Professional Documents

Culture Documents

Evaporator Excel

Uploaded by

awenskieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaporator Excel

Uploaded by

awenskieCopyright:

Available Formats

Simulation of a multiple-effect evaporator

Instructions

1. a. On the Tools menu, click Options, then click the Calculation tab and tick on the Iteration box. On Maximum iterations box write 1000

2. For a forward feed 2-effect evaporator

In the spreadsheet "2-Effect"

a. Insert parameter values in the yellow cells

b. Turn the "SWITCH" ON (set the value in the cell B9 (red cell) equal to 1)

c. Iterate (by pressing F9) until "FINISH" or "ALARM" signal is shown in the control panel

d. If a signal to "REDUCE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, reduce the value of either T

s

or m

win

in cells B28 or B29 respectively and start again from 2b

e. If a signal to "INCREASE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, increase the value of either T

s

or m

win

in cells B28 or B29 respectively and start again from 2b

f. When "FINISH" is shown in the control panel, read the results in the green cells (B34-B38)

g. If a solution can not be reached under any combination of T

s

and m

win

values, change the heat transfer area in the cells H19 and/or J19 and/or M19

and repeat steps 2a to 2f

h. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell B9 equal to 0) and repeat steps 2a to 2f

3. For a forward-feed 4-effect evaporator

In the spreadsheet "4-Effect Forward"

a. Insert parameter values in the yellow cells

b. Turn the "SWITCH" ON (set the value in the cell B9 (red cell) equal to 1)

c. Iterate (by pressing F9) until "FINISH" or "ALARM" signal is shown in the control panel

d. If a signal to "REDUCE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, reduce the value of either T

s

or m

win

in the cells B28 or B29 respectively and start again from 2b

e. If a signal to "INCREASE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, increase the value of either T

s

or m

win

in the cells B28 or B29 respectively and start again from 2b

f. When "FINISH" is shown in the control panel, read the results in the green cells (B33-B37)

g. If a solution can not be reached under any combination of T

s

and m

win

values, change the heat transfer area in the cells H19 and/or J19 and/or L19 and/or N19

and/or Q19 and repeat steps 2a to 2f

h. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell B9 equal to 0) and repeat steps 2a to 2f

4. For a backward-feed 4-effect evaporator

In the spreadsheet "4-Effect Backward"

a. Insert parameter values in the yellow cells

b. Turn the "SWITCH" ON (set the value in the cell B9 (red cell) equal to 1)

c. Iterate (by pressing F9) until "FINISH" or "ALARM" signal is shown in the control panel

d. If a signal to "REDUCE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, reduce the value of either T

s

or m

win

in the cells B28 or B29 respectively and start again from 2b

e. If a signal to "INCREASE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, increase the value of either T

s

or m

win

in the cells B28 or B29 respectively and start again from 2b

f. When "FINISH" is shown in the control panel, read the results in the green cells (B33-B37)

g. If a solution can not be reached under any combination of T

s

and m

win

values, change the heat transfer area in the cells H19 and/or J19 and/or L19 and/or N19

and/or Q19 and repeat steps 2a to 2f

h. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell B9 equal to 0) and repeat steps 2a to 2f

1. a. On the Tools menu, click Options, then click the Calculation tab and tick on the Iteration box. On Maximum iterations box write 1000

c. Iterate (by pressing F9) until "FINISH" or "ALARM" signal is shown in the control panel

d. If a signal to "REDUCE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, reduce the value of either T

s

or m

win

e. If a signal to "INCREASE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, increase the value of either T

s

or m

win

f. When "FINISH" is shown in the control panel, read the results in the green cells (B34-B38)

g. If a solution can not be reached under any combination of T

s

and m

win

values, change the heat transfer area in the cells H19 and/or J19 and/or M19

h. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell B9 equal to 0) and repeat steps 2a to 2f

c. Iterate (by pressing F9) until "FINISH" or "ALARM" signal is shown in the control panel

d. If a signal to "REDUCE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, reduce the value of either T

s

or m

win

e. If a signal to "INCREASE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, increase the value of either T

s

or m

win

f. When "FINISH" is shown in the control panel, read the results in the green cells (B33-B37)

g. If a solution can not be reached under any combination of T

s

and m

win

values, change the heat transfer area in the cells H19 and/or J19 and/or L19 and/or N19

h. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell B9 equal to 0) and repeat steps 2a to 2f

c. Iterate (by pressing F9) until "FINISH" or "ALARM" signal is shown in the control panel

d. If a signal to "REDUCE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, reduce the value of either T

s

or m

win

e. If a signal to "INCREASE T

s

or m

win

" is shown in the control panel, turn the SWITCH OFF, increase the value of either T

s

or m

win

f. When "FINISH" is shown in the control panel, read the results in the green cells (B33-B37)

g. If a solution can not be reached under any combination of T

s

and m

win

values, change the heat transfer area in the cells H19 and/or J19 and/or L19 and/or N19

h. To recalculate for different parameter values turn the "SWITCH" OFF (set the value in the cell B9 equal to 0) and repeat steps 2a to 2f

The following assumptions are used

1) The pressure drop in the vapour lines is neglected

2) The effect of superheating on the vapour enthalpy due to the BPE is neglected

3) The heat losses to the environment are taken into account. If cells B23 or B24 for Ulos and Ao

L

are set equal to 0, the heat losses are neglected

4) The condensate from each effect exits at the condensation temperature

5) The condenser is assumed to be a surface condenser

The following empirical relationships are used in the calculations

a) Heat capacity of liquid foods (equation of Dickerson), J/kg

o

C

where x

w

is the mass fraction of water content

b) Boiling Point Elevation,

o

C

where x

s

is the mass fraction of solids content

c) Heat capacity of liquid water, J/kg

o

C

where T is temperature in

o

C

d) Enthalpy of saturated steam and vapour, kJ/kg

where T is temperature in

o

C

e) Latent heat of vaporization of water, kJ/kg

where T is temperature in

o

C

f) Vapour pressure of liquid water, atm (Ref. 15)

where with T in Kelvin

w p

x 2508 1672 c + =

2

p

T 015 . 0 T 34 . 1 4211 c + =

2

v

T 0017 . 0 T 919 . 1 2501 H + =

T

16 . 273

= u

( ) | |

( )

( ) 2195983 . 2 1 10 10 x 42873 . 0 10 1 10 x 50474 . 1 log 02808 . 5 ) 1 ( 79586 . 10 p log

1 76955 . 4 3

1

1

29692 . 8

4

w

+ |

.

|

\

|

+ u + u =

u

2

T 0018 . 0 T 265 . 2 2501 =

3

s

2

s s

x 2 . 21 x 8 . 8 x 7 . 2 BPE + =

T

16 . 273

= u

3) The heat losses to the environment are taken into account. If cells B23 or B24 for Ulos and Ao

L

are set equal to 0, the heat losses are neglected

( ) | |

( )

( ) 2195983 . 2 1 10 10 x 42873 . 0 10 1 10 x 50474 . 1 log 02808 . 5 ) 1 ( 79586 . 10 p log

1 76955 . 4 3

1

1

29692 . 8

4

w

+ |

.

|

\

|

+ u + u =

u

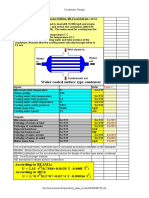

Forward-Feed 2-Effect Evaporator

Control panel

SWITCH= 1

FINISHED

0.000

Input data

Feed flow rate, m

f

= 10000 kg/h

Feed solids content, x

f

= 10%

Desired product solids content, X

spec

= 30%

Feed temperature, T

f

= 70

o

C

Temperature of the environment, T

e

= 20

o

C

Overall Heat transfer coeffic. for heat losses, U

los

= 0

W/m

2o

C

Outside Area of each effect of the evaporator, Ao

L

= 50

m

2

Cooling water temper. at the inlet of the cond., Tw

in

= 25

o

C

Control variables

Steam temperature, T

s

= 122

o

C

Mass flow rate of cooling water in the conden.,m

Win

= 38300 kg/h

Results

Concentrated product flow rate, m

p

= 3332 kg/h

Solids content at the outlet, x

p

= 30.0%

Steam consumption, m

s

= 3937 kg/h

Steam economy 1.7 kg/kg

Cooling water flow rate, m

Win

= 38300 kg/h

Parameters 1st EFFECT 2nd EFFECT CONDENSER

Heat transfer area (m

2

), A

80 80 Heat transf. area

Overall heat transfer coef. (W/m

2o

C), U

1800 1000 Overal heat transf. coef.

Liquid flow rate at the inlet (kg/s), m

i 2.778 1.878 Cooling water flow rate in

Solids content at the inlet, x

i 0.1 0.148 Cooling water temper. in

Liquid temperature at the inlet (

o

C), T

i 70 105.3 Water vapour temper. in

Boiling temperature (

o

C), T

b 105.3 79.8 Cooling water temp. out

Saturation temperature (

o

C), T

v 105.0 79.2 Condensation temperat.

Saturation pressure (atm), P 1.194 0.453 Water vapour pressure

Temperature drop (

o

C), 16.7 25.2

Boiling Point Elevation (

o

C), BPE

0.3 0.6

Heat capacity of liquid at inlet (J/kg

o

C), c

pi 3929 3809

Heat capacity of liquid at outlet(J/kg

o

C), c

po

3809 3427

Heat losses (W), q

L

0 0

Evaporation rate (kg/s), m

v

0.899 0.953

Liquid flow rate at the outlet (kg/s), m

o

1.878 0.925

Solids content at the outlet, x

o 0.148 0.300

Heating steam/vapour flow rate (kg /s), m

s 1.094 0.899

Heating steam/vapour temperature (

o

C), T

s 122 105.0

steam/vapour/condensate cooling water liquid food

m

f

, x

f

, T

f

m

s

,T

s

m

v1

,T

v1

m

c1

,T

c1 m

c2

,T

c2

m

Win

T

win

m

Wout

T

wout

m

c

,T

c

m

i2

, x

i2

, T

i2

m

p

, x

p

,T

p

m

o1

, x

o1

,T

o1

T

b1

T

b2

m

v2

,T

v2

CONDENSER

50

m

2

2500

W/m

2o

C

10.639 kg/s

25

o

C

79.2

o

C

74.5

o

C

79.1

o

C

0.452 atm

steam/vapour/condensate cooling water liquid food

m

f

, x

f

, T

f

m

s

,T

s

m

v1

,T

v1

m

c1

,T

c1 m

c2

,T

c2

m

Win

T

win

m

Wout

T

wout

m

c

,T

c

m

i2

, x

i2

, T

i2

m

p

, x

p

,T

p

m

o1

, x

o1

,T

o1

T

b1

T

b2

m

v2

,T

v2

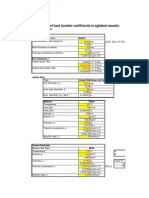

Forward-Feed 4-Effect Evaporator

Control panel

SWITCH= 1

FINISHED

0.0000

Input data

Feed flow rate, m

f

= 20000 kg/h

Feed solids content, x

f

= 9%

Desired product solids content, X

spec

= 48%

Feed temperature, T

f

= 60

o

C

Temperature of the environment, T

e

= 20

o

C

Overall Heat transfer coeffic. for heat losses, U

los

= 0

W/m

2o

C

Outside Area of each effect of the evaporator, Ao

L

= 50

m

2

Cooling water temper. at the inlet of the cond., Tw

in

= 25

o

C

Control variables

Steam temperature, T

s

= 75

o

C

Mass flow rate of cooling water in the conden.,m

Win

= 530000 kg/h

Results

Concentrated product flow rate, m

p

= 3756 kg/h

Solids content at the outlet, x

p

= 47.9%

Steam consumption, m

s

= 4244 kg/h

Steam economy 3.8 kg/kg

Cooling water flow rate, m

Win

= 530000 kg/h

1st EFFECT 2nd EFFECT 3rd EFFECT 4th EFFECT

Heat transfer area (m

2

), A

270 270 270 270

Overall heat transfer coef. (W/m

2o

C), U

2200 1800 1300 506

Liquid flow rate at the inlet (kg/s), m

i 5.556 4.481 3.372 2.230

Solids content at the inlet, x

i 0.09 0.112 0.148 0.224

Liquid temperature at the inlet (

o

C), T

i 60 70.4 65.0 57.3

Boiling temperature (

o

C), T

b 70.4 65.0 57.3 37.1

Saturation temperature (

o

C), T

v 70.2 64.7 56.9 35.7

Saturation pressure (atm), P 0.310 0.244 0.170 0.058

Temperature drop (

o

C), 4.6 5.2 7.4 19.8

Boiling Point Elevation (

o

C), BPE

0.2 0.3 0.4 1.6

Heat capacity of liquid at inlet (J/kg

o

C), c

pi 3954 3900 3808 3618

Heat capacity of liquid at outlet(J/kg

o

C), c

po

3900 3808 3618 2979

Heat losses (W), q

L

0 0 0 0

Evaporation rate (kg/s), m

v

1.075 1.109 1.142 1.188

Liquid flow rate at the outlet (kg/s), m

o

4.481 3.372 2.230 1.042

Solids content at the outlet, x

o 0.112 0.148 0.224 0.479

Heating steam/vapour flow rate (kg /s), m

s 1.179 1.075 1.109 1.142

Heating steam/vapour temperature (

o

C), T

s 75 70.2 64.7 56.9

m

i2

, x

i2

, T

i2

m

c2

,T

c2

m

f

, x

f

, T

f

m

s

,T

s

m

v1

,T

v1

m

c1

,T

c1 m

c4

,T

c4

m

v3

,T

v3

m

c3

,T

c3

T

b4

m

Win

T

win

m

Wout

T

wout

m

c

,T

c

m

o2

, x

o2

,T

o2

m

i3

, x

i3

, T

i3

m

i4

, x

i4

, T

i4

m

p

, x

p

,T

p

m

o3

, x

o3

,T

o3

m

o1

, x

o1

,T

o1

m

v2

,T

v2

T

b3

T

b1

T

b2

steam/vapour/condensate cooling water liquid food

m

v4

,T

v4

CONDENSER

Heat transf. area 150

m

2

Overal heat transf. coef. 2500

W/m

2o

C

Cooling water flow rate in 147.2 kg/s

Cooling water temper. in 25

o

C

Water vapour temper. in 35.7

o

C

Cooling water temp. out 29.7

o

C

Condensation temperat. 35.7

o

C

Water vapour pressure 0.058 atm

m

i2

, x

i2

, T

i2

m

c2

,T

c2

m

f

, x

f

, T

f

m

s

,T

s

m

v1

,T

v1

m

c1

,T

c1 m

c4

,T

c4

m

v3

,T

v3

m

c3

,T

c3

T

b4

m

Win

T

win

m

Wout

T

wout

m

c

,T

c

m

o2

, x

o2

,T

o2

m

i3

, x

i3

, T

i3

m

i4

, x

i4

, T

i4

m

p

, x

p

,T

p

m

o3

, x

o3

,T

o3

m

o1

, x

o1

,T

o1

m

v2

,T

v2

T

b3

T

b1

T

b2

steam/vapour/condensate cooling water liquid food

m

v4

,T

v4

Backward-Feed 4-Effect Evaporator

Control panel

SWITCH= 1

FINISHED

0.000

Input data

Feed flow rate, m

f

= 20000 kg/h

Feed solids content, x

f

= 9%

Desired product solids content, X

spec

= 48%

Feed temperature, T

f

= 60

o

C

Temperature of the environment, T

e

= 20

o

C

Overall Heat transfer coeffic. for heat losses, U

los

= 0

W/m

2o

C

Outside Area of each effect of the evaporator, Ao

L

= 50

m

2

Cooling water temper. at the inlet of the cond., Tw

in

= 25

o

C

Control variables

Steam temperature, T

s

= 75

o

C

Mass flow rate of cooling water in the conden.,m

Win

= 220000 kg/h

Results

Concentrated product flow rate, m

p

= 3745 kg/h

Solids content at the outlet, x

p

= 48.1%

Steam consumption, m

s

= 4327 kg/h

Steam economy 3.8 kg/kg

Cooling water flow rate, m

Win

= 220000 kg/h

1st EFFECT 2nd EFFECT 3rd EFFECT 4th EFFECT

Heat transfer area (m

2

), A

270 270 270 270

Overall heat transfer coef. (W/m

2o

C), U

1214 1400 1270 1044

Liquid flow rate at the inlet (kg/s), m

i 2.202 3.312 4.350 5.556

Solids content at the inlet, x

i 0.227 0.151 0.115 0.090

Liquid temperature at the inlet (

o

C), T

i 57.7 49.6 40.5 60.0

Boiling temperature (

o

C), T

b 66.5 57.7 49.6 40.5

Saturation temperature (

o

C), T

v 64.9 57.2 49.3 40.3

Saturation pressure (atm), P 0.246 0.173 0.118 0.074

Temperature drop (

o

C), 8.5 7.2 7.7 8.8

Boiling Point Elevation (

o

C), BPE

1.6 0.4 0.3 0.2

Heat capacity of liquid at inlet (J/kg

o

C), c

pi 3611 3801 3892 3954

Heat capacity of liquid at outlet(J/kg

o

C), c

po

2974 3611 3801 3892

Heat losses (W), q

L

0 0 0 0

Evaporation rate (kg/s), m

v

1.162 1.110 1.037 1.206

Liquid flow rate at the outlet (kg/s), m

o

1.040 2.202 3.312 4.350

Solids content at the outlet, x

o 0.481 0.227 0.151 0.115

Heating steam/vapour flow rate (kg /s), m

s 1.202 1.162 1.110 1.037

Heating steam/vapour temperature (

o

C), T

s 75 64.9 57.2 49.3

m

i2

, x

i2

, T

i2

m

c2

,T

c2

m

f

, x

f

, T

f

m

s

,T

s

m

c1

,T

c1

m

v1

,T

v1

m

c4

,T

c4

m

c3

,T

c3

m

v3

,T

v3

T

b4

m

Win

T

win

m

Wout

T

wout

m

c

,T

c

m

o2

, x

o2

,T

o2

m

i3

, x

i3

, T

i3

m

o4

, x

o4

, T

o4

m

p

, x

p

,T

p

m

o3

, x

o3

,T

o3

m

i1

, x

i1

,T

i1

T

b3

T

b1

T

b2

steam/vapour/condensate cooling water liquid food

m

v2

,T

v2

m

v4

,T

v4

CONDENSER

Heat transf. area 150

m

2

Overal heat transf. coef. 2500

W/m

2o

C

Cooling water flow rate in 61.1 kg/s

Cooling water temper. in 25

o

C

Water vapour temper. in 40.3

o

C

Cooling water temp. out 36.4

o

C

Condensation temperat. 40.2

o

C

Water vapour pressure 0.074 atm

m

i2

, x

i2

, T

i2

m

c2

,T

c2

m

f

, x

f

, T

f

m

s

,T

s

m

c1

,T

c1

m

v1

,T

v1

m

c4

,T

c4

m

c3

,T

c3

m

v3

,T

v3

T

b4

m

Win

T

win

m

Wout

T

wout

m

c

,T

c

m

o2

, x

o2

,T

o2

m

i3

, x

i3

, T

i3

m

o4

, x

o4

, T

o4

m

p

, x

p

,T

p

m

o3

, x

o3

,T

o3

m

i1

, x

i1

,T

i1

T

b3

T

b1

T

b2

steam/vapour/condensate cooling water liquid food

m

v2

,T

v2

m

v4

,T

v4

You might also like

- Calculations On An Adiabatic Continuous DryerDocument11 pagesCalculations On An Adiabatic Continuous DryerCaleb Somai0% (1)

- EvapDocument7 pagesEvapwestewrNo ratings yet

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationCathal McKeownNo ratings yet

- Atfd Design Calculation: Data Energy Balance Agitator Shell DesignDocument1 pageAtfd Design Calculation: Data Energy Balance Agitator Shell DesignManoj BNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- Multi Organics-MEEP-180118-31.12.2018 PDFDocument28 pagesMulti Organics-MEEP-180118-31.12.2018 PDFArjun KrishnakumarNo ratings yet

- Tonne of Refrigeration, How To Calculate Required TR - Pharma EngineeringDocument12 pagesTonne of Refrigeration, How To Calculate Required TR - Pharma EngineeringpratikNo ratings yet

- Cooling Water CalculationDocument20 pagesCooling Water CalculationShahzaibUsman100% (1)

- CEB2063 - Evaporation - Lecture 1 (Group 1)Document28 pagesCEB2063 - Evaporation - Lecture 1 (Group 1)Scorpion RoyalNo ratings yet

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilNo ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- Pipe DimensionDocument7 pagesPipe DimensionLily NurdianaNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- Agitated Vessel Heat TransferDocument6 pagesAgitated Vessel Heat TransferkitofanecoNo ratings yet

- Distillation Tower DesignDocument66 pagesDistillation Tower DesignHavocFireNo ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- 150 KLPD MEE Mass BalanceDocument8 pages150 KLPD MEE Mass BalancePrathmesh Gujarati100% (5)

- Insulation Thickness & Heat LossDocument5 pagesInsulation Thickness & Heat Losszahid nawazNo ratings yet

- P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) FormulasDocument4 pagesP&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulasjnmanivannan100% (1)

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- Shell Side Fluid SteamDocument6 pagesShell Side Fluid SteamrajachemNo ratings yet

- Agitator-Batch Size-JacketDocument6 pagesAgitator-Batch Size-JacketSagarNo ratings yet

- Steam Pressure DropDocument8 pagesSteam Pressure DropDavid Muñoz CastroNo ratings yet

- Heat Exchanger CalculatorDocument6 pagesHeat Exchanger CalculatorJM Flores De SilvaNo ratings yet

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- Lurgi PSI Evaporator PaperDocument13 pagesLurgi PSI Evaporator PaperMariAle Droz CastroNo ratings yet

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Document5 pagesCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiNo ratings yet

- Heat Transfer Calculations Evaporator #1 Evaporator #2Document6 pagesHeat Transfer Calculations Evaporator #1 Evaporator #2Joshua JohnsonNo ratings yet

- Steam Coil DesignDocument2 pagesSteam Coil DesignHendri SinagaNo ratings yet

- Calculation Overall Heat TransferDocument4 pagesCalculation Overall Heat TransferDavid LambertNo ratings yet

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertNo ratings yet

- Mean Metal Temperature CalculationDocument28 pagesMean Metal Temperature CalculationAvijit DasguptaNo ratings yet

- Air Cooler Design (Ujian)Document36 pagesAir Cooler Design (Ujian)Wahyu JatiNo ratings yet

- Ejector Dry Air Equi CalcsDocument5 pagesEjector Dry Air Equi Calcsgagewang100% (1)

- Condenser Design CalculationDocument11 pagesCondenser Design CalculationAlMakhie0% (1)

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDocument12 pagesA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- Shell & Tube Condenser Design Method: Propanol WaterDocument4 pagesShell & Tube Condenser Design Method: Propanol WaterwestewrNo ratings yet

- Excel Crop Care Limited: "Multi Effect Evaporator Plant"Document9 pagesExcel Crop Care Limited: "Multi Effect Evaporator Plant"Sparsh ShukalNo ratings yet

- Boiler Efficiency Calculation Tabel Data MethodDocument2 pagesBoiler Efficiency Calculation Tabel Data MethodSomplak KudaNo ratings yet

- Specifition-Sheet For Evaporator 1. Customer Details A. B. C. D. E. 2. Data Required For EvaporatorDocument2 pagesSpecifition-Sheet For Evaporator 1. Customer Details A. B. C. D. E. 2. Data Required For EvaporatorTowfiq Hossain TaskuNo ratings yet

- Tower HMBDocument26 pagesTower HMBAnkur KoulNo ratings yet

- Simulation of A Multiple-Effect EvaporatorDocument36 pagesSimulation of A Multiple-Effect EvaporatorSamsouma SoumiaNo ratings yet

- Psychrometrics SolutionsDocument7 pagesPsychrometrics Solutionssaateh100% (1)

- B10 - Guided Interpretation #10Document12 pagesB10 - Guided Interpretation #10Markus LandingtonNo ratings yet

- Two-Stage Air Compressor Lab ReportDocument11 pagesTwo-Stage Air Compressor Lab ReportWill Haynes83% (6)

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationVirendra Bhagat100% (1)

- Contoh Soal Heat ExchangerDocument9 pagesContoh Soal Heat ExchangerLuthfy AditiarNo ratings yet

- Calculation of Sterilizing Values: Example 1 of Pham's PaperDocument2 pagesCalculation of Sterilizing Values: Example 1 of Pham's PaperMr ThanhNo ratings yet

- Combined Convection and Radiation PDFDocument62 pagesCombined Convection and Radiation PDFTatiana Rosario100% (3)

- Multiple Effect EvaporatorDocument19 pagesMultiple Effect Evaporatorchemical_yayang2932100% (1)

- Refri - STTFDocument5 pagesRefri - STTFAli AkbarNo ratings yet

- Affidavit of LossDocument1 pageAffidavit of LossawenskieNo ratings yet

- Melody COEDocument1 pageMelody COEawenskieNo ratings yet

- APMC - PCO Resignation - ReantasoJohnDocument1 pageAPMC - PCO Resignation - ReantasoJohnawenskieNo ratings yet

- Employment AgreementDocument4 pagesEmployment AgreementawenskieNo ratings yet

- Template Resigning PCODocument1 pageTemplate Resigning PCOawenskie0% (1)

- NDA NComDocument5 pagesNDA NComawenskieNo ratings yet

- Proposal - TripleDragon - Sitel Group - May2021Document1 pageProposal - TripleDragon - Sitel Group - May2021awenskieNo ratings yet

- Employment AgreementDocument3 pagesEmployment AgreementawenskieNo ratings yet

- Auto Repair ContractDocument1 pageAuto Repair ContractawenskieNo ratings yet

- Ms. Ana Katrina Pilapil: Type of Car Transmission Color RateDocument1 pageMs. Ana Katrina Pilapil: Type of Car Transmission Color RateawenskieNo ratings yet

- Membership FormDocument1 pageMembership FormNovey CasioNo ratings yet

- Circular No 40-2020 Typhoon Ulysess Readiness PDFDocument1 pageCircular No 40-2020 Typhoon Ulysess Readiness PDFawenskieNo ratings yet

- Fire Code of The Philippines 2008Document475 pagesFire Code of The Philippines 2008RISERPHIL89% (28)

- Job Aid For The Use of Offline eBIRForms Package PDFDocument36 pagesJob Aid For The Use of Offline eBIRForms Package PDFMarjorie Calantog BergadoNo ratings yet

- 3D Static and Dynamic AnalysisDocument32 pages3D Static and Dynamic AnalysisvanmurthyNo ratings yet

- CE 579 Lecture 6 Stability - Differential Equations-TorsionDocument16 pagesCE 579 Lecture 6 Stability - Differential Equations-TorsionbsitlerNo ratings yet

- Penawaran Overhoul Engine Acera 6.4Document1 pagePenawaran Overhoul Engine Acera 6.4Aneh Bin AjaibNo ratings yet

- Kansai DMM2203 D F PDFDocument31 pagesKansai DMM2203 D F PDFisrael amilNo ratings yet

- R320LC 7Document673 pagesR320LC 7Ricardo VilcaNo ratings yet

- HTD 250 En-ItDocument60 pagesHTD 250 En-ItbrasgNo ratings yet

- Zanotti DFZDocument44 pagesZanotti DFZHubert Von Süßer BusartzNo ratings yet

- FD100 分Document17 pagesFD100 分Hadi FaisalNo ratings yet

- Qip (Iit Indore) - Steel-Concrete Composite StructuresDocument33 pagesQip (Iit Indore) - Steel-Concrete Composite StructuresLong LothaNo ratings yet

- Cat 320D Hyd - And.elec Diagram PDFDocument28 pagesCat 320D Hyd - And.elec Diagram PDFluis angel ruiz gomez100% (4)

- PW130 7Document24 pagesPW130 7Csongor Molnár100% (1)

- BPT 13 Balanced Pressure Thermostatic Steam TrapDocument2 pagesBPT 13 Balanced Pressure Thermostatic Steam Trapmember1000No ratings yet

- CSTSB4/N4: M4 Sized Stud Type Terminal Blocks, Suitable For Operation With Screwdriver and Nut DriverDocument2 pagesCSTSB4/N4: M4 Sized Stud Type Terminal Blocks, Suitable For Operation With Screwdriver and Nut Driversamiransw2014No ratings yet

- EMH332 Tutorial 4Document1 pageEMH332 Tutorial 4Chris ZiyuenNo ratings yet

- 15780Document16 pages15780uddinnadeemNo ratings yet

- BOSCH - Master Brake Cylinder & EPDM SealsDocument3 pagesBOSCH - Master Brake Cylinder & EPDM Sealsgautamnaveen1986No ratings yet

- Globalpmc - Doc - Rev 4Document51 pagesGlobalpmc - Doc - Rev 4Salman HussainNo ratings yet

- MEBS6006 1516 04-LoadDocument74 pagesMEBS6006 1516 04-LoadFaizul Zainudin100% (1)

- Naufal - Flare Technologies - PPTX (Tanpa Video)Document12 pagesNaufal - Flare Technologies - PPTX (Tanpa Video)Naufal AlhadyNo ratings yet

- Conservation of MomentumDocument9 pagesConservation of MomentumStraight As StudyNo ratings yet

- Numerical Study of A Self Priming Regenerative Pump For Improved Performance Using Geometric ModificationsDocument6 pagesNumerical Study of A Self Priming Regenerative Pump For Improved Performance Using Geometric ModificationssachinparamaneNo ratings yet

- Problem Sheet 3 Heat, Work and The First Law of Thermodynamics PDFDocument4 pagesProblem Sheet 3 Heat, Work and The First Law of Thermodynamics PDFS DNo ratings yet

- Panasonic Servisni Manual SXC 9-12 KWDocument136 pagesPanasonic Servisni Manual SXC 9-12 KWzimroviNo ratings yet

- Metal Seated Ball ValveDocument12 pagesMetal Seated Ball ValvezazamoteurNo ratings yet

- Thermowell InstallationDocument8 pagesThermowell Installationprasoon_eilNo ratings yet

- CXC Physics Notes: Section ADocument13 pagesCXC Physics Notes: Section AAlecha WeysNo ratings yet

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDocument18 pagesDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajNo ratings yet

- Wheel BalancingDocument13 pagesWheel BalancingSheerazNo ratings yet

- CNC Machine ToolsDocument137 pagesCNC Machine ToolsDr_M_Soliman88% (8)

- Lube Level Swichgage: L129 SeriesDocument2 pagesLube Level Swichgage: L129 SeriesFlavio MedranoNo ratings yet