Professional Documents

Culture Documents

FH Double-Grip Packer Technical Datasheet

Uploaded by

Evolution Oil ToolsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FH Double-Grip Packer Technical Datasheet

Uploaded by

Evolution Oil ToolsCopyright:

Available Formats

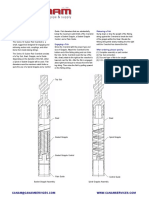

FH Double-Grip Hydrostatic Single-String Packer

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document

not be reproduced in any way, in whole or part or distributed outside the customers organization without the express written consent of Evolution. The document

contains confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Product 210-10-00 1 Rev.E0 July 2012

The Model FH Double-Grip Hydrostatic Single String Packer is a retrievable packer set by either

the hydrostatic head of the well, tubing pressure, or both.

FEATURES

No tubing manipulation required. The setting mechanism of this packer is

released with pump pressure. The packer can be set after the well is flanged up

and the tubing is displaced.

Heavy duty operational to hydrostatic pressures of 12,000 to 15,000 psi.

Hydraulic set for low Hydrostatic Head Wells. The FH Hydrostatic Packer can

be set by tubing pressure alone at any depth. When the hydrostatic head is less

than 1,500 psi, however, the packer must be set hydraulically.

Setting mechanism. The design of the setting mechanism ensures sustained

pack-off force throughout the life of the packer. This tool does not depend on

trapped hydraulic pressure, but mechanically locks initial setting forces into the

Packing Elements. Any additional bottom hole pressure or mechanical load due

to tubing expansion is transmitted as additional pack-off force. Reduction of

bottom hole pressure or tubing contraction, however, does not diminish the

initial setting force.

Multiple Packing Element System.

Hydraulic Hold-Down. The pistons of the Hydraulic Hold-Down are protected

against dulling while running in the hole by Restraining Pins installed inside the

Piston Springs. After the tool is set, The Restraining Pins shear, allowing the

Pistons to bite into the casing before the pressure differential from below is

sufficient to move the packer.

No Mandrel movement after setting. All downward movement of the receptacle

with respect of the tubing, and all upward movement at the tubing with respect

to the Receptacle during setting is trapped in the Body Lock Ring. Once set,

the packer will withstand slackoff or upstrain (within the limits of the shear value

selected). All slackoff goes into the packing elements, whereas all upstrain goes

through the Shear Ring (or Shear Nut) to the Slip Ring and slips to the casing.

Optional rotational release. An optional right-hand rotational release with a

safety shear value of 50,000 lbs (40,000 lbs on size 43) is available on special

order.

FH Double-Grip Hydrostatic Single-String Packer

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document

not be reproduced in any way, in whole or part or distributed outside the customers organization without the express written consent of Evolution. The document

contains confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Product 210-10-00 2 Rev.E0 July 2012

Running Procedure

The Model FH Packer is actuated by pressuring the tubing to obtain a differential at the packer. To

accomplish this, a means for temporarily plugging the tubing below the packer must be provided. For

example, run:

1. A Model E Hydro-Trip Pressure Sub below the FH Packer.

2. A Model C Differential Displacing Valve at some point below the FH Packer, provided that

operations will not require pressuring the tubing internally prior to opening the differential displacing

valve, or

3. A Flow Control Seating Nipple at some point below the packer. A blanking plug may then be run

and retrieved by standard wire line techniques.

If more than one Model FH Packer is to be run, one of the above temporary tubing plugging devices

must be run below the lowermost packer. When the tubing is pressured in this case, all of the

Hydrostatic Packers will be set simultaneously.

OPERATION

NOTE: Using a Model E Hydro-Trip Pressure Sub.

1. For applications where the hydrostatic pressure is 1,500 psi or above:

Run the packer to setting depth, flange up the well and displace tubing. Place a ball in the tubing

string and pump down to seat in the Model E Hydro-Trip Pressure Sub below the Model FH

Packer. Increase the tubing pressure to approximately 1,000 psi over the annulus pressure at the

packer. (At hydrostatic pressure over 7,000 psi, the actuating pressure will increase with increasing

hydrostatic pressure due to load on segment retainer.) This shears the shear screws in the

segment retainer, allowing it to move up, releasing the ring segments, and unlocking the

connector mandrel from the mandrel. The hydrostatic pressure of the well fluid then forces the

connector mandrel down into the atmospheric chamber. This action moves the receptacle down

toward the slip ring, setting the slips and packing off the tool. The downward movement of the

receptacle, packing element mandrel and connector mandrel, etc., is held by the body lock ring

engaging the mandrel. If, after the packer is set, the tubing contracts, the mandrel can move up

until the shear ring retainer contacts the shock absorber at the bottom of the setting sleeve. This

movement will be retained in the body lock ring. If the tubing elongates, the downward force of the

mandrel is transmitted through the body lock ring, packing element mandrel, receptacle, packing

elements and cone, adding to the setting force.

After the packing elements are sealed off, any differential pressure from below the tool will actuate

the hydraulic hold-down pistons and engage them in the casing. The tubing pressure differential

is then increased across the hydro-trip pressure sub ball seat to pump the ball through the finger-

type ball seat and allow it to gravitate to the bottom. The ball seat fingers will expand into the

recess provided and leave the tubing full opening.

2. For applications where the hydrostatic pressure is less than 1,500 psi:

The Model FH Hydrostatic Packer is designed to allow the packer to be set hydraulically at

shallow depths where the hydrostatic pressure is not sufficient to effectively set the packer.

FH Double-Grip Hydrostatic Single-String Packer

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document

not be reproduced in any way, in whole or part or distributed outside the customers organization without the express written consent of Evolution. The document

contains confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Product 210-10-00 3 Rev.E0 July 2012

NOTE: In near zero hydrostatic applications the FH Packer has little internal friction to resist

tubing rotation. Left-hand torque applied to the FH Mandrel in the set position can thread the body

lock ring down onto the upward looking face of the connector sleeve. Continued rotation can

unthread the left-hand connection between the connector sleeve and the element mandrel thus

releasing the pack-off. If tubing rotation is anticipated on a future shallows set job, the connection

between the connector mandrel and the element mandrel should be locked together with an

appropriate thread locking compound with the consideration that there should be a method of

breaking the connection. The connections should not be set screwed together, as the cross

sections would not effectively accept a set screw.

For this application, the packer is dressed with an additional number of shear screws to increase the

actuating pressure to 2,000 psi. The actuating pressure is increased from 1,000 psi to 2,000 psi under

this condition in order to provide additional stretch in the tubing at the time the packer is set so that

there is a greater likelihood that the rebound will shoulder the mandrel against the shear ring when the

hydro-trip pressure sub is sheared out. In order to allow adequate safety factor, the hydro-trip pressure

sub must be dressed to require 3,500 psi differential to blow the ball through the sub.

NOTE: In order for the packer to be set, the hydro-trip pressure sub must allow the tubing pressure

to be increased over the annulus pressure to a level sufficient to release the ring segments. It is

important to NOTE that in wells that take fluid under hydrostatic pressure alone, it is possible to obtain

a differential across the ball without pressuring the tubing. If the tubing below the ball is isolated from

the annulus (as with a permanent packer below the hydrostatic packer), the ball could shear the hydro-

trip pressure sub, without setting the packer. Under these conditions, provisions should be made for

running a seating nipple and landing a plug on wire line.

Using a Model C Differential Displacing Valve

If operations do not call for pressuring the tubing internally, a Model C Differential Displacing Valve

may be used instead of the hydro-trip pressure sub. The differential displacing valve offers distinct

advantages in cases where it is advantageous to displace the tubing after the well is flanged up and the

tubing sealed off in a packer below the Hydrostatic Packer. The differential displacing valve is opened

by pressuring the tubing (not sufficiently to set the Hydrostatic Packer). The tubing may then be

displaced. Drop a ball to set the Hydrostatic Packer and close the differential displacing valve.

Using a Blanking Plug

If a seating nipple or Model L Sliding Sleeve is run below the Hydrostatic Packer, The packer may be

set by landing a plug in the sleeve or nipple. (In most cases, the plug can be run, the packer set and the

plug retrieved in one trip in the well.)

NOTE: Remember that the segment retainer of the Model FH Packer is actuated by tubing

pressure. This prohibits pressure testing with a tubing tester through the packer. However, the packer

can be dressed with sufficient shear strength to allow limited testing of lower packers, etc.

The ball sets in the Model E Hydro-Trip Pressure Sub and the Model C Differential Displacing Valve

have a restricted ID until the packer is set and the ball seat sheared. Remember this is wither collar

locators or thru-tubing perforating guns are used. The minimum ID of the ball seat is listed in the

respective unit covering each tool.

FH Double-Grip Hydrostatic Single-String Packer

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document

not be reproduced in any way, in whole or part or distributed outside the customers organization without the express written consent of Evolution. The document

contains confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Product 210-10-00 4 Rev.E0 July 2012

For Selectively Setting and Individually Testing up to Three FH Packers

The Model FH Packer is adaptable to individual setting and testing by a simple adjustment of shear

screws in the segment retainer housing. Dress the lowermost packer with two brass shear screws.

(When dressing packers for this type hookup, all packers going on one string should be dressed with

shear screws from one box to ensure similarity of shear valves.) Dress the second (middle packer in

three packer hookups or upper in two packer hookups) with five brass shear screws, and a third (upper)

packer with eight brass shear screws. This allows the packers to be set individually. The first will set

with approximately 1,000, the second 2,000 and the third 3,000 psi differential at the packer. In order to

test the packers individually, a means of temporary communication between the tubing and the casing

(e.g., a Model L Sliding Sleeve below each packer) will be necessary. The lower packer can be set

and tested down the casing. The second packer can then be set, the sleeve below it opened, and the

second packer tested down the casing. The third packer is set and tested the same way. It is

recommended that a blanking plug be used to temporarily plug the tubing for setting the packers due to

the higher pressures involved.

FH Double-Grip Hydrostatic Single-String Packer

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document

not be reproduced in any way, in whole or part or distributed outside the customers organization without the express written consent of Evolution. The document

contains confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Product 210-10-00 5 Rev.E0 July 2012

Specification Guide

Casing Packer

Preferred Range of

Casing ID's

Absolute Limits of

Slip & Button Travel

O.D.

T and C

Wt (lbs)

Size Bore Min Max

Gage &

Guide Ring

OD

Packing

Element

OD

Packing

Element

Spacer

OD

Min Max

Thread

Specific

ations

Box up /

Pin

Down

4

1/2"

9.5-13.5 43 A 3.910 4.090 3.771 3.625 3.771 3.755 4.105

15-18 43 B 4.250 4.408 4.125 3.938 4.125 4.095 4.443

5"

11.5-15

26

43C

1.978

4.408 4.560 4.250 4.156 4.25 4.251 4.591

20-23

45

A2

4.625 4.778 4.500

15.5-20

45

A4

4.778 4.950 4.641

4.375 4.500 4.514 4.950

5

1/2"

13-15.5

26

45 B 4.950 5.190 4.781 4.688 4.781 4.764 5.196

20-23 45 C 5.191 5.390 5.062

6"

15-18 45 D 5.391 5.560 5.156

4.938 5.062 5.000 5.631

34

45

E2

5.561 5.609 5.406

28-32

45

E4

1.995

5.610 5.791 5.484

5.250 5.406 5.122 5.791

2 - 3/8

OD EU 8

RD

6 5/8

24-28

7" 38

46

A4

2.416 5.791 5.921 5.588 5.375 5.475 5.375 5.923

2 - 7/8

OD EU &

RD

6

5/8"

17-20

7" 38

47

A2

5.830 5.937 5.656

6 5/8 17-20

32-35

47

A4

5.938 6.135 5.812

5.500 5.656 5.562 6.139

26-29

47

B2

6.136 6.276 5.968

20-26

47

B4

6.276 6.456 6.078

5.750 5.968 5.858 6.456

7"

17-20

47

C2

6.456 6.578 6.266

33.7-39

47

C4

6.579 6.797 6.453

6.125 6.266

24-29.7

47

D2

6.798 7.025 6.672

7

5/8"

20-24

47

D4

2.000

or

2.416

7.025 7.125 6.812

6.500 6.672

6.259 7.260

2 - 3/8 or

2 - 7/8

OD EU 8

Rd

44-49

49

A2

7.511 7.687 7.312

32-40

49

A4

7.688 7.921 7.531

7.000 7.312

8

5/8"

20-28 49 B 7.922 8.191 7.781 7.500 7.781

7.301 8.214

47-53

51

A2

8.343 8.681 8.218

40-47

51

A4

8.681 8.835 8.437

7.938 8.218 8.178* 8.972*

9

5/8"

29.3-36 51 B

2.000

OR

2.500

OR

3.000

8.836 9.063 8.593 8.375 8.593 8.345** 9.083A**

2 - 3/8, 2

- 7/8

or 3 - 1/2

OD EU 8

Rd

You might also like

- WX-958 Electrostatic Generator Operating ManualDocument5 pagesWX-958 Electrostatic Generator Operating ManualWilliam Oliver20% (5)

- SMP Tiltrotator Installation ManualDocument36 pagesSMP Tiltrotator Installation ManualVeikko OnnelaNo ratings yet

- WR Retrieving Tool Product DatasheetDocument2 pagesWR Retrieving Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- Pump Documentation LEWA DOKU - 532316Document80 pagesPump Documentation LEWA DOKU - 532316miltonmontaldoNo ratings yet

- Ex215 - 1 - OPERATIONAL PRINCIPLE PDFDocument126 pagesEx215 - 1 - OPERATIONAL PRINCIPLE PDFkhaled boulahlib100% (2)

- 4-06 Tandem Side Loading Stripper PackerDocument14 pages4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- Bdmi SM-6013 1 PDFDocument27 pagesBdmi SM-6013 1 PDFFatoni Gea AirlanggaNo ratings yet

- Technical: BTR-1.0 Tubing Retrievable MandrelDocument3 pagesTechnical: BTR-1.0 Tubing Retrievable MandrelRebeca RodriguezNo ratings yet

- Two-Way Swivel Redress Kit Assembly InstructionsDocument10 pagesTwo-Way Swivel Redress Kit Assembly InstructionsEvolution Oil ToolsNo ratings yet

- Full-Opening Multiple-Stage Cementing Equipment: Halliburton Part No. 100004670.NX (813.01759.NX)Document48 pagesFull-Opening Multiple-Stage Cementing Equipment: Halliburton Part No. 100004670.NX (813.01759.NX)Doni KurniawanNo ratings yet

- 2024 - 13.375 TST-2 Service PackerDocument15 pages2024 - 13.375 TST-2 Service PackerDhenny FarialNo ratings yet

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- Seal Assemblies (Locator, Anchor, Latch)Document2 pagesSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanNo ratings yet

- Ps 0412 0600obh WDocument1 pagePs 0412 0600obh WHunterNo ratings yet

- 2021 16.0 TST-2 Service PackerDocument15 pages2021 16.0 TST-2 Service PackerDhenny FarialNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- 2023 10.75 TST-2 Service PackerDocument15 pages2023 10.75 TST-2 Service PackerDhenny FarialNo ratings yet

- Wireline Hydraulic Straddle PackerDocument1 pageWireline Hydraulic Straddle PackerKim MissonNo ratings yet

- 1PackerSystem PackerAccessories&tools PDFDocument21 pages1PackerSystem PackerAccessories&tools PDFAnand aashishNo ratings yet

- 1070 PDFDocument8 pages1070 PDFmbhadelNo ratings yet

- SFO 2 Tech ManualDocument9 pagesSFO 2 Tech ManualVictor HugoNo ratings yet

- Kline General CatalogDocument30 pagesKline General CatalogservicemenruNo ratings yet

- Liner PackersDocument1 pageLiner PackersMohamed ElabbasyNo ratings yet

- MH Hyd Tac Tm-353!01!3Document6 pagesMH Hyd Tac Tm-353!01!3David MannNo ratings yet

- Sliding SleveDocument4 pagesSliding SleveMarceloNo ratings yet

- Using Two eRED Valves As Shallow-Set Barriers During A Completion Deployment OperationDocument2 pagesUsing Two eRED Valves As Shallow-Set Barriers During A Completion Deployment OperationLoganBohannonNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- Bimbar Inflatable PDFDocument36 pagesBimbar Inflatable PDFcarlosdh_03No ratings yet

- Sheave Selection GuideDocument1 pageSheave Selection GuideFauzanNo ratings yet

- BJ Sliding SleeveDocument1 pageBJ Sliding SleeveilkerkozturkNo ratings yet

- Packer HP 6 Technical LiteratureDocument7 pagesPacker HP 6 Technical LiteratureRaul Diaz100% (1)

- Technical Specification 3.5 CompletionDocument43 pagesTechnical Specification 3.5 Completionbasil ameenNo ratings yet

- Wire Line SettingDocument19 pagesWire Line SettingNagarjunSHNo ratings yet

- FSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes ReliabilityDocument2 pagesFSP 28"-2000 Psi Diverter/BOP: Diverters' Simplicity Maximizes Reliabilitymehmet sait öztürkNo ratings yet

- Venturetech XK 90 Power Swivel Spec SheetDocument1 pageVenturetech XK 90 Power Swivel Spec Sheetwilliam pinzonNo ratings yet

- Sur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitDocument3 pagesSur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitTamer Hesham AhmedNo ratings yet

- Downhole Instrumentation Qualification RPDocument4 pagesDownhole Instrumentation Qualification RPabinadi1230% (1)

- Jar Safety Clamps 2010Document21 pagesJar Safety Clamps 2010Oswal Agusto Cabrera PantojaNo ratings yet

- New BDMI L 4.5 HE0Document6 pagesNew BDMI L 4.5 HE0Natanael SaputraNo ratings yet

- AFT-2 Equalizing Check ValvesDocument25 pagesAFT-2 Equalizing Check ValvesHassane AmadouNo ratings yet

- Control Unit Model: WC-CUDocument3 pagesControl Unit Model: WC-CUmahsaNo ratings yet

- Cementing Plugs AND Ancillary EquipmentDocument16 pagesCementing Plugs AND Ancillary EquipmentTeguh Akbar HarahapNo ratings yet

- Halliburton Otis W-Running ToolDocument1 pageHalliburton Otis W-Running ToolLoganBohannonNo ratings yet

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDocument13 pagesC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanNo ratings yet

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopPastor VelasquezNo ratings yet

- MZ Alternate Path Multizone Packer: ApplicationsDocument3 pagesMZ Alternate Path Multizone Packer: ApplicationsRodolfo RiderNo ratings yet

- Bgi900 Manual 1.0.0Document70 pagesBgi900 Manual 1.0.0Andrea Liliana Moreno RiosNo ratings yet

- Series 10 Sucker Rod Overshots: Releasing A FishDocument4 pagesSeries 10 Sucker Rod Overshots: Releasing A Fishfelipe100% (1)

- 9.625'' Seal NippleDocument1 page9.625'' Seal NippleMohamed Mahmoud Rezk DimoNo ratings yet

- Design Overview: Basic Design and Maintenance InstructionsDocument5 pagesDesign Overview: Basic Design and Maintenance Instructionsazze bouzNo ratings yet

- JOT Oil Tools CatalogueDocument55 pagesJOT Oil Tools CatalogueInderjeet HoodaNo ratings yet

- Redback Operations ManualDocument11 pagesRedback Operations ManualDon BraithwaiteNo ratings yet

- (General Assembly) : MRP PackerDocument1 page(General Assembly) : MRP PackerAli AliNo ratings yet

- TechWest Liner EquipmentDocument71 pagesTechWest Liner EquipmentDon BraithwaiteNo ratings yet

- Rupture Disk FUL-FLO Sampler: HalliburtonDocument2 pagesRupture Disk FUL-FLO Sampler: Halliburtonsaeed65No ratings yet

- ArtificialDocument47 pagesArtificialShihabsirNo ratings yet

- Wireline Retriever: Instruction Manual 8820Document5 pagesWireline Retriever: Instruction Manual 8820GNo ratings yet

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 pagesC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Hyflo™ III Liner Packer With C-2™ Profile, Hyflo III Liner Packer With HR™ Profile, Hyflo™ III Liner Packer With RH™ ProfileDocument5 pagesHyflo™ III Liner Packer With C-2™ Profile, Hyflo III Liner Packer With HR™ Profile, Hyflo™ III Liner Packer With RH™ Profilemsm.ele2009No ratings yet

- OptiSleeve Sliding SleeveDocument3 pagesOptiSleeve Sliding SleeveRichard More LeonNo ratings yet

- Drill Stem Testing RD Sampler: SmartstarDocument1 pageDrill Stem Testing RD Sampler: SmartstarDenier RubianoNo ratings yet

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaNo ratings yet

- Features/Description: 080-2047-120 MFH Hydrostatic Set Retrievable Packer, 6 5/8" 24#, 7" 38# 080-2047-120Document8 pagesFeatures/Description: 080-2047-120 MFH Hydrostatic Set Retrievable Packer, 6 5/8" 24#, 7" 38# 080-2047-120Rama KrishnaNo ratings yet

- Mechanical Setting Tool Set Run InstructionsDocument3 pagesMechanical Setting Tool Set Run InstructionsEvolution Oil ToolsNo ratings yet

- Tubing Drain Technical DatasheetDocument3 pagesTubing Drain Technical DatasheetEvolution Oil ToolsNo ratings yet

- ERB Pulling Tool Product DatasheetDocument3 pagesERB Pulling Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- Mechanical Setting Tool Redress InstructionsDocument32 pagesMechanical Setting Tool Redress InstructionsEvolution Oil ToolsNo ratings yet

- ELWE Separation Sleeve Technical DatasheetDocument3 pagesELWE Separation Sleeve Technical DatasheetEvolution Oil ToolsNo ratings yet

- Integrator-X (AS-1X) Product DatasheetDocument4 pagesIntegrator-X (AS-1X) Product DatasheetEvolution Oil ToolsNo ratings yet

- EL Sliding Sleeve Redress Kit Product DatasheetDocument2 pagesEL Sliding Sleeve Redress Kit Product DatasheetEvolution Oil ToolsNo ratings yet

- Mechanical Setting Tool Product DatasheetDocument3 pagesMechanical Setting Tool Product DatasheetEvolution Oil ToolsNo ratings yet

- SLXA Sliding Sleeve PDSDocument2 pagesSLXA Sliding Sleeve PDSEvolution Oil ToolsNo ratings yet

- 101937-Technical Unit WR Retrieving Tool 4 1-2Document4 pages101937-Technical Unit WR Retrieving Tool 4 1-2Evolution Oil ToolsNo ratings yet

- NEFU Sliding Sleeve Product DatasheetDocument3 pagesNEFU Sliding Sleeve Product DatasheetEvolution Oil ToolsNo ratings yet

- SLXX Separation Sleeve Operating InstructionsDocument8 pagesSLXX Separation Sleeve Operating InstructionsEvolution Oil ToolsNo ratings yet

- SLA Sliding Sleeve Product DatasheetDocument2 pagesSLA Sliding Sleeve Product DatasheetEvolution Oil ToolsNo ratings yet

- 101948-Technical Unit-WR Retrieving Tool 5 1/2Document4 pages101948-Technical Unit-WR Retrieving Tool 5 1/2Evolution Oil ToolsNo ratings yet

- Flow Control BrochureDocument16 pagesFlow Control BrochureEvolution Oil ToolsNo ratings yet

- CT Hanger Technical DatasheetDocument2 pagesCT Hanger Technical DatasheetEvolution Oil ToolsNo ratings yet

- Beam Gas Separator Case HistoryDocument4 pagesBeam Gas Separator Case HistoryEvolution Oil ToolsNo ratings yet

- Clutched Down Hole Swivel Operating InstructionsDocument10 pagesClutched Down Hole Swivel Operating InstructionsEvolution Oil ToolsNo ratings yet

- A-Hanger Technical DatasheetDocument2 pagesA-Hanger Technical DatasheetEvolution Oil ToolsNo ratings yet

- Quarter Turn Anchor TDS US (Quarter Turn Anchor US)Document2 pagesQuarter Turn Anchor TDS US (Quarter Turn Anchor US)Evolution Oil ToolsNo ratings yet

- SLXX Separation Sleeve Technical DatasheetDocument2 pagesSLXX Separation Sleeve Technical DatasheetEvolution Oil ToolsNo ratings yet

- Quarter Turn Anchor TDS US (Quarter Turn Anchor US)Document2 pagesQuarter Turn Anchor TDS US (Quarter Turn Anchor US)Evolution Oil ToolsNo ratings yet

- Instrument Hangers Technical DatasheetDocument3 pagesInstrument Hangers Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLRN Lock Mandrel Technical DatasheetDocument2 pagesSLRN Lock Mandrel Technical DatasheetEvolution Oil ToolsNo ratings yet

- EFSB Instrument Hanger Technical DatasheetDocument2 pagesEFSB Instrument Hanger Technical DatasheetEvolution Oil ToolsNo ratings yet

- By-Pass Blanking Plugs Technical DatasheetDocument2 pagesBy-Pass Blanking Plugs Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLXN Lock Mandrel Technical DatasheetDocument2 pagesSLXN Lock Mandrel Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLPXN Blanking Plug Technical DatasheetDocument3 pagesSLPXN Blanking Plug Technical DatasheetEvolution Oil ToolsNo ratings yet

- SLX Lock Mandrel Technical DatasheetDocument3 pagesSLX Lock Mandrel Technical DatasheetEvolution Oil ToolsNo ratings yet

- PRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Document10 pagesPRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Habibur RahamanNo ratings yet

- F Fa Analog EngDocument44 pagesF Fa Analog EngИлья ГлининNo ratings yet

- HRD K3V K5V Series Parts DiagramsDocument27 pagesHRD K3V K5V Series Parts Diagramsaiulica2098% (47)

- HanbellRC2 TM ManualDocument109 pagesHanbellRC2 TM Manualdcallahanmasonbarry100% (3)

- D923 - 07 Standard Practices For Sampling Electrical Insulating LiquidsDocument14 pagesD923 - 07 Standard Practices For Sampling Electrical Insulating LiquidsAdel Fawzi100% (2)

- Micro Diaphragm Gas Pumps: Operating and Installation InstructionsDocument22 pagesMicro Diaphragm Gas Pumps: Operating and Installation InstructionsgsaNo ratings yet

- Merlion Plus E350 Electrical Powered Heavy Duty Cold Water High Pressure Cleaner User GuideDocument51 pagesMerlion Plus E350 Electrical Powered Heavy Duty Cold Water High Pressure Cleaner User Guide박일호No ratings yet

- Dual Media Filters - O&M - ManualDocument17 pagesDual Media Filters - O&M - Manualmasoodism100% (1)

- Winters CatalogueDocument247 pagesWinters CataloguevicenteNo ratings yet

- SASSCO Company ProfileDocument25 pagesSASSCO Company ProfileStudent ForeignNo ratings yet

- Hydraulics Basic LevelDocument14 pagesHydraulics Basic LevelIndhusekaran NatarajanNo ratings yet

- Effects of Water HammerDocument10 pagesEffects of Water Hammerjkl012No ratings yet

- Safe handling guide for chlorosilanesDocument26 pagesSafe handling guide for chlorosilanesWilliam ChangNo ratings yet

- MIV Product Overview Valves and FittingsDocument13 pagesMIV Product Overview Valves and FittingsugljevikNo ratings yet

- Airframe Structures General ConceptsDocument101 pagesAirframe Structures General ConceptsH R VALANo ratings yet

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Document1 pageSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonNo ratings yet

- Catalogo ToyoDocument28 pagesCatalogo ToyoAnonymous Nn0adyNo ratings yet

- Engine Systems InspectionDocument29 pagesEngine Systems InspectionGetachew Tikue100% (1)

- Safety ValvesDocument62 pagesSafety Valveslifemillion2847No ratings yet

- MA KR 2000 KR C4 enDocument136 pagesMA KR 2000 KR C4 enluk100% (1)

- ABCO plus Automatic Blowdown Controller user manualDocument35 pagesABCO plus Automatic Blowdown Controller user manualAbhishek VermaNo ratings yet

- Flow Switch Spec SheetDocument2 pagesFlow Switch Spec SheetJavier AffifNo ratings yet

- Fire Fighting Drawing ListDocument18 pagesFire Fighting Drawing ListIshwar AltNo ratings yet

- Flange ball valve dimensions and connection typesDocument2 pagesFlange ball valve dimensions and connection typesTrong Hung NguyenNo ratings yet

- UR319 Series Filters: Ultipleat SRT Return Line FiltersDocument4 pagesUR319 Series Filters: Ultipleat SRT Return Line FiltersLouis MarcianoNo ratings yet