Professional Documents

Culture Documents

6T30 6T40-45 Rebuilders Kwik Reference Guide - KRG - 6T30 6T40-45

Uploaded by

rebuilder67Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6T30 6T40-45 Rebuilders Kwik Reference Guide - KRG - 6T30 6T40-45

Uploaded by

rebuilder67Copyright:

Available Formats

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Clutch Clearances Adjusted By:

Low-Reverse .............................................Not Adjustable

Forward 1-2-3-4.........................................Not Adjustable

Overdrive 4-5-6 .........................................Not Adjustable

Intermediate 2-6 ........................................Not Adjustable

Direct 3-5-R...............................................Not Adjustable

Unit Endplays Location Selective

Torque Specifications

A/Trans Control Bolt ........................................ 71 Lb. In.

A/Trans Flex Plate Bolt .................................... 45 Lb. Ft.

A/Trans Fluid Pump Bolt to Converter Housing

First Pass............................................... 89 Lb. In.

Final Pass.............................................. 45 Turn

A/Trans Fluid Pump Cover Bolt .......................106 Lb. In.

Control Solenoid Valve Assembly (w/TCM and Body)

to Case Bolt M6x97 ............................. 89 Lb. In.

M5x40.5 .......................... 62 Lb. In.

Control Valve Body Assembly (Complete) Bolt 62 Lb. In.

Control Valve Body to Case Bolt

M6x53 ............................. 97 Lb. In.

M6x60 ............................. 97 Lb. In.

Control Valve Body Cover Bolt ........................106 Lb. In.

Torque Specifications

Drain Plug.................................................................106 Lb. In.

Fluid Level Hole Plug ...............................................106 Lb. In.

Fluid Pressure Test Hole Plug..................................106 Lb. In.

Front Differential Carrier Baffle Bolt -

Converter Housing ........................................106 Lb. In.

Front Differential Carrier Baffle Bolt - Case..............106 Lb. In.

Input Shaft Support Bolt ...........................................106 Lb. In.

Input Speed Sensor Bolt .......................................... 80 Lb. In.

Manual Shift Detent Spring ......................................106 Lb. In.

Output Speed Sensor Bolt........................................ 80 Lb. In.

Torque Converter and Differential Housing Bolt

First Pass ...................................................... 89 Lb. In.

Final Pass...................................................... 50 Turn

N//A

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Clutch Application

Range Gear

1 2 3 4 5 6

4-5-6

Clutch

3-5 Rev

Clutch

2-6

Clutch

Low & Rev Clutch

(One Way Clutch)

Low &

Reverse Clutch

1-2-3-4

Clutch

PARK P Applied*

REV R Applied Applied

NEU N Applied

D

1st Braking Holding Applied Applied

1st Holding Applied

2nd Applied Applied

3rd Applied Applied

4th Applied Applied

5th Applied Applied

6th Applied Applied

Expected Operating Condition if Component in Column Number is Inoperative

Column # Condition

1 No Fourth, Fifth or Sixth Gears

2 No Reverse, No Third or Fifth Gears

3 No Second or Sixth Gears

4 No First Gear

5 No Reverse, No engine braking in First Gear

6 No First, Second, Third or Fourth Gears

*Applied with

no load

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Solenoid Application

Gear Shift Sol. 1

1-2-3-4 CL PC

Sol 5 N.L.

2-6 CL PC

Sol 4 N.L.

3-5 Rev CL PC

Sol 2 N. H.

Low Rev 4-5-6 CL

PC Sol 3 N. H.

Gear Ratio

PARK ON OFF OFF OFF ON --

REVERSE ON OFF OFF ON ON 2.940

NEUTRAL ON OFF OFF OFF ON --

1ST BRAKING ON ON OFF OFF ON 4.584

1ST OFF ON OFF OFF OFF 4.584

2ND OFF ON ON OFF OFF 2.964

3RD OFF ON OFF ON OFF 1.912

4TH OFF ON OFF OFF ON 1.446

5TH OFF OFF OFF ON ON 1.000

6TH OFF OFF ON OFF ON 0.746

For Shift Solenoid 1, ON = Solenoid Energized (Pressurized) OFF = Solenoid De-energized (No Pressure).

For Pressure Control Solenoids, ON = Pressurized. OFF = No Pressure

Normal resistance Pressure Control Solenoid 3-5 ohms at 70F. Shift solenoid 16-20 ohms at 70F

N.L. = Normally Low

N.H. = Normally High

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Solenoid Resistance

Solenoid Resistance (at 70F)

Pressure Control Solenoid 3 (Low/Reverse/4-5-6) 3-5 Ohms

Pressure Control Solenoid 2 (3-5-Reverse) 3-5 Ohms

TCCPressure Control Solenoid 3-5 Ohms

Shift Solenoid 1 16-20 Ohms

Pressure Control Solenoid 5 (1-2-3-4) 3-5 Ohms

Pressure Control Solenoid 4 (2/6) 3-5 Ohms

Line Pressure Control Solenoid 3-5 Ohms

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Solenoid ID

Component Number

Pressure Control Solenoid 3

(Low/Reverse/4-5-6)

1

Pressure Control Solenoid 2 (3-5-Reverse) 2

TCCPressure Control Solenoid 3

Shift Solenoid 1 4

Pressure Control Solenoid 5 (1-2-3-4) 5

Pressure Control Solenoid 4 (2/6) 6

Line Pressure Control Solenoid 7

Transmission Fluid Pressure Switch

(TFP 2) (3-5-Reverse)

8

Transmission Fluid Pressure Switch

(TFP 3) (2/6)

9

Transmission Fluid Pressure Switch

(TFP1) (1-2-3-4)

10

Pass Through Connector 11

Transmission Fluid Pressure Switch

(TFP 4) (Low/Reverse/4-5-6)

12

Bottom of Solenoid Assembly

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Gear Ratio

Gear Ratio

1st/low 4.584:1

2nd 2.964:1

3rd 1.912:1

4th 1.446:1

5th 1:1

6th 0.746:1

Reverse 2.94:1

Effective Final Drive Gear Ratio 2.89/3.17/3.87

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Line Pressure Information

Gear Line

Pressures at Idle*

P 338-379 kPa (49-55 psi)

R 621-689 kPa (90-100 psi)

N 338-379 kPa (49-55 psi)

D 338-379 kPa (49-55 psi)

L 338-379 kPa (49-55 psi)

Pressure at Wide Open Throttle (WOT) Stall *

P 338-379 kPa (49-55 psi)

R 1,868-2,068 kPa (271-300 psi)

N 338-379 kPa (49-55 psi)

D 1,868-2,068 kPa (271-300 psi)

L 1,868-2,068 kPa (271-300 psi)

*All pressures are approximate

Pressure Tap and Oil Level Plug

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Sprag Rotation

CAUTION

DO NOT CLEAN IN WATER OR WITH WATER-

BASED SOLVENTS. DAMAGE TO THE

COMPONENT MAY OCCUR.

NOTE

THE LOW ONE-WAY CLUTCH

CANNOT BE DISASSEMBLED.

Clean and inspect the low one-way clutch for cracks and damaged

splines. The internal splined section should rotate clockwise and lock

when rotated counterclockwise. If any damage is found or the clutch

does not rotate or lock, install a new low one-way clutch.

Inspect the forward clutch surface for damage. If the surface is burned

or worn excessively, install a new one-way clutch.

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Connector

Pin Wire Circuit Function

1 0.5 RD/WH 1840 Battery Positive Voltage

2 0.35 BK/WH 451 Ground

3 0.5 D-GN 6307 Clutch Start Neutral Start (PPEI_#3) Signal

4-5 - - Not Used

6 0.35 TN/BK 2500 High Speed GMLANSerial Data Bus +

7 0.35 TN/BK 2500 High Speed GMLANSerial DataBus +

8 0.35 TN 2501 High Speed GMLANSerial Data Bus -

9-11 - - Not Used

12 0.5 PK 2139 Ignition Voltage

13 0.5 D-BU 5985 Serial Data Wake-Up Signal

14 0.35 TN 2501 High Speed GMLANSerial Data Bus -

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Valve Body

1 First-Reverse and 4-5-6 Clutch Regulator Valve Train

2 1-2-3-4 Clutch Boost Valve Train

3 1-2-3-4 Clutch Regulator Valve Train

4 2-6 Clutch Regulator Valve Train

5 3-5 Reverse Clutch Regulator Valve Train

6 Clutch Piston Dam Feed Regulator Valve Train

7 TCCRegulator Apply Valve Train

8 Clutch Select Valve Train

9 Actuator Feed Limit Valve Train

10 Manual Valve

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

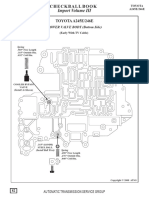

Checkball Locations

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Pump

Item Description

300 Torque Converter Fluid Seal Retainer

301 Torque Converter Fluid Seal Assembly

302 A/Trans Fluid Pump Cover Bolt

303 A/Trans Fluid Pump Body

304 Pump Blowoff Ball Valve

305 Pump Blowoff Valve Spring

306 Pressure Regulator Valve Bore Plug Retainer

307 Pressure Regulator Valve Bore Plug

308 Pressure Regulator Valve Spring

309 Pressure Regulator Valve

310 Torque Converter Clutch Blowoff Ball Valve

311 Torque Converter Clutch Blowoff Ball Valve Spring

312 Torque Converter Clutch Control Valve

313 Torque Converter Clutch Control Valve Spring

314 Torque Converter Clutch Control Valve Spring Retainer

315 A/Trans Fluid Pump Drive Gear

316 A/Trans Fluid Pump Driven Gear

317 Cover to Body Locating Pin

318 A/Trans Fluid Pump Cover Assembly

319 Torque Converter Fluid Seal Assembly

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Bushing/Bearing Locations

Item Description

211

Front Differential Carrier

Bearing Assembly AWDModels

223 Drive Sprocket Bearing Assembly

226 Drive Sprocket Thrust Washer

228 Drive Sprocket Bearing Assembly

231

Differential Sun Gear to

Differential Housing Bearing Assembly

233 Front Differential Carrier Bearing Assembly

530

Reaction Carrier Hub Thrust

Bearing Assembly

538

3-5-Reverse and 4-5-6

Clutch Housing Thrust Bearing

556 Output Sun Thrust Bearing Assembly

565

Reaction Sun Gear Thrust

Bearing Assembly

568 Input Carrier Thrust Bearing Assembly

569 Input Sun Gear Thrust Bearing Assembly

572 Input Sun Gear Thrust Bearing Assembly

573 Output Carrier Thrust Bearing Assembly

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Air Test

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Technical Tips for Rebuilding this unit

Drain Plug

The drain plug is located on the lower automatic

transmission case assembly.

It is installed vertically on the lowest point of the

transmisison.

When removing the drain plug, approximately 50%

of the fluid will drain.

Drain plugs require no sealant, but they must be torqued

to specification.

NOTE

TORQUE CONVERTER FAILURE

COULD CAUSE LOSS OF DRIVE

GEAR AND/OR LOSS OF POWER

Be sure to install the converter in a straight up and down

position to avoid damage to the internal seal.

Do not over-tighten the lift tools because the torque

converter may become damaged.

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Technical Tips for Rebuilding this unit

Fluid Level Control Valve (Inside Transmission) Fluid Level Control Valve (Outside Transmission)

The Fluid Level Control valve is designed to control the fluid level in the case by trapping oil in the Control Valve Body Cover

Assembly.

It reacts to temperature changes in the fluid to OPEN or CLOSE a fluid passage.

At low temperatures the control valve allows fluid to drain into the sump - 60C (140F) or below.

Above 60C, the fluid will remain in the valve body cover not allowing it to drain back into the case.

As the temperature increases, the passage gets blocked, trapping fluid in the valve body cover.

The trapped fluid helps to maintain the proper level in the valve body cover for proper operation of the hydraulic system in the

transmission.

Rebuilders Kwik

Reference Guide

Transmission Type: 6T30/6T40-45

New - 7/2013

Technical Tips for Rebuilding this unit

Output Speed Sensors (OSS)

possible

cable

crushed

possible

cable

crushed

Input Speed Sensors (ISS)

Manual Shift Detent w/Shaft

Position Switch Lever Assembly

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- 6F35 GearspdfDocument6 pages6F35 GearspdfNuman283% (12)

- Suzuki GS850 Service ManualDocument454 pagesSuzuki GS850 Service ManualAndre Serjey Paseschnikoff67% (3)

- GM 6L50 80 90Document42 pagesGM 6L50 80 90Tony Holmes100% (10)

- GM 6L50 80 90Document42 pagesGM 6L50 80 90Tony Holmes100% (10)

- GM 6L50 80 90Document42 pagesGM 6L50 80 90Tony Holmes100% (10)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- 6T40 Manual PDFDocument10 pages6T40 Manual PDFJesus Teodoro Mendoza Guerra100% (3)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- 722 9Document6 pages722 9rebuilder67100% (7)

- McCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFDocument25 pagesMcCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- Acura Honda Transmission Clutch Clearance SpecsDocument8 pagesAcura Honda Transmission Clutch Clearance Specspankituna5487100% (2)

- 09G Tech 2!!Document14 pages09G Tech 2!!Manos Stavrou78% (9)

- 6T40Document2 pages6T40Abbode Horani100% (3)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- AW 80SC 6 Speed FWD - SonnaxDocument45 pagesAW 80SC 6 Speed FWD - Sonnaxaxeldub100% (9)

- 6t40 UpdatesDocument40 pages6t40 UpdatesFernando Barragán B100% (2)

- SAP ATRA Webinar RE5RO5ADocument66 pagesSAP ATRA Webinar RE5RO5ACarlos Pereira86% (7)

- Aw60 41sn Zip BookDocument8 pagesAw60 41sn Zip BookRiki Nurzaman100% (3)

- Overview 6T40-45 TransmissionDocument14 pagesOverview 6T40-45 TransmissionLeigh100% (1)

- 6T40 ManualDocument10 pages6T40 ManualSandor Jakab100% (4)

- Atra BulletinDocument2 pagesAtra Bulletinossoski100% (3)

- Technical Service Information Technical Service Information: CVT 7 - JF015E/RE0F11A/F1CJBDocument2 pagesTechnical Service Information Technical Service Information: CVT 7 - JF015E/RE0F11A/F1CJBmohammad100% (2)

- Atra Seminar 1990-2011 PDFDocument5,067 pagesAtra Seminar 1990-2011 PDFJosé Luis100% (13)

- DPS6 IntroDocument35 pagesDPS6 Introossoski100% (6)

- 62TE CompounderDocument4 pages62TE CompounderFSR1407100% (5)

- ZF8HP RebuildDocument62 pagesZF8HP RebuildKhristina Stefanova94% (16)

- ATRA 41TE Rebuild (Chrysler A 604)Document115 pagesATRA 41TE Rebuild (Chrysler A 604)Patricio Bacigalupi100% (4)

- GE-Gas Turbine SparesDocument12 pagesGE-Gas Turbine Sparesmrjoshiroshan100% (2)

- Rexroth 28250 PumpandservDocument40 pagesRexroth 28250 PumpandservWillington Augusto Ariza100% (2)

- A1083290 - MAN - CG+MP16II RevBDocument104 pagesA1083290 - MAN - CG+MP16II RevBhardev88% (8)

- 6T40 45Document8 pages6T40 45yasin100% (1)

- Jatco JF613E, RE6F01A, W6AJA, F6AJA, AJO, Introduction: Sponsored byDocument49 pagesJatco JF613E, RE6F01A, W6AJA, F6AJA, AJO, Introduction: Sponsored byainginer100% (7)

- AWTF80-81SC Huyndai VeracruzDocument6 pagesAWTF80-81SC Huyndai VeracruzRafael H Juliao Bolaño100% (1)

- Gears RE5R05A PDFDocument8 pagesGears RE5R05A PDFossoskiNo ratings yet

- Aw5550SnZip 1580008475 PDFDocument10 pagesAw5550SnZip 1580008475 PDFyhovany100% (1)

- 6F35N IntroDocument47 pages6F35N Introacmemail583No ratings yet

- Af-40 VB DiagDocument4 pagesAf-40 VB Diagsanya72100% (2)

- 6T40 DetayDocument52 pages6T40 Detaysuattosun100% (11)

- 6F35Document5 pages6F35Nancy Garcia100% (1)

- 6L45Document1 page6L45PedroMecanico100% (2)

- 6T40 45 Diag FixesDocument69 pages6T40 45 Diag Fixesjosue100% (12)

- The 09G Flared Shift ProblemsDocument3 pagesThe 09G Flared Shift ProblemsJose Cencič100% (1)

- Jatco6speed Intro PDFDocument49 pagesJatco6speed Intro PDFleeroy381100% (1)

- Gears June 2015Document68 pagesGears June 2015Rodger Bland100% (2)

- Import Checkball Vol III 82-92 PDFDocument11 pagesImport Checkball Vol III 82-92 PDFJulio Chalbaud100% (1)

- Looking Inside 09g Part 3Document8 pagesLooking Inside 09g Part 3Irina Veresinina100% (2)

- 16K in PDFDocument2 pages16K in PDFossoskiNo ratings yet

- 5L40 eDocument1 page5L40 ePedroMecanicoNo ratings yet

- 2007 ATRA Seminar Manual ContentsDocument272 pages2007 ATRA Seminar Manual Contentschoco84No ratings yet

- Fdocuments - in - Manual Atsg Awf21 Colegio Atsg Awf21 If Looking For A Book Manual Atsg Awf21Document3 pagesFdocuments - in - Manual Atsg Awf21 Colegio Atsg Awf21 If Looking For A Book Manual Atsg Awf21JorgeNo ratings yet

- 6T40 Internal: Presented By: Bill Brayton ATRA Senior Research TechnicianDocument45 pages6T40 Internal: Presented By: Bill Brayton ATRA Senior Research TechnicianAntonio Del Angel80% (5)

- 948te Zf9hp48 Zip inDocument12 pages948te Zf9hp48 Zip inRonald100% (1)

- 6T40 Gen2 Zip in PDFDocument10 pages6T40 Gen2 Zip in PDFAlberto Del Rio Mejia100% (1)

- Welcome To Today's Presentation Sponsored byDocument47 pagesWelcome To Today's Presentation Sponsored byfadrique54No ratings yet

- Toyota U140, U240 4-Speed Transmission GuideDocument6 pagesToyota U140, U240 4-Speed Transmission Guidejuan carlos garcia100% (1)

- CVTDocument240 pagesCVTمحمد جاسم100% (2)

- 18speed FullerDocument100 pages18speed FullerPieter Coetzer100% (4)

- Manual de Servicio/partes/operacion Compresor Quincy Modelo 350 - 350 Quincy Compressor Manual Operation/service/spare PartsDocument20 pagesManual de Servicio/partes/operacion Compresor Quincy Modelo 350 - 350 Quincy Compressor Manual Operation/service/spare PartsTalleres Lilo100% (2)

- Solenoid ValvesDocument71 pagesSolenoid ValvesAlberto De la Cruz100% (1)

- HLDocument15 pagesHLthierrylindoNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Document33 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Luciano LiuzziNo ratings yet

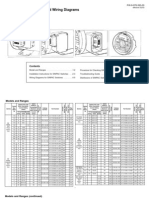

- Installation Instructions and Wiring Diagrams For All Models and RangesDocument8 pagesInstallation Instructions and Wiring Diagrams For All Models and RangesMaria MusyNo ratings yet

- 4L30-E 1-2 Band FailureDocument5 pages4L30-E 1-2 Band Failurerebuilder67No ratings yet

- 4L30-E Line Pressure TapsDocument1 page4L30-E Line Pressure Tapsrebuilder67No ratings yet

- Allisson 4000MH Transmission Owners ManualDocument65 pagesAllisson 4000MH Transmission Owners Manualrebuilder67100% (1)

- Allison 3000 Shift SelectorDocument10 pagesAllison 3000 Shift Selectorrebuilder670% (1)

- Tractor Operator AgricultureDocument9 pagesTractor Operator AgricultureConstantin CarpenNo ratings yet

- Product Information: Diesel Extra LD 15W40Document2 pagesProduct Information: Diesel Extra LD 15W40movie hunterNo ratings yet

- Sany 230C - Sy230c8c3kDocument268 pagesSany 230C - Sy230c8c3kLS Hidráulica ManilhaNo ratings yet

- MT 2010Document8 pagesMT 2010kokonunezNo ratings yet

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDocument43 pagesAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraNo ratings yet

- An Introduction To Boiler Maintenance EditedDocument7 pagesAn Introduction To Boiler Maintenance EditedPritv SavalagiNo ratings yet

- F1440Document6 pagesF1440Gustavo SuarezNo ratings yet

- GARDNER DENVER Style PZ10-11 Fluid End Assembly 5000 PSIDocument3 pagesGARDNER DENVER Style PZ10-11 Fluid End Assembly 5000 PSISebastian ParraNo ratings yet

- Training Report HPGCLDocument34 pagesTraining Report HPGCLSidhant BhayanaNo ratings yet

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456No ratings yet

- New ChangeDocument68 pagesNew ChangeAnoop Kamla PandeyNo ratings yet

- Cressi-Sub Regulator User Manual: 1st Stage ComponentsDocument39 pagesCressi-Sub Regulator User Manual: 1st Stage ComponentsSergio GlezNo ratings yet

- TD302REC: Specifications Standard EquipmentDocument2 pagesTD302REC: Specifications Standard EquipmentfuffinoNo ratings yet

- Chapter-1, Simple StressDocument71 pagesChapter-1, Simple Stresssherlockhisham100% (2)

- Cia 1 Paper 2022-23Document3 pagesCia 1 Paper 2022-23veerendra kumarNo ratings yet

- AB Die Casting EngDocument24 pagesAB Die Casting Engkaniappan sakthivelNo ratings yet

- A17-23495A Installation Manual KS12-BCV-413B L1100Document19 pagesA17-23495A Installation Manual KS12-BCV-413B L1100davalgonzalezNo ratings yet

- Memoria Muro Mamposteria Escalera QuickMasonryDocument7 pagesMemoria Muro Mamposteria Escalera QuickMasonryJulio Marcial Ramos QuinteroNo ratings yet

- Fluid Mechanics Test and Exam DetailsDocument8 pagesFluid Mechanics Test and Exam DetailsDiego FungNo ratings yet

- DX SPLIT Acum L Cadx l50hzDocument21 pagesDX SPLIT Acum L Cadx l50hzFARIDNo ratings yet

- ADAMS Lecture 1 Introduction To ADAMSDocument19 pagesADAMS Lecture 1 Introduction To ADAMSAneesh KalraNo ratings yet

- PART-66 Training - Aircraft Maintenance LicenceDocument11 pagesPART-66 Training - Aircraft Maintenance LicenceFemi AgbanaNo ratings yet

- Certificado - Flange Adapter 125MM - XindaDocument3 pagesCertificado - Flange Adapter 125MM - XindaGR CarlosNo ratings yet

- Self-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMDocument219 pagesSelf-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMblue4882No ratings yet

- Bearing Capacity of Rockspub101172495Document13 pagesBearing Capacity of Rockspub101172495Mehdi Mir100% (1)

- Slide Valves - Flachschieber - Klizni Ventili - Valvole A GhigliottinaDocument54 pagesSlide Valves - Flachschieber - Klizni Ventili - Valvole A GhigliottinaTiberiu PalNo ratings yet

- New Holland - Grader 156-7Document16 pagesNew Holland - Grader 156-7Cristian Cernega100% (1)