Professional Documents

Culture Documents

Coiled Tubing Smart-J Tension Packer Technical Datasheet

Uploaded by

Evolution Oil Tools0 ratings0% found this document useful (0 votes)

295 views4 pagesThe Evolution Coiled Tubing Smart-J Tension Packer (CT-Smart-J Packer) provides a compact, economical retrievable packer for use where a set-down type packer for coiled tubing operations. Although designed primarily for waterflooding, this packer can also be used for such pressuring operations as formation fracturing in shallow or low-fluid-level wells.

With the Smart-J mechanism built into the mandrel of the CT-Smart-J Packer, you do not have to remove the tool from the hole to reset. Simply lift the run down the length of the J-mechanism (6 inches). The packer will only operate in tension.

- See more at: http://eotools.com/index.php/component/virtuemart/271/22/completion-tools/packers/coiled-tubing-smart-j-tension-packer-detail#sthash.6cB67epE.dpuf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Evolution Coiled Tubing Smart-J Tension Packer (CT-Smart-J Packer) provides a compact, economical retrievable packer for use where a set-down type packer for coiled tubing operations. Although designed primarily for waterflooding, this packer can also be used for such pressuring operations as formation fracturing in shallow or low-fluid-level wells.

With the Smart-J mechanism built into the mandrel of the CT-Smart-J Packer, you do not have to remove the tool from the hole to reset. Simply lift the run down the length of the J-mechanism (6 inches). The packer will only operate in tension.

- See more at: http://eotools.com/index.php/component/virtuemart/271/22/completion-tools/packers/coiled-tubing-smart-j-tension-packer-detail#sthash.6cB67epE.dpuf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

295 views4 pagesCoiled Tubing Smart-J Tension Packer Technical Datasheet

Uploaded by

Evolution Oil ToolsThe Evolution Coiled Tubing Smart-J Tension Packer (CT-Smart-J Packer) provides a compact, economical retrievable packer for use where a set-down type packer for coiled tubing operations. Although designed primarily for waterflooding, this packer can also be used for such pressuring operations as formation fracturing in shallow or low-fluid-level wells.

With the Smart-J mechanism built into the mandrel of the CT-Smart-J Packer, you do not have to remove the tool from the hole to reset. Simply lift the run down the length of the J-mechanism (6 inches). The packer will only operate in tension.

- See more at: http://eotools.com/index.php/component/virtuemart/271/22/completion-tools/packers/coiled-tubing-smart-j-tension-packer-detail#sthash.6cB67epE.dpuf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

This document is uncontrolled when printed.

2014 Evolution Oil Tools Inc. All rights reserved.

www.eotools.com Toll Free: 1-800-265-TOOL

CT_Smart-J _Packer-TDS_Rev-A (Coiled Tubing

Smart-J Tension Packer) September 2014 Completion Tools

Coiled Tubing Smart-J Tension Packer

Tension-set packer for coiled tubing operations

Applications

Tension packer for coiled tubing

Waterflooding operations

Pressure testing

Can be used as a completion packer

Features & Benefits

Packer can be set without rotating tubing.

Short And Compact - Increases the efficiency of

handling, shipping, and storing of the tool

Rocker-Type Slip Design - Eliminates the need for

extra drag blocks, slip tie links, and guide grooves,

allowing for shorter overall length but ones

permanently free from stuck or cocked slips.

Easy To Operate - A simple and reliable J-Slot

mechanism, actuated from the surface by tubing

rotation, makes the packer easy to set and release.

Packing Element System - For temperatures up to

250 F, the standard 80 D (durometer) element can

be used with sizes 41 through 51, and for

applications above 250 F, a 90 D element is

available. The Size 53 and 55 tools use a 70 D

element, rated to 225 F. Standard and alternate

elements are also available for higher temperatures.

Full-Bore - Larger than tubing drift diameter. Any

instruments capable of passing thru the tubing can

be run thru the packer. Full ID also assists in

preventing screen-out and subsequent plugging of

the tubing during fracturing.

Redress Kits available, extending tool life

Description

The Evolution Coiled Tubing Smart-J

Tension Packer (CT-Smart-J Packer)

provides a compact, economical

retrievable packer for use where a set-

down type packer for coiled tubing

operations. This packer can be set

without rotating the tubing.

Although designed primarily for

waterflooding, this packer can also be

used for such pressuring operations as

formation fracturing in shallow or low-

fluid-level wells.

With the Smart-J mechanism built into

the mandrel of the CT-Smart-J Packer,

you do not have to remove the tool

from the hole to reset. Simply lift the run

down the length of the J-mechanism (6

inches). The packer will only operate in

tension.

Coiled Tubing Smart-J Tension Packer

www.eotools.com

Operation

To Set Packer

Run the packer to desired setting depth, making the

last movement down before attempting actual set.

The packer operates with a continuous J mechanism.

Each time the packer is moved down, and then up in

the well, the J system automatically moves from the

running position to the set position or vice versa.

For instance, when running the packer in the well, if

the tubing is stopped and then moved upwards, the

packer will be in the set position and the slips will

engage the casing walls. The application of additional

tension will then cause the packer elements to seal

against the casing.

To Release Packer

Repeating the downward motion will relax the slips

and disengage the packer from the casing.

Emergency Release

For use under extreme conditions, two

safety release methods are available.

1. The CT-Smart-J Packer has an

emergency Shear Ring installed on

the Body, below the Guide.

Application of from 25,000 to 50,000

lbs. tension (dependent on strength

of Shear Ring) will shear the Shear

Ring, permitting the Cone, Packing

Element and Guide to drop against

the Bottom Sub where they will

remain as the Packer is retrieved

from the well.

2. If it is not desirable or practical to pull

50,000 lbs. through the tubing, apply

approximately 10,000 lbs. strain and

rotate the tubing 20 or more turns to

the right. This unscrews the left-

hand safety thread between the Top

Sub and the Body and allows

removal of the tubing string and the

Top Sub. To remove the remaining

portion of the Packer, install a set of

Jars made up above an overshot,

socket or spear (or the Top Sub),

engage the Packer Body and actuate

the Jars to free the Packer Body from

the casing.

Redress Kits (including such items as

packing elements, seal rings, etc.) are

available.

This document is uncontrolled when printed.

2014 Evolution Oil Tools Inc. All rights reserved.

www.eotools.com Toll Free: 1-800-265-TOOL

CT_Smart-J _Packer-TDS_Rev-A (Coiled Tubing

Smart-J Tension Packer) September 2014 Completion Tools

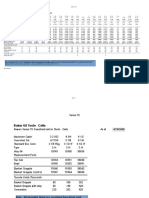

Specifications

Casing Packer

Preferred Range

of Casing IDs

Guide

Ring

OD

Packer

Element

OD

Minimum

Collapsed

Diameter

of Slips

Maximum

Casing ID

Slip

Travel

Thread

Spec.

Box x

Pin

Item

Number

OD

Weight

Lbs/ft

Size Bore MIN MAX

4 9.5-13.5 43A 1.895 3.910 4.160 3.771 3.719 3.787 4.170

2 3/8

EUE

104979

5 20-23 45A2 1.978 4.625 4.778 4.500 4.375 4.543 4.966 105138

7 26-29 47B2 2.416 6.136 6.276 5.968 5.781 5.919 6.528

2 7/8

EUE

105139

Additional sizes and ranges available upon request

Coiled Tubing Smart-J Tension Packer

www.eotools.com

CANADA

#3, 1820 30

th

Ave NE

Calgary, Alberta T2E 7M5

Toll Free: 1-800-265-TOOL (8665)

Main: 403-243-1442

Fax: 403-258-2614

6415A - 63 St. Close

Lloydminster, Alberta T9V 3B5

Tel: 780-522-8294

Fax: 780-875-6337

4512 81 Ave

Edmonton, Alberta

Tel: 587-758-9091

Cell: 780-919-1722

Cell: 780-893-1019

UNITED STATES OF AMERICA

P.O. Box 5363

2908 Coffey Street

Victoria, Texas 77903

Main: 361-575-7900

Fax: 361-575-8081

2400 Kermit Hwy

Odessa, Texas 79764

Cell: 432-638-7902

www.eotools.com

You might also like

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- 2024 - 13.375 TST-2 Service PackerDocument15 pages2024 - 13.375 TST-2 Service PackerDhenny FarialNo ratings yet

- Botil Model BTCN Mechanical Set PackerDocument2 pagesBotil Model BTCN Mechanical Set PackerReivaj JavierNo ratings yet

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- All OvershotsDocument25 pagesAll OvershotsnjileoNo ratings yet

- WOT - Tech Data Sheets PDFDocument43 pagesWOT - Tech Data Sheets PDFAmbroise RICHARDNo ratings yet

- FH Double-Grip Packer Technical DatasheetDocument3 pagesFH Double-Grip Packer Technical DatasheetEvolution Oil ToolsNo ratings yet

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDocument13 pagesC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanNo ratings yet

- PPS Catalogue 2016v4 (English)Document44 pagesPPS Catalogue 2016v4 (English)Kamry AhmadNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- Weatherford Lamb Libya Limited - Casing Exit & Selective ReDocument75 pagesWeatherford Lamb Libya Limited - Casing Exit & Selective ReRicardo Hurtado HernándezNo ratings yet

- Kappa Bridge Plug R4Document6 pagesKappa Bridge Plug R4herbster28No ratings yet

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactDocument4 pagesHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromNo ratings yet

- Wire Line Set Retrievable Packer: Drilling & Down-Hole Completion ToolsDocument11 pagesWire Line Set Retrievable Packer: Drilling & Down-Hole Completion Toolsparag padoleNo ratings yet

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocument2 pagesD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNo ratings yet

- Lot 8 Dafora Appendix B Standards and Specifications DaforaDocument81 pagesLot 8 Dafora Appendix B Standards and Specifications DaforaZamfirMarianNo ratings yet

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 pagesC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- The Most Accurate Whipstock OrientationDocument2 pagesThe Most Accurate Whipstock OrientationSaeed AraNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsmahsaNo ratings yet

- Casing Cutting Procedure - WFDDocument5 pagesCasing Cutting Procedure - WFDprateek132106No ratings yet

- OKC Millhead ModificationDocument22 pagesOKC Millhead ModificationRazvan RaduNo ratings yet

- Hydraulic Tubing Anchor 147973629Document1 pageHydraulic Tubing Anchor 147973629Pedro Antonio Mejia SuarezNo ratings yet

- TechWest Liner EquipmentDocument71 pagesTechWest Liner EquipmentDon BraithwaiteNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Packer 7in Crest-II Sapex SpecDocument3 pagesPacker 7in Crest-II Sapex SpecbayuNo ratings yet

- Packer HP 6 Technical LiteratureDocument7 pagesPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- Ubsurface Lickline Ools S S TDocument2 pagesUbsurface Lickline Ools S S Tbreynner100% (1)

- CPST Pressure Setting Tool PDFDocument1 pageCPST Pressure Setting Tool PDFmahsaNo ratings yet

- Bi Directional Coiled Tubing Jar Manual R0Document18 pagesBi Directional Coiled Tubing Jar Manual R0hantaodulutNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- Laser DrillingDocument19 pagesLaser Drillingmts1234100% (1)

- 2003 Liner Hangers CatalogDocument104 pages2003 Liner Hangers CatalogFABGOILMAN100% (1)

- 2 JFE BEAR Design FeatureDocument15 pages2 JFE BEAR Design FeatureDaniel ChiriacNo ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- Thread Make-Up ProcedureDocument5 pagesThread Make-Up ProcedureVova PanchenkoNo ratings yet

- E-Hydro Trip Sub Technical DatasheetDocument4 pagesE-Hydro Trip Sub Technical DatasheetEvolution Oil ToolsNo ratings yet

- Control tubing pressure with hydro trip subDocument5 pagesControl tubing pressure with hydro trip subyasirismNo ratings yet

- ETI-CPW Packer Manual Spare PartDocument4 pagesETI-CPW Packer Manual Spare PartDidin DelgadoNo ratings yet

- Mechanical Setting Procudere of CR & Bridge PlugDocument7 pagesMechanical Setting Procudere of CR & Bridge PlugChandra FadhillahNo ratings yet

- Coiled Tubing Down Hole ToolsDocument9 pagesCoiled Tubing Down Hole Toolsanthony lakpahNo ratings yet

- Kickover Tools KOT SeriesDocument6 pagesKickover Tools KOT SeriesfelipeNo ratings yet

- Tubing and Casing Roller PDFDocument12 pagesTubing and Casing Roller PDFnasr yassinNo ratings yet

- Top-Co Type 361 Integral Centralizer Sub for Deep WellsDocument2 pagesTop-Co Type 361 Integral Centralizer Sub for Deep WellsEmenike Donald EjiejiNo ratings yet

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- JOT Oil Tools CatalogueDocument55 pagesJOT Oil Tools CatalogueInderjeet HoodaNo ratings yet

- 15 Fishing Tools PDFDocument15 pages15 Fishing Tools PDFjoo123456789No ratings yet

- Ring Type Joint Gaskets Styles: R, RX, BXDocument2 pagesRing Type Joint Gaskets Styles: R, RX, BXiswantmachooNo ratings yet

- (J. A Short) Drilling A Source Book On Oil and Ga PDFDocument588 pages(J. A Short) Drilling A Source Book On Oil and Ga PDFZana QadirNo ratings yet

- Oil States Swab Cups PDFDocument2 pagesOil States Swab Cups PDFramudo ZNo ratings yet

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraeeNo ratings yet

- MH Hyd Tac Tm-353!01!3Document6 pagesMH Hyd Tac Tm-353!01!3David MannNo ratings yet

- Bop Test Info PDFDocument18 pagesBop Test Info PDFjairaso2950No ratings yet

- Logan Lubricated Bumper Sub (English)Document20 pagesLogan Lubricated Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaNo ratings yet

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- Geothermal Well Design PDFDocument7 pagesGeothermal Well Design PDFLaurencius YanuarNo ratings yet

- 26 Mill-EZ Composite Bridge PlugDocument2 pages26 Mill-EZ Composite Bridge PlugzbhdzpNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- R3 Packer Technical DatasheetDocument4 pagesR3 Packer Technical DatasheetEvolution Oil Tools50% (2)

- Mechanical Setting Tool Set Run InstructionsDocument3 pagesMechanical Setting Tool Set Run InstructionsEvolution Oil ToolsNo ratings yet

- Mechanical Setting Tool Redress InstructionsDocument32 pagesMechanical Setting Tool Redress InstructionsEvolution Oil ToolsNo ratings yet

- ERB Pulling Tool Product DatasheetDocument3 pagesERB Pulling Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- 101948-Technical Unit-WR Retrieving Tool 5 1/2Document4 pages101948-Technical Unit-WR Retrieving Tool 5 1/2Evolution Oil ToolsNo ratings yet

- EL Sliding Sleeve Redress Kit Product DatasheetDocument2 pagesEL Sliding Sleeve Redress Kit Product DatasheetEvolution Oil ToolsNo ratings yet

- SLXA Sliding Sleeve PDSDocument2 pagesSLXA Sliding Sleeve PDSEvolution Oil ToolsNo ratings yet

- Mechanical Setting Tool Product DatasheetDocument3 pagesMechanical Setting Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- SLA Sliding Sleeve Product DatasheetDocument2 pagesSLA Sliding Sleeve Product DatasheetEvolution Oil ToolsNo ratings yet

- Beam Gas Separator Case HistoryDocument4 pagesBeam Gas Separator Case HistoryEvolution Oil ToolsNo ratings yet

- WR Retrieving Tool Product DatasheetDocument2 pagesWR Retrieving Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- Integrator-X (AS-1X) Product DatasheetDocument4 pagesIntegrator-X (AS-1X) Product DatasheetEvolution Oil ToolsNo ratings yet

- Flow Control BrochureDocument16 pagesFlow Control BrochureEvolution Oil ToolsNo ratings yet

- 101937-Technical Unit WR Retrieving Tool 4 1-2Document4 pages101937-Technical Unit WR Retrieving Tool 4 1-2Evolution Oil ToolsNo ratings yet

- NEFU Sliding Sleeve Product DatasheetDocument3 pagesNEFU Sliding Sleeve Product DatasheetEvolution Oil ToolsNo ratings yet

- Tubing Drain Technical DatasheetDocument3 pagesTubing Drain Technical DatasheetEvolution Oil ToolsNo ratings yet

- ELWE Separation Sleeve Technical DatasheetDocument3 pagesELWE Separation Sleeve Technical DatasheetEvolution Oil ToolsNo ratings yet

- EFSB Instrument Hanger Technical DatasheetDocument2 pagesEFSB Instrument Hanger Technical DatasheetEvolution Oil ToolsNo ratings yet

- By-Pass Blanking Plugs Technical DatasheetDocument2 pagesBy-Pass Blanking Plugs Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLXX Separation Sleeve Technical DatasheetDocument2 pagesSLXX Separation Sleeve Technical DatasheetEvolution Oil ToolsNo ratings yet

- Quarter Turn Anchor TDS US (Quarter Turn Anchor US)Document2 pagesQuarter Turn Anchor TDS US (Quarter Turn Anchor US)Evolution Oil ToolsNo ratings yet

- SLX Lock Mandrel Technical DatasheetDocument3 pagesSLX Lock Mandrel Technical DatasheetEvolution Oil ToolsNo ratings yet

- CT Hanger Technical DatasheetDocument2 pagesCT Hanger Technical DatasheetEvolution Oil ToolsNo ratings yet

- A-Hanger Technical DatasheetDocument2 pagesA-Hanger Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLXX Separation Sleeve Operating InstructionsDocument8 pagesSLXX Separation Sleeve Operating InstructionsEvolution Oil ToolsNo ratings yet

- Quarter Turn Anchor TDS US (Quarter Turn Anchor US)Document2 pagesQuarter Turn Anchor TDS US (Quarter Turn Anchor US)Evolution Oil ToolsNo ratings yet

- Instrument Hangers Technical DatasheetDocument3 pagesInstrument Hangers Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLPXN Blanking Plug Technical DatasheetDocument3 pagesSLPXN Blanking Plug Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLXN Lock Mandrel Technical DatasheetDocument2 pagesSLXN Lock Mandrel Technical DatasheetEvolution Oil ToolsNo ratings yet

- Clutched Down Hole Swivel Operating InstructionsDocument10 pagesClutched Down Hole Swivel Operating InstructionsEvolution Oil ToolsNo ratings yet

- SLRN Lock Mandrel Technical DatasheetDocument2 pagesSLRN Lock Mandrel Technical DatasheetEvolution Oil ToolsNo ratings yet

- Sangath Conversion Gate01Document21 pagesSangath Conversion Gate01Åyushi ShankhdharNo ratings yet

- 1) Specific SpeedDocument2 pages1) Specific SpeedLynder ArmamentoNo ratings yet

- Heat Exchanger Technology Review From PEI MagazineDocument4 pagesHeat Exchanger Technology Review From PEI MagazineStephen ChuaNo ratings yet

- RECENT ADVANCES IN OX2 ENGINE TECHNOLOGYDocument9 pagesRECENT ADVANCES IN OX2 ENGINE TECHNOLOGYManojkumar ManoNo ratings yet

- Technical ProposalDocument4 pagesTechnical ProposalolescootNo ratings yet

- Data Sheet: PIKO 5.5 10ADocument2 pagesData Sheet: PIKO 5.5 10ADuško TovilovićNo ratings yet

- 45 G 4 eDocument11 pages45 G 4 eMuskan BatraNo ratings yet

- Susara ProjekatDocument17 pagesSusara ProjekatNebojsa RadenkovicNo ratings yet

- 2010 Rooftop Package Product CatalogueDocument91 pages2010 Rooftop Package Product CatalogueDiêm Công ViệtNo ratings yet

- Sharma 2017Document48 pagesSharma 2017Ameen UllahNo ratings yet

- Thermal Power PlantDocument22 pagesThermal Power PlantAchik AgrawalNo ratings yet

- Biodiesel Production From Non-Edible Plant OilsDocument27 pagesBiodiesel Production From Non-Edible Plant OilsRenanto Pandu WirawanNo ratings yet

- Briggs Stratton Motor Kosilice - DeloviDocument20 pagesBriggs Stratton Motor Kosilice - Delovicetojevic@hotmail.comNo ratings yet

- A Bridgeless Totem-Pole Interleaved PFC Converter For Plug-In Electric Vehicles PDFDocument4 pagesA Bridgeless Totem-Pole Interleaved PFC Converter For Plug-In Electric Vehicles PDFLeMeniz InfotechNo ratings yet

- LEADLINE EVR Catalogue UpdatedDocument16 pagesLEADLINE EVR Catalogue UpdatedERWIN ESCANILLANo ratings yet

- Questions Bank Electronic BasicDocument96 pagesQuestions Bank Electronic Basiccsar_pc0% (1)

- Status of Biofuelled Turbec Microturbines: Bio-Fuelled Micro Gas Turbines in EuropeDocument10 pagesStatus of Biofuelled Turbec Microturbines: Bio-Fuelled Micro Gas Turbines in EuropedfvgdfvdfvdsvsfvssacsasNo ratings yet

- Gamesa g128 45 MW enDocument6 pagesGamesa g128 45 MW enAndrei PavelNo ratings yet

- India's Leading Solar Trade Fair Attracts Over 6,000 VisitorsDocument24 pagesIndia's Leading Solar Trade Fair Attracts Over 6,000 VisitorsluckynaveenrajNo ratings yet

- Andrew Keane - Integration of Distributed GenerationDocument133 pagesAndrew Keane - Integration of Distributed GenerationAdhi Tharsia PutraNo ratings yet

- Energy (R) Evolution: A Sustainable Energy Outlook For CanadaDocument120 pagesEnergy (R) Evolution: A Sustainable Energy Outlook For Canadarto2951100% (1)

- Claus Unit ReliabilityDocument5 pagesClaus Unit Reliabilitybakhtiari_afNo ratings yet

- 17 SML Smart Construction Products and Processes - en PDFDocument16 pages17 SML Smart Construction Products and Processes - en PDFEkky CecilNo ratings yet

- Ventilation of Transformer RoomDocument4 pagesVentilation of Transformer Roomsauro100% (1)

- Product Datasheet Green Up Troffer RC320Document1 pageProduct Datasheet Green Up Troffer RC320Bahrowi Adi WijayaNo ratings yet

- 57th Batch BARC Trainees Magazine - KaarvaanDocument108 pages57th Batch BARC Trainees Magazine - Kaarvaansudipbhunia22100% (2)

- Isolation, Identification and Characterization of Ethanol Tolerant Yeast Species From Fruits For Production of Bio-EthanolDocument7 pagesIsolation, Identification and Characterization of Ethanol Tolerant Yeast Species From Fruits For Production of Bio-Ethanolinternational journal of modern chemistry and applied scienceNo ratings yet

- Experiment 1Document3 pagesExperiment 1Myzhel InumerableNo ratings yet

- API GravityDocument4 pagesAPI GravitySridaar KanaiyaNo ratings yet

- Waterotor 53424Document24 pagesWaterotor 53424wijayanataNo ratings yet