slabs ProjectDocument57 pagesVoided Slabs ProjectHitesh ShindeNo ratings yet

- One Way SlabDocument5 pagesOne Way SlabShoaib Mohammad Quraishi100% (2)

- Steel Truss Roof Structure For Kattumana Porialar 24.4.2014Document6 pagesSteel Truss Roof Structure For Kattumana Porialar 24.4.2014Ahmad AnasNo ratings yet

- Effective LengthDocument17 pagesEffective LengthJob NantawatNo ratings yet

- STAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters SuchDocument6 pagesSTAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters Suchsivasan10006098No ratings yet

- Topic 3 Design of Beams-Part 2Document41 pagesTopic 3 Design of Beams-Part 2Amirul Ashraf100% (1)

- 2-Shearwall Final Print PDFDocument147 pages2-Shearwall Final Print PDFCon CanNo ratings yet

- Development LengthDocument22 pagesDevelopment LengthAlok MamNo ratings yet

- Design Recommendations For Steel Deck Floor SlabsDocument32 pagesDesign Recommendations For Steel Deck Floor Slabswayzane100% (1)

- Retaining Wall With Surcharge PDFDocument3 pagesRetaining Wall With Surcharge PDFvikas WaghmareNo ratings yet

- Retaining Wall With Relief SlabDocument7 pagesRetaining Wall With Relief Slabrajivkannan100% (2)

- Cantilever SlabDocument16 pagesCantilever SlabMukhlish AkhatarNo ratings yet

- On RCC DetailingDocument22 pagesOn RCC DetailingjadeaachiNo ratings yet

- Analysis and Design of Flat Slabs Using Various Codes: Dr. Pradeep Kumar RamancharalaDocument53 pagesAnalysis and Design of Flat Slabs Using Various Codes: Dr. Pradeep Kumar RamancharalaSwapnilNo ratings yet

- Deep BeamDocument30 pagesDeep BeamKrishan Dutt Yadav100% (1)

- MasterSeries Student Masonry Retaining EtcDocument21 pagesMasterSeries Student Masonry Retaining EtcekaNo ratings yet

- Piled Raft Foundations For Tall BuildingsDocument8 pagesPiled Raft Foundations For Tall Buildingsrenzo1221No ratings yet

- SAP2000 Section PropertiesDocument3 pagesSAP2000 Section PropertiesCon Can100% (1)

- Stiffner Design For Beam Column ConnectionsDocument84 pagesStiffner Design For Beam Column ConnectionsfabnameNo ratings yet

- Advanced Reinforced Concrete Analysis and Design (2008) - Book. Eng. Mohammed Osama YousefDocument51 pagesAdvanced Reinforced Concrete Analysis and Design (2008) - Book. Eng. Mohammed Osama YousefJulio Humberto Díaz RondánNo ratings yet

- Seismic Design and Analysis of Concrete Liquid-Containing TanksDocument11 pagesSeismic Design and Analysis of Concrete Liquid-Containing TanksCarlos CuevaNo ratings yet

- Beam Frame Example of A Parking Structure International Version TN461-SI PDFDocument30 pagesBeam Frame Example of A Parking Structure International Version TN461-SI PDFLau Kim HwaNo ratings yet

- Construction of Slabs On GroundDocument7 pagesConstruction of Slabs On GroundAshrafNo ratings yet

- List of Queries:: A Few General Queries On SAP2000/ETABS/SAFEDocument48 pagesList of Queries:: A Few General Queries On SAP2000/ETABS/SAFERohan Polekar100% (1)

- Reinforced Concrete Design - Direct Design MethodDocument20 pagesReinforced Concrete Design - Direct Design Methodpatrik gan100% (3)

- Seismic Behaviour of Irregular StructureDocument24 pagesSeismic Behaviour of Irregular StructureLalit ChaudhariNo ratings yet

- DOS Tall Building FinalDocument50 pagesDOS Tall Building Finalsoham trivediNo ratings yet

- Ductile Detailing of Beam As Per IS 13920Document4 pagesDuctile Detailing of Beam As Per IS 13920Civil FundaNo ratings yet

- Two Way Concrete Floor Slab With Beams Design DetailingDocument70 pagesTwo Way Concrete Floor Slab With Beams Design DetailingBryanTiznadoAguilarNo ratings yet

- Design of Overhead RCC Rectangular WaterDocument4 pagesDesign of Overhead RCC Rectangular WaterAhmed AwadNo ratings yet

- محاضرات تحليل انشائي الخزاناتDocument50 pagesمحاضرات تحليل انشائي الخزاناتdadhouNo ratings yet

- Column Design Examples PDFDocument2 pagesColumn Design Examples PDFDavid33% (3)

- Watertight Roof Slabs Guidelines & General PrinciplesDocument29 pagesWatertight Roof Slabs Guidelines & General PrinciplesGoanengineerNo ratings yet

- Design of Raft FoundationDocument3 pagesDesign of Raft FoundationBikram BhusalNo ratings yet

- Manual On The Design and Construction of Well and Pile FoundationsDocument140 pagesManual On The Design and Construction of Well and Pile FoundationsRajeshNo ratings yet

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Raft ReportDocument40 pagesRaft ReportGautam PaulNo ratings yet

- Grid Z (Say) Grid Y (Say)Document3 pagesGrid Z (Say) Grid Y (Say)Gautam PaulNo ratings yet

- Calculating The Seismic Design Force and Seismic Base Shear For A Reinforced Concrete Building StructureDocument19 pagesCalculating The Seismic Design Force and Seismic Base Shear For A Reinforced Concrete Building StructureGautam PaulNo ratings yet

- Dog Legged Staircase 463Document2 pagesDog Legged Staircase 463errinchenw100% (1)

- AISC Design Guide 34-Steel Framed Stairway DesignDocument114 pagesAISC Design Guide 34-Steel Framed Stairway Designfzhou100% (9)

- Modulus of Elasticity of Concrete - Determination and Importance in DesignDocument8 pagesModulus of Elasticity of Concrete - Determination and Importance in DesignGautam PaulNo ratings yet

- Pad Footing Design ExampleDocument6 pagesPad Footing Design ExampleGautam PaulNo ratings yet

- Report GI-0255Rev0 PDFDocument39 pagesReport GI-0255Rev0 PDFGautam PaulNo ratings yet

- Etabs ReportDocument361 pagesEtabs ReportGautam PaulNo ratings yet

- Dog Legged Stair CaseDocument10 pagesDog Legged Stair CaseĐÀO NGỌC TÙNGNo ratings yet

- Changes To 2016 AISC Spec and COSP - Eric Bolin PDFDocument81 pagesChanges To 2016 AISC Spec and COSP - Eric Bolin PDFsourabh mahana100% (1)

- RCC62 v3-4Document12 pagesRCC62 v3-4Anonymous dHyxmDNo ratings yet

- Report GI-0255Rev0 PDFDocument39 pagesReport GI-0255Rev0 PDFGautam PaulNo ratings yet

- Joints in Concrete SlabsDocument2 pagesJoints in Concrete SlabsmutyokaNo ratings yet

- Check For Retaining Wall With DBDocument2 pagesCheck For Retaining Wall With DBGautam PaulNo ratings yet

- Raft Foundation DesignDocument10 pagesRaft Foundation DesignGautam PaulNo ratings yet

- Raft Foundation DesignDocument10 pagesRaft Foundation DesignGautam PaulNo ratings yet

- Concrete EC2Document186 pagesConcrete EC2Ivan Grad100% (1)

- Slab Design by Wood Armer MethodDocument2 pagesSlab Design by Wood Armer MethodUmesh Patil75% (4)

- Concrete Slab Load Calculation PDFDocument54 pagesConcrete Slab Load Calculation PDFEddie TaiNo ratings yet

- Tekla Mdeling Guide 21.0Document306 pagesTekla Mdeling Guide 21.0Tân ĐạtNo ratings yet

- Staad Pro - Mat FoundationDocument16 pagesStaad Pro - Mat FoundationV.m. Rajan100% (1)

- Column DesignDocument24 pagesColumn DesignSudan ShresthaNo ratings yet

- Staad Pro - Mat FoundationDocument16 pagesStaad Pro - Mat FoundationV.m. Rajan100% (1)

- Concrete Nominal Cover For Reinforcement As Per BS en 1992Document2 pagesConcrete Nominal Cover For Reinforcement As Per BS en 1992Gautam PaulNo ratings yet

- Tekla Mdeling Guide 21.0Document306 pagesTekla Mdeling Guide 21.0Tân ĐạtNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Crack Width Evaluation For Flexural RC MembersDocument10 pagesCrack Width Evaluation For Flexural RC MembersAly AnisNo ratings yet

- Budgeting Worksheet 97Document20 pagesBudgeting Worksheet 97Gautam PaulNo ratings yet

- Reinforced Strip FoundationDocument22 pagesReinforced Strip FoundationGautam PaulNo ratings yet

- Bayer Snap Fit Joints For PlasticsDocument26 pagesBayer Snap Fit Joints For PlasticsEllen NicDiarmadaNo ratings yet

- Screw Thread MeasurementDocument56 pagesScrew Thread MeasurementAbhishek Kumar100% (1)

- AS5100C3Draft (070327)Document83 pagesAS5100C3Draft (070327)pmali2No ratings yet

- Practical 3 - Friction and Minor Losses in PipesDocument12 pagesPractical 3 - Friction and Minor Losses in PipesAisha Bint IdrisNo ratings yet

- Design of Multi Storied Building ReportDocument19 pagesDesign of Multi Storied Building ReportKevin HuangNo ratings yet

- ++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesDocument9 pages++ Drift-Velocity Closure Relationships For Slug Two-Phase High-Viscosity Oil Flow in PipesAnonymous H9n5g3aaCENo ratings yet

- Non Destructive TestingDocument4 pagesNon Destructive Testingأحمد دعبسNo ratings yet

- D66&G198 ManualDocument8 pagesD66&G198 Manualerwin1bakkerNo ratings yet

- New 2018 Version of ASTM E74 Standard Explained Webinar PDFDocument70 pagesNew 2018 Version of ASTM E74 Standard Explained Webinar PDFrobert0% (1)

- Rock Slope StabilityDocument4 pagesRock Slope StabilityAparna CkNo ratings yet

- Acros Organics Acta N°009Document20 pagesAcros Organics Acta N°009Atomer FormationNo ratings yet

- We Will Be Denied Libra Cryptocurrency As Our DNA Is Mapped That Is The Beast System Anthony PatchDocument9 pagesWe Will Be Denied Libra Cryptocurrency As Our DNA Is Mapped That Is The Beast System Anthony PatchAshish RajeNo ratings yet

- Improvement of Gas Turbine Performance TestDocument4 pagesImprovement of Gas Turbine Performance TestKrishna VenkataramanNo ratings yet

- Pressure and Manometers-Worked Examples For Fluid MechanicsDocument6 pagesPressure and Manometers-Worked Examples For Fluid MechanicsLuvin RajNo ratings yet

- Design Guide For MassBloc Retaining WallDocument17 pagesDesign Guide For MassBloc Retaining WallKen LiewNo ratings yet

- Stevia Poster 2007r2Document1 pageStevia Poster 2007r2Mukul SriNo ratings yet

- Design 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Document8 pagesDesign 3-Phase Core Type of Transformer and Modification of Symmetrical Star Shaped Core-IJAERDV04I0183936Editor IJAERDNo ratings yet

- Image DenoisingDocument54 pagesImage DenoisingShivkant ThakurNo ratings yet

- Force in A Statically Indeterminate Cantilever Truss 2Document18 pagesForce in A Statically Indeterminate Cantilever Truss 2ainul hamizahNo ratings yet

- Topic 11: Measurement & Data ProcessingDocument17 pagesTopic 11: Measurement & Data ProcessingkatNo ratings yet

- HTTPS://WWW - Scribd.com/document/341958468/civil Engineering Reference Manual PDFDocument12 pagesHTTPS://WWW - Scribd.com/document/341958468/civil Engineering Reference Manual PDFRadjalon EngcongNo ratings yet

- Mathematical Model For HAZOP Study Time Estimation PDFDocument9 pagesMathematical Model For HAZOP Study Time Estimation PDFAnonymous 6qbIdsGOINo ratings yet

- Citric Acid Crosslinked Carboxymethyl Cellulosebased Composite Hydrogel Films For Drug Delivery PDFDocument11 pagesCitric Acid Crosslinked Carboxymethyl Cellulosebased Composite Hydrogel Films For Drug Delivery PDFLalit TeloNo ratings yet

- Shahs System of Astrology Book 1Document575 pagesShahs System of Astrology Book 1Centre for Traditional Education100% (3)

- The Phase Rule and Phase Diagrams-T and CDocument31 pagesThe Phase Rule and Phase Diagrams-T and CKunwarPawanSinghBhatiNo ratings yet

- Unit 4Document108 pagesUnit 4Mainali Ishu100% (1)

- MAT1001 Practice-M5L3Document5 pagesMAT1001 Practice-M5L3johnNo ratings yet

- Determination and Analysis of Growth Factors of Cualerpa Racemosa Communities in PasihagonDocument6 pagesDetermination and Analysis of Growth Factors of Cualerpa Racemosa Communities in PasihagonMichelle Castillon MaghanoyNo ratings yet

- A Manual For The: TH Omas R. Duls KiDocument16 pagesA Manual For The: TH Omas R. Duls KiKanchanNo ratings yet