Professional Documents

Culture Documents

12525-2500116-0 - Strength Calculation For Superheater 3 Unit I

Uploaded by

HMMSPOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12525-2500116-0 - Strength Calculation For Superheater 3 Unit I

Uploaded by

HMMSPCopyright:

Available Formats

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE : 1 of 9

BOILER MAKER'S NO. : GB - 101

Strength Calculation for

SUPER HEATER 3

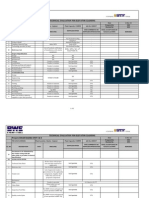

DESIGN DATA

S.No

Design Code

Description

Design Pressure

bar(g)

Hydrotest pressure

bar(g)

Design Temperature

C

SH-3 Main Inlet Header

160

240

428

SH-3 Inlet Connection Pipe

160

240

428

SH-3 Intermediate Inlet Header

160

240

428

160

240

428

159

240

473+50

3

4

5

SH-3 Inlet Connection Tube

IBR 1950 With Latest

SH 3 Tubes

Amendments

SH-3 Outlet Connection Tube

159

240

479

SH-3 Intermediate Outlet Header

159

240

479

SH-3 Outlet Connection Pipe

159

240

479

SH-3 Main Outlet Header

159

240

472

6

7

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE :

2 of 9

HEADER THICKNESS CALCULATION : Reg 342(a) and Reg 270

WP x D

T =

---------------

+ 0.762

mm

-------------- Eqn (72)

2 f E - WP

Where ,

WP =

Design Pressure of Header in bar (g)

Max. Internal diameter in mm

Permissible Working stress at the working metal temp in MPa ( As per ASME Sec. II Part-D [Metric] )

Required thickness to be calculated in mm

Ligament Efficiency

Super Heater 3 Drawings

1

2

3

4

5

6

Super Heater-3 Assembly

Arrangement and Details of SH-3 Main Inlet Header.

Arrangement and Details of SH-3 Intermediate Inlet Header.

Arrangement and Details of SH 3 Inlet and Outlet Coils

Details of SH 3 Inlet and Outlet Coils

Arrangement and Details of SH-3 Intermediate Outlet Header.

Arrangement and Details of SH-3 Main Outlet Header.

Size

Sl.

No.

Drawing. No.

DU No.

Part

No.

OD

Nom. Thk. Min.Thk *

mm

mm

mm

mm

Material

Specification

12525 01 01339

12525 01 01337

12525 01 01341

12525 01 01344

12525 01 01345

12525 01 01350

12525 01 01351

Design

Design

Temp.

Pr. (WP)

bar (g)

Stress

Value

(f)

MPa

Ligament

Efficiency

E **

Reqd.

Thk. (T)

mm

Provided

Minimum

Thk.

mm

12525 01 01337

10-4440-001,

10-4440-002

01

323.9

265.6

33.32

29.16

SA-335 Gr.P22

428

160.0

114.0

0.82

25.5

29.16

12525 01 01341

10-4440-004

01

141.3

108.0

19.05

16.67

SA-335 Gr.P22

428

160.0

114.0

0.81

11.0

16.67

12525 01 01350

10-4440-006

01

141.3

108.0

19.05

16.67

SA-335 Gr.P22

479

159.0

96.9

0.81

13.0

16.67

12525 01 01351

10-4440-008,

10-4440-009

01

323.9

262.7

35.0

30.63

SA-335 Gr.P22

472

159.0

101.7

0.82

28.4

30.63

PROVIDED THK > REQUIRED THK.

HENCE SAFE.

* Min. Thk. = Nom.Thk - Mill Negative Tolerance

** Least Value of Ligament efficiency (Ref. Page 3 of this Calculation)

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

:0

TIRUCHIRAPPALLI

DATE

:08-06-2011

PAGE : 3 of 9

Doc.No : 12525-2500116

CALCULATION OF LIGAMANT EFFICIENCY FOR HEADER : IBR Reg.215

Long. Efficiency

SL.

No.

Drawing No.

DU No.

P. No.

02

Diagonal Efficiency

Cir.Efficiency

Hole

dia or

mean

dia (d)

Pitch

(Least

Value)

P

E1=

(P-d)/P

Angle

108.0

608

0.82

Hole

dia or

mean

dia (d)

Circ.

Pitch

Pc

E2 =

2(Pc-d)/Pc

Long.

Pitcha

Hole

dia or

mean

dia (d)

Angle

Governing

efficiency Lower

Value of E1, E2,

E3

Cos

Sin

E3

0.82

12525 01 01337

10-4440-001,

10-4440-002

02, 03

280

88.7

39.18

228.2

0.78

0.63

1.06

0.53

0.32

0.82

0.82

12525 01 01341

10-4440-004

02, 04

34.6

180

0.81

60

34.6

58

96.0

0.53

0.85

0.92

0.60

0.32

0.89

0.81

12525 01 01350

10-4440-006

02, 04

34.0

180

0.81

60

34.0

58

96.0

0.53

0.85

0.92

0.60

0.32

0.90

0.81

12525 01 01351

10-4440-008,

10-4440-009

02

108.0

608

0.82

0.82

02, 03

135

85.1

340.35

1.5

1.50

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE : 4 of 9

MAXIMUM UNCOMPENSATED HOLES IN HEADER: IBR Reg.187

D

P

T

f

e

=

=

=

=

=

Outside diameter of Header in mm

Working Pressure in bar (g)

Working Metal Temperature in C

Allowable Stress at Working Metal Temp. in MPa ( As per ASME Sec. II Part-D [Metric] )

Actual thickness of the Header in mm

Refer graph value (Fig 9b)

K

PxD

-----------------1.82 x f x e

------- Eqn. (20)

LIST OF HOLES IN HEADER

Sl.

No.

1

DRAWING. NO.

DU No.

Part

No.

OD

Thk. e

Work.

Pr.

P

mm

mm

bar (g)

MPa

323.9

29.2

160

428

Work.

Temp.

o

Stress

value

'f'

Dia.(OD)

x Thk.

114.0

0.86

Hole ID

Graph

value

mm

mm

mm

9443.3

108.0

89

Required

Compensation

Check

12525 01 01337

10-4440-001,

10-4440-002

02

03

323.9

29.2

160

428

114.0

0.86

9443.3

69.4

89

Not Required

12525 01 01341

10-4440-004

02,04

141.3

16.7

160

428

114.0

0.65

2355.3

34.6

76

Not Required

12525 01 01350

10-4440-006

02,04

141.3

16.7

159

479

96.9

0.76

2355.3

34.0

67

Not Required

10-4440-008,

10-4440-009

02

323.9

30.6

159

472

101.7

0.91

9919.4

108.0

76

Required

03

323.9

30.6

159

472

101.7

0.91

9919.4

62.2

76

Not Required

12525 01 01351

Note :

Refer Compensation calculation in Page 6 of this calculation.

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE : 5 of 9

STUB THICKNESS CALCULATION : IBR Reg.156 & Reg.338(a)

WP x D

T = --------------- + C ------------------ Eqn. (87)

2f + WP

where,

WP =

D =

f

=

T

=

C =

Design Pressure in bar (g)

External dia of stub in mm

Permissible stress for the mtrl. at the design temp in MPa ( As per ASME Sec. II Part-D [Metric] )

Required thk. of stub to be calculated in mm

0 mm , for design pressure > 70 kg/cm2

MINIMUM THICKNESS OF BRANCH : IBR Reg.156(c)

tmin

0.015 do + 3.2

mm

where, do = the outside diameter of the branch (in mm.)

LIST OF BRANCH STUB

Size

Sl.

No.

Drawing. No.

1

12525 01 01337

2

3

12525 01 01351

4

DU No.

10-4440-001,

10-4440-002

10-4440-008,

10-4440-009

Part

No.

D (do)

Nom.Thk

Material

Specification

Design

Temp.

o

Design

Pressure

Stress

Value (f)

Reqd. Thk.

as per

Min.Reqd.

Thk. as

per

Reg.338(a)

Reg.156(c)

Provided

Minimum

Thk. *

bar (g)

MPa

"T" mm

mm

mm

SA-335 Gr.P22

428

160.0

114.0

9.27

5.32

16.67

11.13

SA-335 Gr.P22

428

160.0

114.0

5.83

4.53

9.74

141.3

19.05

SA-335 Gr.P22

472

159.0

101.7

10.24

5.32

16.67

88.9

15.24

SA-335 Gr.P22

472

159.0

101.7

6.45

4.53

13.34

mm

mm

02

141.3

19.05

03

88.9

02

03

PROVIDED THICKNESS > REQUIRED THICKNESS.

HENCE SAFE.

* Provided Minimum Thk. = Nom.Thk - Mill Negative Tolerance

LIST OF BRANCH TUBE

Size

Sl.

No.

Drawing. No.

DU No.

Part

No.

D (do)

Min.Thk

mm

mm

Material

Specification

Design

Temp.

o

Design

Pressure

Stress

Value (f)

bar (g)

MPa

Reqd. Thk.

as per

Min.Reqd.

Thk. as

per

Reg.338(a)

Reg.338(b)

mm

mm

mm

Provided

Minimum

Thk.

12525 01 01341

10-4440-004

02, 04

42.2

3.8

SA-213 Gr.T22

428

160.0

114.0

2.77

3.25

3.8

12525 01 01350

10-4440-006

02, 04

42.2

4.19

SA-213 Gr.T22

479

159.0

96.9

3.21

3.25

4.19

PROVIDED THICKNESS > CALCULATED THICKNESS & MIN. REQD.THK. AS PER CODE.

HENCE SAFE.

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE : 6 of 9

COMPENSATION CALCULATION FOR HEADER STUB OPENINGS : IBR Reg.279

dn

ts

tn

en

es

fn

fs

=

=

=

=

=

=

=

Inside dia of Nozzle/Stub

Actual thickness of Header

Actual thickness of Nozzle/Stub

Equivalent thickness of Nozzle/Stub

Equivalent thickness of Unpierced Header

Nozzle/Stub Allowable Stress

Header Allowable stress

Smaller of values = 2.5ts or 2.5tn

bi

Nozzle/Stub projection inside.

Ci

(ts + 76) or (dn/2), whichever is greater

Cw

Fillet weld area

Area Removed X

= dn x es

Available Compensation Area Y

P.No./

Mark

No.

Material

Specn.

12525 01 01337

03

12525 01 01351

03

Sl.

No.

Drawing. No.

= [ 2 (tn-en) b x (fn/fs) ] + [ 2 (ts - es ) Ci ] + [ 2tn x bi x fn/fs ] + CW

dn

ts

tn

en

es*

fn

fs

bi

Ci

Cw

Y

2

mm

mm

mm

mm

MPa

MPa

mm

mm

mm

mm

mm

SA-335 Gr.P22

108

29.2

16.7

9.27

20.8

114.0

114.0

42

105.2

363

2247.1

2735.7

ADEQUATE

SA-335 Gr.P22

108

30.6

16.7

10.24

23.0

101.7

101.7

42

106.6

363

2487.7

2516.9

ADEQUATE

Available Compensation Area Y > Area Removed X

Hence Adequate.

Min. Thickness of Unpierced Header (where E=1)

WP x D

es* =

Y>X

mm2

mm

---------------

+ 0.762

mm

-------------- Eqn (72)

2 f E - WP

Where ,

WP =

Design Pressure of Header in bar (g)

Max. Internal diameter in mm

Permissible Working stress at the working metal temp in MPa ( As per ASME Sec. II Part-D )

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE : 7 of 9

HEADER END CAP THICKNESS CALCULATION : IBR Reg.278

WP x D x K

T

------------------

+C

mm

2f

where ,

WP =

Working Pressure of Header Endcap in bar (g)

Outside dia of Endcap in mm

Permissible stress for the mtrl. at the working metal temp in MPa ( As per ASME Sec. II Part-D [Metric] )

Required thk. to be calculated in mm

Diameter of opening in mm

Height of the Head measured on its outside surface from the junction of the dished part with cylindrical shell in mm

Shape Factor (from IBR Fig.23D)

H/D

Depth Ratio

0.75

0 mm

mm

Size

Sl.

No.

Drawing. No.

DU No.

Part

No.

mm

Nom

Thk.

Mm

mm

H/D

K**

Material

Specification

Design

Design

Pr. (WP)

Temp.

bar (g)

Provided

Reqd.

Thk. (T)

mm

Minimum Thk. *

Stress

Value

(f)

MPa

mm

12525 01 01337

10-4440-001,

10-4440-002

04

323.9

33.32

81.0

0.25

1.05

SA-234 Gr.WP22

160

428

114.0

24.6

29.2

12525 01 01341

10-4440-004

03

141.3

15.88

35.3

0.25

1.05

SA-234 Gr.WP22

160

428

114.0

11.2

13.9

12525 01 01350

10-4440-006

03

141.3

15.88

35.3

0.25

1.05

SA-234 Gr.WP22

159

479

96.9

12.9

13.9

12525 01 01351

10-4440-008,

10-4440-009

04

323.9

33.32

81.0

0.25

1.05

SA-234 Gr.WP22

159

472

101.7

27.3

30.6

PROVIDED THK > REQUIRED THK.

HENCE SATISFACTORY.

* Provided Minimum Thk. = Nom.Thk - Mill Negative Tolerance

**Shape Factor K (Curve for plain drum head) according to IBR reg.277(d) and Fig.23D

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE :

8 of 9

COIL TUBE THICKNESS CALCULATION : IBR Reg.156 & Reg.338(a)

WP x D

T = ---------------- + C ------------------ Eqn. (87)

2f + WP

where,

WP =

D

=

f

=

T

=

C

=

Design Pressure in bar (g)

Outer dia of tube in mm

Permissible stress for the mtrl. at the design temp in MPa ( As per ASME Sec. II Part-D [Metric] )

Required thk. of tubes to be calculated in mm

0 mm , for design pressure > 70 kg/cm2

Description

Design Temp.

C

Design Pr.

bar(g)

Material Specification

Stress Value (f)

MPa

523

159.0

SA-213 Gr.T91

117.7

SH 3 Outlet Coils

LIST OF TUBES

Size

Sl.

No.

Drawing. No.

Description

Part No.

Material

Specification

Design

Temp.

Reqd. Thk.

Min.Reqd.

as per

Thk. as per

Reg.338(a)

Design

Pressure

Stress

Value (f)

Minimum

Provided Thk.

Reg. 338(b)

bar (g)

MPa

mm

mm

mm

D (do)

Thk

mm

mm

42.2

3.81

SA-213 Gr.T91

463

159.0

137.4

2.31

3.25

3.81

42.2

3.81

SA-213 Gr.T91

523

159.0

117.7

2.67

3.25

3.81

42.2

3.81

SA-213 Gr.T91

463

159.0

137.4

2.31

3.25

3.81

42.2

3.81

SA-213 Gr.T91

523

159.0

117.7

2.67

3.25

3.81

42.2

3.81

SA-213 Gr.T91

523

159.0

117.7

2.67

3.25

3.81

42.2

3.81

SA-213 Gr.T91

463

159.0

137.4

2.31

3.25

3.81

42.2

3.81

SA-213 Gr.T91

523

159.0

117.7

2.67

3.25

3.81

For DU No. : 10-440-005

1

VAR-I to VARIV : Tubes

02 & 03

3

VAR-VII : Tubes 02 to 04

4

5

VAR-III :Tubes

04

VAR-V, VAR-VI,

VAR-VIII to

VAR-XII

02 to 04

VAR-I to VARXII : Inlet Conn.

Tube

01

42.2

3.8

SA-213 Gr.T22

428

160.0

114.0

2.77

3.25

3.80

VAR-I to VARII: Outlet Conn.

Tube

04

42.4

4.19

SA-213 Gr.T22

479

159.0

96.9

3.21

3.25

4.19

10

VAR III & IV :

Outlet Coils

42.4

4.19

SA-213 Gr.T22

479

159.0

96.9

3.21

3.25

4.19

11

VAR-VII :

Tubes

05

42.4

4.19

SA-213 Gr.T22

479

159.0

96.9

3.21

3.25

4.19

12

VAR-V, VAR-VI,

VAR-VIII to

VAR-XII : Outlet

Conn. Tube

05

42.4

4.19

SA-213 Gr.T22

479

159.0

96.9

3.21

3.25

4.19

12525 01 01344,

12525 01 01345

PROVIDED THICKNESS > CALCULATED THICKNESS & MIN. REQD.THK. AS PER CODE.

HENCE SAFE.

G.B. ENGINEERING ENTERPRISES PVT. LTD.

REV.

: 0

TIRUCHIRAPPALLI

DATE

: 08-06-2011

Doc.No : 12525-2500116

PAGE : 9 of 9

CONNECTION PIPE & FITTINGS THICKNESS CALCULATION : IBR Reg.338(a)

WP x D

T = --------------- + C ------------------ Eqn. (87)

2f + WP

where,

WP =

D

=

f

=

T

=

C

=

Design Pressure in bar (g)

External dia of Pipe/Fitting in mm

Permissible stress for the mtrl. at the design temp in MPa ( As per ASME Sec. II Part-D )

Minimum thk. of Pipe/Fitting to be calculated in mm

0 mm , for design pressure > 70 kg/cm

MINIMUM THICKNESS OF BRANCH : IBR Reg.156(c)

tmin

0.015 do + 3.2

mm

where, do = the outside diameter of the branch (in mm.)

Size

Sl.

No.

Drawing. No.

DU No.

Part No.

D (do)

Nom.Thk

mm

mm

Material

Specification

Design

Temp.

o

Reqd. Thk. Reqd. Thk.

as per

as per

Provided

Minimum

Thk. *

Design

Pressure

Stress

Value (f)

Reg.338(a)

Reg.156(c)

bar (g)

MPa

T mm

mm

mm

10-4440-003

03

141.3

15.88

SA-335 Gr.P22

428

160.0

114.0

9.27

5.32

13.90

10-4440-007

08

141.3

15.88

SA-335 Gr.P22

479

159.0

101.7

10.24

5.32

13.90

10-4440-010

11

88.9

11.13

SA-335 Gr.P22

428

160.0

114.0

5.83

4.53

9.74

10-4440-011

13

88.9

11.13

SA-335 Gr.P22

472

159.0

101.7

6.45

4.53

9.74

10-4440-003

04

141.3

15.88

SA-234 Gr.WP22

428

160.0

114.0

9.27

5.32

13.90

10-4440-007

141.3

15.88

SA-234 Gr.WP22

479

159.0

96.9

10.71

5.32

13.90

10-4440-010

12

88.9

11.13

SA-234 Gr.WP22

472

159.0

101.7

6.45

4.53

9.74

2

12525 01 01339

ELBOW

5

12525 01 01339

6

EQUAL TEE

7

12525 01 01339

* Provided Minimum Thk. = Nom.Thk - Mill Negative Tolerance

PROVIDED THK > REQUIRED THK.

HENCE SAFE.

DESCRIPTION

NAME

DATE

PREPARED BY

AEE

08-06-2011

CHECKED BY

SMR

08-06-2011

APPROVED BY

SAT

08-06-2011

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Unigraphics NX Student ManualDocument744 pagesUnigraphics NX Student Manualkimabat83% (12)

- Qpedia Oct14 Heat Transfer Calculations of ThermosyphonDocument5 pagesQpedia Oct14 Heat Transfer Calculations of ThermosyphonHMMSPNo ratings yet

- War and Peace Chapter I SummaryDocument2,882 pagesWar and Peace Chapter I SummaryHMMSPNo ratings yet

- An Overview of Heat Transfer PhenomenaDocument538 pagesAn Overview of Heat Transfer PhenomenaSchreiber_DiesesNo ratings yet

- An Overview of Heat Transfer PhenomenaDocument538 pagesAn Overview of Heat Transfer PhenomenaSchreiber_DiesesNo ratings yet

- Boilers, Superheaters and Reheaters - Babcock & Wilcox CompanyDocument0 pagesBoilers, Superheaters and Reheaters - Babcock & Wilcox Companyhozipek0% (1)

- Visit Report for APH Gearbox Drive Unit ShopDocument2 pagesVisit Report for APH Gearbox Drive Unit ShopHMMSPNo ratings yet

- Cable Tray Layout - I - Rev 2Document9 pagesCable Tray Layout - I - Rev 2HMMSPNo ratings yet

- 389 - 00!12!13-Thermocables Ltd-Cables (C & I) - UnpricedDocument6 pages389 - 00!12!13-Thermocables Ltd-Cables (C & I) - UnpricedHMMSPNo ratings yet

- Heat treatment vendor shop evaluation reportDocument2 pagesHeat treatment vendor shop evaluation reportHMMSPNo ratings yet

- English Job Resume CV) Job Interview Question and Answser English Tips PDFDocument7 pagesEnglish Job Resume CV) Job Interview Question and Answser English Tips PDFPepbdNo ratings yet

- FlyerDocument2 pagesFlyerHMMSPNo ratings yet

- Visit Report: Energy IndiaDocument3 pagesVisit Report: Energy IndiaHMMSPNo ratings yet

- Social AccountabilityDocument3 pagesSocial AccountabilityHMMSPNo ratings yet

- Ref Air PreheatersdfgdfgDocument1 pageRef Air PreheatersdfgdfgHMMSPNo ratings yet

- Pipe Specification Doniambo: Max MaxDocument3 pagesPipe Specification Doniambo: Max MaxHMMSPNo ratings yet

- Annexure HDocument1 pageAnnexure HHMMSPNo ratings yet

- CHP GuideDocument173 pagesCHP GuidemanolojethroNo ratings yet

- Invitation PowerGen 2014dfgdfgDocument2 pagesInvitation PowerGen 2014dfgdfgHMMSPNo ratings yet

- Company Organizaasdasdtion ChartDocument4 pagesCompany Organizaasdasdtion ChartHMMSPNo ratings yet

- TE-Boiler Claddingsdfsdf - Bansal RoofingDocument5 pagesTE-Boiler Claddingsdfsdf - Bansal RoofingHMMSPNo ratings yet

- B16 STDDFGDFGDocument2 pagesB16 STDDFGDFGHMMSPNo ratings yet

- 4.TEPRES en SmallDocument206 pages4.TEPRES en SmallHMMSPNo ratings yet

- Ati Corrosion Resistant Titanium Alloys Tds En4 v1Document5 pagesAti Corrosion Resistant Titanium Alloys Tds En4 v1HMMSPNo ratings yet

- TE-Boiler Cladsdfsdfding - Kailash RoofingDocument5 pagesTE-Boiler Cladsdfsdfding - Kailash RoofingHMMSPNo ratings yet

- Form 28Document3 pagesForm 28guhanbadboyNo ratings yet