Professional Documents

Culture Documents

Axial Movement From Mating Cam Sections Rotating at Different Speeds.-Certain Copper Tubes Used in Connection With Steam-Heating

Uploaded by

ladygaga_pito0 ratings0% found this document useful (0 votes)

29 views2 pagesCertain copper tubes used in connection with steam-heating apparatus are covered with strips of copper, the strip being wound around the tube and soldered. The strip and the solder must be removed from the ends of the tubes to provide a bare length of 1 inch for connection to a tank or header. This "stripping" is done by using a machine having three cutters, which are held radially and feed inward as the cutter-head rotates about the tube.

Original Description:

Original Title

Axial Movement.original

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCertain copper tubes used in connection with steam-heating apparatus are covered with strips of copper, the strip being wound around the tube and soldered. The strip and the solder must be removed from the ends of the tubes to provide a bare length of 1 inch for connection to a tank or header. This "stripping" is done by using a machine having three cutters, which are held radially and feed inward as the cutter-head rotates about the tube.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesAxial Movement From Mating Cam Sections Rotating at Different Speeds.-Certain Copper Tubes Used in Connection With Steam-Heating

Uploaded by

ladygaga_pitoCertain copper tubes used in connection with steam-heating apparatus are covered with strips of copper, the strip being wound around the tube and soldered. The strip and the solder must be removed from the ends of the tubes to provide a bare length of 1 inch for connection to a tank or header. This "stripping" is done by using a machine having three cutters, which are held radially and feed inward as the cutter-head rotates about the tube.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

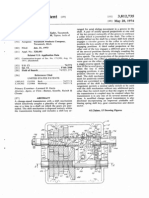

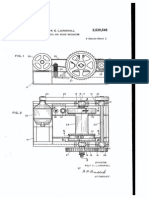

Axial Movement from Mating Cam Sections Rotating at Different

Speeds.- Certain copper tubes used in connection with steam-heating

apparatus are covered with strips of copper, the strip being wound around the

tube and soldered. The strip and the solder must be removed from the ends of

the tubes to provide a bare length of 1 inch for connection to a tank or header.

This "stripping" of the tube ends is done by using a machine having three

cutters, which are held radially and feed inward as the cutter-head rotates

about the tube. The machine used for this work is shown by the sectional and

plan views. The end of a wound tube ( represented by the zigzag lines) is

pushed over a stationary pilot B. Fig.14, which fits snugly inside the tube. An

air-operated clamp is next tightened and the tube is ready for the stripping

operation. The head of the machine, which contains the three cutters (one of

which is shown at D), revolves continually at the rate of 600 revolutions per

minute, and when a clutch is tripped by a foot-pedal, the three tools feed

inward a distance 3/4 inch at the rate of about 0.018 inch per revolution. The

mechanism for obtaining and controlling this feeding movement is the

interesting feature of the machine.

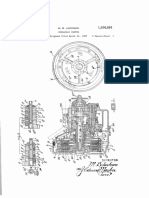

The drive from the motor to the cutter-head is through gears F and G. Gear G

is attached to the main spindle K, which connects with the cutter-head. A head

L, which is rotated by the cutter-head proper, is free to slide for a limited

distance along spinelle K. Attached to sliding head L there is a cam M which

fits a mating cam N. Cam N is free to revolve on spindle K, and it has attached

to it a gear H which meshes with the gear J.

Before the tool feeding movement begins, cam M drives the mating section N

through the step or shoulder O (see plan view), and gears H and J revolve idly.

When the tools are to be fed inward, cam N is rotated 40'1/2 revolutions to 40

revolutions of cam M. The result is that cam N exerts a wedging effect

against M, causing the latter, with head L, to slide along the spindle. When

this sliding movement occurs, racks R, attached to sliding head L, transmit

this movement through pinions to racks S, attached to the cutter-holders. The

method of obtaining this differential movement between cam sections M and

N will now be described.

In order to start the tool-feeding movement, a clutch trip lever is raised by

depressing a foot-pedal. This releases a clutch dog or plunger connecting plate

P through a clutch with the shaft of worm-wheel W, which is rotated

continually from the driving shaft. As soon as plate P begins to revolve, the

dog or clutch lever R is forced out of the notch in plate P, thus connecting,

through a clutch, the driving shaft with gear J; consequently, cam section N is

now driven from shaft E through gears J and H, and since it rotates 40 1/2

revolutions to 40 revolutions of cam M, the wedging action and traversing

movement previously referred to occurs. This difference in the speeds odf

cams M and N is due, of course, to the rations of gears F and G as compared

with gears J and H. Gear F has 25 teeth and G 40 teeth; hence, for each turn of

gear G, F makes 40/25 turn.

Therefore, 40 turns of G require 40/25 x 40=64

turns of shaft E and gear F. For each turn of gear J, H makes 31/49 turn, as J

has teeth and H 49 teeth; hence, if J makes 64 turns then H will make 31/49 x

64= 40 1/2 turns.

While the driving shaft is turning sixty-four times in order to complete one

cycle in the movement of the feeding mechanism, plate P is turned 64/65

revolution, as the worm-wheel W has sixty-five teeth. At the end of the cycle,

clutch lever R is again opposite the notch in plate P and gear J is disconnected

from the driving shaft, thus stopping the feeding movement automatically.

Shoulder O on cam N is also around to the point where section M can slide

back into engagement, which it is forced to do by means of springs concealed

in the cutter-head. The difference in the speeds of the two cam sections is so

slight that this re-engagement occurs easily and without objectionable shock.

You might also like

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Antonio Sanchez 100% Rotary Engine PDFDocument36 pagesAntonio Sanchez 100% Rotary Engine PDFAntonio Sánchez100% (1)

- To Study of Various Type of DynamometersDocument5 pagesTo Study of Various Type of DynamometersAshik GR100% (1)

- Dynamometer: Types of Dynamometers: There Are Mainly Two Types of DynamometersDocument11 pagesDynamometer: Types of Dynamometers: There Are Mainly Two Types of DynamometersKumar BabuNo ratings yet

- 1.15 The Slider-Crank Chain: Mechanisms and MachinesDocument8 pages1.15 The Slider-Crank Chain: Mechanisms and MachinesNAGU2009No ratings yet

- Kinematics of Machinery (AU 402) : Types of Kinematic Chain With Four Lower PairsDocument11 pagesKinematics of Machinery (AU 402) : Types of Kinematic Chain With Four Lower PairsJanardhanaNo ratings yet

- Mechanical ActuatorsDocument39 pagesMechanical ActuatorsKashif UsmanNo ratings yet

- Engineering Vol 72 1901-11-29Document31 pagesEngineering Vol 72 1901-11-29ian_newNo ratings yet

- Unit 5 ATDocument72 pagesUnit 5 ATmonikandakumar ramachandranNo ratings yet

- Crank and Slotted Link MechanismDocument5 pagesCrank and Slotted Link MechanismSaravanan ViswakarmaNo ratings yet

- United States Patent (191: Von Kale! Et AlDocument18 pagesUnited States Patent (191: Von Kale! Et AlJoão Paulo Canto RibeiroNo ratings yet

- Inversion of The MechanismDocument5 pagesInversion of The MechanismRanjit Rajendran100% (1)

- Apron MechanismDocument7 pagesApron Mechanismgopalpaul0% (2)

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- Inversion of MechanismDocument6 pagesInversion of MechanismAakuchikuNo ratings yet

- Assignment 2Document1 pageAssignment 2SRI RAMNo ratings yet

- Experiment 1 - Crank and RodDocument3 pagesExperiment 1 - Crank and Rodalextty75% (12)

- 01 Compound Planetary Speed Reducer2Document4 pages01 Compound Planetary Speed Reducer2leonardo doyleNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- MTM 2Document28 pagesMTM 2RajendrakumarNo ratings yet

- TOM Exp.Document9 pagesTOM Exp.Aneesh KumarNo ratings yet

- Study of Gears and Four Bars MechanismDocument6 pagesStudy of Gears and Four Bars MechanismBarry JohnNo ratings yet

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Document8 pagesApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNo ratings yet

- Symposium On The Lift and Escalator TechnologiesDocument4 pagesSymposium On The Lift and Escalator TechnologiesfreddyjoertyNo ratings yet

- Gear TrainsDocument37 pagesGear TrainsEbrahim Hanash100% (1)

- April 2, 1940.: P. Ravigneaux - 2,195,783Document9 pagesApril 2, 1940.: P. Ravigneaux - 2,195,783Stefan IlicNo ratings yet

- Sample ProblemsDocument3 pagesSample ProblemsSwati SatyendraNo ratings yet

- Tutorial-1 Sub:-Kinematics of MachineDocument11 pagesTutorial-1 Sub:-Kinematics of MachineParth JadavNo ratings yet

- 10 Me 44Document80 pages10 Me 44teiborlin marngarNo ratings yet

- Class 10Document3 pagesClass 10BINAYAK DATTA ROYNo ratings yet

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- Us1866891 PDFDocument8 pagesUs1866891 PDFbelchior alvaroNo ratings yet

- Quick Return MechanismDocument3 pagesQuick Return MechanismKIRAN P ABRAHAMNo ratings yet

- Lecture 4Document28 pagesLecture 4Hassan AliNo ratings yet

- Unit Iv PDFDocument34 pagesUnit Iv PDFpriyankarNo ratings yet

- Question BankDocument7 pagesQuestion BankmunirajNo ratings yet

- Improved Yarn Traversing Mechanism For A Filter Winder: Dr. Milind KoranneDocument6 pagesImproved Yarn Traversing Mechanism For A Filter Winder: Dr. Milind KoranneShobhit JaiswalNo ratings yet

- Research Paper On Automatic Gear Shift MechanismDocument10 pagesResearch Paper On Automatic Gear Shift MechanismmwjhkmrifNo ratings yet

- Single Slider Crank Chain MechanismDocument8 pagesSingle Slider Crank Chain MechanismThinesh Rau KrishnamurtyNo ratings yet

- KomDocument2 pagesKomPartha SarathyNo ratings yet

- FlywheelDocument62 pagesFlywheelSudarson KarthikeyanNo ratings yet

- Lab 4 Tappet Shedding IqbalDocument6 pagesLab 4 Tappet Shedding IqbalEngr Mujahid MehdiNo ratings yet

- Experiment 1 Crank and RodDocument3 pagesExperiment 1 Crank and Rodlucas100% (1)

- Ae19302 QBDocument4 pagesAe19302 QBTomble BravoNo ratings yet

- Tom-Assignment 1Document2 pagesTom-Assignment 1jamunaa83No ratings yet

- TappetDocument10 pagesTappetoronno5No ratings yet

- Let Off MechanismDocument10 pagesLet Off MechanismTamanna Ahmed100% (2)

- Inversions of Double Slider Crank ChainDocument23 pagesInversions of Double Slider Crank ChainAnkit JadhavNo ratings yet

- Kinematics and Theory of MachinesDocument109 pagesKinematics and Theory of MachinesSachin BahugunaNo ratings yet

- Chapter 8. Other MechanismsDocument8 pagesChapter 8. Other MechanismsAshish SinglaNo ratings yet

- Hyundai HD78 Transmission M2S5, M3S5Document42 pagesHyundai HD78 Transmission M2S5, M3S5Bigfair HD78100% (1)

- Kinematic Systems and Working Principles of Semi Automatic LathesDocument4 pagesKinematic Systems and Working Principles of Semi Automatic Lathes21UME003 TUSHAR DEBNo ratings yet

- Kom Unit 5 - Question Bank Answers: Skip To ContentDocument24 pagesKom Unit 5 - Question Bank Answers: Skip To ContentMohammed Al-OdatNo ratings yet

- Us2291241 PDFDocument5 pagesUs2291241 PDFbelchior alvaroNo ratings yet

- MM Presentation Gear and TumblerDocument24 pagesMM Presentation Gear and Tumblersachin prajapatiNo ratings yet

- IndicatorsDocument54 pagesIndicatorsmihalikj2190No ratings yet

- Submitted To:-: Sir FaisalDocument10 pagesSubmitted To:-: Sir FaisalSaad khanNo ratings yet

- Apl 220014Document2 pagesApl 220014Elprince MidoNo ratings yet

- 4$20 Triangles$20 ProofsDocument23 pages4$20 Triangles$20 ProofsBaskaran SeetharamanNo ratings yet

- Comparative Study of Steel Structure With and Without Floating Columns in EtabsDocument13 pagesComparative Study of Steel Structure With and Without Floating Columns in EtabsBehroz BehzadNo ratings yet

- BCIT COMP 8505 Final Project Covert Channel Exfiltration by Wesley Kenzie, June 2011Document39 pagesBCIT COMP 8505 Final Project Covert Channel Exfiltration by Wesley Kenzie, June 2011Wesley KenzieNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetbhavin24uNo ratings yet

- Solved Worksheet-Cell and Specialized Cells 3Document3 pagesSolved Worksheet-Cell and Specialized Cells 3Everything Everything100% (1)

- Pearson Product-Moment Correlation Coefficient Table of Critical ValuesDocument2 pagesPearson Product-Moment Correlation Coefficient Table of Critical ValuesOdy AjjaNo ratings yet

- Mackie USB Driver InstructionsDocument4 pagesMackie USB Driver InstructionsSamuel CotoNo ratings yet

- Introduction To DatabasesDocument33 pagesIntroduction To Databases米皮皮No ratings yet

- Processing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWDocument411 pagesProcessing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWbehzad100% (4)

- Caterpillar Product Line 13Document7 pagesCaterpillar Product Line 13GenneraalNo ratings yet

- Case StudyDocument10 pagesCase StudyVintage ArtNo ratings yet

- Triosonate in F (TWV 42-F7)Document17 pagesTriosonate in F (TWV 42-F7)EDMILSON BRUNO DO NASCIMENTONo ratings yet

- Switching Circuits & Logic Design: Registers and CountersDocument37 pagesSwitching Circuits & Logic Design: Registers and Counters555-193614No ratings yet

- Development and Experimental Evaluation of Machine Learning Techniques For An Intelligent Hairy Scalp Detection SystemDocument29 pagesDevelopment and Experimental Evaluation of Machine Learning Techniques For An Intelligent Hairy Scalp Detection SystemBilly GeneNo ratings yet

- G3412 - 450 KW Performance DataDocument3 pagesG3412 - 450 KW Performance DataJacob De CasillasNo ratings yet

- WhiteLED1 8Document12 pagesWhiteLED1 8Smyle KatariaNo ratings yet

- 15Document20 pages15Allen Rey YeclaNo ratings yet

- A Report On Traffic Volume StudyDocument33 pagesA Report On Traffic Volume StudyManoj Durairaj100% (1)

- BS en 00405-2001 + A1-2009 PDFDocument48 pagesBS en 00405-2001 + A1-2009 PDFShan Sandaruwan AbeywardeneNo ratings yet

- EC205 Mathematics For Economics and Business: The Straight Line and Applications IIDocument3 pagesEC205 Mathematics For Economics and Business: The Straight Line and Applications IIpereNo ratings yet

- List of Books s8 ElectiveDocument2 pagesList of Books s8 ElectivemaniNo ratings yet

- Spelling RulesDocument5 pagesSpelling RulesvijthorNo ratings yet

- Tecumseh Parts List OHV 135Document5 pagesTecumseh Parts List OHV 135M MNo ratings yet

- TOFD Dead Zone CalculatorDocument4 pagesTOFD Dead Zone CalculatorWill SmithNo ratings yet

- Plate - 3 (FLOT)Document2 pagesPlate - 3 (FLOT)patrick dgNo ratings yet

- ORC - Airbag SystemDocument13 pagesORC - Airbag SystemGarikoitz FranciscoeneNo ratings yet

- Gas Turbine Compressor WashingDocument8 pagesGas Turbine Compressor Washingwolf_ns100% (1)

- Spesiikasi PerallatanDocument10 pagesSpesiikasi PerallatanRafi RaziqNo ratings yet

- Mohamad Fakhari Mehrjardi - 1Document18 pagesMohamad Fakhari Mehrjardi - 1Hilmi SanusiNo ratings yet