Professional Documents

Culture Documents

Test Cases MM Complete Flow

Uploaded by

rodrigues_franc1565Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Cases MM Complete Flow

Uploaded by

rodrigues_franc1565Copyright:

Available Formats

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

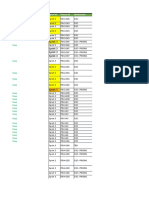

A B C D E F G H I

ITP MM Flows

Integration test process Purchase order

No Flow Transactions Description Master data Org. unit Document numbers Result Comments

1.1 MRP - Purchase requisition - Create

Purchase order - Enter P.O.

Confirmation - Goods receipt

MD02 - ME57/58 - ME21N -

ME22N - MIGO

Normal purchasing Standard P.O. / Domestic supplier

1.2 MRP - Purchase requisition - Create

Purchase order - Enter P.O.

Confirmation - Goods receipt

MD02 - ME57/58 - ME21N -

ME22N - MIGO

Normal purchasing Standard P.O. / Foreign supplier within EU

1.3 MRP - Purchase requisition - Create

Purchase order - Enter P.O.

Confirmation - Goods receipt

MD02 - ME57/58 - ME21N -

ME22N - MIGO

Normal purchasing Standard P.O. / Foreign supplier outside

EU

1.4 MRP - Purchase requisition - Create

Purchase order - Enter P.O.

Confirmation - Goods receipt

MD02 - ME57/58 - ME21N -

ME22N - MIGO

Normal purchasing with MO-charge Standard P.O. / Any supplier

1.5 Create Purchase order - Goods receipt ME21N - MIGO Purschasing of consumtion materials (no mtrl.no in

R/3)

Standard P.O. / Account assignment K

1.5 Create Purchase order - Goods receipt ME21N - MIGO Purschasing of industrialization/resale materials Standard P.O. 6610 4500148294

1.6 Create Purchase order - Goods receipt ME21N - MIGO Subcontracting Standard P.O. / Item category L (fill up

subcontracting stock for component)

1.7 Customer order (TAS) - MRP -

Purchase requisition - Create Purchase

order

MD02 - ME57/58 - ME21N Third party purchase order (check with test-person

for SD)

Standard P.O. / Item category S / Account

assignment Z (refer to customer order on

item level)

1.8 Create Purchase order - Goods receipt -

Transfer posting consignment to own

ME21N - MIGO - MIGO Vendor consignment Standard P.O. / Item category K

1.9 Create Purchase order - Goods receipt -

Usage decision

ME21N - MIGO - QA11 -

MIGO

Normal purchasing with inspection lot Standard P.O. / Domestic supplier /

Material with inspection type 01

2.0 Create return position at PO from

external vendor

ME22N Return order from external vendor Standard P.O. / Any supplier

2.1 Create Goods receipt for return from

external vendor

MIGO Create Goods receipt for return from external

vendor A01-Goods reciept, R01-Purchase order

Standard P.O. / Any supplier

1 (9)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

A B C D E F G H I

ITP MM Flows

Integration test process MIGO postings

No Flow Transactions Description Master data Org. unit Document numbers Result Comments

1.1 Transfer posting 301 Tranferposting plant to plant (one step)

1.2 Transfer posting 302 Tranferposting plat to plant (one step) - reversal

1.3 Transfer posting 309 Tranfer posting material to material

1.4 Transfer posting 309E Transfer posting sales order, material to material

1.5 Transfer posting 310 Tranfer posting material to material - reversal

1.6 Transfer posting 310E Transfer posting sales order, material to material -

reversal

1.7 Transfer posting 311 Transfer posting storage location (one step)

1.8 Transfer posting 311E Transfer posting storage location (one step) -

sales order

1.9 Transfer posting 312 Transfer posting storage location (one step) -

reversal

1.10 Transfer posting 312E Transfer posting storage location (one step) -

sales order - reversal

1.11 Transfer posting 322 Transfer posting Quality inspection to unrestricted

1.12 Transfer posting 411E Ombokning kundorder till egen

Transfer posting sales order to own

1.13 Ombokning

Transfer posting

412E Ombokning kundorder till egen - annullering

Transfer posting sales order to own - reversal

1.14 Ombokning

Transfer posting

453 Ombokning eget frn kundretur

Transfer posting to own stock from return from

customer

1.15 Ombokning

Transfer posting

454 Ombokning eget frn kundretur - annullering

Transfer posting to own stock from return from

customer - reversal

2 (9)

1

2

3

4

A B C D E F G H I

ITP MM Flows

Integration test process MIGO postings

No Flow Transactions Description Master data Org. unit Document numbers Result Comments

20

21

22

23

24

25

26

27

28

29

30

31

32

1.16 Godsmottagnig

Goods reciept

101 Godsmottagning bestllning till lager

Goods reciept for purchase order into

warehouse/stores

1.17 Godsmottagnig

Goods reciept

102 Godsmottagning bestllning till lager - annullering

Goods reciept for purchase order into warehouse -

reversal

1.18 Godsmottagnig

Goods reciept

122 Retur till leverantr

Return delivery to vendor

1.19 Godsuttag

Goods issue

201 GU fr kostn.stlle

Consumption for cost center from warehose

1.20 Godsuttag

Goods issue

202 RE f kostnadsstlle

Consumption for cost center from warehose -

Reversal

1.21 Godsuttag

Goods issue

231 GU fr kundorder

Consumption for sales order from warehouse

1.22 Godsuttag

Goods issue

232 RE fr kundorder

Consumption for sales order from warehouse -

Reversal

1.23 Godsuttag

Goods issue

551 GU skrotning

Withdrawal for scrapping from unrestricted- use

stock

1.24 Godsuttag

Goods issue

552 RE skrotning

Withdrawal for scrapping from unrestricted- use

stock - Reversal

3 (9)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

A B C D E F G H I

ITP MM Flows

Integration test process Stock transfer

No Flow Transactions Description Master data Org. unit Document numbers Result Comments

1.1 Pur.req. - Create purchase order-

Delivery - Transport order - Goods issue -

Goods receipt

ME58 - ME21 - VL10 -

VL71 - LT12 - VL02N -

MIGO

Doc.type UB / No batch management for material

1.2 Create purchase order- Delivery -

Transport order - Goods issue -Goods

receipt

ME21 - VL10 - VL71 -

LT12 - VL02N - MIGO

Doc.type UB / No batch management for material

2.1 Create purchase order- Delivery -

Transport order - Goods issue -Goods

receipt

ME21 - VL10 - VL71 -

LT12 - VL02N - MIGO

Doc.type UB / Batch management for material

3.1 Pur.req. - Create purchase order-

Delivery - Transport order - Goods issue -

Goods receipt

ME58 - ME21 - VL10 -

VL71 - LT12 - VL02N -

MIGO

Document type UB / Material has strategy group

20 in receiving plant

3.2 Create purchase order- Delivery -

Transport order - Goods issue -Goods

receipt

ME21 - VL10 - VL71 -

LT12 - VL02N - MIGO

Document type UB / Material has strategy group

20 in receiving plant

3.3 Pur.req. - Create purchase order-

Delivery - Transport order - Goods issue -

Goods receipt

ME58 - ME21 - VL10 -

VL71 - LT12 - VL02N -

MIGO

Document type UB / Material has strategy group

50 in receiving plant

3.4 Create purchase order- Delivery -

Transport order - Goods issue -Goods

receipt

ME21 - VL10 - VL71 -

LT12 - VL02N - MIGO

Document type UB / Material has strategy group

50 in receiving plant

4 (9)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

A B C D E F G H I

ITP MM Flows

Integration test process Intercompany stock

No Flow Transactions Description Masterdata Org. unit Document numbers Result Comments

1.1 Purchase requisition- create purchase

order- delivery- transport order -

Goods issue - Create invoice - Goods

receipt - Enter incoming invoice

ME58 - ME21N - VL10 -

VL71 - LT12 - VL02N -

VF01 - MIGO - MIRO

Purchase order type NB, Internal vendor INT**** in

purchase org. ****, Master data allocation between

INT**** and PE****. No batch management for

material.

1.2 Purchase requisition- create purchase

order- delivery- transport order -

Goods issue - Create invoice - Goods

receipt - Enter incoming invoice

ME58 - ME21N - VL10 -

VL71 - LT12 - VL02N -

VF01 - MIGO - MIRO

Purchase order type NB, Internal vendor INT**** in

purchase org. ****, Master data allocation between

INT**** and PE****. Batch management for material.

2.1 Automatic creation of purchase order

from requisition

ME59

Intercompany return Flow

3.1 Create return order position at existing

purchase order created after

2009.01.01

ME22N

3.2 Create delivery in background at

orignal supplying plant

VL10

3.3 Create goods issue at returning plant MIGO - Goods reciept -

outbound delivery

3.4 Create goods recievment of return

order

VL02N storage location and batchno has to be filled in

when needed

3.5 Create credit invoice (Invoice type

"IG")

VF01

3.6 Enter incoming credit invoice MIRO

5 (9)

ITP MM Flows

Integration test process Inventory - stock taking individual material selection

No Flow Transactions Description

3.1 Skapa

inventeringsdokument

Create inventory

document

MI01 Material utan partihantering

Material without batch

handeling

3.2 Utskrift

Printout

MI21 Material utan partihantering

Material without batch

handeling

3.3 Registrera Inventering

Enter inventory count

MI04 Material utan partihantering

Material without batch

handeling

3.4 Lista

Inventeringsdifferenser

List inventory differences

MI20 Material utan partihantering

Material without batch

handeling

3.5 Boka Differenser

Post differences

MI07 Material utan partihantering

Material without batch

handeling

4.1 Skapa

inventeringsdokument

Create inventory

document

MI01 Material med partihantering

Material with batch handeling

4.2 Utskrift

Printout

MI21 Material med partihantering

Material with batch handeling

4.3 Registrera Inventering

Enter inventory count

MI04 Material med partihantering

Material with batch handeling

4.4 Lista

Inventeringsdifferenser

List inventory differences

MI20 Material med partihantering

Material with batch handeling

4.5 Boka Differenser

Post differences

MI07 Material med partihantering

Material with batch handeling

Inventory - stock taking individual material selection

Master data Org. unit Document numbers

Result Comments

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

A B C D E F G H I

ITP MM Flows

Integration test process Lists

No Flow Transactions Description Masterdata Org. unit Document numbers Result Comments

1.1 Material document list.

Materialdokument lista

MB51

1.2 Purchase documents for material ME2M

1.3 Purchase documents for vendor ME2L

1.4 Report tree Z005 Test reports that you normally use

9 (9)

You might also like

- Test Cases MM Migo PostingDocument2 pagesTest Cases MM Migo Postingrodrigues_franc1565No ratings yet

- SAP MM - Practice Book - IVDocument38 pagesSAP MM - Practice Book - IVsaisundargatti365No ratings yet

- Sub-Process Transaction Code BPP TitleDocument4 pagesSub-Process Transaction Code BPP TitlePMPROITNo ratings yet

- Sap S4 Hana MMDocument12 pagesSap S4 Hana MMJosé RoblesNo ratings yet

- BPML FIT v1.1Document12 pagesBPML FIT v1.1nguyencaohuygmailNo ratings yet

- Movement Type S/S T.Code DescriptionDocument1 pageMovement Type S/S T.Code Descriptioncreater127abNo ratings yet

- Fi MM SD ScenariosDocument4 pagesFi MM SD ScenariosAnwar Bin Saleem MirzaNo ratings yet

- Mto ScenarioDocument45 pagesMto ScenarioVi KraNo ratings yet

- MM-03 Inventory Management & Physical InventoryDocument38 pagesMM-03 Inventory Management & Physical InventoryDivyang PatelNo ratings yet

- Import Purchase ProcessDocument9 pagesImport Purchase Processnbhaskar bhaskar100% (1)

- SAP MM - Practice Book - IV - 2018Document37 pagesSAP MM - Practice Book - IV - 2018praneeth varmaNo ratings yet

- Sap-V1 0Document87 pagesSap-V1 0mehdi benjellounNo ratings yet

- Refurbishment of Repairable SparesDocument18 pagesRefurbishment of Repairable SparesSantrupta PandaNo ratings yet

- 5.1.5 MM-MIGO-GR-Goods Receipt Against PO-StockDocument4 pages5.1.5 MM-MIGO-GR-Goods Receipt Against PO-StockNeelesh BansalNo ratings yet

- BP080 Future Process AWCCS Inventroy V2.2Document65 pagesBP080 Future Process AWCCS Inventroy V2.2raman_200100% (2)

- SAP NoteBookDocument31 pagesSAP NoteBookMuhammad Kashif ShabbirNo ratings yet

- Product Costing Detailed Designv5Document59 pagesProduct Costing Detailed Designv5adit1435No ratings yet

- Sap TcodesDocument22 pagesSap TcodesMahender reddyNo ratings yet

- Guidelines For Writing Expediting Report 15.03.01 SOP-01 R01 21-06-2019...Document13 pagesGuidelines For Writing Expediting Report 15.03.01 SOP-01 R01 21-06-2019...jeswin80% (5)

- MM and Store PDFDocument265 pagesMM and Store PDFAshish Tirkey100% (1)

- Integration Unit Test Scenario: Project - IT Script 1. Test IDDocument7 pagesIntegration Unit Test Scenario: Project - IT Script 1. Test IDAnuradha VadlamaniNo ratings yet

- O2C - Order - ZBVF With Contract ZCQDocument10 pagesO2C - Order - ZBVF With Contract ZCQadriana_sferreiraNo ratings yet

- Client DiscusssionDocument18 pagesClient DiscusssionANIL SINGHNo ratings yet

- Module Wise TCode ListDocument66 pagesModule Wise TCode ListshyamghotaleNo ratings yet

- Pipeline Material ProcurementDocument19 pagesPipeline Material ProcurementTejas KadamNo ratings yet

- Warehouse CycleDocument34 pagesWarehouse Cyclerommel_007100% (1)

- T 1Document2 pagesT 1Mere HamsafarNo ratings yet

- Code MIGO-Transfer Posting Accounting EntriesDocument3 pagesCode MIGO-Transfer Posting Accounting EntriesShiv P100% (1)

- Fs SO Upload ProgramDocument8 pagesFs SO Upload ProgramVENKATESAN VEERASAMYNo ratings yet

- SAP MM Tcodes ListDocument184 pagesSAP MM Tcodes ListAshutosh Agarwal100% (1)

- Fdocuments - in - SD by AmarDocument106 pagesFdocuments - in - SD by AmarPayal MohantyNo ratings yet

- SAP SD Transaction Codes ListDocument5 pagesSAP SD Transaction Codes ListsraraaNo ratings yet

- Discreet vs Process vs Repetitive Manufacturing in SAP PPDocument7 pagesDiscreet vs Process vs Repetitive Manufacturing in SAP PPKoustubha KhareNo ratings yet

- Rework in ManufacturingDocument4 pagesRework in ManufacturingSameenaNaseemNo ratings yet

- MM&SD Flow2Document13 pagesMM&SD Flow2paulusnipponboyNo ratings yet

- Audit of The Inventory and Warehousing Cycle: Chapter 2DDocument34 pagesAudit of The Inventory and Warehousing Cycle: Chapter 2DCyndi SyifaaNo ratings yet

- MHI AuthorisationDocument21 pagesMHI Authorisationnainesh959No ratings yet

- SIT PH8 10 Subcontracting RepairDocument13 pagesSIT PH8 10 Subcontracting RepairhasibNo ratings yet

- Tcodes ListDocument25 pagesTcodes ListPriya AbrolNo ratings yet

- Sprint 3 Process Tracking ReportDocument32 pagesSprint 3 Process Tracking ReportPratik MandlikNo ratings yet

- User guide for plant maintenance processesDocument49 pagesUser guide for plant maintenance processeschandu80% (5)

- ENTERPRISE STRUCTURE AND SALES DOCUMENT PROCESSINGDocument24 pagesENTERPRISE STRUCTURE AND SALES DOCUMENT PROCESSINGGowrikishore KishoreNo ratings yet

- SAP MM Tables GuideDocument4 pagesSAP MM Tables GuideEstqNo ratings yet

- ETE - 12 - InterCompany Stock TransferDocument28 pagesETE - 12 - InterCompany Stock TransferRicardo Coutinho AmaralNo ratings yet

- Vendor Return Process in SAP EWMDocument15 pagesVendor Return Process in SAP EWMjanipashaNo ratings yet

- SAP TcodesDocument47 pagesSAP Tcodesdushyant mudgalNo ratings yet

- Standard BI Content Extractors & Queries ListDocument151 pagesStandard BI Content Extractors & Queries Listnira505033% (3)

- Accounting Entries Related To MM TransactionsDocument2 pagesAccounting Entries Related To MM TransactionskittuNo ratings yet

- Sap Material ManagementDocument4 pagesSap Material ManagementVignesh SaravananNo ratings yet

- B1B-Sales Order Processing ETO - BBPDocument12 pagesB1B-Sales Order Processing ETO - BBPGRMUDIMELA REDDYNo ratings yet

- Direct Production or Collective Order Scenario OverviewDocument15 pagesDirect Production or Collective Order Scenario Overviewsrinivasa varmaNo ratings yet

- List of SAP MM Transaction Codes: All Transaction Are Stored in Table TSTC. Transaction For MM Module Start With MDocument3 pagesList of SAP MM Transaction Codes: All Transaction Are Stored in Table TSTC. Transaction For MM Module Start With Mganesanmani1985No ratings yet

- Process for WIP and OSP TrackingDocument6 pagesProcess for WIP and OSP TrackingsourabhparandeNo ratings yet

- Sap MM Tables MVT 02Document7 pagesSap MM Tables MVT 02baazkiNo ratings yet

- Return Delivery For STODocument3 pagesReturn Delivery For STOPadma RajuNo ratings yet

- Sales Orders, Billing, Customers, Excise TaxesDocument6 pagesSales Orders, Billing, Customers, Excise TaxesshivanshuNo ratings yet

- Receiving Export MaterialsDocument9 pagesReceiving Export MaterialsRanjit SinghNo ratings yet

- AV-OP-01 Contract Review Iss 2Document5 pagesAV-OP-01 Contract Review Iss 2Kevin DeLimaNo ratings yet

- Equity Valuation: Models from Leading Investment BanksFrom EverandEquity Valuation: Models from Leading Investment BanksJan ViebigNo ratings yet

- Discografia Deep Purple Anthology1991Document13 pagesDiscografia Deep Purple Anthology1991rodrigues_franc1565No ratings yet

- Discografia Deep Purple California Jamming Live 1974Document19 pagesDiscografia Deep Purple California Jamming Live 1974rodrigues_franc1565No ratings yet

- Discografia Deep Purple in The Absence of Pink - Knebworth 1985Document14 pagesDiscografia Deep Purple in The Absence of Pink - Knebworth 1985rodrigues_franc1565No ratings yet

- Discografia Deep Purple Made in Japan Edicion 25 AniversarioDocument21 pagesDiscografia Deep Purple Made in Japan Edicion 25 Aniversariorodrigues_franc1565No ratings yet

- Discografia Deep Purple Total Abandon (Live in Australia 1999)Document23 pagesDiscografia Deep Purple Total Abandon (Live in Australia 1999)rodrigues_franc1565No ratings yet

- Discografia Deep Purple The Battle Rages On... 1993Document16 pagesDiscografia Deep Purple The Battle Rages On... 1993rodrigues_franc1565No ratings yet

- Discografia Deep Purple Knocking at Your Back Door1992Document14 pagesDiscografia Deep Purple Knocking at Your Back Door1992rodrigues_franc1565No ratings yet

- Discografia Deep Purple The Gemini Suite1998Document20 pagesDiscografia Deep Purple The Gemini Suite1998rodrigues_franc1565No ratings yet

- Discografia Deep Purple Singles As & Bs1993Document15 pagesDiscografia Deep Purple Singles As & Bs1993rodrigues_franc1565No ratings yet

- Discografia Deep Purple 30 Very Best of 1998Document21 pagesDiscografia Deep Purple 30 Very Best of 1998rodrigues_franc1565No ratings yet

- Discografia Deep Purple Purpendicular1996Document19 pagesDiscografia Deep Purple Purpendicular1996rodrigues_franc1565No ratings yet

- Discografia Deep Purple Live in Japan1993Document16 pagesDiscografia Deep Purple Live in Japan1993rodrigues_franc1565No ratings yet

- Discografia Deep Purple Extended Versions 2000Document24 pagesDiscografia Deep Purple Extended Versions 2000rodrigues_franc1565No ratings yet

- Discografia Deep Purple Slaves and Masters1990Document12 pagesDiscografia Deep Purple Slaves and Masters1990rodrigues_franc1565No ratings yet

- Discografia Deep Purple King Biscuit Flower Hour1995Document18 pagesDiscografia Deep Purple King Biscuit Flower Hour1995rodrigues_franc1565No ratings yet

- Discografia Deep Purple This Time Around Live in Tokyo 75Document26 pagesDiscografia Deep Purple This Time Around Live in Tokyo 75rodrigues_franc1565No ratings yet

- Discografia Deep Purple Smoke On The Water The Best Of1994Document17 pagesDiscografia Deep Purple Smoke On The Water The Best Of1994rodrigues_franc1565No ratings yet

- Discografia Deep Purple Bananas 2003Document33 pagesDiscografia Deep Purple Bananas 2003rodrigues_franc1565No ratings yet

- Discografia Deep Purple The Essential 2003Document32 pagesDiscografia Deep Purple The Essential 2003rodrigues_franc1565No ratings yet

- Discografia Deep Purple The Friends and RelativesDocument34 pagesDiscografia Deep Purple The Friends and Relativesrodrigues_franc1565No ratings yet

- Discografia Deep Purple Come Hell or High Water1994Document17 pagesDiscografia Deep Purple Come Hell or High Water1994rodrigues_franc1565No ratings yet

- Discografia Deep Purple in Profile2001Document25 pagesDiscografia Deep Purple in Profile2001rodrigues_franc1565No ratings yet

- Discografia Deep Purple Live at The Olympia1998Document22 pagesDiscografia Deep Purple Live at The Olympia1998rodrigues_franc1565No ratings yet

- Discografia Deep Purple Re-Machined A Tribute To Deep PurpleDocument38 pagesDiscografia Deep Purple Re-Machined A Tribute To Deep Purplerodrigues_franc1565No ratings yet

- Discografia Deep Purple Concerto For Group and OrchestraDocument32 pagesDiscografia Deep Purple Concerto For Group and Orchestrarodrigues_franc1565No ratings yet

- Discografia Deep Purple MK 3-The Final Concerts1996Document18 pagesDiscografia Deep Purple MK 3-The Final Concerts1996rodrigues_franc1565No ratings yet

- Discografia Deep Purple The Early Years2004Document35 pagesDiscografia Deep Purple The Early Years2004rodrigues_franc1565No ratings yet

- Discografia Deep Purple 30 Very Best ofDocument33 pagesDiscografia Deep Purple 30 Very Best ofrodrigues_franc1565No ratings yet

- Discografia Deep Purple Soundboard Series 2001Document28 pagesDiscografia Deep Purple Soundboard Series 2001rodrigues_franc1565No ratings yet

- Samart Bank Form - V 310118 PDFDocument2 pagesSamart Bank Form - V 310118 PDFJoe Pianist Samart RukpanyaNo ratings yet

- Nesta: What We DoDocument24 pagesNesta: What We DoNestaNo ratings yet

- GST Detailed AnalysisDocument10 pagesGST Detailed AnalysisKritibandhu SwainNo ratings yet

- Bsbfia401 2Document2 pagesBsbfia401 2nattyNo ratings yet

- Case Study - Sugar BowlDocument5 pagesCase Study - Sugar BowlAbdur RahmanNo ratings yet

- Ub23m03 561476Document1 pageUb23m03 561476Ratul KochNo ratings yet

- Economics ProjectDocument27 pagesEconomics ProjectAnkita SenNo ratings yet

- Test TTTDocument2 pagesTest TTTEng Eman Hannoun100% (1)

- Practice 1Document5 pagesPractice 1huynhtronghieu060605No ratings yet

- Case Study LawDocument3 pagesCase Study Lawabdul waleed100% (3)

- The Concept of Relationship Marketing: Lesson 2.1Document66 pagesThe Concept of Relationship Marketing: Lesson 2.1Love the Vibe0% (1)

- Creating A BudgetDocument2 pagesCreating A BudgetLaci NunesNo ratings yet

- Essay About MonopolyDocument15 pagesEssay About MonopolyNguyễn Lan HươngNo ratings yet

- Palm Heights Tower Web BrochureDocument19 pagesPalm Heights Tower Web BrochureGaurav RaghuvanshiNo ratings yet

- Chapter 6Document7 pagesChapter 6Erika GueseNo ratings yet

- ResourceResourceADocument322 pagesResourceResourceASergey PostnykhNo ratings yet

- Managerial Accounting Sia PDFDocument176 pagesManagerial Accounting Sia PDFManpreet Singh61% (28)

- IAS 33 Earnings Per Share: ImportanceDocument8 pagesIAS 33 Earnings Per Share: Importancemusic niNo ratings yet

- Smith Company Statement of Realization and LiquidationDocument5 pagesSmith Company Statement of Realization and LiquidationTRCLNNo ratings yet

- 12BIỂU MẪU INVOICE-PACKING LIST- bookboomingDocument7 pages12BIỂU MẪU INVOICE-PACKING LIST- bookboomingNguyễn Thanh ThôiNo ratings yet

- Technical Efficiency of KsfeDocument3 pagesTechnical Efficiency of KsfeGokul HarikrishnanNo ratings yet

- The Green Register - Spring 2011Document11 pagesThe Green Register - Spring 2011EcoBudNo ratings yet

- 1067 1001 File PDFDocument256 pages1067 1001 File PDFpriya.sunderNo ratings yet

- Balaji Wafers (FINAL)Document38 pagesBalaji Wafers (FINAL)Urja BhavsarNo ratings yet

- DFMA Lab 1Document13 pagesDFMA Lab 1roshni muthaNo ratings yet

- Dabba WalaDocument16 pagesDabba Walarobin70929No ratings yet

- BCG Matrix ModelDocument10 pagesBCG Matrix ModelGiftNo ratings yet

- Assets MCDocument19 pagesAssets MCpahuyobea cutiepatootieNo ratings yet

- NikeDocument33 pagesNikeRocking Heartbroker DebNo ratings yet

- HSTM CatalogDocument10 pagesHSTM CatalogcccheelNo ratings yet