Professional Documents

Culture Documents

Ur319 PDF

Uploaded by

mecanicochileOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ur319 PDF

Uploaded by

mecanicochileCopyright:

Available Formats

Features

Patented Ultipleat (laid-over pleat) filter medium pack

Coreless, cageless element configuration

Pall Stress-Resistant Technology (SRT) Media

In-to-out filter element flow path

Flows to 760 L/min (200 US gpm)

Pressures to 41 bar (600 psi)

Port size 1

1

2", 2" and 2

1

2"

Notes and Specifications

Maximum Working Pressure: 41 bar (600 psi)

Rated Fatigue Pressure: 41 bar (600 psi)

(10

6

cycles per NFPA T2.06.01R2-2001)

Burst Pressure: 145 bar (2100 psi)

Temperature Range: Fluorocarbon Seals: -29C to

120C (-20F to 250F)

60C (140F) maximum in

HWCF or water glycol fluids

Filter Element Burst Pressure: 10 bard (150 psid)

Materials of Construction: Tube: Carbon steel

Head and Cover: Ductile

Cast Iron

Ultipleat SRT

Element Construction: Inorganic fibers impregnated

and bonded with epoxy

resins. Polymer endcaps.

Anti-static media design.

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G.

Housing pressure drop is directly proportional to

specific gravity.

UR319 Series

Ultipleat

SRT Filters

UR319YR85 series Ultipleat SRT filter housing.

Data Sheet IMUR319ENa

0 0

0.75

1.25

0.50

1.75

5

10

15

20

25

0 50 100 150 200

Flow (US gpm)

P

(

b

a

r

d

)

P

(

p

s

i

d

)

Flow (L/min)

-24 Ports

-32 Ports

-40 Ports

0 300 450 600 760 150

1.50

1.00

0.25

Element Pressure Drop

Multiply actual flow rate times factor in table below to

determine pressure drop with fluid at 32 cSt (150 SUS), 0.9

S.G. Correct for other fluids by multiplying new viscosity in

cSt/32 (SUS/150) x new S.G./0.9. Note: factors are per

1000 L/min and per 1 US gpm.

319 Series Filter Elements bard/1000 L/min (psid/US gpm)

Length

Code AZ AP AN AS AT

08 5.52 (0.302) 2.30 (0.126) 1.82 (0.100) 1.32 (0.072) 0.82 (0.045)

13 3.31 (0.182) 1.38 (0.076) 1.09 (0.060) 0.79 (0.043) 0.49 (0.027)

20 2.18 (0.120) 0.91 (0.050) 0.72 (0.040) 0.52 (0.029) 0.33 (0.018)

40 1.10 (0.060) 0.46 (0.025) 0.36 (0.020) 0.26 (0.014) 0.16 (0.009)

Media

Substrate

Support Layer

(not shown)

Proprietary

Cushion

Layer

O-ring Seal

Proprietary

Outer Helical

Wrap

Up and

Downstream

Mesh Layers

SRT

Media

Auto-Pull

Element

Removal Tabs

Coreless/

Cageless

Design

Table 1: Housing Orientation Options

Code Option

C Cap service (tube up)

H Head service (tube down)

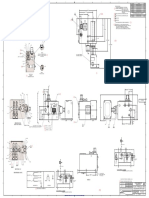

Dimensional Drawings

G1/4 to ISO228

Drain Port

G1/4 to ISO228

Vent Port

Element removal clearance

Overall

length

49.3 mm

1.94 in

49.3 mm

1.94 in

379 mm

14.92 in

107.9

73 mm

2.87 in

88.9 mm

3.5 in

114.3 mm

4.5 in

66.7 mm

2.62in

152.4 mm

6 in

41.3 mm

1.62 in

34.9 mm

1.37in

34.9 mm

1.37in

57.2 mm

2.25 in

114.3 mm

4.5 in

M12x1.5-6H

To BS3643

23 min. full thread

Typ 3 places

C Option H Option

C Option H Option Element Element

Overall Overall Removal Removal Empty

Length Length Length Clearance Clearance Weight

Code mm (in) mm (in) mm (in) mm (in) kg (lb)

08 424 (16.69) 437 (17.22) 230 (9) 100 (3.9) 18 (40)

13 559 (21.99) 572 (22.52) 370 (14.5) 100 (3.9) 21 (46)

20 729 (28.69) 742 (29.22) 530 (21) 100 (3.9) 23 (51)

40 1237 (48.69) 1250 (49.22) 1040 (41) 100 (3.9) 30 (66)

Table 2: Housing Port Options

Code Port

A24 1

1

2" SAE J514 straight thread

D24 1

1

2" Flange J518C code 61 with

1

2"-13 UNC holding bolts

A32 2" SAE J514 straight thread

D32 2" Flange J518C code 61 with

1

2"-13 UNC holding bolts

D40 2

1

2" Flange J518C code 61 with

1

2"-13 UNC holding bolts

C24 1

1

2" BSP ISO 228 threads

F24 1

1

2" ISO 6162 split flange with M12 x 1.75 holding bolts

C32 2" BSP ISO 228 threads

F32 2" ISO 6162 split flange with M12 x 1.75 holding bolts

F40 2

1

2" ISO 6162 split flange with M12 x 1.75 holding bolts

Table 4: Housing & Element

Length Options

Code Length (in)*

08 8

13 13

20 20

40 40

Table 6: Differential Pressure Indicator Options*

Code Indicator H Dim.

778NZ P type Visual indicator with thermal lockout 21mm (0.83in)

860MZ D type Visual indicator with no thermal lockout 21mm (0.83in)

861CZ L type Electrical switch (SPDT) with 6" leads 38mm (1.50in)

861CZ M type Electrical switch (SPDT) with 78mm (3.07in)

DIN43650 connector and matching cap

861CZ R type Electrical switch (SPDT) and neon light 89mm (3.50in)

indicator with DIN43650 connector and cap

771BZ S type Electrical switch (SPDT) with 3-pin 57mm (2.24in)

MS connector

* Nominal length

Because of developments in technology these data or procedures may be subject to change. Consequently

we advise users to review their continuing validity annually. Part numbers quoted above are protected by the

Copyright of Pall Europe Limited.

, Pall and Ultipleat are trademarks of Pall Corporation.

Filtration. Separation. Solution is a service mark of Pall Corporation.

indicates a trademark registered in the USA.

Copyright 2007, Pall Corporation.

July 2007. Printed in England. IMUR319ENa

Visit us on the web at www.pall.com

Pall Corporation has offices and plants throughout the world in locations including: Argentina,

Australia, Austria, Belgium, Brazil, Canada, China, France, Germany, Hong Kong, India,

Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New Zealand, Norway,

Poland, Puerto Rico, Russia, Singapore, South Africa, Spain, Sweden, Switzerland, Taiwan,

Thailand, United Arab Emirates, United Kingdom, United States, and Venezuela. Distributors

are located in all major industrial areas of the world.

Pall Industrial Manufacturing

New York - USA

+1 888 333 7255 toll free

+1 516 484 3600 telephone

+1 516 484 6247 fax

Portsmouth - UK

+44 (0)23 9230 3303 telephone

+44 (0)23 9230 2507 fax

Element P/N: UE 319 Z

Housing P/N: UR 319 ++ Z 9 YR85

Ordering Information

Table 1 Table 2 Table 4 Table 5

Table 3 Table 4

* Other indicator options are available; contact Pall.

Seal Kit P/N: UR 319 SKZ

Table 3: Filter Element Options

Code

x(c)

1000 CST Rating*

based on ISO 16889

AZ 3 08/04/01

AP 5 12/07/02

AN 7 15/11/04

AS 12 16/13/04

AT 22 17/15/08

* Use only if R indicator

option is selected from

Table 6.

Table 7: Indicator Pressure

Setting Options*

Code Valve

084 For A Valve Option

Housings (1.1 bard - 16 psid)

091 For G and N Valve Options

Housings (3.5 bard - 50 psid)

* Other setting options are available;

contact Pall.

Table 5: Housing Bypass Valve Options

Code Valve

A 1.7 bard - 25 psid Use 084 code indicator only

G 4.5 bard - 65 psid Use 091 code indicator only

N Non-Bypass - Use 091 code indicator only

Notes: Z indicates fluorocarbon seals are standard. Other options are available;

contact Pall. The number 9 at the end of the Housing P/N designates 2 indicator

ports, one fitted with a plastic shipping plug and the other with a blanking plug

(P/N HC9000A104Z).

Indicator P/N: RC Z

Table 6 Table 7 Table 9

Table 9: R type Indicator Options

Code Option

110AC 110V AC

220AC 220V AC

24DC 24V DC

(C option housing shown)

Note: If no differential pressure indicator is selected B Type blanking plug

(P/N HC9000A104Z) must be ordered separately and fitted to replace the

plastic shipping plug.

*Other seal material options are available; Contact Pall.

Table 8: M & R-Type

Indicator Codes*

Code Option

YM M option

YR R option

* Use only if R or M Indicator

is selected from Table 6

Table 8

* CST: Cyclic Stabilization Test to

determine filter rating under stress

conditions, based on SAE ARP4205

You might also like

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- Service Bulletin: Subject: Ingestive Cleaning of Solar Gas Turbine EnginesDocument6 pagesService Bulletin: Subject: Ingestive Cleaning of Solar Gas Turbine EnginesIfran SierraNo ratings yet

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- Product Manual 40183 (Revision K, 8/2018) : EML100 ActuatorDocument24 pagesProduct Manual 40183 (Revision K, 8/2018) : EML100 Actuatoracil stop100% (1)

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadNo ratings yet

- Data Sheet RVO 07011Document2 pagesData Sheet RVO 07011cvg ertd100% (1)

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- Don GTS BrochureDocument8 pagesDon GTS BrochuresanigzlNo ratings yet

- Manual Mto 1203 - 5,6 MWDocument98 pagesManual Mto 1203 - 5,6 MWAgustin BaratcabalNo ratings yet

- SIL Certified Large Electric Sonic Valve (LESV) Gas Fuel Control ValveDocument60 pagesSIL Certified Large Electric Sonic Valve (LESV) Gas Fuel Control ValveLéandre Ettekri NdriNo ratings yet

- Standard Design of Wazu (Wadu) KhanaDocument3 pagesStandard Design of Wazu (Wadu) KhanaSohail ShaikhNo ratings yet

- Industrial gas generator parts catalogueDocument62 pagesIndustrial gas generator parts cataloguejuanaNo ratings yet

- 6.13 - E7011-3-11-16 - Handbook Filtration - HYDAC International PDFDocument22 pages6.13 - E7011-3-11-16 - Handbook Filtration - HYDAC International PDFMaximiliano DreyerNo ratings yet

- SBLM2500 Ind 162Document6 pagesSBLM2500 Ind 162Daniil SerovNo ratings yet

- Sotera Diaphragm Pumps (DV Motor)Document8 pagesSotera Diaphragm Pumps (DV Motor)Imran Shahzad KhanNo ratings yet

- Peppers Catalogue GlandsDocument28 pagesPeppers Catalogue GlandsVlad Andronache100% (1)

- Caterpillar Gas Engine Data Update for GERPDocument2 pagesCaterpillar Gas Engine Data Update for GERPvictor.ciprianiNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- 3050-OlvDocument86 pages3050-OlvMuhammad Darussalam Herdani100% (1)

- Baa1 PDFDocument149 pagesBaa1 PDFfebyNo ratings yet

- F Class Inspection Maintenance Fact SheetDocument1 pageF Class Inspection Maintenance Fact SheetMartinNo ratings yet

- Nireco Servojet Sj2: GeneralDocument8 pagesNireco Servojet Sj2: GeneralKen JunNo ratings yet

- Section B-B Shuttle Valve: Valve, Hydraulic, Self Sequencing RatchetDocument2 pagesSection B-B Shuttle Valve: Valve, Hydraulic, Self Sequencing Ratchetnikon reddyNo ratings yet

- Install bevel gears for peak performanceDocument3 pagesInstall bevel gears for peak performancejemanuelvNo ratings yet

- Nigeria Gas Specification - GACNDocument1 pageNigeria Gas Specification - GACNOlusegun OyebanjiNo ratings yet

- Supplementary Data: Mobile Power Generation Titan™ 130S Gas Turbine-Driven Generator SetDocument17 pagesSupplementary Data: Mobile Power Generation Titan™ 130S Gas Turbine-Driven Generator SetGAS PLANTNo ratings yet

- GE Air Valve Installation and Maintenance GuideDocument7 pagesGE Air Valve Installation and Maintenance Guidecachuco1234No ratings yet

- Hil Co Master CatalogDocument88 pagesHil Co Master CatalogcolimecNo ratings yet

- VH60-100 Presentation Philippe ChabinDocument46 pagesVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- Compressor Over-Lubrication PresentationDocument38 pagesCompressor Over-Lubrication Presentation1mmahoneyNo ratings yet

- Installation, Care and Operation Manuals and Parts List: Main IndexDocument1 pageInstallation, Care and Operation Manuals and Parts List: Main IndexWalter Nuñez LopezNo ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladNo ratings yet

- Computers: Acer - N20H2 : SF114-33Document2 pagesComputers: Acer - N20H2 : SF114-33Alhams TorrentNo ratings yet

- Start Up AirDocument2 pagesStart Up AirIsaac FloresNo ratings yet

- 275GL Series 12V 275GL+: Gas Engine With ESM 2Document2 pages275GL Series 12V 275GL+: Gas Engine With ESM 2Jaadi 786100% (1)

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Parts ListDocument31 pagesParts ListMohammed ElarbedNo ratings yet

- 8277e200 g004Document38 pages8277e200 g004CRUCUERNo ratings yet

- H2S & Total Sulfur AnalyzersDocument16 pagesH2S & Total Sulfur AnalyzersBryan TungNo ratings yet

- Ss Mobilith SHCDocument2 pagesSs Mobilith SHCFarrukh JamalNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- DNFT A-6348 Led-Ps PDFDocument4 pagesDNFT A-6348 Led-Ps PDFhugoheloNo ratings yet

- EX18195003 - 001-6901-01 Rev 0 OBSDocument2 pagesEX18195003 - 001-6901-01 Rev 0 OBSRichardNo ratings yet

- Pulsation Damper Sizing RevDocument13 pagesPulsation Damper Sizing RevFrancesca CoattiNo ratings yet

- NIC 13.20 Rev.01Document15 pagesNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- Lube Oil System: MLN Block 405, Algeria Operator TrainingDocument10 pagesLube Oil System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Equipment Definition: Component LiteratureDocument17 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- N67 TE2F: 1/ GeneralDocument3 pagesN67 TE2F: 1/ General林哲弘100% (1)

- LM5000 Generator Parts and EquipmentDocument59 pagesLM5000 Generator Parts and EquipmentAnibal QuezadaNo ratings yet

- Aeroderivative Gas TurbinesDocument2 pagesAeroderivative Gas TurbinesTufan Maity100% (1)

- Sundyne LMC-347 Compressor Cross Section DiagramDocument1 pageSundyne LMC-347 Compressor Cross Section DiagrammohammadNo ratings yet

- TM25Document4 pagesTM25Richarson Ochoa100% (1)

- ABB MotorsDocument22 pagesABB MotorsKhaled HassanNo ratings yet

- Gefico Brochure +UFDocument40 pagesGefico Brochure +UF1zorro10% (1)

- Proyecto de Modernización Refineria Talara: Document Code / Codigo: Purchase Order/Orden de Compra N°Document10 pagesProyecto de Modernización Refineria Talara: Document Code / Codigo: Purchase Order/Orden de Compra N°Michael H. PrevooNo ratings yet

- Smart Fuel Level Indicator SystemDocument4 pagesSmart Fuel Level Indicator SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Datasheet Amt102 EncoderDocument8 pagesDatasheet Amt102 EncoderPablo Davila100% (1)

- Boss DD-7 Service NotesDocument24 pagesBoss DD-7 Service NotesFernando GómezNo ratings yet

- Understanding NLPDocument2 pagesUnderstanding NLPAbdul Ghafoor HaiderNo ratings yet

- Understanding NLPDocument2 pagesUnderstanding NLPAbdul Ghafoor HaiderNo ratings yet

- Cathodic Protection Monitoring Systems For PipelinesDocument1 pageCathodic Protection Monitoring Systems For PipelinesAbdul Ghafoor HaiderNo ratings yet

- Vitamin D Is Called TheDocument6 pagesVitamin D Is Called TheAbdul Ghafoor HaiderNo ratings yet

- Financing Decisions Creditors and InvestorsDocument35 pagesFinancing Decisions Creditors and InvestorsPramod KumarNo ratings yet

- Fix Nikon Fee ErrorDocument5 pagesFix Nikon Fee ErrorAbdul Ghafoor HaiderNo ratings yet

- Hello WorldDocument1 pageHello WorldAbdul Ghafoor HaiderNo ratings yet