Professional Documents

Culture Documents

OTE Outotec MillMapper Eng Lores

Uploaded by

jadetorresCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OTE Outotec MillMapper Eng Lores

Uploaded by

jadetorresCopyright:

Available Formats

Benefits

n Optimizes liner life and design

n Early detection of liner failure

n Remotely operated, no manual entry required

n Higher overall mill availability

n Improved forecasting from more accurate

and reliable data

n Improved safety

Outotec

MillMapper

Measure Model Manage

MillMapper (developed by Scanalyse which is now part

of Outotec) is a globally patented technology for mill

liner condition monitoring and modelling. Unique in

the industry, MillMapper provides an unprecedented

level of information and allows your maintenance

and operational personnel to extend liner life cycles,

optimize liner design, prevent liner failures, optimize

throughput and improve the performance of your mill.

Regular condition monitoring of mill liners helps

improve the overall comminution performance.

Services Technical Services Comminution

Operating principle

Scanning

Initially, the mill is scanned using a state-of-the-art laser

scanner either by personnel entering the mill or remotely,

by mounting the scanner on a support beam. Scanning is

performed in as little as 15 minutes and can be scheduled

to coincide with your planned inspection shutdown.

Using a specially calibrated terrestrial laser scanner,

MillMapper records the entire visible internal surface

of the mill, as opposed to conventional methods where

only a few arbitrarily selected points are measured.

Unlike Ultrasonic Thickness Gauge (UTG) and manual

measurements, MillMapper provides liner thickness

measurements over the entire internal mill surface.

Up to ten million thickness points are used to produce

a 3D model and subsequent wear tracking curves.

3D Modelling

Following the scan, the raw data is uploaded and

processed to deliver a high denition 3D model. This is

colour-coded according to liner thickness and provides

point thickness measurements on all wear surfaces

to an accuracy of 3mm. The software automatically

detects high wear zones and asymmetric wear patterns.

Cracked liners, loose plates and broken grates are also

easily detected.

Reporting

Following automatic detection and agging of the wear

hot spots, the software produces precise wear curves

and intelligent forecasting based on trend data gathered

from over ten million thickness points on the liner.

The reporting software also produces cross sectional

and longitudinal prole curves and reline efciencies.

Operators can therefore establish critical thresholds

that dene reline criteria and also make informed

decisions based on automated, consistent and repeatable

measurements followed by rigorous statistical analysis.

Worlds rst mill condition

monitoring technology

Several years of research in applying terrestrial laser scanners to a range of industrial machinery lead to the

development of the worlds first in-situ measurement, modelling and management of liners in grinding mills.

MillMappers globally patented, unique monitoring technology provides accurate measurement of liner thickness,

weight and condition for the entire mill surface.

The intelligent software tracks and forecasts wear on your shell, discharge and feed end liners, providing accurate

information on mill charge and a wide range of metallurgical parameters.

Wear curves for lifters and plates over two different

life cycles

Feed end of SAG mill showing extreme wear patterns on

Inner liner

The advanced data

processing converts

the grey-scale surface

model to a 3D liner

thickness model

Measure Model Manage

Optimizing liner design

Liner designs can be optimized by providing historical

cross-sectional and longitudinal wear plots for

each liner type. Optimized liner design can increase

throughput tonnage, extend reline schedules and

minimize material wastage.

Reline forecasting

Reline forecasts are determined with advanced tonnage-

based modelling techniques specically designed to

capture high wear zones within the mill.

Reline schedules can be optimized with condence, the

advanced forecasting algorithms capture dynamic wear

rates over each liner lifecycle and historical data of

several lifecycles can be compared to the current one.

Quick and simple

A mill scan usually takes between 15 and 30 minutes

which can be simply integrated into regular shutdown

schedules. This means a reduction in the duration of

inspection shutdowns.

MillMapper deliverables

A detailed report from the MillMapper data is generated

within a short time frame. Outotecs highly experienced

MillMapper team reviews these reports and discusses

recommendations in a one-to-one consultation. Sites

are also encouraged to download the 3D models

and reports from their scan and, using the integrated

MillMapper software, can conduct a virtual inspection

of the mill and review, in complete detail, any

particular point.

n Detailed initial wear report

n One-to-one consultation follow-up

n 3D model and software

n Database package of sites wear history

Proven at site

MillMapper has provided clients with crucial

recommendations that have prevented catastrophic

liner failure and subsequent ongoing damage. At one

particular site, imminent relines were recommended

after detecting accelerated wear in several of the mills,

saving over AU$18M in 2009 in potential production

losses and repairs.

Liner wear rates and high wear proles have provided

clients with the ability to forecast changeouts more

accurately. This reliable forecasting has allowed clients

to extend shutdown cycles and liner life. By extending

scheduled shutdowns from 12 to 16 months, one client

was able to save AU$330K in a calendar year, with

an ongoing reduction in operating costs of AU$80K

per annum.

Cross sectional proles shown over complete liner life

A

u

s

t

r

l

a

l

i

a

,

M

a

y

2

0

1

3

.

Improved safety

Laser scanning can be performed remotely by mounting

the scanner on a support beam. Remote scanning

eliminates the need to perform a conned space entry,

thus reducing safety risks, minimizing inspection

downtimes and negating the need for lengthy safety

procedures.

Advantages

Through improved knowledge of liner wear, MillMapper

can optimize the liner life and design, detect early

liner failure and deliver higher overall mill availibility.

MillMapper also has the following benets over

conventional thickness measurement techniques:

n Scanner mounted on a support beam for

remote entry

n Improves safety by eliminating conned

space entry

n Minimizes inspection shutdown times

n Captures wear data on the entire mill

n Reliable reline forecasting

n Optimizes liner designs

n Denes metallurgical parameters

n Identies and prevents catastrophic liner failure

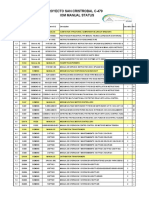

Process Before MillMapper With MillMapper

Liner thickness measurement

20-30 spot measurements with UTG

or basic manual techniques

10 million thickness points captured in as little

as 15 minutes

No entry required

Automated, consistent, repeatable

measurement

Reduced inspection downtime

Evaluate wear patterns

in the mill

Rely on visual inspection and spot

measurements

Colour-coded 3D model and indepth report

indicating accurate wear patterns, cracks and

hotspots

Calculate mill charge

Estimate by counting number of lifters

exposed / rely on inaccurate load cell

Highly accurate charge downtime and mass

measurement derived from scan le

Schedule reline

Based on past history, spot

measurements and estimations

Reliable forecasting

Optimization with tonnage-based wear tracking

Liner prole assessment

Manual spot measurements Liner thickness and prole measurements at all

locations in the mill

services@outotec.com

www.outotec.com

Copyright 2013 Outotec Oyj. All rights reserved.

Outotec provides leading technologies and services for the sustainable use of Earths natural resources.

As the global leader in minerals and metals processing technology, Outotec has developed over

decades many breakthrough technologies. The company also provides innovative solutions

for industrial water treatment, the utilization of alternative energy sources and the

chemical industry. Outotec shares are listed on NASDAQ OMX Helsinki.

Scanner inserted on a beam

You might also like

- Multotec Injection Moulded Screening Systems-Digital-4c504Document6 pagesMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoNo ratings yet

- Kubria Cone Crushers: Cutting-Edge Technology in Hard Rock CrushingDocument5 pagesKubria Cone Crushers: Cutting-Edge Technology in Hard Rock CrushingtonyNo ratings yet

- 236 04-204 Gmax BrochureDocument4 pages236 04-204 Gmax BrochurealtemiraNo ratings yet

- AirScrape Data Sheet en (7364)Document6 pagesAirScrape Data Sheet en (7364)Antonio Marcos SilvaNo ratings yet

- CR600 Sizer Brochure PDFDocument8 pagesCR600 Sizer Brochure PDFAdil DouziNo ratings yet

- NT Features PDFDocument15 pagesNT Features PDFJoel Miguel Angel PachecoNo ratings yet

- HPGR en WebDocument11 pagesHPGR en WebFranciscoNo ratings yet

- 13 18 517-443-A Middle Pulp Lifter Chrome Moly St. 2435: Item Qty. P.D.B. Description Material Ref. WT (KG)Document1 page13 18 517-443-A Middle Pulp Lifter Chrome Moly St. 2435: Item Qty. P.D.B. Description Material Ref. WT (KG)jhonNo ratings yet

- Catalogo Giratorio MetsoDocument5 pagesCatalogo Giratorio MetsoPaulaNo ratings yet

- Wemco 11 BrochureDocument8 pagesWemco 11 Brochuresalvador_10No ratings yet

- 7.2 Crusher Erection and Maintenance Data - FlsmidthDocument3 pages7.2 Crusher Erection and Maintenance Data - FlsmidthWILSON JUAN DE DIOS QUISPE YUPANQUINo ratings yet

- Rocvent Catalogue PDFDocument48 pagesRocvent Catalogue PDFrudarNo ratings yet

- XL1100 BrochureDocument8 pagesXL1100 BrochureCristian Avila ContrerasNo ratings yet

- Plano de Ensamble 3D (60"x113") Traylor "NT" Giratory Crusher Assembly PDFDocument1 pagePlano de Ensamble 3D (60"x113") Traylor "NT" Giratory Crusher Assembly PDFRenato DezaNo ratings yet

- Celdas de FlotacionDocument4 pagesCeldas de FlotacionRodrigo Zura0% (1)

- Manual For Printing8Document401 pagesManual For Printing8betojulio100% (1)

- Pebble Crusher Specific EnergyDocument10 pagesPebble Crusher Specific Energy12milehillNo ratings yet

- 18 Hofmann Hofnuts Brochure A4Document2 pages18 Hofmann Hofnuts Brochure A4Jorge VillalobosNo ratings yet

- Dynamic Modeling and Simulation of Cone Crushing Circuits PDFDocument7 pagesDynamic Modeling and Simulation of Cone Crushing Circuits PDFmarceladeveraNo ratings yet

- Cavity Level’s Effect on Cone Crusher PerformanceDocument15 pagesCavity Level’s Effect on Cone Crusher Performanceavca65No ratings yet

- White Paper On Conveyor Belt CapacityDocument3 pagesWhite Paper On Conveyor Belt Capacityhimangshu mandal100% (1)

- Building The Worlds Largest HPGRDocument21 pagesBuilding The Worlds Largest HPGReyfferNo ratings yet

- Enduron Screens CatalogueDocument12 pagesEnduron Screens Catalogueekrem0867No ratings yet

- CR800 Hybrid Low ResDocument8 pagesCR800 Hybrid Low RestappannNo ratings yet

- Liner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750Document1 pageLiner Assembly-Antamina Project: .63 Total Gap Typical 16 423.21 Available Length 10750jhonNo ratings yet

- MARCY 8 X 6 Ball Mill, Shell, Gear and Liners, Parts UnitDocument2 pagesMARCY 8 X 6 Ball Mill, Shell, Gear and Liners, Parts UnitRicardo Rodriguez100% (1)

- Pans PDFDocument8 pagesPans PDFJorge Prado DiazNo ratings yet

- Fajas TransportadorasDocument11 pagesFajas TransportadorasAnibal Aldava Crispin100% (1)

- David Garcia's 500mm Granite Crushing ProcessDocument1 pageDavid Garcia's 500mm Granite Crushing ProcessDavid GarciaNo ratings yet

- Descripciones H8800Document3 pagesDescripciones H8800jhonNo ratings yet

- Chancador Primario FlsmithDocument15 pagesChancador Primario FlsmithArkadioNo ratings yet

- b5-150 Screens EngDocument7 pagesb5-150 Screens Engjahangir_alam44_6764No ratings yet

- RME Data Sheet - Millmast HandlerDocument1 pageRME Data Sheet - Millmast HandlerСергейNo ratings yet

- Siemens manuals for San Cristobal substation project C-479Document18 pagesSiemens manuals for San Cristobal substation project C-479Allen Marcelo Ballesteros LópezNo ratings yet

- GyratoryCrusher Brochure PDFDocument8 pagesGyratoryCrusher Brochure PDFHerfer FmasNo ratings yet

- Burger 2005 Batu Hijau Mill Throughput ModelDocument21 pagesBurger 2005 Batu Hijau Mill Throughput Modelboanerges wino pattyNo ratings yet

- Automation and Optimization of Primary Gyratory CrusherDocument55 pagesAutomation and Optimization of Primary Gyratory Crusherthe requiem LastNo ratings yet

- OTE Outotec Flotation Technologies Eng WebDocument12 pagesOTE Outotec Flotation Technologies Eng Webpmanquera89No ratings yet

- Gearless Drives For Medium-Power Belt Conveyors: MotionDocument6 pagesGearless Drives For Medium-Power Belt Conveyors: MotionchalogdNo ratings yet

- 11 - Transport Cross-Beam For Roll UnitsDocument43 pages11 - Transport Cross-Beam For Roll UnitsCHRISTIAN ROJAS VALENZUELANo ratings yet

- OTE Thickener Drives Eng Web PDFDocument4 pagesOTE Thickener Drives Eng Web PDFAbdessamad JannaneNo ratings yet

- Kreiselbrecher enDocument7 pagesKreiselbrecher enDiegoAlvarezHuguezNo ratings yet

- RAPTOR Cone CrusherDocument4 pagesRAPTOR Cone CrusherLuis Miguel La TorreNo ratings yet

- RollSizers crush materials with low-height technologyDocument5 pagesRollSizers crush materials with low-height technologyIrvanda ZiaurrahmanNo ratings yet

- Metsim MMD Sizer Simulation Parameters and Crusher CapacitiesDocument6 pagesMetsim MMD Sizer Simulation Parameters and Crusher CapacitiesWalter Andrés OrqueraNo ratings yet

- Optimising gold recovery through advanced control of sulphide gradeDocument15 pagesOptimising gold recovery through advanced control of sulphide grademushava nyoka100% (1)

- Media - Brochures - Brochures For Kilns and Firing - HRBMFloreslowresDocument4 pagesMedia - Brochures - Brochures For Kilns and Firing - HRBMFloreslowresOmar Jesus CocaNo ratings yet

- FlotationTechnology BrochureDocument16 pagesFlotationTechnology BrochureMiguel EduardoNo ratings yet

- HEPICS Whitepaper Improved MP1000 Liner PerformanceDocument3 pagesHEPICS Whitepaper Improved MP1000 Liner PerformanceYousef AlipourNo ratings yet

- COnveyor SkirtsDocument4 pagesCOnveyor SkirtsdivashmNo ratings yet

- Deep Cone Paste ThicknerDocument38 pagesDeep Cone Paste ThicknerzementheadNo ratings yet

- Screen BrochureDocument7 pagesScreen Brochurelrodriguez_892566No ratings yet

- AFG Alpine Fluidised Bed Opposed Jet Mills (En)Document10 pagesAFG Alpine Fluidised Bed Opposed Jet Mills (En)alevandrorNo ratings yet

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Document5 pagesCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonNo ratings yet

- H-E Parts White Paper MP1000 BoddingtonDocument3 pagesH-E Parts White Paper MP1000 BoddingtonJorge VillalobosNo ratings yet

- 1238 Jaw Crusher PDFDocument12 pages1238 Jaw Crusher PDFRasoolKhadibiNo ratings yet

- OTE Outotec CrusherMapper Eng LoresDocument4 pagesOTE Outotec CrusherMapper Eng LoresjadetorresNo ratings yet

- The Use of 3D Scanning in The Turbine Blade Industry.....Document1 pageThe Use of 3D Scanning in The Turbine Blade Industry.....MohanrajRajangamNo ratings yet

- Floormap3d PDFDocument4 pagesFloormap3d PDFSalah JallaliNo ratings yet

- Crushing ScadaDocument1 pageCrushing ScadajadetorresNo ratings yet

- 20230117032741premier Brochure Full - 2023-01 (January 17)Document8 pages20230117032741premier Brochure Full - 2023-01 (January 17)jadetorresNo ratings yet

- Chef'S Top Picks - : Smoked Salmon Bagel - 590 Smoked Salmon Benedict - 675Document9 pagesChef'S Top Picks - : Smoked Salmon Bagel - 590 Smoked Salmon Benedict - 675jadetorresNo ratings yet

- Blue Royale 0 65 BrochureDocument12 pagesBlue Royale 0 65 BrochureAna Patricia SanchezNo ratings yet

- 20160921101425CCX Brochure - FULL - 2016-08 (Aug)Document4 pages20160921101425CCX Brochure - FULL - 2016-08 (Aug)Carlo OlivarNo ratings yet

- Outotec Flotation - TankCell E500Document2 pagesOutotec Flotation - TankCell E500jadetorresNo ratings yet

- Goldroom ScadaDocument1 pageGoldroom ScadajadetorresNo ratings yet

- Grinding ScadaDocument1 pageGrinding ScadajadetorresNo ratings yet

- Water - DAO 90-35Document12 pagesWater - DAO 90-35HjktdmhmNo ratings yet

- Sipart PS2 Electropneumatic PositionersDocument26 pagesSipart PS2 Electropneumatic PositionersjadetorresNo ratings yet

- Liner HandlerDocument1 pageLiner HandlerjadetorresNo ratings yet

- Krebs - GMax BrochureDocument8 pagesKrebs - GMax BrochurejadetorresNo ratings yet

- Ultrasonic LevelDocument2 pagesUltrasonic LeveljadetorresNo ratings yet

- Sitrans T Measuring Instrument For TemperatureDocument56 pagesSitrans T Measuring Instrument For TemperaturejadetorresNo ratings yet

- Sitrans I Isolating Power Supplies & Output IsolatorsDocument8 pagesSitrans I Isolating Power Supplies & Output IsolatorsjadetorresNo ratings yet

- Sitrans L Level InstrumentDocument314 pagesSitrans L Level InstrumentjadetorresNo ratings yet

- Sitrans F FlowmetersDocument338 pagesSitrans F FlowmetersjadetorresNo ratings yet

- OTE Outotec CrusherMapper Eng LoresDocument4 pagesOTE Outotec CrusherMapper Eng LoresjadetorresNo ratings yet

- Process ProtectionDocument26 pagesProcess ProtectionjadetorresNo ratings yet

- Sirius: Selection GuideDocument2 pagesSirius: Selection GuidejadetorresNo ratings yet

- Communication & SoftwareDocument26 pagesCommunication & SoftwarejadetorresNo ratings yet

- Level Measurement GuideDocument21 pagesLevel Measurement GuidejadetorresNo ratings yet

- OTE Outotec Grinding Technologies Eng WebDocument12 pagesOTE Outotec Grinding Technologies Eng WebjadetorresNo ratings yet

- Simocode - Rele InteligenteDocument26 pagesSimocode - Rele InteligenteAlejandro Soto AltamiranoNo ratings yet

- OTE Maintenance Inspection For Grinding Eng WebDocument2 pagesOTE Maintenance Inspection For Grinding Eng WebjadetorresNo ratings yet

- OTE Outotec HIGmills Eng WebDocument4 pagesOTE Outotec HIGmills Eng WebjadetorresNo ratings yet

- Build 02Aug.2006 Sepro Mineral Systems Corp. FALCON SPARES - MODEL 1350B-1401 SB1350B - PHILSAGADocument1 pageBuild 02Aug.2006 Sepro Mineral Systems Corp. FALCON SPARES - MODEL 1350B-1401 SB1350B - PHILSAGAjadetorresNo ratings yet

- R03 IND560drive TM ENDocument40 pagesR03 IND560drive TM ENjadetorresNo ratings yet

- Discharge End Discharge End: Movement 1 Movement 2Document1 pageDischarge End Discharge End: Movement 1 Movement 2jadetorresNo ratings yet

- Progress in Used Tyres Management in The European Union: A ReviewDocument12 pagesProgress in Used Tyres Management in The European Union: A ReviewAnonymous lPFeDds1gANo ratings yet

- IJEP 0010 Styles Et Al FinalDocument15 pagesIJEP 0010 Styles Et Al FinalFonfo LawrenceNo ratings yet

- Hammer MillDocument4 pagesHammer MillLinh Tran100% (2)

- Ribbon BlenderDocument19 pagesRibbon BlenderAzul En AbrilNo ratings yet

- Machines and Processes For The Cement IndustryDocument19 pagesMachines and Processes For The Cement IndustryAli Alshaqah100% (1)

- AMIT 135 - Lesson 5 Crushing - Mining Mill Operator TrainingDocument26 pagesAMIT 135 - Lesson 5 Crushing - Mining Mill Operator Trainingtolun edu100% (1)

- 07 RP-RP in Various ModeDocument43 pages07 RP-RP in Various Modeaff bearNo ratings yet

- EV Catalog Update FinalDocument16 pagesEV Catalog Update FinalveshydNo ratings yet

- Properties of Concrete2, 5th EditionDocument2,866 pagesProperties of Concrete2, 5th EditionUsman Ilyas100% (5)

- Hgi 130501093720 Phpapp01Document20 pagesHgi 130501093720 Phpapp01oscop2009No ratings yet

- Tariff Schedule Final16 17Document30 pagesTariff Schedule Final16 17Vikalp TiwariNo ratings yet

- DG Cement Internship ReportDocument30 pagesDG Cement Internship ReportYasir Haroon100% (2)

- Orica Fragmentation ImDocument5 pagesOrica Fragmentation ImDanu DutoNo ratings yet

- 12 Machinery EbookDocument135 pages12 Machinery EbookPimen AjjahNo ratings yet

- Porciuncula PPrep v.2Document17 pagesPorciuncula PPrep v.2Luiz PorciunculaNo ratings yet

- Roller Mill Equipment Design ReportDocument9 pagesRoller Mill Equipment Design ReportChelseaNo ratings yet

- Tittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant LocationDocument5 pagesTittle: Design Basis: 500MTD TSP. Site Condition: We Have Chosen Feni As Our Plant Locationসাইদুর রহমানNo ratings yet

- Size Reduction Equipments and Grinding System Kaps EngineersDocument4 pagesSize Reduction Equipments and Grinding System Kaps EngineersKrish PatelNo ratings yet

- Miracle Mills 100 Series Hammer Mill: Typical ApplicationsDocument2 pagesMiracle Mills 100 Series Hammer Mill: Typical ApplicationsanderNo ratings yet

- Gamac Series: Grinding Aids For Cement ProductionDocument2 pagesGamac Series: Grinding Aids For Cement Productionmahreza189No ratings yet

- Bhel EpdDocument80 pagesBhel EpdKrs HereNo ratings yet

- Pongkor Process Plant OverviewDocument17 pagesPongkor Process Plant OverviewImam SidikNo ratings yet

- Ball MillDocument7 pagesBall MillAndres Acosta RozoNo ratings yet

- A Project Report On Employee Satisfaction 2Document78 pagesA Project Report On Employee Satisfaction 2Harshal ThakurNo ratings yet

- DYNO-MILL KD - Tomášová Lea, S.R.ODocument3 pagesDYNO-MILL KD - Tomášová Lea, S.R.OBhavin SolankiNo ratings yet

- Project - Final Project For Postgraduate Study University of AbujaDocument39 pagesProject - Final Project For Postgraduate Study University of AbujaFolorunsho AdelekeNo ratings yet

- Reference List of Large Motor StartersDocument30 pagesReference List of Large Motor StartersAndre Juanda100% (1)

- Calcined Alumina Powders DatasheetDocument2 pagesCalcined Alumina Powders Datasheet4spsachinNo ratings yet

- Cemeng Mediagrinding Classifier MillsDocument6 pagesCemeng Mediagrinding Classifier MillsD S VenkateshNo ratings yet