Professional Documents

Culture Documents

Appendix 25 VDA 6 3 Process Audit

Uploaded by

Seda De Drasnia100%(1)100% found this document useful (1 vote)

773 views12 pagesOriginal Title

Appendix_25_VDA_6_3_Process_Audit.xls

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

773 views12 pagesAppendix 25 VDA 6 3 Process Audit

Uploaded by

Seda De DrasniaCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 12

Traceability Audit to Suppliers

SQE / SD- Check-list

Supplier:

Supplier SAP-Number: Part number:

Supplier DUNS-Number: Expedition date:

Supplier's Plant Location: Bar code serial nr.

Participants from Supplier: Delivery note:

Benteler's SQE / SD or Auditor: Production date:

Date: Batch-number:

Accepable Not Acceptable

1. The Supplier is responsible for the traceability

and proper marking of the product during all

phases of production and delivery.

Defined accuracy of containment: marking of single

parts (serial traceability) or batch traceability on

container base, per shift, week, day etc.

The traceability must be assured for all

components.

Are the materials and products identified (labels,

datecode etc.) and is the status clearly visible (blocked,

rework, released etc.)?

Does exist a flow diagram showing the traceability flow?

Is the traceability ensured according to the traceability

reference number after?. Is it ensured also after

repacking procedures?

For example documentation of:

-traceability reference number

-quantity per packaging unit

-material No.

-material descrip

Does the supplier follow the first in - first out principle?

(identification of material, identification of storage

locations etc.)

Traceability Test: Pick up a label of finished

product (ODETTE) and check the traceability at

supplier's facility tracking the product flow until

raw material including the traceability of

parameters

Is the information stored according to legal

requirements, customer requirements and internal

procedures? How is the information stored?. Is the

storage-place protected against fire?

3. Is it ensured the traceability of critical

parameters through all the phases of the

productive process?

Supplier's means of storage information regarding

parameters, for example: electronic files (hard disc),

Documentation of parameters on supplier's official

forms and storage of these documents in safe places in

order to ensure the traceability of paremete

4. Where parts/materials submitted or provided

by Benteler are to be machined or processed,

the supplier must guarantee that his products

can be traced back to the specific delivery note /

batch or serial numbers submitted by Benteler.

Benteler's identification submitted to the supplier . How

the identification of the parts / material match with

Benteler's identifications after processing.

5. Is it guarranteed the traceability for reworked

components or parts going out of the normal

process flow?

How the components return to the normal flow, which

controls are implemented and how these components

or batches are identified. Material flow chart could be

checked in order to identified exactly the places where

the material goes out of the process.

6. Is it guarranteed the traceability for parts

going out for additional process (e.g.

subcontrated processes like washing, coating,

paintig, plating)

To check the supplier's procedure about the

management of product going out for additional

processes. The material flow chart could help to identify

the places where the material goes out and return to the

intern process flow.

7. Does the supplier use labels according to the

Benteler regional specification?

Clear identification of each packaging unit including the

traceability reference number (or with a reference to it),

which must be according to the requirements (e.g.

VDA/Odette, AIAG labels etc.) of the Benteler plant

receiving the product / material.

Lot or batch dimension used by the supplier in

order to assure traceability under the same

identification:

Result Remark: if the traceability can not be

assured, then a detailed report must be

written.

Action plan required until:

Second audit required? Yes No

Date / Signature (Benteler) Date / Signature (Supplier)

Information to trace:

Remarks

Was detected a risk with this lot or batch

dimension?

Traceability requirements

Description /

What to be checked ?

Evaluation (Entry with x)

2. The supplier shall ensure full traceability of

items supplied by him through the

implementation of appropriate technical and

organisational measures.

The possibility of establishing the origin of

primary material and the suppliers production

data at any time must be guaranteed.

The supplier shall guarantee traceability of all

delivery note numbers stated (identity code, ...)

for all individual stages within the production

phases.

PU_38_Supplier-Traceability Check-List.xlt / 5660 / June 2009 / File: 246670598.xls.ms_office

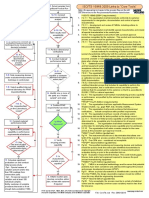

This excel-sheet generates all report pages for the process audit

according to VDA 6.3

Date, audited unit, audited process, auditor and report no. can only

be inputted in the questionnaire , they are generated automatically in

all other sheets.

[Yellow highlighted fields have to be filled manually!!!]

The product-oriented grouping of single process steps to "product

groups" can be done in the "Summary of questions". This has to be

evaluated manually.

The evaluation of the questions must be filled in the questionnaire.

The first page and the action plan can be filled by additional contents.

na = not assessed, not applicable

Report no.:

Audited company/unit

Auditing company / unit

Auditors

Audited process / product / service

Audit Date

Reason for the audit

Degree of conformity 100.0

Remarks to the evaluation:

Remarks to effectiveness check in

related preaudit:

Completion of action plan /

responsibility / Scheduled date

New audit necessary Yes No

Distributor

Sign and Date audited unit

Sign and Date auditor

VDA 6, Part 3 Process Audit

Overall Evaluation

First page - page 3 of 12

Audited Company:

Report no.:

No. Question Notice

1 Product Development Planning

1.1 Are the customer requirements available?

1.2 Is a product development plan available and are the targets maintained?

1.3 Are the resources for the realization of the product development planned?

1.4 Have the product requirements been determined und considered?

1.5 Has the feasibility been determined based on the available requirements?

1.6 Are the necessary personnel and technical conditions for the project process planned/available?

2 Product Development (Design)

2.1 Is the design FMEA raised and are improvement measures established?

2.2 Is the design FMEA updated in the project process and are the established measures realized?

2.3 Is a quality plan prepared?

2.4 Are the required releases/qualification records at the respective times?

2.5 Are the required resources available?

3 Process Development Planning

3.1 Are the product requirements available?

3.2 Is a process development plan available and are the targets maintained?

3.3 Are the resources for the realization of serial production planned?

3.4 Have the process requirements been determined and considered?

3.5 Are the necessary personnel and technical preconditions for the project process planned/available?

3.6 Is the process FMEA raised and are improvement measures established?

4 Realizing Process Development

4.1 Is the process FMEA updated when amendments are made during the project and are the established

measures implemented?

4.2 Is a quality plan prepared?

4.3 Are the required releases / qualification records available at the respective times?

4.4 Is a pre-production carried out under serial conditions for the serial release?

4.5 Are the production and Inspection documents available and complete?

4.6 Are the required resources available?

VDA 6.3 Process Audit

Questionnaire

Auditor(s):

Date:

Value

10

Questionnaire page 4 of 12

Audited Company:

Report no.:

No. Question Notice

Auditor(s):

Date:

Value

B Serial Production

5 Suppliers/ Input Material

5.1 Are only approved quality capable suppliers used?

5.2 Is the agreed quality of the purchase parts guaranteed?

5.3 Is the quality performance evaluated and are corrective actions introduced when there are deviations from

the requirements?

5.4 Are target agreements for continual improvement of products and process made and implemented with

the suppliers?

5.5 Are the required releases for the supplied serial products available and the required improvement

measures implemented?

5.6 Are the procedures agreed with the customer, regarding customer-supplied products, maintained?

5.7 Are the stock levels of input material matched to production needs?

5.8 Are input material/internal residues delivered and stored according to their purpose?

5.9 Is the personnel qualified for the respective tasks?

6 Production

Process step 1

Process step 2

Process step 3

Process step 4

Process step 5

6.1 Personnel / Qualification 1 2 3 4 5

6.1.1 Are the employees given responsibility and monitoring the product/process quality?

6.1.2 Are the employees given responsibility and authority for production equipment and environment?

6.1.3 Are the employees suitable to perform the required tasks and is their qualification maintained?

6.1.4 Is there a personnel plan with a replacement ruling?

6.1.5 Are instruments to increase employee motivation effectively implemented?

6.2 Production Material/ Equipment

6.2.1 Are the product-specific quality requirements fulfilled with the production equipment/tools?

6.2.2 Can the quality requirements be monitored effective during serial production with the implemented

inspection, measuring and test equipment?

6.2.3 Are the work and inspection stations appropriate to the needs?

6.2.4 Are the relevant details in the production and inspection documents complete and maintained?

6.2.5 Are the necessary auxiliary means available for adjustments?

6.2.6 Is an approval for production starts issued and are adjustment details, as well as deviations recorded?

6.2.7 Are the required corrective actions carried out on schedule and checked for effectiveness?

Questionnaire page 5 of 12

Audited Company:

Report no.:

No. Question Notice

Auditor(s):

Date:

Value

6.3 Transport/ Parts Handling/ Storage/Packaging

6.3.1 Are the quantities/ Production lot size matched to the requirements and are they purposefully forwarded

to the next work station?

6.3.2 Are products/components appropriately stored and are the transport means/packaging equipment tuned

to the special properties of the product/ components?

6.3.3 Are rejects, rework and adjustment parts, as well as internal residues strictly separated and identified?

6.3.4 Is the material and parts flow secured against mix ups/ exchanges by mistake and traceability

guaranteed?

6.3.5 Are tools, equipment and inspection, measuring and test equipment stored correctly?

6.4 Fault analysis/Correction/ Continual Improvement

6.4.1 Are quality and process data recorded complete and ready to be evaluated?

6.4.2 Are the quality und process data statistically analysed and are improvement program derived from this?

6.4.3 Are the causes of product and process nonconformities analysed and the corrective actions checked for

their effectiveness?

6.4.4 Are processes and products regularly audited?

6.4.5 Are product and process subject to continual improvement?

6.4.6 Are target parameters available for product und process and is their compliance monitored?

6 Production

Process step 6

Process step 7

Process step 8

Process step 9

Process step 10

6.1 Personnel/ Qualification 6 7 8 9 10

6.1.1 Are the employees given responsibility and monitoring the product/process quality?

6.1.2 Are the employees given responsibility and authority for production equipment and environment?

6.1.3 Are the employees suitable to perform the required tasks and is their qualification maintained?

6.1.4 Is there a personnel plan with a replacement ruling?

6.1.5 Are instruments to increase employee motivation effectively implemented?

6.2 Production Material/ Equipment

6.2.1 Are the product-specific quality requirements fulfilled with tile production equipment/tools?

6.2.2 Can the quality requirements be monitored effective during serial production with the implemented

inspection, measuring and test equipment?

6.2.3 Are the work and inspection stations appropriate to the needs?

6.2.4 Are the relevant details in the production and inspection documents complete and maintained?

6.2.5 Are the necessary auxiliary means available for adjustments?

6.2.6 Is an approval for production starts issued and are adjustment details, as well as deviations recorded?

6.2.7 Are the required corrective actions carried out on schedule and checked for effectiveness?

Questionnaire page 6 of 12

Audited Company:

Report no.:

No. Question Notice

Auditor(s):

Date:

Value

6.3 Transport/ Parts Handling/ Storage/Packaging

6.3.1 Are the quantities/ Production lot size matched to the requirements and are they purposefully forwarded

to the next work station?

6.3.2 Are products/components appropriately stored and are the transport means/packaging equipment tuned

to the special properties of the product/ components?

6.3.3 Are rejects, rework and adjustment parts, as well as internal residues strictly separated and identified?

6.3.4 Is the material and parts flow secured against mix ups/ exchanges by mistake and traceability

guaranteed?

6.3.5 Are tools, equipment and inspection, measuring and test equipment stored correctly?

6.4 Fault analysis/Correction/ Continual Improvement

6.4.1 Are quality and process data recorded complete and ready to be evaluated?

6.4.2 Are the quality und process data statistically analysed and are improvement program derived from this?

6.4.3 Are the causes of product and process nonconformities analysed and the corrective actions checked for

their effectiveness?

6.4.4 Are processes and products regularly audited?

6.4.5 Are product and process subject to continual improvement?

6.4.6 Are target parameters available for product und process and is their compliance monitored?

7 Customer Service, Customer Satisfaction, Service

7.1 Are Customer Requirements Fulfilled at Delivery?

7.2 Is Customer Service guaranteed?

7.3 Are fault analyses carried out when there are deviations from the quality requirements and are

improvement measures implemented?

7.4 Are fault analysis carried out when there are deviations from the quality requirements and are

improvement measures implemented?

7.5 Is the personnel qualified fr each task?

Questionnaire page 7 of 12

Auditierter Bereich 0 prepared by /erstellt von: date / Datum:

Auditierter

Prozess

0 revised by / gendert durch: date / Datum:

action plan No. / Manahmenplan Nr.: 0

Section and

Element

No. / Nr.

Notice / Feststellung Class / Bew.

Corrective and preventive Actions /

Korrektur- und Vorbeugemanahmen

Resposibility /

Verantwortung

(Name)

target date /

Termin 2

5

%

5

0

%

7

5

%

1

0

0

%actual completion

date

comment / Bemerkung

1.1 no findings - no actions necessary

1.2 no findings - no actions necessary

1.3 no findings - no actions necessary

1.4 no findings - no actions necessary

1.5 no findings - no actions necessary

1.6 no findings - no actions necessary

2.1 no findings - no actions necessary

2.2 no findings - no actions necessary

2.3 no findings - no actions necessary

2.4 no findings - no actions necessary

2.5 no findings - no actions necessary

3.1 no findings - no actions necessary

3.2 no findings - no actions necessary

3.3 no findings - no actions necessary

3.4 no findings - no actions necessary

3.5 no findings - no actions necessary

3.6 no findings - no actions necessary

4.1 no findings - no actions necessary

4.2 no findings - no actions necessary

4.3 no findings - no actions necessary

4.4 no findings - no actions necessary

4.5 no findings - no actions necessary

4.6 no findings - no actions necessary

5.1 no findings - no actions necessary

5.2 no findings - no actions necessary

5.3 no findings - no actions necessary

5.4 no findings - no actions necessary

5.5 no findings - no actions necessary

5.6 no findings - no actions necessary

5.7 no findings - no actions necessary

5.8 no findings - no actions necessary

5.9 no findings - no actions necessary

6.1.1 no findings - no actions necessary

6.1.2 no findings - no actions necessary

6.1.3 no findings - no actions necessary

6.1.4 no findings - no actions necessary

6.1.5 no findings - no actions necessary

6.2.1 no findings - no actions necessary

6.2.2 no findings - no actions necessary

6.2.3 no findings - no actions necessary

6.2.4 no findings - no actions necessary

6.2.5 no findings - no actions necessary

6.2.6 no findings - no actions necessary

6.2.7 no findings - no actions necessary

6.3.1 no findings - no actions necessary

6.3.2 no findings - no actions necessary

6.3.3 no findings - no actions necessary

6.3.4 no findings - no actions necessary

6.3.5 no findings - no actions necessary

6.4.1 no findings - no actions necessary

6.4.2 no findings - no actions necessary

6.4.3 no findings - no actions necessary

6.4.4 no findings - no actions necessary

6.4.5 no findings - no actions necessary

6.4.6 no findings - no actions necessary

6.1.1 no findings - no actions necessary

6.1.2 no findings - no actions necessary

6.1.3 no findings - no actions necessary

6.1.4 no findings - no actions necessary

6.1.5 no findings - no actions necessary

6.2.1 no findings - no actions necessary

6.2.2 no findings - no actions necessary

progress / status

VDA 6.3 Process audit

6.2.3 no findings - no actions necessary

6.2.4 no findings - no actions necessary

6.2.5 no findings - no actions necessary

6.2.6 no findings - no actions necessary

6.2.7 no findings - no actions necessary

6.3.1 no findings - no actions necessary

6.3.2 no findings - no actions necessary

6.3.3 no findings - no actions necessary

6.3.4 no findings - no actions necessary

6.3.5 no findings - no actions necessary

6.4.1 no findings - no actions necessary

6.4.2 no findings - no actions necessary

6.4.3 no findings - no actions necessary

6.4.4 no findings - no actions necessary

6.4.5 no findings - no actions necessary

6.4.6 no findings - no actions necessary

7.1 no findings - no actions necessary

7.2 no findings - no actions necessary

7.3 no findings - no actions necessary

7.4 no findings - no actions necessary

7.5 no findings - no actions necessary

A Product development process

a) Product development (Design)

.1 .2 .3 .4 .5 .6 .1 .2 .3 .4 .5

1 Planning 10 2 Realization E

DE

100

b) Process development

.1 .2 .3 .4 .5 .6 .1 .2 .3 .4 .5 .6

3 Planning 4 Realization E

PE

B Serial Production

.1 .2 .3 .4 .5 .6 .7 .8 .9

5 Suppliers / Input material

E

Z

6 Production ( Evaluation per process step)

6.1 Personnel/Qualification 6.2 Production material / Equipment 6.3 Transport/Parts handling 6.4 Fault analysis / Corrections / CIP

.1 .2 .3 .4 .5 .1 .2 .3 .4 .5 .6 .7 .1 .2 .3 .4 .5 .1 .2 .3 .4 .5 .6

Process step 1

E

1

Process step 2

E

2

Process step 3

E

3

Process step 4

E

4

Process step 5

E

5

Process step 6

E

6

Process step 7

E

7

Process step 8

E

8

Process step 9

E

9

Process step 10

E

10

Assessment of the sub-elements with quality system reference Element B6 (Mean value Steps 1-n)

E

U1

(%) E

U2

(%) E

U3

(%) E

U4

(%) E

PG

.1 .2 .3 .4 .5

7 Customer services / satisfaction

E

K

Degree of conformity E

PG

according to product groups Element B6 (%) (Mean value E

1

E

n

)

E

PG

(%)

Overall degree of conformity E

P

:

Comment: Question is not applicable: entry na

Audited process

Product Development Process / Serial Production

VDA 6, Part 3 - Process audit: Summary of the Evaluated Questions

Report No. Date Auditor

100.0

Product groups

Process step

Audited unit

elements evaluated of . No

E E E E E

E

K PG Z PE DE

P

+ + + +

=

Summary of questions page 10 of 12

A Product development process

Evaluation elements

Product development (Design)

E

DE 100

Process development

E

PE

B Serial production

Evaluation elements

Suppliers / Input material

E

Z

Customer services / satisfaction

E

K

E

1

E

2

E

3

E

4

E

5

E

6

E

7

E

8

E

9

E

10

Degree of conformity (Mean value E

1

-E

n

)

E

PG

Evaluation of the sub-elements with quality system reference (Mean value Process steps 1-n)

Sub-elements

Personnel / Qualification

E

U1

Production material / equipment

E

U2

Transport / parts handling / Storage

E

U3

Fault analysis, corrections, CIP

E

U4

Conformity

%

Conformity

%

Product Development Process / Serial Production

VDA 6, Part 3 - Process audit: Summary of the results

Report No.:

Conformity

%

Audited unit:

Date: Auditor:

Audited process:

0 20 40 60 80 100

0 20 40 60 80 100

0 20 40 60 80 100

Summary of results page 11 of 12

Comments

A process problem which may potentially lead to a

product nonconformance and which is not accepted

by the majority of all internal/ external customers.

Examples: apparent optical defect, rework at internal

customer. A claim is also to be expected from

customers with a critical attitude

Unsatisfactory compliance with

requirements, major nonconformities

8

6

4

Evaluation of compliance with

individual requirements

A process problem which may potentially lead to a

product nonconformance and which will surely be

claimed by all internal/ external customers. Examples:

safety risk, missing work steps, damages causing

functional disturbances. Rework at internal customer.

Points

No comments

Deviation from target but without effect on function. A

process problem which may potentially lead to a

product nonconformance but which is hardly claimed

by the internal/ external customer.

0

Full compliance with requirements

Predominant compliance with

requirements, minor nonconformities

Partial compliance with requirements;

more severe nonconformities

No compliance with requirements

10

You might also like

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- VDA6.3 - Engl06 04 04 PDFDocument26 pagesVDA6.3 - Engl06 04 04 PDFjpenjerryNo ratings yet

- Production Part Approval Process A Complete Guide - 2019 EditionFrom EverandProduction Part Approval Process A Complete Guide - 2019 EditionNo ratings yet

- Checklist Audit ISO TS 16949Document14 pagesChecklist Audit ISO TS 16949Demi RamaNo ratings yet

- PPAP ChecklistDocument4 pagesPPAP ChecklistHirbod HirmandNo ratings yet

- The ISO 9001:2015 Implementation Handbook:: Using the Process Approach to Build a Quality Management SystemFrom EverandThe ISO 9001:2015 Implementation Handbook:: Using the Process Approach to Build a Quality Management SystemNo ratings yet

- PPAP Process-Guide ExampleDocument5 pagesPPAP Process-Guide ExampleN.B.P0% (1)

- Apqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderDocument7 pagesApqp 23 Elements What Is APQP 23 Elements?: 1. Customer OrderAdrian Alcorta100% (1)

- 18 Point Ppap Plan Approval-WaiverDocument4 pages18 Point Ppap Plan Approval-WaiverBrenda GillNo ratings yet

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduNo ratings yet

- Excel Tool Prozessaudit VDA 6.3 2010 enDocument29 pagesExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenNo ratings yet

- Questions Process Audit: P2. Project ManagementDocument11 pagesQuestions Process Audit: P2. Project ManagementR JNo ratings yet

- Production Part Approval ProcessDocument6 pagesProduction Part Approval ProcessleonardoNo ratings yet

- Assessment Manual ExamDocument19 pagesAssessment Manual ExamSaurabhNo ratings yet

- C6 TurtleDiagramProductManufacturingProcess产品制造过程乌龟图 EnDocument1 pageC6 TurtleDiagramProductManufacturingProcess产品制造过程乌龟图 EnBAla100% (2)

- VDA 6.3 Process Audit and Checklist For The Car Industry - NimonikAppDocument6 pagesVDA 6.3 Process Audit and Checklist For The Car Industry - NimonikApprodolfo barbosaNo ratings yet

- Aptiv Customer Specific Requirements June 20th 2022Document15 pagesAptiv Customer Specific Requirements June 20th 2022Hosam Elden Mostafa MasaranyNo ratings yet

- IATF Implementation Plan and Co-Ordinator RolesDocument3 pagesIATF Implementation Plan and Co-Ordinator RolesKumaravel50% (2)

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- APQP Sample FormatDocument32 pagesAPQP Sample FormatManigandan RNo ratings yet

- Ppap Level III RequirementsDocument1 pagePpap Level III Requirementsapi-383246575% (4)

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocNo ratings yet

- Process Check Item Method Standard Result Judgement: Index: Auditor: Product Code: Auditee: Lot No: Date: CustomerDocument1 pageProcess Check Item Method Standard Result Judgement: Index: Auditor: Product Code: Auditee: Lot No: Date: CustomerDuy LeNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- APQP Workbook TrainingDocument31 pagesAPQP Workbook TrainingFranciscoNo ratings yet

- IATF 16949 - 2016-Exam Paper With AnswersDocument11 pagesIATF 16949 - 2016-Exam Paper With Answersrashwin singhNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- APQP FormsDocument23 pagesAPQP FormsJOECOOL670% (1)

- Control Plan & FmeaDocument9 pagesControl Plan & FmeaManu SharmaNo ratings yet

- Presentation of The NSA: New Supplier AssessmentDocument35 pagesPresentation of The NSA: New Supplier AssessmentMojtaba MousaviNo ratings yet

- VDA FMEA TemplateDocument53 pagesVDA FMEA Templatewatna0% (2)

- PPAP ChecklistDocument2 pagesPPAP ChecklistSudhagarNo ratings yet

- Layered Process Audit FormDocument3 pagesLayered Process Audit FormPawan Sehrawat100% (7)

- Vda63 Audit Report EnglishDocument8 pagesVda63 Audit Report Englishjhmagagnin100% (1)

- Apqp PlanDocument3 pagesApqp Plananon-448387100% (1)

- Supplier APQP Training SupplementDocument78 pagesSupplier APQP Training SupplementjcperezNo ratings yet

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNo ratings yet

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Sop SeDocument60 pagesSop SemanttupandeyNo ratings yet

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- IATF IA CHecklistDocument2 pagesIATF IA CHecklistDamodaran RajanayagamNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- Guidelines For Control PlanDocument4 pagesGuidelines For Control PlanArjun Rathore100% (1)

- QMS Audit Report Sample IatfDocument39 pagesQMS Audit Report Sample IatfMANGESH100% (2)

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- Ppap ChecklistDocument2 pagesPpap ChecklistTrushant Nakum75% (4)

- Apqp Ppap TrainingDocument2 pagesApqp Ppap TrainingAnkur DhirNo ratings yet

- IATF Audit Observation 21.06.2021-23.06.2021Document6 pagesIATF Audit Observation 21.06.2021-23.06.2021Karan MalhiNo ratings yet

- Turtle DiagramDocument22 pagesTurtle DiagramVikas0% (1)

- Product Audit FormDocument2 pagesProduct Audit Formcong da0% (1)

- Sample of PM DiagramDocument1 pageSample of PM DiagramKarim HakimNo ratings yet

- Pecb Iatf 16949 Lead Auditor Exam Preparation GuideDocument14 pagesPecb Iatf 16949 Lead Auditor Exam Preparation GuideR.BALASUBRAMANI100% (1)

- Problem Solving Tool Template 5DDocument1 pageProblem Solving Tool Template 5DAlex NogueiraNo ratings yet

- IATF 16949 2016 Gap Tool InstructionsDocument11 pagesIATF 16949 2016 Gap Tool InstructionsJosé María Moreno63% (8)

- 8D Report FormatDocument2 pages8D Report Formatwilliamnuevo100% (3)

- VDA6.3 QuestionsDocument17 pagesVDA6.3 QuestionsSónia Queiroz100% (1)

- Daimler-Chrysler Layered Process AuditsDocument27 pagesDaimler-Chrysler Layered Process AuditsR JNo ratings yet

- D451333 eDocument15 pagesD451333 eSeda De DrasniaNo ratings yet

- LSS GB SIPOC Diagram Johnson Anderson2Document2 pagesLSS GB SIPOC Diagram Johnson Anderson2Seda De DrasniaNo ratings yet

- Total Productive Maintenance WorksheetDocument2 pagesTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- Aceptance Agreement 031921 ADocument6 pagesAceptance Agreement 031921 ASeda De DrasniaNo ratings yet

- Reglamento ReachDocument849 pagesReglamento ReachSeda De DrasniaNo ratings yet

- VSM InstructionsDocument34 pagesVSM InstructionsSeda De DrasniaNo ratings yet

- Reach B2O3Document19 pagesReach B2O3Seda De DrasniaNo ratings yet

- Supply Chain Management Project ReportDocument33 pagesSupply Chain Management Project Reportgauravu_5100% (1)

- Perform JaguarDocument8 pagesPerform JaguarSeda De DrasniaNo ratings yet

- Reglamento ReachDocument849 pagesReglamento ReachSeda De DrasniaNo ratings yet

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentSeda De Drasnia100% (4)

- APQP Second EditionDocument113 pagesAPQP Second EditionSeda De DrasniaNo ratings yet

- M - 34106 Cohen KappaDocument8 pagesM - 34106 Cohen KappaSeda De DrasniaNo ratings yet

- Value Stream MappingDocument35 pagesValue Stream MappingNevets NonnacNo ratings yet

- TS16949 Records RequirementDocument2 pagesTS16949 Records RequirementSeda De DrasniaNo ratings yet

- STJLR-99-9999 - Iss 2Document17 pagesSTJLR-99-9999 - Iss 2Seda De DrasniaNo ratings yet

- Perform JaguarDocument8 pagesPerform JaguarSeda De DrasniaNo ratings yet

- STJLR-99-9999 - Iss 2Document17 pagesSTJLR-99-9999 - Iss 2Seda De DrasniaNo ratings yet

- E Commerce Business Plan ExampleDocument22 pagesE Commerce Business Plan Examplegshearod2u100% (2)

- Rate Rebasing Concepts For Public Consultation, MWSSDocument13 pagesRate Rebasing Concepts For Public Consultation, MWSSImperator FuriosaNo ratings yet

- Agility Vs FlexibilityDocument13 pagesAgility Vs FlexibilityDeepakNo ratings yet

- Comparrative Analysis of Npa of Private Sector and Public Sector BankDocument79 pagesComparrative Analysis of Npa of Private Sector and Public Sector Bankhoney sriNo ratings yet

- Operam Academy BIM CoursesDocument19 pagesOperam Academy BIM CoursesShazad LatifNo ratings yet

- Chapter 4 - Part 1Document14 pagesChapter 4 - Part 1billtanNo ratings yet

- Cash AuditDocument9 pagesCash AuditChipo TuyaraNo ratings yet

- 461 110 Falk Torus Elastomeric Coupling CatalogDocument20 pages461 110 Falk Torus Elastomeric Coupling CatalogLazzarus Az GunawanNo ratings yet

- Ijarah BNM PD 2018 PDFDocument62 pagesIjarah BNM PD 2018 PDFaraary86No ratings yet

- C1H021021 - Almas Delian - Resume MIS Bab 1Document2 pagesC1H021021 - Almas Delian - Resume MIS Bab 1Almas DelianNo ratings yet

- Competitive Analysis - How To Conduct A Competitive AnalysisDocument32 pagesCompetitive Analysis - How To Conduct A Competitive AnalysisHaroon AzizNo ratings yet

- A Case Study On RIL vs. RNRL DisputeDocument6 pagesA Case Study On RIL vs. RNRL DisputeAparajita SharmaNo ratings yet

- Procedure For Identification of Aspect Impact & HIRADocument1 pageProcedure For Identification of Aspect Impact & HIRAArjun Rathore100% (2)

- Cola WarsDocument24 pagesCola WarsPradIpta Kaphle100% (3)

- Performance ApprisalDocument7 pagesPerformance ApprisalSHERMIN AKTHER RUMANo ratings yet

- Project ManagementxxDocument34 pagesProject ManagementxxAli Akand AsifNo ratings yet

- Paper Uad Submit ReviewDocument5 pagesPaper Uad Submit Reviewpelangi puspaNo ratings yet

- TOGAF 9.1 - Level 1 and 2 Student Handbook - ITpreneurs PDFDocument64 pagesTOGAF 9.1 - Level 1 and 2 Student Handbook - ITpreneurs PDFZain AtifNo ratings yet

- Busman 106 Activity Sheet No. 1Document2 pagesBusman 106 Activity Sheet No. 1melanie jadeNo ratings yet

- Competency Model BooksDocument4 pagesCompetency Model Bookshoa quynh anhNo ratings yet

- EY Global Fraud SurveyDocument28 pagesEY Global Fraud SurveyannnooonnyyyymmousssNo ratings yet

- SAP IS Blue Print DocumentDocument4 pagesSAP IS Blue Print DocumentSupriyo DuttaNo ratings yet

- Nestle GlobalizationDocument30 pagesNestle GlobalizationDaryll Peter Griffith60% (5)

- LBO Model - ValuationDocument6 pagesLBO Model - ValuationsashaathrgNo ratings yet

- International College of Business and Technology Btec HND Diploma in Business (Management & Human Resources) Assignment Cover Sheet 2014/2015Document25 pagesInternational College of Business and Technology Btec HND Diploma in Business (Management & Human Resources) Assignment Cover Sheet 2014/2015nileshdilushanNo ratings yet

- Rajaram Exam Fees P16mba7Document2 pagesRajaram Exam Fees P16mba7Encom VeluNo ratings yet

- Y Combinator S Pocket Guide To Seed Fundraising 1692908038Document1 pageY Combinator S Pocket Guide To Seed Fundraising 1692908038DanNo ratings yet

- Unit 5 - Partnership ActDocument28 pagesUnit 5 - Partnership ActNataraj PNo ratings yet

- Pas1192 6 2018Document76 pagesPas1192 6 2018JohnNo ratings yet

- SAP - Customizing Guide: Printed by Ahmad RizkiDocument11 pagesSAP - Customizing Guide: Printed by Ahmad RizkiJosé FaiaNo ratings yet