Professional Documents

Culture Documents

Afterburner - Gas Turbine, Turbojet, Turbofan) Rolls Royce - T PDF

Uploaded by

Estevam Gomes de Azevedo100%(1)100% found this document useful (1 vote)

676 views11 pagesAfterburning is a method used to augment the thrust of jet engines by injecting and burning additional fuel in the jet exhaust. This increases the temperature and velocity of the exhaust, providing more thrust. The key aspects of afterburning are:

1) Additional fuel is burned in the jet pipe between the engine turbine and propelling nozzle, using the oxygen in the exhaust gases.

2) A variable area propelling nozzle is required to accommodate the increased exhaust flow during afterburning and prevent pressure increases.

3) Afterburning provides increased thrust but also significantly higher fuel consumption compared to normal engine operation.

Original Description:

Original Title

Afterburner - Gas turbine, turbojet, turbofan) Rolls Royce - T.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAfterburning is a method used to augment the thrust of jet engines by injecting and burning additional fuel in the jet exhaust. This increases the temperature and velocity of the exhaust, providing more thrust. The key aspects of afterburning are:

1) Additional fuel is burned in the jet pipe between the engine turbine and propelling nozzle, using the oxygen in the exhaust gases.

2) A variable area propelling nozzle is required to accommodate the increased exhaust flow during afterburning and prevent pressure increases.

3) Afterburning provides increased thrust but also significantly higher fuel consumption compared to normal engine operation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

676 views11 pagesAfterburner - Gas Turbine, Turbojet, Turbofan) Rolls Royce - T PDF

Uploaded by

Estevam Gomes de AzevedoAfterburning is a method used to augment the thrust of jet engines by injecting and burning additional fuel in the jet exhaust. This increases the temperature and velocity of the exhaust, providing more thrust. The key aspects of afterburning are:

1) Additional fuel is burned in the jet pipe between the engine turbine and propelling nozzle, using the oxygen in the exhaust gases.

2) A variable area propelling nozzle is required to accommodate the increased exhaust flow during afterburning and prevent pressure increases.

3) Afterburning provides increased thrust but also significantly higher fuel consumption compared to normal engine operation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

16: Afterburning

Contents

Introduction

Operation of afterburning

Construction

Burners

Jet pipe

Propelling nozzle

Control system

Thrust increase

Fuel consumption

INTRODUCTION

1. Afterburning (or reheat) is a method of

‘augmenting the basic thrust of an engine to improve

the aircraft take-off, climb and (for military aircraft)

combat performance. The increased power could be

obtained by the use of a larger engine, but as this

‘would increase the weight, frontal area and overall

fuel consumption, afterburning provides the best

method of thrust augmentation for short periods.

Page

169

170

173

173

175

178

2. Afterburning consists of the introduction and

‘burning of fuel between the engine turbine and the jet

pipe propelling nozzle, utilzing the unburned oxygen

in the exhaust gas to support combustion (fig. 16-1).

‘The resultant increase in the temperature of the

exhaust gas gives an increased velocity of the jet

leaving the propelling nozzle and therefore increases

the engine thrust.

3. As the temperature of the afterburner flame can

be in excess of 1,700 deg. C., the bumers are usually

arranged so that the flame is concentrated around

the axis ofthe jet pipe. This allows a proportion of the

‘turbine discharge gas to flow along the wall of the jt

pipe and thus maintain the wall temperature at a safe

value,

169

BY-PASS AIRFLOW

AFTERBURNER

Fig. 16-1. Principle of afterburning

4. The area of the afterburning jet pipe is largerthan

‘2 normal jet pipe would be for the same engine, to

obtain a reduced velocity gas stream To provide for

‘operation under all conditions, an afterbumning jet

pipe is fitted with either a two-posttion or a variable-

area propelling nozzle (fig. 16-2). The nozzle is

closed during non-afterburning operation, but when

afterburning is selected the gas temperature

increases and the nozzle opens to give an exit area

suitable for the resultant increase in the volume of

the gas stream. This prevents any increase in

pressure occurring in the jet pipe which would affect

‘the functioning of the engine and enables afterburn-

ing to be used over a wide range of engine speeds.

5. The thrust of an afferburning engine, without

afterburning in operation, is slightly less than that of

a similar engine not fitted with afterburning

‘equipment; this is due to the added restrictions in the

Jet pipe. The overall weight of the power plant is also

increased because of the heavier jet pipe and after-

‘burning equipment

6. Afterburning is achieved on low by-pass engines

by mixing the by-pass and turbine streams before the

afterburner fuel injection and stabilizer system is

reached so that the combustion takes place in the

170

COOLING FLOW

JET PIPE

NOZZLE OPERATING

SLEEVE

VARIABLE

PROPELLING NOZZLE

mixed exhaust stream. An altemative method is to

inject the fuel and stabilize the flame in the individual

by-pass and turbine streams, burning the available

gases up to a common exit temperature at the final

‘nozzle, In this method, the fuel injection is scheduled

separately to the individual streams and it is normal

to provide some form of interconnection between the

flame stabilizers in the hot and cold streams to assist

the combustion processes in the cold by-pass air

OPERATION OF AFTERBURNING

7. The gas stream from the engine turbine enters

the jet pipe at a velocity of 750 to 1,200 feet per

ssecand, but as this velocity is far too high for a stable

flame to be maintained, the flow is diffused before it

enters the afterburner combustion zone, Le. the flow

velocity is reduced and the pressure is increased.

However, as the speed of burning kerosine at normal

mixture ratios is only a few feet per second, any fuel

lit even in the diffused air stream would be blown

away. A form of flame stabilizer (vapour gutter) is,

therefore, located downstream of the fuel bumers to

provide a region in which turbulent eddies are formed

to assist combustion and where the local gas velocity

is further reduced to a figure at which flame stabi

lization occurs whilst combustion is in operation.

MOVABLE EYELIDS

EYELID OPERATING RAMS

Nozze TWO-POSITION NOZZLE

OPERATING RAMS

VARIABLE-AREA NOZZLE

INTERLOCKING FLAPS

Fig. 16-2 Examples of afterburning jet pipes and propelling nozzles.

im

You might also like

- Design of Gas Turbine Combustion ChamberDocument11 pagesDesign of Gas Turbine Combustion ChamberSai Rahul100% (1)

- Mini Jet EngineDocument3 pagesMini Jet EngineGOWRRAJU ANILNo ratings yet

- AMTE 213 Gas Turbine EngineDocument6 pagesAMTE 213 Gas Turbine EngineanonimusNo ratings yet

- Stabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesFrom EverandStabilization and Dynamic of Premixed Swirling Flames: Prevaporized, Stratified, Partially, and Fully Premixed RegimesNo ratings yet

- Understanding The 914 RotaxDocument15 pagesUnderstanding The 914 Rotaxpride3351No ratings yet

- Gas Turbine Combustion Chamber Design Aspects & Current TrendsDocument24 pagesGas Turbine Combustion Chamber Design Aspects & Current TrendsPRAVEENNo ratings yet

- 2.2-AGKS Jet Engine + ApuDocument48 pages2.2-AGKS Jet Engine + ApuDavid Nicolau FernandezNo ratings yet

- BSIDocument112 pagesBSIaliNo ratings yet

- Performance Characteristics of Axial FansDocument4 pagesPerformance Characteristics of Axial Fanskutts76No ratings yet

- Afterburner ReviewDocument34 pagesAfterburner ReviewMASOUD100% (2)

- Engine Start Sys ShowDocument26 pagesEngine Start Sys ShowInterogator5No ratings yet

- List of Turbine Blade Materials: CoolingDocument4 pagesList of Turbine Blade Materials: CoolingNah Sr AdNo ratings yet

- Controller - PM866Document4 pagesController - PM866DIEGO FELIPE VEGANo ratings yet

- LMS100 Cut AwayDocument1 pageLMS100 Cut Awayjcarella_1No ratings yet

- 601 - Helicopter Turboshaft EngineDocument13 pages601 - Helicopter Turboshaft EngineVishnu SankarNo ratings yet

- Magneto Ignition SystemDocument1 pageMagneto Ignition SystemUrban TravelNo ratings yet

- Jet PropulsionDocument45 pagesJet PropulsionPranay SahuNo ratings yet

- 30508Document36 pages30508Raphael Felipe Gama RibeiroNo ratings yet

- Environmental Control System: This Article Needs AdditionalDocument15 pagesEnvironmental Control System: This Article Needs AdditionalDhanashree ShaligramNo ratings yet

- GE Turbine n1 n2 PercentDocument10 pagesGE Turbine n1 n2 PercentYukihira SoumaNo ratings yet

- Fans Guide 79037EDocument83 pagesFans Guide 79037EPaul Healy100% (1)

- Conceptual Development of Quiet Turbofan Engines For Supersonic AircraftDocument9 pagesConceptual Development of Quiet Turbofan Engines For Supersonic AircraftVimal ChandNo ratings yet

- Topic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByDocument16 pagesTopic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByTanvi KhuranaNo ratings yet

- Heavy-Duty Gas Turbine T16Document13 pagesHeavy-Duty Gas Turbine T16Zafar AhmedNo ratings yet

- MANDocument6 pagesMANMadhana GopalNo ratings yet

- R-11 Turbojet Engine Specification: ConstructionDocument2 pagesR-11 Turbojet Engine Specification: ConstructionmauryapiaeNo ratings yet

- Ops-Core Dh-132 HelmetDocument4 pagesOps-Core Dh-132 HelmetDenbe SantosNo ratings yet

- Valved Two Stroke EngineDocument10 pagesValved Two Stroke EngineBlaž VerdevNo ratings yet

- Turbofan EngineDocument46 pagesTurbofan EngineBookMaggotNo ratings yet

- Lesson 13 TurbomachineryDocument33 pagesLesson 13 TurbomachineryThomas ParentNo ratings yet

- CFD Assignment 1 (30052157)Document15 pagesCFD Assignment 1 (30052157)Nimesh IshankaNo ratings yet

- Jet PropulsionDocument40 pagesJet PropulsionDileep Kumar Manjhi100% (1)

- Kurzke Achieving Maximum Thermal Efficiency enDocument12 pagesKurzke Achieving Maximum Thermal Efficiency enbfehrmNo ratings yet

- Marine Gas Turbine: PerformanceDocument2 pagesMarine Gas Turbine: PerformanceFederico PinnaNo ratings yet

- Factors Affecting ThrustDocument4 pagesFactors Affecting ThrustShabeer830100% (2)

- Simple Thermodynamics of Jet EnginesDocument6 pagesSimple Thermodynamics of Jet EnginesKok CheongNo ratings yet

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Document227 pagesVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladNo ratings yet

- Brayton Cycle Experiment - Jet EngineDocument10 pagesBrayton Cycle Experiment - Jet EngineAsif MohammedNo ratings yet

- WOW Jet Engines 2019 SDocument80 pagesWOW Jet Engines 2019 SHassan MoazenNo ratings yet

- Turby en Application V3.0Document16 pagesTurby en Application V3.0BOEING21No ratings yet

- 18 Brayton Cycle-Jet EngineDocument14 pages18 Brayton Cycle-Jet Engineinam vfNo ratings yet

- KadenancyEffectAcousticalResonanceEffectValveless Camera ReadyDocument9 pagesKadenancyEffectAcousticalResonanceEffectValveless Camera ReadyAnonymous oyUAtpKNo ratings yet

- En tp100Document2 pagesEn tp100Arne BergmanNo ratings yet

- Gas Turbine Performance by Rainer KurzDocument16 pagesGas Turbine Performance by Rainer KurzSulzerRuudNo ratings yet

- Basic GT EngineDocument22 pagesBasic GT EngineabuhurairamunirNo ratings yet

- MQ-9 DatasheetDocument3 pagesMQ-9 Datasheetshedboy71No ratings yet

- Parker TubingDocument85 pagesParker TubingPatrick StivénNo ratings yet

- Nozzle Selection and Design CriteriaDocument11 pagesNozzle Selection and Design CriteriajbmccavalcantiNo ratings yet

- Aiaa/Asme/Sae/Asee 24Th Joint Propulsion ConferenceDocument7 pagesAiaa/Asme/Sae/Asee 24Th Joint Propulsion ConferenceMorgen GumpNo ratings yet

- Gas Turbine SpecificationDocument94 pagesGas Turbine SpecificationAbRoxNo ratings yet

- Jet Engine Starting and Ignition SystemDocument5 pagesJet Engine Starting and Ignition SystemGopesh ObalappaNo ratings yet

- Turbojet EngineDocument33 pagesTurbojet EngineAqish ShaikhNo ratings yet

- Protection and Condition Monitoring of The LM5000 Gas TurbineDocument9 pagesProtection and Condition Monitoring of The LM5000 Gas TurbineSudeshNo ratings yet

- Turbines - Real-Time Modeling Methods For Gas T (BookFi - Org) Turbines - Real-Time - Modeling - Methods - For - Gas - T PDFDocument95 pagesTurbines - Real-Time Modeling Methods For Gas T (BookFi - Org) Turbines - Real-Time - Modeling - Methods - For - Gas - T PDFAbbas MohajerNo ratings yet

- RocketDocument19 pagesRocketapi-305077843No ratings yet

- Aerodynamics and Aircraft PropulsionDocument25 pagesAerodynamics and Aircraft PropulsionNarendra PalandeNo ratings yet

- 2007 CatalogDocument129 pages2007 CatalogmendperNo ratings yet

- Afterburner NotesDocument2 pagesAfterburner NotesGame Technical And ReviewNo ratings yet

- Gas Turbine - Traning Report Bhel - 14 PageDocument14 pagesGas Turbine - Traning Report Bhel - 14 PageVivek PatelNo ratings yet

- Wollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentDocument6 pagesWollo University: Kombolcha Institute of Technology Mechanical Engineering DepartmentMelie BackNo ratings yet

- 43-204 Aircraft Visual Inspection-FAA ACDocument236 pages43-204 Aircraft Visual Inspection-FAA ACTDHNo ratings yet

- Lista de Aeronaves e Respectivos Motores AplicadosDocument1 pageLista de Aeronaves e Respectivos Motores AplicadosEstevam Gomes de AzevedoNo ratings yet

- 01srt Training Booklet 2019 Softcopy FinalDocument58 pages01srt Training Booklet 2019 Softcopy FinalAnonymous GNBs2mXX0DNo ratings yet

- 7 Aircraft Consumable Secrets Every Buyer Should KnowDocument6 pages7 Aircraft Consumable Secrets Every Buyer Should KnowEstevam Gomes de AzevedoNo ratings yet

- Lista de Aeronaves e Respectivos Motores AplicadosDocument1 pageLista de Aeronaves e Respectivos Motores AplicadosEstevam Gomes de AzevedoNo ratings yet

- Inspection Fundamentals PDFDocument34 pagesInspection Fundamentals PDFdikshaNo ratings yet

- RB211-535C/E4/E4B: User Guide SB Catego RiesDocument1 pageRB211-535C/E4/E4B: User Guide SB Catego RiesEstevam Gomes de AzevedoNo ratings yet

- Embraer 190 SeatsDocument13 pagesEmbraer 190 SeatsEstevam Gomes de AzevedoNo ratings yet

- 4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190Document58 pages4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190AHMEDNo ratings yet

- A320Document8 pagesA320Estevam Gomes de Azevedo50% (2)

- 4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190Document58 pages4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190AHMEDNo ratings yet

- Avianca RotablesDocument42 pagesAvianca RotablesEstevam Gomes de AzevedoNo ratings yet

- FAA AlertDocument123 pagesFAA AlertEstevam Gomes de AzevedoNo ratings yet

- Executive Summary # Hk4455Document1 pageExecutive Summary # Hk4455Estevam Gomes de AzevedoNo ratings yet

- CICARÉ SVH4 - Technical Caracteristics (NP)Document2 pagesCICARÉ SVH4 - Technical Caracteristics (NP)Estevam Gomes de AzevedoNo ratings yet

- 4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190Document58 pages4o - Encontro Anual de Investidores Da Embraer - Programa EMBRAER 170-190AHMEDNo ratings yet

- Jabiru JEM0001-8 - Engine Overhaul ManualDocument200 pagesJabiru JEM0001-8 - Engine Overhaul ManualEstevam Gomes de Azevedo100% (1)

- CICARÉ 12 - Technical CaracteristicsDocument2 pagesCICARÉ 12 - Technical CaracteristicsEstevam Gomes de AzevedoNo ratings yet

- LM5000 V004t16a004-85-Gt-26 PDFDocument7 pagesLM5000 V004t16a004-85-Gt-26 PDFEstevam Gomes de AzevedoNo ratings yet

- Rolls-Royce GnomeDocument48 pagesRolls-Royce GnomeEstevam Gomes de Azevedo100% (2)

- CICARÉ 7B - Technical CaracteristicsDocument2 pagesCICARÉ 7B - Technical CaracteristicsEstevam Gomes de AzevedoNo ratings yet

- CICARÉ 12 - Technical CaracteristicsDocument2 pagesCICARÉ 12 - Technical CaracteristicsEstevam Gomes de AzevedoNo ratings yet

- CICARÉ 12 - Technical CaracteristicsDocument2 pagesCICARÉ 12 - Technical CaracteristicsEstevam Gomes de AzevedoNo ratings yet

- CICARÉ 7B - Technical CaracteristicsDocument2 pagesCICARÉ 7B - Technical CaracteristicsEstevam Gomes de AzevedoNo ratings yet

- Albatros Leporelo L39Document7 pagesAlbatros Leporelo L39Estevam Gomes de AzevedoNo ratings yet

- Ac43 209Document70 pagesAc43 209Estevam Gomes de Azevedo100% (1)

- Systems Descriptions Auxiliary Power Unit: Issue 002Document10 pagesSystems Descriptions Auxiliary Power Unit: Issue 002Estevam Gomes de AzevedoNo ratings yet

- Airbus 49 A300 A310 Auxiliary Power Unit APU PDFDocument141 pagesAirbus 49 A300 A310 Auxiliary Power Unit APU PDFEstevam Gomes de Azevedo100% (1)

- Albatros Leporelo L39 PDFDocument24 pagesAlbatros Leporelo L39 PDFEstevam Gomes de Azevedo100% (3)

- AAK Newsletter-June-2016 N°1Document4 pagesAAK Newsletter-June-2016 N°1EstevamNo ratings yet

- Hssive-Xi-Chem-4. Chemical Bonding and Molecular Structure Q & ADocument11 pagesHssive-Xi-Chem-4. Chemical Bonding and Molecular Structure Q & AArties MNo ratings yet

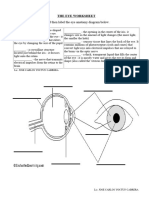

- The Eye WorksheetDocument3 pagesThe Eye WorksheetCally ChewNo ratings yet

- Luxi User's GuideDocument14 pagesLuxi User's GuidephilsouthNo ratings yet

- Aloe Vera An Ancient Herb For Modern Dentistry-A LDocument7 pagesAloe Vera An Ancient Herb For Modern Dentistry-A LRuth Ransel Yadao ValentinNo ratings yet

- QFW Series SteamDocument8 pagesQFW Series Steamnikon_fa50% (2)

- Burj Khalifa: Engineer Abdul MananDocument29 pagesBurj Khalifa: Engineer Abdul MananabdulmananNo ratings yet

- Opentext Documentum Archive Services For Sap: Configuration GuideDocument38 pagesOpentext Documentum Archive Services For Sap: Configuration GuideDoond adminNo ratings yet

- Elad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086Document61 pagesElad Shapira - Shall We Play A Game - Lessons Learned While Playing CoreWars8086james wrightNo ratings yet

- Competent Testing Requirements As Per Factory ActDocument3 pagesCompetent Testing Requirements As Per Factory Actamit_lunia100% (1)

- Th-Sunday Magazine 6 - 2Document8 pagesTh-Sunday Magazine 6 - 2NianotinoNo ratings yet

- GMDSSDocument1 pageGMDSSRahul rajeshNo ratings yet

- DCNF Vs Hhs Nov 2020Document302 pagesDCNF Vs Hhs Nov 2020SY LodhiNo ratings yet

- Mod 2 MC - GSM, GPRSDocument61 pagesMod 2 MC - GSM, GPRSIrene JosephNo ratings yet

- His 101 Final ReportDocument15 pagesHis 101 Final ReportShohanur RahmanNo ratings yet

- Blank Freeway Walls Replaced With Local Designs - Press EnterpriseDocument5 pagesBlank Freeway Walls Replaced With Local Designs - Press EnterpriseEmmanuel Cuauhtémoc Ramos BarajasNo ratings yet

- Richard IIIDocument36 pagesRichard IIIXuan Mai Nguyen ThiNo ratings yet

- Design of Ka-Band Low Noise Amplifier Using CMOS TechnologyDocument6 pagesDesign of Ka-Band Low Noise Amplifier Using CMOS TechnologyEditor IJRITCCNo ratings yet

- VDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentDocument36 pagesVDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentR JNo ratings yet

- Annual Report 2022 2Document48 pagesAnnual Report 2022 2Dejan ReljinNo ratings yet

- Zanussi Parts & Accessories - Search Results3 - 91189203300Document4 pagesZanussi Parts & Accessories - Search Results3 - 91189203300Melissa WilliamsNo ratings yet

- Hydrotest Test FormatDocument27 pagesHydrotest Test FormatRähûl Prätäp SïnghNo ratings yet

- The Meanings of Goddess PT IIIDocument14 pagesThe Meanings of Goddess PT IIILevonce68No ratings yet

- Lesson Tasks: Lesson Plan: Addition and Subtraction To 20Document2 pagesLesson Tasks: Lesson Plan: Addition and Subtraction To 20Марина СтанојевићNo ratings yet

- System Administration ch01Document15 pagesSystem Administration ch01api-247871582No ratings yet

- Vishakha BroadbandDocument6 pagesVishakha Broadbandvishakha sonawaneNo ratings yet

- ENGL102 Othello Act 3 Discussion QuestionsDocument2 pagesENGL102 Othello Act 3 Discussion QuestionsDaniel DenningNo ratings yet

- A Review On PRT in IndiaDocument21 pagesA Review On PRT in IndiaChalavadi VasavadattaNo ratings yet

- RA-035659 - CIVIL ENGINEER - Cebu - 5-2022Document157 pagesRA-035659 - CIVIL ENGINEER - Cebu - 5-2022Ash AlbainNo ratings yet

- Syllabus: Cambridge IGCSE (9-1) Art & Design 0989Document27 pagesSyllabus: Cambridge IGCSE (9-1) Art & Design 0989Jashan LoombaNo ratings yet

- M 995Document43 pagesM 995Hossam AliNo ratings yet