Professional Documents

Culture Documents

7qctools Training Slides

Uploaded by

dhir.ankurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7qctools Training Slides

Uploaded by

dhir.ankurCopyright:

Available Formats

9/10/2014

1

7 QC Tools

Training module

on

1

7 QC Tools

By Ankur Dhir

Learning Objectives:

Hands-on learning of Quality Tools and

Continuous Improvement Tools !

Learn TRANSFORM monthly reports to deliver

more important information instantly

Agenda:

10:00-10:30 : Process Flow Chart,

10 30 11 15 Cause and Effect Diagram 10.30-11.15 Cause and Effect Diagram,

11.15-11.45 Check sheet,

11.45 -12.15 Histogram

12:150 - 01: 00 : Pareto Chart,

01:00 2.00 Lunch

2.00 -3.00 pm, Scatter Plot, Stratification

3.00 4.30 Control Chart,

4.30-5.00 Quality Tools in Reporting,

5.00-5.30 quiz and test

Trainer profile

Qualification: B-tech, Advanced Diploma in

Quality Management, Certified Quality Manager

(ASQ), Lead Auditor ISO 9001, 14001, OHSAS .

Six Sigma Green Belt , Lean champion ( Lean

Institute)

Work Experience : more than 12 year experience in

field of quality, environment and Safety as

Management representative, consultancy, Auditing

and trainings . Have delivered more than

H bbi L i hil t l ( ll ti t

3

Hobbies: Learning , philately ( collecting stamps,

and vintage coins)

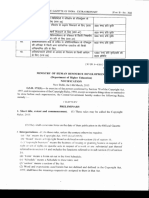

I n f l u en t i a l P r o f es si o n a l s w h o s h a p ed

QUALITY GURUS

4

f f p

t h e Qu a l i t y p a t h

9/10/2014

2

5 6

Ishikawas Basic Tools of Quality

Kaoru Ishikawa developed seven basic visual tools of quality

so that the average person could analyze and interpret data.

These tools have been used worldwide by companies,

managers of all levels and employees

7 Q C Tools

managers of all levels and employees.

What are 7 QC Tools ?

QC tools are the means for Colleting data ,

analyzing data , identifying root causes and

measuring the results.

8

THESE TOOLS ARE RELATED TO

Numerical DATA processing

USER HAS TO DEVELOP THE

SOLUTION & IMPLEMENT

9/10/2014

3

Pareto Diagram

Stratification

Scatter Diagram

7 QC TOOLS

9

Cause and Effect Diagram

Histogram

Check Sheet

Control Chart/Graph

Detecting causes of

Record of facts

Defining the

problem

Identification of

problem

Control

Chart

Scatter

Diagram

Histogra

m

Cause &

Effect

Diagram

Pareto

Diagra

m

Stratifi

cation

Check

sheet

Graphs

Application of QC tools in Problem Solving

10

Process control

( Standardization )

Evaluation of result

Implementation

Develop

Improvement

method

( Solution )

problem

Quality Tool Box Flow Chart

Flowchart

Also called: process flowchart, process flow diagram.

Description

A flowchart is a picture of the separate steps of a process in sequential order.

Elements that may be included are: sequence of actions, materials or services

entering or leaving the process (inputs and outputs), decisions that must be

made, people who become involved, time involved at each step and/or process

7 Q C Tools

measurements.

The process described can be anything: a manufacturing process, an

administrative or service process, a project plan. This is a generic tool that can

be adapted for a wide variety of purposes.

) to see if they agree that the process is drawn accurately.

Quality Tool Box - Flow Chart

When to Use a Flowchart

To develop understanding of how a process is done.

To study a process for improvement.

To communicate to others how a process is done.

7 Q C Tools

When better communication is needed between people involved with the

same process.

To document a process.

When planning a project.

9/10/2014

4

Steps in Making Flow Chart

Flowchart Basic Procedure

Materials needed: Sticky notes or cards, a large piece of flipchart paper ,

marking pens.

Steps

Define the process to be diagrammed. Write its title at the top of the work

surface.

Discuss and decide on the boundaries of your process: Where or when does the

process start? Where or when does it end? Discuss and decide on the level of

7 Q C Tools

detail to be included in the diagram.

Brainstorm the activities that take place. Write each on a card or sticky note.

Sequence is not important at this point, although thinking in sequence may help

people remember all the steps.

Arrange the activities in proper sequence.

When all activities are included and everyone agrees that the sequence is

correct, draw arrows to show the flow of the process.

Review the flowchart with others involved in the process (workers, supervisors,

suppliers, customers

Detailed Flow Chart

High Level Flow

Chart

Flow Chart example

7 Q C Tools

Cause & Effect Diagram

1. What is Cause & effect Diagram ?

A cause and effect diagram is a fish-bone diagram that

presents a systematic representation of the relationship

between the effect (result) and affecting factors (causes).

Solving a problem in a scientific manner requires

15

g p q

clarification of a cause and effect relationship, where the

effect (e.g., the result of work) varies according to factors

(e.g., facilities and machines used, method of work, workers,

and materials and parts used). To obtain a good work result,

we must identify the effects of various factors and develop

measures to improve the result accordingly.

Cause & Effect Diagram

2. When is it used and what results will be obtained?

A cause and effect diagram is mainly used to study

the cause of a certain matter. As mentioned above,

the use of a cause and effect diagram allows

16

clarification of causal relation for efficient problem

solving. It is also effective in assessing measures

developed and can be applied to other fields

according to your needs.

9/10/2014

5

Can obtain a clear

overall picture of causal

relation. (A change in

the cause triggers a

variation in the

result.) Can clarify

the cause and effect

Method Usage Result

Cause & Effect Diagram

Used when

clarifying a cause

and effect

relationship.[Used

during a phase to

analyze causes.]

Man Machine

E

f

f

e

c

t

Cause and Effect Cause and Effect

Diagram Diagram

Man Machine

E

f

f

e

c

t

Cause and Effect Cause and Effect

Diagram Diagram

17

relationship.

Can list up all causes

to identify important

causes.

Can determine the

direction of action

(countermeasure).

y ]

Used to develop

countermeasures.

[Used during a phase to plan

countermeasures.]

Material Method

Cause (4Ms) Result

(Controlled State)

Material Method

Cause (4Ms) Result

(Controlled State)

Cause & Effect Diagram

Mechanism of

Copying Machine

Quality of

Copying Paper

Smudges onthe

copiedsurface

Internal devices not

workingsmoothly

Malfunctionof

theroller

Printingtoo

lightly

Toothin

Folded

Runningout

of stock

Dampened

y

i

n

g

E

r

r

o

r

s

!

Mechanism of

Copying Machine

Quality of

Copying Paper

Smudges onthe

copiedsurface

Internal devices not

workingsmoothly

Malfunctionof

theroller

Printingtoo

lightly

Toothin

Folded

Runningout

of stock

Dampened

y

i

n

g

E

r

r

o

r

s

!

18

User Surrounding

Environment

Keyboardhandling

error

Error inselectinga

scaleof reduction

Errorin

placementof

paper (setting

its faceup)

Error in

selecting

shading

Deteriorationof

performancedue

tohigh

temperatures

Nicotine-

stained

Dirtonthe

glass

surface

Dust

M

a

n

y

C

o

p

y

User Surrounding

Environment

Keyboardhandling

error

Error inselectinga

scaleof reduction

Errorin

placementof

paper (setting

its faceup)

Error in

selecting

shading

Deteriorationof

performancedue

tohigh

temperatures

Nicotine-

stained

Dirtonthe

glass

surface

Dust

M

a

n

y

C

o

p

y

Check sheet

Description

A check sheet is a structured, prepared form for collecting and

analyzing data. This is a generic tool that can be adapted for a

wide variety of purposes.

When to Use a Check Sheet

When data can be observed and collected repeatedly by the same

7 Q C Tools

p y y

person or at the same location.

When collecting data on the frequency or patterns of events,

problems, defects, defect location, defect causes, etc.

Check Sheet

1. What is Check sheet ?

A check sheet is a sheet designed in advance to allow easy

collection and aggregation of data. By just entering check

marks on a check sheet, data can be collected to extract

necessary information, or a thorough inspection can be

performed in an efficient manner eliminating a possibility

20

performed in an efficient manner, eliminating a possibility

of skipping any of the required inspection items.

A check sheet is also effective in performing stratification

(categorization).

9/10/2014

6

Check Sheet

2. When is it used and what results will be obtained?

Please refer to the table on next slide for the usage

and benefits of a check sheet. It is frequently used in

daily business operations, often not specifically for

21

QC purposes.

Ensures collection of

required data.

Allows a thorough

inspection of all check

items.

C d t d

Method Usage Result

Check Sheet

Check Sheet Check Sheet

Day

Process

Process 1

Process 2

Process 3

Check Sheet Check Sheet

Day

Process

Process 1

Process 2

Process 3

Used to collect

data.

Used when

performing a

th h i ti

22

Can understand

tendencies and

variations.

Can record required

data.

thorough inspection.

Used during phases to monitor

the situation, analyze causes,

review effectiveness of an

action, perform

standardization, and

implement a selected control

measure

Check Sheet Procedure

23

Decide what event or problem will be observed. Develop

operational definitions.

Decide when data will be collected and for how long.

Design the form. Set it up so that data can be recorded

simply by making check marks or Xs or similar symbols

and so that data do not have to be recopied for analysis

7 Q C Tools

and so that data do not have to be recopied for analysis.

Label all spaces on the form.

Test the check sheet for a short trial period to be sure it

collects the appropriate data and is easy to use.

Each time the targeted event or problem occurs, record data

on the check sheet.

Check sheet Example

The figure below shows a check sheet used to collect data on telephone

interruptions. The tick marks were added as data was collected over

several weeks.

7 Q C Tools

9/10/2014

7

Check Sheet

A check sheet used to identify defects

Date

Defect

Vertical Scratch

Total

Date

Defect

Vertical Scratch

Total

25

Scratch

Dent

Scratch

Dent

Histogram

1. What is Histogram ?

When creating a histogram, a range of data is divided into

smaller sections having a uniformspan,and the number of data

contained in each section (the number of occurrences) is

counted to develop a frequency distribution table Then a

26

counted to develop a frequency distribution table. Then, a

graph is formed from this table by using vertical bars, each

having the height proportional to the number of occurrences in

eachsection.

Histogram

2. When is it used and what results will be obtained?

A histogram is mainly used to analyze a process by

examining the location of the mean value in the

graph or degree of variations, to find a problempoint

that needs to be improved. Its other applications are

listed in the table below.

27

Histogram Construction

Collect at least 50 consecutive data points from a process.

Use the histogram worksheet to set up the histogram.

Histogram Analysis

Before drawing any conclusions from your histogram, satisfy yourself that the

Histogram

Microsoft Office

el 97-2003 Worksh

Double Click on file to

construct Histogram.

Note : Use Paste Values

7 Q C Tools

process was operating normally during the time period being studied.

If any unusual events affected the process during the time period of the

histogram, your analysis of the histogram shape probably cannot be

generalized to all time periods.

Analyze the meaning of your histograms shape.

9/10/2014

8

Histogram

Typical Histogram Shapes and What They Mean

Normal. A common pattern is the bell-shaped curve known as the

normal distribution. In a normal distribution, points are as likely

to occur on one side of the average as on the other.

Example : Distribution of heights (in cm) of all employees.

7 Q C Tools

Histogram

Skewed. The skewed distribution is asymmetrical because a natural

limit prevents outcomes on one side. The distributions peak is off

center toward the limit and a tail stretches away from it.

For example, a distribution of analyses of time difference between

employees arriving at work (clock in time) and official company

start time.

Typical Histogram Shapes and What They Mean

7 Q C Tools

Or , differences in actual turn around to resolve certain types of

complaints compared to goal for that segment.

These distributions are called right- or left-skewed according to the

direction of the tail.

TAIL

This is right-

skewed since the

tail is at our right

Histogram

Double-peaked or bimodal.

The bimodal distribution looks like the back of a two-humped

camel.

The outcomes of two processes with different distributions are

combined in one set of data.

Typical Histogram Shapes and What They Mean

7 Q C Tools

For example, a distribution of production data from a two-shift

operation might be bimodal, if each shift produces a different

distribution of results. Stratification often reveals this problem.

Method Usage Result

Histogram

Histogram Histogram

Standard

Range

Histogram Histogram

Standard

Range

Used to assess the actual

conditions.

Used to analyze a process to

identify a problem point that needs

to be improved by finding the

location of the mean value or

degree of variations in the graph.

Used to examine that the target

Can identify the

location of the mean

(central) value or

degree of variations.

Can find out the scope

of a defect by inserting

32

Range of

Variations

X Axis (Values

Actually

Measured) Range of

Variations

X Axis (Values

Actually

Measured)

Used to examine that the target

quality is maintained throughout

the process.

Others

[Used during phases to

monitor the situation, analyze

causes, and review

effectiveness of an action.]

standard values.

Can identify the

condition of

distribution (e.g.,

whether there is an

isolated, extreme

value).

9/10/2014

9

Histogram

Frequency Distribution Table

Cutting Length of Steel Wire]

Standard

Lower Limit Upper Limit

Standard

Standard Value

Product

(Standard: 255 5 mm)

Section

Frequency Marking

Occurrences Mean

33

[Histogram of Cutting Length of Steel

Wire]

Description

A Pareto chart is a bar graph.

The lengths of the bars represent frequency or cost (time or money), and are

arranged with longest bars on the left and the shortest to the right.

In this way the chart visually depicts which situations are more significant.

Pareto Chart or Pareto Analysis

Based on 80-20 Rule :

80% of the problem is caused by 20% of the causes

7 Q C Tools

When to Use a Pareto Chart

When analyzing data about the frequency of problems or causes in a

process.

When there are many problems or causes and you want to focus on the

most significant.

When analyzing broad causes by looking at their specific components.

First Example of Pareto Chart

Example 1 shows how many customer complaints were received in each

of five categories of processes or departments.

7 Q C Tools

Example 2 takes the largest category, documents, from Example #1,

breaks it down into six categories of document-related complaints, and

shows cumulative values.

Second Example of Pareto Chart

7 Q C Tools

If all complaints cause equal distress to the customer, working on

eliminating document-related complaints would have the most impact, and

of those, working on quality certificates should be most fruitful.

9/10/2014

10

Pareto Chart Procedure

Decide what categories you will use to group items.

(Horizontal Axis or X Axis)

Decide what measurement is appropriate. Common

measurements are frequency, quantity, cost and time.

(Vertical Axis or Y Axis)

Pareto Chart

Double Click on file to

construct Pareto Chart

Note : Use paste Values

Microsoft Office

el 97-2003 Worksh

7 Q C Tools

Decide what period of time the Pareto chart will cover: One work cycle? One full

day? A week?

Collect the data, recording the category each time. (Or assemble data that

already exist.)

Subtotal the measurements for each category.

Pareto Diagram

1. What is Pareto diagram ?

A Pareto diagram is a combination of bar and line graphs of

accumulated data, where data associated with a problem

(e.g., a defect found, mechanical failure, or a complaint

from a customer) are divided into smaller groups by cause

or by phenomenon and sorted for example by the number

38

or by phenomenon and sorted, for example, by the number

of occurrences or the amount of money involved. (The

name Pareto came from an Italian mathematician who

created the diagram.)

Pareto Diagram

2. When is it used and what results will be obtained?

Please refer to the table on next slide for the

usage and benefits of a Pareto diagram. It is

mainly used to prioritize matters, and because

f f

39

of its easiness of use, the diagram is used in a

wide variety of fields.

Pareto Diagram Pareto Diagram

(No. of Occurrences)

Pareto Diagram Pareto Diagram

(No. of Occurrences)

Used to identify a problem.

Used to identify the cause of

a problem.

Used to review the effects of

an action to be taken.

Allows clarification of

important tasks.

Allows identification

of a starting point

(which task to start

with)

Method Usage Result

Pareto Diagram

40

Used to prioritize

actions.(Used during

phases to monitor the

situation, analyze causes,

and review effectiveness of

an action.)

with).

Allows projection of

the effects of a measure

to be taken

9/10/2014

11

Pareto Diagram

To identify a course of

action to be emphasized

usinga varietyof data

Example

Assessment using Pareto

diagram (prioritization)

Confirmation of Effect

(Comparison)

Frequently used to check

the effect of an

41

using a variety of data.

Details of A

improvement.

Improved

Construct Pareto of M&M colors

Produce a Pareto Chart of colors of M&M chocolate in a pack of M&M

Compare differences between your colleagues

80% of your M&M content consists of what color?

7 Q C Tools

Stratification

1. What is Stratification ?

Stratification means to divide the whole into smaller portions

according to certain criteria. In case of quality control,

stratification generally means to divide data into several groups

according to common factors or tendencies (e g type of defect

43

according to common factors or tendencies (e.g., type of defect

andcause of defect).

Dividing into groups fosters understanding of a situation.

This represents the basic principle of qualitycontrol.

Stratification

2. When is it used and what results will be obtained?

The common and basic principle of quality control is

stratification, i.e., to think a matter out by breaking it

into smaller portions. Stratification has a number of

useful purposes. The table below shows only a few

examples of these purposes.

44

p p p

9/10/2014

12

Stratification (Categorization)

Description

Stratification is a technique used in combination with other data

analysis tools. When data from a variety of sources or categories

have been lumped together, the meaning of the data can be

impossible to see. This technique separates the data so that patterns

can be seen.

When to Use Stratification

Before collecting data.

7 Q C Tools

When data come from several sources or conditions, such as shifts,

days of the week, suppliers or population groups.

When data analysis may require separating different sources or

conditions.

Stratification Procedure

Before collecting data, consider which information about the

sources of the data might have an effect on the results. Set up the

data collection so that you collect that information as well.

When plotting or graphing the collected data on a scatter

diagram, control chart, histogram or other analysis tool, use

diff t k l t di ti i h d t f i

Stratification (CATEGORIZATION OF DATA)

7 Q C Tools

different marks or colors to distinguish data fromvarious sources.

Data that are distinguished in this way are said to be stratified.

Analyze the subsets of stratified data separately.

Example of Stratification We want to reduce number of complaints but looking at the

data by Region

CountofCaseDescription

RD Total

1 118

2 137

3 47

4 68

(Region) Number of Complaints

Analyze the subsets of

stratified data (category)

separately. In this case, its

recommended to look at the

bl i b i

7 Q C Tools

5 42

6 49

7 15

8 18

9 20

(blank)

GrandTotal 514

problem region by region.

Method Usage Result

Stratification

Grouping by day,

time, place,

worker, or

process

X

Number of Units

Used to observe variations

among strata.

Used to identify the

relationship between cause

and effect.

Used to identify a purpose

Allows observation

of variations among

strata.

By performing a

cause analysis using

th t tifi d d t

48

Y

Z

y p p

and means to serve the

purpose

[Used during phases to monitor

the situation, analyze causes,

revieweffectiveness of an action,

performstandardization, and

implement a selected control

measure.]

the stratified data,

the following can be

accomplished.

1.Identification and control of a

problem

2.Division of data (obtained by

using each QC tool) into several

groups

9/10/2014

13

Stratification

Item Method of Stratification

Elapse of time

Hour, a.m., p.m., immediately after start of work,

shift, daytime, nighttime, day, week, month

Variations among workers

Worker, age, male, female, years of experience,

shift, team, newly employed, experienced worker

Variations among work

methods

Processing method, work method, working

conditions (temperature, pressure, and speed),

temperature

Variations among Measurement tool, person performing

49

measurement/inspection

methods

measurement, method of measurement, inspector,

sampling, place of inspection

Scatter Diagram

1. What is Scatter Diagram ?

A scatter diagramis used to examine the relationship between

the two, paired, interrelated data types, such as height and

weight of a person. A scatter diagramprovides a means to

find whether or not these two data types are interrelated It is

50

find whether or not these two data types are interrelated. It is

also utilized to determine how closely they are related to

identifya problempoint that should be controlledor improved.

Scatter Diagram

2. When is it used and what results will be obtained?

The table on next slide shows some examples of

scatter diagrams usage. If, for example, there is a

relationship where an increase in the number of

rotations (x) causes an increase in abrasion (y), there

exists positive correlation. If, on the other hand, the

51

p , ,

existence of a relationship where an increase in the

number of rotations (x) causes a decline in abrasion

(y) indicates that there is negative correlation.

Method Usage Result

Scatter Diagram

Used to identify a relationship

between two matters.

Used to identify a relationship

between two matters and establish

countermeasures based on their

cause and effect relation.

Example Usage

Scatter Diagram Scatter Diagram

Axi s

x Axi s

A

b

r

a

s

i

o

n

Scatter Diagram Scatter Diagram

Axi s

x Axi s

A

b

r

a

s

i

o

n

Can identify cause

and effect relation.

Can understand the

relationship

between two

52

p g

1.Relationship between thermal

treatment temperature of a steel

material and its tensile strengths

2.Relationship between visit made

by a salesman and volume of sales

3.Relationship between the number

of persons visiting a department

store and volume of sales

4 Others

Number of

Rotations

Number of

Rotations

[Used during phases to monitor the

situation, analyze causes, and review

effectiveness of an action.]

results.

9/10/2014

14

Scatter Diagram

(

m

i

c

r

o

n

)

Axi s

(

m

i

c

r

o

n

)

Axi s

53

A

b

r

a

s

i

o

n

x Axi s

Number of

Rot at i ons

A

b

r

a

s

i

o

n

x Axi s

Number of

Rot at i ons

Control Chart

Also called: statistical process control (SPC)

Description

The control chart is a graph used to study how a process changes

over time. Data are plotted in time order.

A control chart always has a central line for the average, an

upper line for the upper control limit and a lower line for the

7 Q C Tools

pp pp

lower control limit.

These lines are determined from historical data.

By comparing current data to these lines, you can draw

conclusions about whether the process variation is consistent (in

control) or is unpredictable (out of control, affected by special

causes of variation).

Control Chart (Control Chart / Graph 1)

1. What is Control Chart ?

A control chart is used to examine a process to see if

it is stable or to maintain the stability of a process.

This method is often used to analyze a process. To

do so, a chart is created from data collected for a

55

certain period of time, and dots plotted on the chart

are examined to see howthey are distributed or if they

are within the established control limit. After some

actions are taken to control and standardize various

factors, this method is also used to examine if a

process is stabilized by these actions, and if so, to

keep the process in a stable state.

Control Chart

2. When is it used and what results will be obtained?

There are two types of control charts: one used for

managerial purposes and the other for analytical

purposes. A control chart is used to identify dots that

are outside the control limit, which indicate some

anomalies in a process. In addition, seven

56

p ,

consecutive dots showing values that are below or

above the mean (central) value, or an increment or a

decline represented by seven consecutive dots also

indicate a problemin a process.

We need to examine what has caused such a

tendency or an increment/decline.

9/10/2014

15

Method Usage Result

Control Chart

Control Chart Control Chart Control Chart Control Chart

[Used during phases to

monitor the situation,

l i

Used to observe a

change caused by

elapse of time.

Can identify a change

caused by elapse of

time.

Can judge the

process if it is in its

normal state or there

57

x-R Control Chart x-R Control Chart

analyze causes, review

effectiveness of an

action, perform

standardization, and

implement a selected

control measure

In the example x bar -R

control chart, X bar

represents the central value,

while Rindicates the range.

normal state or there

are some anomalies

by examining the dots

plotted on the chart.

Control Chart for Managerial Purposes: Extends the line indicating the control limit used for analytical purposes to

plot data obtained daily to keep a process in a good state.

Control Chart for Analytical Purposes: Examines a process if it is in a controlled state by collecting data for a certain

period of time. If the process is not controlled, a survey is performed to identify its cause and develop

countermeasures.

Control Chart

Examplesof Values

RepresentedbyDots

Valuesabovethe

control limit

representedby

seven

consecutivedots

Examplesof Values

RepresentedbyDots

Valuesabovethe

control limit

representedby

seven

consecutivedots

58

x-Control Chart

GroupNumber

Adecline

representedby

seven

consecutivedots

x-Control Chart

GroupNumber

Adecline

representedby

seven

consecutivedots

Graph

1. What is Graph ?

A graph is a graphical representation of data, which allows a

person to understand the meaning of these data at a glance.

Unprocessed data simply represent a list of numbers, and

finding certain tendencies or magnitude of situation fromthese

59

finding certain tendencies or magnitude of situation fromthese

numbers is difficult, sometimes resulting in an interpretational

error. A graph is a effective means to monitor or judge the

situation, allowing quick and precise understanding of the

current or actual situation.

A graph is a visual and summarized representation of data that

needto be quicklyand preciselyconveyed to others.

Graph

2. When is it used and what results will be obtained?

A graph, although it is listed as one of the QC tools, is

commonly used in our daily life and is the most

familiar means of assessing a situation.

60

9/10/2014

16

Method Usage Result

Graph

0

20

40

60

80

100

120

1st Qtr 2nd Qtr 3rd Qtr 4th Qtr

East

Changes in a time-sequential

order line graph

Amounts bar graph, etc.

Ratios pie graph, band

Can observe changes in

a time-sequential order,

ratios, and amounts.

A graphs is the most

frequently used tool to

i th i

61

1st Qtr

13%

2ndQtr

17%

3rdQtr

57%

4thQtr

13%

chart, etc.

(The items listed above are

representative examples.)

examine the various

matters such as those

listed on the left.

Graph

S

a

l

e

s

(milli on)

[Bar Graph of Sal es]

Survey Peri od: Dec. 1999

Prepared by: M/T

[Band Chart of Expenses]

(mill ion)

Before

Taking

Actions

Chemi cal s Chemicals

(430) (430)

Oils Oils

(200) (200)

Electricity El ectri city

(170) (170)

(Total: 8 million)

S

a

l

e

s

(milli on)

[Bar Graph of Sal es]

Survey Peri od: Dec. 1999

Prepared by: M/T

[Band Chart of Expenses]

(mill ion)

Before

Taking

Actions

Chemi cal s Chemicals

(430) (430)

Oils Oils

(200) (200)

Electricity El ectri city

(170) (170)

(Total: 8 million)

62

Sal es

Offi ce

Iwate Tokyo Osaka Shizuoka

After

Taking

Actions

Chemi cals Chemical s

(240) (240)

Oil s Oi ls

(150) (150)

El ectricity Electrici ty

(108) (108)

(Total: 4.95 million)

Sal es

Offi ce

Iwate Tokyo Osaka Shizuoka

After

Taking

Actions

Chemi cals Chemical s

(240) (240)

Oil s Oi ls

(150) (150)

El ectricity Electrici ty

(108) (108)

(Total: 4.95 million)

Pareto Diagram To identify the current status and issues

Stratification Basic processing performed when

collecting data

Scatter Diagram To identify the relationship between two

things

Cause and Effect Diagram

To sum up 7 QC tools (Numerical data ) are used as follow:

63

To identify the cause and effect relationship

Histogram To see the distribution of data

Check Sheet To record data collection

Control Chart/Graph To find out abnormalities and identify the

current status

Thank you

64

Thank you

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sagittarius ProfileDocument3 pagesSagittarius ProfileWAQAS SHARIFNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- BasicCalculus12 Q3 Ver4 Mod3 The Derivatives V4Document34 pagesBasicCalculus12 Q3 Ver4 Mod3 The Derivatives V4karren100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Blaine Ray HandoutDocument24 pagesBlaine Ray Handoutaquilesanchez100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lux Level Calculation: WILSON ELECTRICAL ENGINEERING BOOKS (Simplified Edition 2020)Document1 pageLux Level Calculation: WILSON ELECTRICAL ENGINEERING BOOKS (Simplified Edition 2020)Wilson (Electrical Engineer)No ratings yet

- Sheiko 13week Beginner ProgramDocument16 pagesSheiko 13week Beginner ProgramAnders DahlNo ratings yet

- Asq Presentation Iso 13485Document48 pagesAsq Presentation Iso 13485dhir.ankur100% (1)

- Bsi MD Risk Management For Medical Devices QaDocument10 pagesBsi MD Risk Management For Medical Devices Qadhir.ankurNo ratings yet

- MDR Classification DocumentDocument17 pagesMDR Classification Documentdhir.ankurNo ratings yet

- Arithmetic Mean PDFDocument29 pagesArithmetic Mean PDFDivya Gothi100% (1)

- 1.2 Patent Rules 1970 - 11 March 2015Document95 pages1.2 Patent Rules 1970 - 11 March 2015dhir.ankurNo ratings yet

- 4 Qi Imbalances and 5 Elements: A New System For Diagnosis and TreatmentDocument5 pages4 Qi Imbalances and 5 Elements: A New System For Diagnosis and Treatmentpixey55100% (1)

- What Is APQPDocument2 pagesWhat Is APQPshanramaNo ratings yet

- Project Report - Performance Anaylysis of Mutual Funds in IndiaDocument52 pagesProject Report - Performance Anaylysis of Mutual Funds in Indiapankaj100% (1)

- Checklist MDRDocument162 pagesChecklist MDRdhir.ankurNo ratings yet

- Iso37001 Implementation Guide en MyDocument12 pagesIso37001 Implementation Guide en MylovishNo ratings yet

- Ipr NotesDocument179 pagesIpr NotesRajan MeenaNo ratings yet

- 3.2 Copyrights (Amendment) Act, 2012Document14 pages3.2 Copyrights (Amendment) Act, 2012Ankur DhirNo ratings yet

- 4.3 Design (Amendment) Rules, 2008Document26 pages4.3 Design (Amendment) Rules, 2008dhir.ankurNo ratings yet

- 3.3 Copyright Rules, 2013Document41 pages3.3 Copyright Rules, 2013dhir.ankurNo ratings yet

- Trade Mark RulesDocument282 pagesTrade Mark Ruleslovingboy22No ratings yet

- Manual of Trade Marks: Practice & ProcedureDocument143 pagesManual of Trade Marks: Practice & ProcedureSaurabh KumarNo ratings yet

- Halalindia EcodesDocument5 pagesHalalindia Ecodesdhir.ankurNo ratings yet

- Flowchart For Reporting Ethics IssuesDocument1 pageFlowchart For Reporting Ethics Issuesdhir.ankurNo ratings yet

- QMR Q F PR03 001 Job Description MatrixDocument1 pageQMR Q F PR03 001 Job Description Matrixdhir.ankurNo ratings yet

- Application Form HALALDocument4 pagesApplication Form HALALdhir.ankurNo ratings yet

- Establishing An Integrated Management SyDocument65 pagesEstablishing An Integrated Management Sydhir.ankurNo ratings yet

- DNV Brochure FOOD Tcm163-344274Document12 pagesDNV Brochure FOOD Tcm163-344274dhir.ankurNo ratings yet

- Process FlowDocument1 pageProcess Flowdhir.ankurNo ratings yet

- Pharma News 27 June 2022 PDF-1Document13 pagesPharma News 27 June 2022 PDF-1dhir.ankurNo ratings yet

- Chapter2975 PDFDocument25 pagesChapter2975 PDFDivya ChauhanNo ratings yet

- Ananya Consultants Application FormDocument2 pagesAnanya Consultants Application Formdhir.ankurNo ratings yet

- Business Ethics in IndiaDocument7 pagesBusiness Ethics in IndianiviNo ratings yet

- Chapter 1Document10 pagesChapter 1dhir.ankurNo ratings yet

- Key Ethical PrinciplesDocument2 pagesKey Ethical Principlesdhir.ankurNo ratings yet

- EthicsPolicy SampleTemplateDocument4 pagesEthicsPolicy SampleTemplatedhir.ankurNo ratings yet

- MDD Classification Document: Mapping of RequirementsDocument12 pagesMDD Classification Document: Mapping of Requirementsdhir.ankurNo ratings yet

- QCI AIMED Certification ProcessDocument14 pagesQCI AIMED Certification ProcessAnkurNo ratings yet

- Declaration of Conformity MDD Class IDocument2 pagesDeclaration of Conformity MDD Class Idhir.ankurNo ratings yet

- Curriculum Vitae ofDocument4 pagesCurriculum Vitae ofAndrew OlsonNo ratings yet

- 1609 Um009 - en PDocument34 pages1609 Um009 - en PAnonymous VKBlWeyNo ratings yet

- Australia Harvesting Rainwater For Environment, Conservation & Education: Some Australian Case Studies - University of TechnologyDocument8 pagesAustralia Harvesting Rainwater For Environment, Conservation & Education: Some Australian Case Studies - University of TechnologyFree Rain Garden ManualsNo ratings yet

- Bleeding Disorders in Pregnancy: Table 1Document7 pagesBleeding Disorders in Pregnancy: Table 1KharismaNisaNo ratings yet

- Nail Malformation Grade 8Document30 pagesNail Malformation Grade 8marbong coytopNo ratings yet

- Chinese MedicineDocument16 pagesChinese MedicineTrisNo ratings yet

- Bsee 36: Survey of English and American Literature Learning Material 2: Introduction To Literary Theories and CriticismDocument4 pagesBsee 36: Survey of English and American Literature Learning Material 2: Introduction To Literary Theories and CriticismCarlosNorielCabanaNo ratings yet

- DFT UploadDocument13 pagesDFT Uploadmeghraj01No ratings yet

- PTPL Ir 2018Document383 pagesPTPL Ir 2018Guan WenhaiNo ratings yet

- LP Addition of PolynomialsDocument5 pagesLP Addition of PolynomialsJolina Bagwisa LptNo ratings yet

- Boonton Radio Corporation - The Notebook 12Document8 pagesBoonton Radio Corporation - The Notebook 12Luiz Roberto PascotteNo ratings yet

- Service Instruction Selection of Suitable Operating Fluids For ROTAX Engine Type 916 I (Series), 915 I (Series), 912 I (Series), 912 and 914 (Series)Document15 pagesService Instruction Selection of Suitable Operating Fluids For ROTAX Engine Type 916 I (Series), 915 I (Series), 912 I (Series), 912 and 914 (Series)Martin PilatiNo ratings yet

- Theater InstallationDocument7 pagesTheater InstallationtemamNo ratings yet

- McMurdo FastFind 220 PLB DatasheetDocument4 pagesMcMurdo FastFind 220 PLB DatasheetGiorgos PapadopoulosNo ratings yet

- Determining Load Ratios For Technical Rescue Systems and EquipmentDocument2 pagesDetermining Load Ratios For Technical Rescue Systems and EquipmentAhmad Zubair Rasuly0% (1)

- Reading The Bible From Feminist, Dalit, Tribal and Adivasi Perspectives (Course Code: BC 107)Document8 pagesReading The Bible From Feminist, Dalit, Tribal and Adivasi Perspectives (Course Code: BC 107)Arun Stanley100% (2)

- Installation Manual of FirmwareDocument6 pagesInstallation Manual of FirmwareOmar Stalin Lucio RonNo ratings yet

- Research Proposal Sample OutlineDocument17 pagesResearch Proposal Sample OutlineGuidance and Counseling OfficeNo ratings yet

- Heating Curve Lab Report - Ava MonizDocument7 pagesHeating Curve Lab Report - Ava Monizapi-533828039No ratings yet

- Brochure Delegation Training For LeadersDocument6 pagesBrochure Delegation Training For LeadersSupport ALProgramsNo ratings yet

- Ga2 27:6:23Document1 pageGa2 27:6:23john HuntNo ratings yet

- Examples Week1 CompressDocument6 pagesExamples Week1 CompressAngel HuitradoNo ratings yet