Professional Documents

Culture Documents

k3fDV2A Sheet PDF

Uploaded by

Gabriel Dental0 ratings0% found this document useful (0 votes)

49 views2 pagesOriginal Title

k3fDV2A_sheet.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views2 pagesk3fDV2A Sheet PDF

Uploaded by

Gabriel DentalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

LG Programmable Logic Controller

Digital to Analog Conversion Module

K3F-DV2A

K3F-DI2A

Beijing Branch Bangkok Branch

LG Industrial Systems Elevator Co., Ltd. LG Industrial Systems (Thailand) Co., Ltd

T : +86-10-6462-3256 T : +66-2-381-8443

F : +86-10-6462-3255 F : +66-2-381-8445

Bogota Branch Chicago Branch

LG Industrial Systems de Colombia S.A. LG Industrial Systems Co., Ltd. Chicago Office

T : +57-1-310-6077 T : +1-708-692-4500

F : +57-1-310-5831 F : +1-708-692-4501

Dalian Branch Hanoi Branch

Dalian LG Industrial Systems Co., Ltd. LG Industrial Systems Co., Ltd. Hanoi Office

T : +86-411-281-2579 T : +64-4-821-0388

F : +86-411-281-2578 F : +64-4-821-0399

Hong Kong Branch Shanghai Branch

LG Industrial Systems (HK) Ltd. Shanghai LG Industrial Systems Co., Ltd.

T : +852-2598-6615 T : +86-21-6248-2710

F : +852-2598-7105 F : +86-216248-3236

Singapore Branch Taipei Branch

LG Industrial Systems Co., Ltd. LG Industrial Systems (Taiwan) Co. Ltd.

T : +65-323-7361 T : +886-2-516-5010

F : +65-323-7362 F : +886-2-516-5035

Tokyo Branch

LG Industrial Systems Co., Ltd. Tokyo Office

T : +81-3-3589-6362

F : +81-3-3588-1810

LG Industrial Systems Co., Ltd.

Head Office

LG Mullae Building 9

th

F, 10, Mullae-dong 6-ga, Yongdungpo-gu, Seoul, KOREA

Tel : +82-2-2006-3751~6 Fax : +82-2-2006-3951

Home page : http:www.lgis.lg.co.kr/fa

Before handling the product

Read this data sheet carefully prior to any operation, mounting, installation or

start-up of the product.

Materials for MASTE-K

Name Code

MASTER-K KGL-WIN (Programming Software) 702005036

MASTER-K (Instructions & programming) 702006539

MASTER-K CPU Users Manual 702006391

MASTER-K K4F-DV3A/K4F-DV2A/K4F-DI3A/K4F-DI2A/

K3F-DV2A/K3F-DI2A Manual

702006460

Name Code

MASTER-K K3F-DV2A/K3F-DI2A Data Sheet 702006222

Safety Precautions

Be sure to read carefully the safety precautions given in data sheet and users manual before

operating the module and follow them.

The precautions explained here only apply to the K3F-DV2A and K3F-DI2A.

For safety precautions on the PLC system, see the MASTER-K CPU Users Manual.

A precaution is given with a hazard alert triangular symbol to call your attention, and

precautions are represented as follows according to the degree of hazard.

However, a precaution followed with can also result in serious conditions.

Both of two symbols indicate that an important content is mentioned, therefore, be sure to observe

it. Keep this manual handy for your quick reference in necessary.

Design Precautions

Design a safety circuit in the outside of the PLC for system safety in case of disorder of the

external power or PLC module body. Otherwise, it can cause injury due to wrong output or

malfunction.

1) The following shows analog output states.

Channel Specification

Channel Setting

State Used Unused

PLC CPU in RUN state

D/A Conversion

value is output

PLC CPU in STOP state

Voltage : 0V

Current : 4

PLC CPU in Error state Previous value

Voltage : 0V

Current : 4

2) Sometimes, fault of output device or internal circuit can make output abnormal. Design a

supervising circuit in the outside for output signals which can cause serious accidents

Do not run I/O signal lines near to high voltage line or power line.

Separate them as 100 mm or more as possible. Otherwise, noise can cause module

malfunction.

Installation Precautions

Operate the PLC in the environment conditions given in the general specifications.

If operated in other environment not specified in the general specifications, it can

cause an electric shock, a fire, malfunction or damage or degradation of the module.

Make sure the module fixing pro-jections is inserted into the module fixing hole and fixed.

Improper installation of the module can cause malfunction, disorder or falling.

Wiring Precautions

When grounding a FG terminal, be sure to provide class 3 grounding which is dedicated to

the PLC.

Before the PLC wiring, be sure to check the rated voltage and terminal arrangement for the

module and observe them correctly. If a different power, not of the rated voltage, is applied or

wrong wiring is provided, it can cause a fire or disorder of the nodule.

Drive the terminal screws firmly to the defined torque.

If loosely driven, it can cause short circuit, a fire or malfunction.

Be careful that any foreign matter like wire scraps should not enter into the module.

It can cause a fire, disorder or malfunction.

Test RUN and Maintenance Precautions

Do not contact the terminals while the power is applied. It can cause malfunction.

When cleaning or driving a terminal screw, perform them after the power has been turned off.

Do not perform works while the power is applied, which can cause disorder or malfunction.

Do not separate the module from the printed circuit board(PCB), or do not remodel

the module. They can cause disorder, malfunction, damage of the module or a fire.

When mounting or dismounting the module, perform them after the power has been turned off.

Do not perform works while the power is applied, which can cause disorder or malfunction.

Waste Disposal Precautions

When disposing the module, do it as an industrial waste.

1. Introduction

The G6F-DA2V/G6F-DA2I is digital/analog conversion module for use with the GLOFA PLC GM6

series CPU modules. The D/A conversion module is to convert a 12-bit signed binary digital value

to an analog output signal(Voltage or Current).

2. General Specifications

No Item Specifications Standard

1

Operating

temperature

0 ~ 55

2 Storage temperature -25 ~ 70

3 Operating Humidity 5 ~ 95%RH, non-condensing

4 Storage humidity 5 ~ 95%RH, non-condensing

Occasional vibration

Frequency Acceleration Amplitude

Sweep

count

10 f57 Hz - 0.075 mm

57 f 150 Hz 9.8 {1G} -

Continuos vibration

Frequency Acceleration Amplitude

10 f57 Hz - 0.035 mm

5 Vibration

57 f 150 Hz 4.9{0.5G} -

10 times in

each

direction for

X, Y, Z

IEC 1131-2

6 Shocks

*Maximum shock acceleration: 147 {15G}

*Duration time :11 ms

*Pulse wave: half sine wave pulse( 3 times in each of X, Y and Z

directions )

IEC 1131-2

Square wave impulse

noise

1,500 V

LGIS

Standard

Electrostatic

discharge

Voltage :4kV(contact discharge)

IEC 1131-2

IEC 801-2

Radiated

electromagnetic field

27 ~ 500 MHz, 10 V/m

IEC 1131-2

IEC 801-3

Severity

Level

All

power

modules

Digital

I/Os

( Ue

24 V)

Digital I/Os

(Ue < 24 V) Analog

I/Os communication

I/Os

7 Noise immunity

Fast transient

&

burst noise

Voltage 2 kV 1 kV 0.25 kV

IEC 1131-2

IEC 801-4

8 Atmosphere Free from corrosive gases and excessive dust

9 Altitude for use Up to 2,000m

10 Pollution degree 2 or lower

11 Cooling method Self-cooling

DATA SHEET

If not provided with proper prevention, it can cause death, fatal

injury or considerable loss of property.

If not properly observed, it can cause a hazard situation to result in

severe or slight injury or a loss of property.

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

LG Industrial Systems

CAUTION

!

WARNING

!

CAUTION

!

WARNING

!

WARNING

!

MASTER-K

702006222

3. Performance Specifications

Specifications

Items

K3F-DV2A K3F-DI2A

Digital input 16bit(data part :12bits)signed binary(-48 ~ 4047)

Analog output

-10 ~ 10VDC

(External load resistance :

2k ~ 1M )

4 20mADC

(External load resistance :

less than 510 )

Max. resolution 5 (1/4000) 4A(1/4000)

Accuracy 0.5%Full Scale

Max. conversion

speed (ms/channel)

10ms/4 channels

Max. absolute input 15VDC 25 mA DC

Analog output points 4channels/1module

Isolation Between input terminals and the PLC: Photo-coupler isolation

Terminals connected

consumption

9-point terminal block

DC+5V 40mA 40mA

DC+15V 80mA 120mA

Internal

current

consumption

DC-15V 60mA 25mA

Weight 200g 200g

The adjusted value of D/A conversion module at manufacturer has been in the range of

from -10 to 10 VDC or 4 ~ 20mA, and in accordance with it, offset / gain values is fixed .

The output range of K3S-304S is 0.5 A with 15VDC and 0.2A with 15VDC.

4. Parts Name and Functions

This following shows the names of parts and functions of K3F-DV2A and K3F-DI2A module.

No. Descriptions

RUN LED

Indicates the operating status the K3F-DV2A/K3F-DI2A

*Normal mode

-On: Normal operation

-Off: 5 VDC power off or the K3F-DV2A/K3F-DI2A module fault.

5. Handling Precautions

From unpacking to installation, be sure to check the following:

1) Do not drop it off, and make sure that strong impacts should not be applied.

2) Do not dismount printed circuit boards from the case. It can cause malfunctions.

3) During wiring, be sure to check any foreign matter like wire scraps should not enter into the

upper side of the PLC, and in the event that foreign matter entered into it, always eliminate it.

4) Be sure to disconnect electrical power before mounting or dismounting the module.

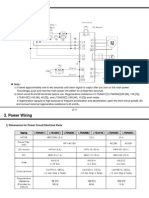

6. Wiring

6.1 Wiring Precaution

1) Separate AC and output signal of D/A conversion module wiring not to be affected by

surge or induced noise of the AC.

2) External wiring has to be at least AWG22(0.3 ) and be selected in consideration of operating

ambiance and/or allowable current.

3) Separate wiring from devices and/or substances generating intense heat, and oil not to make

short-circuit which leads to damage and/or mis-operation.

4) Identify the polarity of terminal block before external power supply is made connected.

5) Separate external wiring sufficiently from high voltage and power supply cable not to cause

induced failure and/or malfunction.

6.2 Wiring example

1) K3F-DV2A

2) K3F-DI2A

*1 For the cable, use a two-core twisted shielded wire

7. Dimension

(Unit : mm)

CAUTION

!

K3F-DV2A

V+

V-

CH0

K3F-DV2A

V+

V-

CH1

V+

V-

CH2

V+

V-

CH3

-10~+10V

RUN

K3F-DI2A

I+

I-

CH0

K3F-DI2A

I+

I-

CH1

I+

I-

CH2

I+

I-

CH3

4 ~ 20

RUN

GND

1

2

D/A

Converter

Circuit

CH3

2 ~

1

7

8

2 ~

1

GND

CH0

*1

*1

D/A

Converter

Circuit

1

2

D/A

Converter

Circuit

CH3

510

7

8

510

GND

CH0

*1

*1

D/A

Converter

Circuit

GND

90.0

K3F-DI2A

I+

I-

CH0

K3F-DI2A

I+

I-

CH1

I+

I-

CH2

I+

I-

CH3

4 ~ 20

RUN

35.0

1

1

0

.

0

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Labs KaliDocument668 pagesLabs Kalivagnersa200093% (14)

- Economy Toeic LC 3 (eBookS SOS)Document132 pagesEconomy Toeic LC 3 (eBookS SOS)Gabriel Dental100% (1)

- CLEO Australia 2014-12Document148 pagesCLEO Australia 2014-12Gabriel DentalNo ratings yet

- Solenoid ValveParker PDFDocument2 pagesSolenoid ValveParker PDFGabriel DentalNo ratings yet

- k3p-07AS Sheet PDFDocument2 pagesk3p-07AS Sheet PDFGabriel DentalNo ratings yet

- 2.1 XDL Drive Wiring DiagramDocument4 pages2.1 XDL Drive Wiring DiagramGabriel DentalNo ratings yet

- Ielts Speaking TopicsDocument39 pagesIelts Speaking TopicsGabriel DentalNo ratings yet

- 03-Streamline English DestinationsDocument103 pages03-Streamline English DestinationsGabriel Dental100% (3)

- L7 Tutorial Appendix Live ICEDocument22 pagesL7 Tutorial Appendix Live ICEGabriel DentalNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Inverter Danfoss Pada BoilerDocument60 pagesInverter Danfoss Pada BoilerFritzNo ratings yet

- BC 600 PB ManualDocument44 pagesBC 600 PB ManualSaasiNo ratings yet

- Item 7.2 - 560SFR02 - DS - enDocument6 pagesItem 7.2 - 560SFR02 - DS - enTiennghia BuiNo ratings yet

- Section 01Document78 pagesSection 01Ahmed FaragNo ratings yet

- Karmaveer Bhaurao Patil Polytechnic, Satara: Control ActionsDocument104 pagesKarmaveer Bhaurao Patil Polytechnic, Satara: Control Actionsmohammd imran azizNo ratings yet

- Ssci - 2020 - 134 Iaiani - Etal Major Accidents Triggered by Malicious Manipulations of The Control System in Process FacilitiesDocument13 pagesSsci - 2020 - 134 Iaiani - Etal Major Accidents Triggered by Malicious Manipulations of The Control System in Process FacilitiesErwan SaifulNo ratings yet

- BMS-11 CxL3 CPM SOO Control System Test - WorkingDocument14 pagesBMS-11 CxL3 CPM SOO Control System Test - WorkingAu Psl FightFor GreatVictoryNo ratings yet

- AlspaDocument344 pagesAlspaCarlos Alfredo Mansilla CalderónNo ratings yet

- GEH-6721 Vol IIDocument720 pagesGEH-6721 Vol IIpascal_chin100% (2)

- Automatic Control of Boiler Operation Using PLC and SCADADocument3 pagesAutomatic Control of Boiler Operation Using PLC and SCADATrilok SawantNo ratings yet

- Secomea Brochure 2018.englishDocument24 pagesSecomea Brochure 2018.englishSebastian Rojas BethNo ratings yet

- Logic Gates in PneumaticsDocument20 pagesLogic Gates in PneumaticsManideep AlluNo ratings yet

- Alpa - Product Datasheet - 2019Document28 pagesAlpa - Product Datasheet - 2019RicardoNo ratings yet

- FB1 1004 enDocument1,592 pagesFB1 1004 enConcucac NovNo ratings yet

- Engineering Design Tool Standard PDFDocument10 pagesEngineering Design Tool Standard PDFabha singhNo ratings yet

- HW FunctionalityDocument35 pagesHW FunctionalityBeto MurguiaNo ratings yet

- Memo LubDocument57 pagesMemo LubjoelNo ratings yet

- Yokogawa 2015 Centum VP For Batch ControlDocument9 pagesYokogawa 2015 Centum VP For Batch ControlArzymanNo ratings yet

- Wiring Diagram s7-200 SiemensDocument126 pagesWiring Diagram s7-200 Siemensgeco87No ratings yet

- Delta PLC Communication Cables Pin Diagram RS-485Document32 pagesDelta PLC Communication Cables Pin Diagram RS-485SLAMET PAMBUDINo ratings yet

- iQ-F - PPT - Ver1.02 (Aug. 2016)Document62 pagesiQ-F - PPT - Ver1.02 (Aug. 2016)Tarek KhafagaNo ratings yet

- PRO1 06E BlocksDocument26 pagesPRO1 06E BlocksING. OSCAR PACHECONo ratings yet

- Barco Sedomat 5000Document4 pagesBarco Sedomat 5000Tahir Samad100% (1)

- MX Component Programming ManualDocument620 pagesMX Component Programming ManualNam NguyễnNo ratings yet

- Internship ReportDocument32 pagesInternship ReportAzrif Moskam100% (1)

- 1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Document21 pages1.1 Scope 1.2: Shell Pakistan Limited (SPL) Petrochemical Engineering Consultants (PEC)Muhammad Ibad AlamNo ratings yet

- Convergence 36Document3 pagesConvergence 36Furqan WarisNo ratings yet

- 300 Series User GuideDocument84 pages300 Series User GuideJason Jones100% (1)

- Photograph: Email: Mobile: +91Document4 pagesPhotograph: Email: Mobile: +91Dinesh DinuNo ratings yet

- User'S Manual: SB70 Series InverterDocument150 pagesUser'S Manual: SB70 Series InverterNguyễn Hữu TuânNo ratings yet