Professional Documents

Culture Documents

Efficient Fertilizer Use - Fertigation Guide

Uploaded by

yafazieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efficient Fertilizer Use - Fertigation Guide

Uploaded by

yafazieCopyright:

Available Formats

Efficient Fertilizer Use Fertigation: by Dr.

Bill Segars

1

SECTION CONTENTS:

Introduction

Soil Chemistry

Water Quality Concerns

Fertilizers for Injection Into Irrigation

Use Fertigation Properly and According to Regulations

Irrigation Scheduling & Fertigation

Other Important Factors to Consider When Fertigating

Fertigation is defined as the application of nutrients using an irrigation system by

introducing the nutrients into the water flowing through the system. The first reported

application of commercial fertilizer through a sprinkler irrigation system was in 1958.

Today, we routinely inject fertilizer solutions and suspensions into irrigation systems via

calibrated injection pumps that insure precision over both space and time.

Fertigation has increased

dramatically in the past 15 years,

particularly for sprinkler and drip

systems. For drip systems, the

expansion is mostly in

horticultural and high value

crops. In agricultural areas with

declining water supplies, drip

systems have also increased.

With increased irrigation, a

corresponding increase in

fertigation has taken place. It will

continue to grow since such

systems result in less water

usage and better uniformity and lend themselves to the technique much more readily

than the less water-efficient and non-uniform furrow and flood systems being replaced.

Effective fertigation requires knowledge of certain plant characteristics such as optimum

daily nutrient consumption rate and root distribution in the soil. Nutrient characteristics

such as solubility and mobility are important and irrigation water quality factors such as

pH, mineral content, salinity and nutrient solubility must be considered.

The need for irrigation is the main factor in fertigation because the irrigation system is

primarily installed to provide water. The opportunity to fertigate is an added benefit. This

chapter will address issues that must be considered to achieve maximum benefits when

fertigating.

Figure 10.1 Overhead sprinkler irrigation system.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

2

Figure 10.2 Growers often plant vegetables under plastic mulch and

fertigate using drip/trickle irrigation.

Soil Chemistry

Cropping and fertilization history as well as basic soil chemical properties also need to

be considered prior to fertigation. Soil testing by the method recommended in a specific

area is the best way to assess current fertility needs. Particular attention should be

given to soil pH and its adjustment to an appropriate range for the crop to be grown.

Proper pH can have a great effect on the availability of residual nutrients in soil as well

as those added via fertigation. Any required soil pH adjustments should be made using

conventional incorporation techniques. Fertigation is not utilized to alter soil pHs.

Cation exchange capacity (discussed in The Soil Defined) is an important consideration

in determining the quantity of cations that will be retained during fertigation. In order to

maintain an acceptable concentration of cations in solution, a soil with a low CEC must

have its cations replaced via fertigation more often than one with a relatively high CEC,

which can hold a greater quantity of ions. Since nutrients are easily added with

fertigation, it is most practical on sandy, droughty soils with low CEC. These soils need

frequent irrigation and nutrient replenishment.

Previous chapters in this book have explained soil movement of nutrient elements when

applied by conventional fertilization methods. Since fertigation does not negate classical

soil chemistry, fertigated nutrients behave similarly to conventionally applied soluble

nutrients followed by rainfall or irrigation. A reminder - only small quantities of nutrients

applied by an overhead sprinkler system are absorbed by the foliage.

There is some concern that since nitrate nitrogen (NO

3

-N) is highly mobile, it may leach

past the root system and reach groundwater. However, leaching of NO

3

-N in the sands

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

3

of the Southern Coastal Plain has been evaluated. Georgia researchers compared

conventional sidedress for corn with fertigation split 6 to 9 times during the growing

season. Soil NO

3

-N with depth was evaluated in late July (near maturity). Soil NO

3

-N for

the fertigated treatments was greater in the surface and to depths of 2 inches than for

the conventional treatment. At a depth of 2 feet, greater concentrations of NO

3

-N were

found for the conventional application. Data such as these support the application of

smaller amounts of N more frequently in order to expose lesser quantities to the

possibility of leaching.

In contrast to nitrate N, phosphorus (P) fertilizer moves very little in the soil. When

broadcast on the soil surface, it will not normally move more than l to 2 inches below the

soil surface. Therefore, fertigation of P is highly inefficient when using sprinkler or flood

irrigation techniques. However, P fertilizer applied in drip systems may be rather

efficient. An advantage of drip irrigation is that plant nutrients can be applied directly in

the root zone. Since the majority of roots in drip-irrigated crops are located within the

wetting zone, drip applied P will be placed in the soil region containing the highest root

density. Therefore, the P applied in this manner is generally used more efficiently by

plants than if the same amount of P were surface applied.

Water Quality Considerations

For successful fertigation, careful attention must be given to water quality. The quality of

water required depends on several factors, but foremost is the type of fertigation. Drip

fertigation requires the highest quality water, i.e., free of suspended solids and

microorganisms that plug small orifices in emitters. Only solutions should be used for

drip/trickle fertigation. As the orifice size increases, e.g. on sprinkler systems,

suspensions can be tolerated.

Precipitation of fertilizers within the irrigation systems can be a very serious problem if

solubilities are exceeded. One such problem commonly encountered is with calcium

concentrations exceeding about 100 ppm. As calcium concentration increases and

phosphates are injected, the probability of precipitation increases. When the water

contains very high levels of calcium and magnesium, an injection of ammonium

phosphates will result in precipitates deposited on pipe walls as well as in orifices and

sprinklers. Often this will completely plug the irrigation system.

If appreciable salts are in the water used for fertigation, one needs to consider the total

amount of salts applied to the crop between leaching rains rather than only the amount

applied in a single fertigation. Crops vary widely in their tolerance to salts; therefore, the

number of irrigations as well as the salt concentration must be considered.

In some areas, high levels of boron (B) in irrigation water is a problem. Some sensitive

crops can tolerate only about 1 ppm B. Total irrigation with water containing l ppm B

applied to sensitive crops on light textured soils should not exceed 3 acre-inches

between leaching rains.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

4

Fertilizers For Injection Into Irrigation

Three qualities are necessary for a good source of fertilizer for fertigation: (1) it must

contain the needed nutrient elements in a form available to plants or in a form that is

readily converted (i.e., urea is readily converted to available NH

4

- and NO

3

-N forms in

good soil conditions); (2) it must be uniformly distributed--either uniformly broadcast for

sprinkler, furrow, or flood or uniformly distributed among emitters for drip/trickle; and (3)

the chemistry of the application must be such that plants are not burned or stunted and

irrigation lines, emitters, or orifices are not restricted or plugged. Considering these

limitations, a rather long list of nutrient sources can still be used. In order to provide for

the latter two limitations listed, the materials must either be in solution or be in

suspension. For drip systems, solution is always needed and only clear liquid should be

used.

Nitrogen is the most fertigated element due to high plant nutritional needs, to its great

mobility in soil following chemical and biological transformation to NO

3

-N, and because

of the many soluble sources of N fertilizers available for fertigation. Many forms of N

have been used in fertigation. Urea and UAN solutions are probably most commonly

used, but most any soluble form of dry fertilizer can be used. Anhydrous ammonia or

any other N fertilizer that has free ammonia should not be applied through sprinkler

systems.

Phosphoric acid, and ammonium phosphate solutions can be used as sources of

phosphorus in drip systems. Ammonium phosphate solutions are subject to precipitation

if injected into water with high calcium and/or magnesium concentrations.

Potassium fertigation is usually accomplished with potassium chloride (muriate of

potash) due to its solubility and relative low cost per pound of K. For most crops, foliage

burns are not a problem due to the great dilutions in irrigation systems. Relatively pure

grades of potassium chloride (white, 62% K

2

O equivalent) are normally used in

fertigation. Potassium nitrate has been used as a source of K and N, and potassium

sulfate as a source of K and S. These K sources are less soluble and cost more per

pound of K than potassium chloride.

Sulfur, when needed, can also be provided as ammonium thiosulfate, ammonium

sulfate or flowable S. It can be readily mixed with UAN and several other soluble

fertilizer grades and injected. Magnesium sulfate (Epson salts) is often used to supply

Mg and S.

Micronutrients such as iron, zinc, copper, and manganese may (if applied in forms such

as sulfates or chlorides) react with salts in the irrigation water and cause precipitation

and clogging. However, many of the micronutrients can be applied as chelates - such as

iron or zinc EDTA. Chelates are generally highly water soluble and consequently, will

cause little clogging or precipitation.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

5

Use Fertigation Properly And According To

Regulations

Fertilizer nutrients have the potential of getting into the irrigation water source if proper

operating procedures and safety devices are not installed or maintained by the operator.

Some states require a permit for fertigation. Be sure you are in compliance with your

local regulations.

Reputable fertilizer and chemical dealers should be able to provide the type of

equipment shown in Figure 10.3.

Figure 10.3 shows a recommended layout for direct injection of nutrients into irrigation

pipelines. The following components are part of the system:

1. Backflow prevention device (check valve) in water line upstream of fertilizer

injection - this prevents reverse flows from the irrigation system down a well or

other water source.

2. Vacuum relief valve - prevents a vacuum from forming upstream of the check

valve.

3. Backflow prevention device (automatic, quick-closing check valve) in fertilizer

feed line - prevents reverse flows of water or fertilizer into the fertilizer storage

tank.

4. Normally closed, solenoid-operated valve - located on the intake side of the

injection pump to prevent fertilizer flow during irrigation system shutdown.

5. Electrical interlock for injection systems using electric-driven fertilizer pumps -

this ensures that the injection pump will shut down if the irrigation pump does.

Figure 10.3

Safety devices and arrangements for fertigation through an engine

powered irrigation system.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

6

6. Low pressure drain valve - to drain water from the pipe between the check valve

and the water source, including any leakage past the check valve.

Irrigation Scheduling And Fertigation

Successful moisture management calls for applying the right amount of water at the

proper time. The amount of water needed will depend principally on the water-holding

capacity of the soil, the soil profile depth, and the crop to be grown.

Research has shown that applying N solutions through sprinkler systems on sandy soils

gives greater efficiency than from preplant broadcast and sidedress applications (Table

10.1). This also allows the N to be applied at the time the crop needs it. The data in

Tables 10.2 and 10.3 illustrate the nutrient uptake of N and K for corn and cotton.

Fertilizer applications can be timed with the irrigation to supply nutrients at the most

optimum growth stage.

Table 10.1: Effect of Multiple Fertilizer Applications on Irrigated Corn

Fertilizer

Schedule

Time of Last

Application* No. of Applications Relative Yield %

Preplant and

two sidedress

8 3 72

Bi-weekly

starting at

emergence

12 7 100

* Weeks after emergence (Source: F. M. Rhoads, University of Florida, Quincy)

Table 10.2: Percent of Nutrients Taken Up by 180-bu. Corn

Days After Emergence %Uptake

N K

2

O

0-25 8 9

26-50

(silk)

35 44

51-75 31 31

76-100

(grain fill)

2 14

101-125 6 2

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

7

Table 10.3: Percent of Nutrients Taken Up by 1 1/2 Bales Cotton at Various

Growth Stages

GROWTH STAGE NITROGEN POTASH

Seedling 6 5

Early Square 14 19

Early Boll 42 36

To Maturity 38 40

Researchers, using sprinkler irrigation, at the Coastal Plain Experiment Station in

Georgia achieved increased N efficiency and highest yields when they applied 25% of

the N at planting, 22.5% at the six, 12 and 18 leaf stages and 7.5% at tasseling. This

technique generally utilizes conventional application of N at planting and the remainder

via fertigation. This method improves N uptake early in the season when root systems

are small and require high N. Later in the season, this sequence of applications

anticipates N requirements while minimizing the risks of nitrate leaching. Fertigation is

also sometimes used to apply supplemental applications of potash, sulfur and certain

micronutrients. The need to apply such nutrients should be determined by plant

analysis.

Frequency and timing of water application have a major impact on yields and operating

costs. For the most efficient use of water it is desirable to frequently determine the soil

moisture conditions throughout the root zone of the crop being grown. Two proven

practical field methods for measuring soil moisture are tensiometers and electrical

resistance meters.

Moisture measuring instruments should be installed at three to five locations in the field.

The installation site should be representative of the soil types in the field and should be

located so that it is convenient to read them on a daily basis. Figure 10.3 illustrates the

installation of tensiometers. Since the tensiometers measure the soil water levels, they

must be placed in a manner that accurately reflects what conditions the root system is

encountering. One should be placed six inches deep and the other 12 inches deep. The

six inch depth tensiometer is used to evaluate when to start irrigating while the twelve

inch depth tensiometer is used to evaluate water penetration into the soil profile plus

over-or-under watering.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

8

Figure 10.5

Installation of tensiometers in a corn field.

A tensiometer (Figure 10.5) reading of less than 20 centibars indicates that the amount

of available moisture in the plow layer is favorable. As the readings become higher, the

amount of available water decreases, indicating drier conditions and a need to start

irrigating. The response of corn to three selected refill points (readings on the

tensiometer) on a loamy fine sand is shown in Table 10.4. The highest yields occurred

by irrigating corn when the tensiometer reached 20 centibars.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

9

Figure 10.5

Diagram of a tensiometer.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

10

Table 10.4: Grain Yields of Irrigated Corn at Three Selected Soil/Water Refill

Levels

Tensiometer

Reading When

Irrigated

Number of

Irrigations

Total

Irrigation

Water Applied

(IN) YieldBu/A

20 11 8.7 190

40 6 7.1 175

60 4 4.7 160

-- -- -- 115

Source: The University of Georgia Coastal Plain Experiment Station

The type and size of the irrigation system will also influence scheduling. Center pivot

systems that make complete 3600 circles require different schedules than center pivot

systems that do not make complete circles. Cable tow systems require altogether

different scheduling. Consult with your irrigation equipment supplier to determine the

most efficient schedule for a particular system and field situation.

Other Important Factors To Consider When

Fertigating

1. Distribution uniformity of the irrigation water is critical for uniform application of

the fertilizer.

2. Surface irrigation systems generally produce surface runoff. Make sure that any

surface runoff during fertigation is picked up and reused on the field being treated

or a similar field that is also being treated. Fertigation may not be suitable on

fields that are very susceptible to runoff (i.e. steep slopes and low infiltration

rates).

3. Make sure the combination of fertilizers and water will not produce clogging if

using a micro-irrigation system.

4. Know how much water is needed to refill the root zone during the irrigation and

plan the fertilizer application accordingly. Over-irrigation during fertigation not

only wastes water but could result in leaching of the fertilizer below the root zone.

5. The type of injection device is critical depending on the type of irrigation system

being used. Some devices will inject at a relatively uniform rate throughout the

irrigation, some will not. Be aware of which type is being used and which type is

required by the situation.

6. Be aware of the requirements for flushing the irrigation system after fertigation.

This may take 10 to 15 minutes. Also run clean water through the injection meter,

discharge hose and check valve.

7. Irrigation systems should be monitored much more closely during fertigation,

continuously if possible.

Efficient Fertilizer Use Fertigation: by Dr. Bill Segars

11

8. Under saline conditions, salinity problems can be intensified by fertigation and

improper irrigation management. The level of salinity in soil may itself be

increased, even temporarily, by fertilizer application as mineral fertilizers are for

the most part soluble salts.

Summary

When the advantages of fertigation are exploited and the disadvantages are minimized,

fertigation can be a very efficient method of fertilization. Although not an end in itself,

fertigation can compliment a good base soil fertility program. An understanding of the

types of soil, water quality, appropriate nutrient materials, safety precautions, and

cropping systems are all important factors in making fertigation useful and economical.

Links to other sections of the Efficient Fertilizer Use Manual

History Mey Soil pH Nitrogen Phosphorus Potassium Secondary

Micronutrients Fluid-Dry Sampling Testing Site-Specific Tillage Environment

Appendices Contributors

You might also like

- Ex - No 15 FertigationDocument7 pagesEx - No 15 FertigationKannan V KannanNo ratings yet

- Fertilizer Use - Dr. MC Rana SirDocument20 pagesFertilizer Use - Dr. MC Rana SirSarita Kumari100% (1)

- Soil Fertility Management Lecture 1Document22 pagesSoil Fertility Management Lecture 1Mia SurayaNo ratings yet

- NT Organic FarmingDocument21 pagesNT Organic FarmingManjunath Ramanna100% (1)

- Lecture 3 Plant NutritionDocument72 pagesLecture 3 Plant NutritionGitta Lakshita AnggariniNo ratings yet

- NPK 1Document5 pagesNPK 1Arief GatotNo ratings yet

- An Innovative Soak Pit To Recharge The Bore WellsDocument16 pagesAn Innovative Soak Pit To Recharge The Bore WellsRajan NarasimmanNo ratings yet

- Slow-Release FertilizersDocument7 pagesSlow-Release FertilizersKate RyncaNo ratings yet

- Irrigation Engineering 4 (3+1) : LESSON 37 Design of Sprinkler Irrigation System IDocument7 pagesIrrigation Engineering 4 (3+1) : LESSON 37 Design of Sprinkler Irrigation System IRupinder BrarNo ratings yet

- Irrigation SystemDocument22 pagesIrrigation SystemshriramuluNo ratings yet

- Mazzei Ag Product - CatelogueDocument16 pagesMazzei Ag Product - CateloguebillpaparounisNo ratings yet

- HerbariumDocument16 pagesHerbariumSHAIRA LYN CUMILANGNo ratings yet

- Contact - Systemic Fungicide PDFDocument2 pagesContact - Systemic Fungicide PDFSandeep Rawal100% (1)

- NMRG Soil Nutrients, Sources and Uptake PDFDocument9 pagesNMRG Soil Nutrients, Sources and Uptake PDFYosephNo ratings yet

- Drip Fertigation in Horticultural CropsDocument7 pagesDrip Fertigation in Horticultural CropsPurushotham PaspuletiNo ratings yet

- Chili Fertigation Investment in MalaysiaDocument9 pagesChili Fertigation Investment in MalaysiaSaifuddin SaidiNo ratings yet

- Improving Dairy Farm Lighting EfficiencyDocument18 pagesImproving Dairy Farm Lighting Efficiencyroco13426ygNo ratings yet

- Drip Irrigation 2013Document88 pagesDrip Irrigation 2013mosne1No ratings yet

- Chemical Fertilizers ExplainedDocument75 pagesChemical Fertilizers ExplainedAgStar CordinationNo ratings yet

- Different Soilless Culture Systems and Their ManagementDocument6 pagesDifferent Soilless Culture Systems and Their ManagementMohammad MashatlehNo ratings yet

- Processor Sweet Corn Crop GuideDocument12 pagesProcessor Sweet Corn Crop Guidevictor vianaNo ratings yet

- Irrigation Scheduling 101Document7 pagesIrrigation Scheduling 101David DollNo ratings yet

- Cochran Fellowship Rpogram Alumni Interview Questions Forbiotech Program...Document2 pagesCochran Fellowship Rpogram Alumni Interview Questions Forbiotech Program...precaute100% (1)

- Fertilizer ApplicationDocument59 pagesFertilizer Applicationbajen_123No ratings yet

- Durian Guidelines for DUS TestingDocument38 pagesDurian Guidelines for DUS TestingAmir ChipNo ratings yet

- Sakata Melon Advantage BrochureDocument4 pagesSakata Melon Advantage BrochureAnonymous 6x3gwRgHP1100% (1)

- Sander Protein SkimmersDocument18 pagesSander Protein Skimmerslleimicojon100% (1)

- Penanaman CiliDocument30 pagesPenanaman Cilinarayanasamy30No ratings yet

- Chap 8 - Seed Propagation PDFDocument29 pagesChap 8 - Seed Propagation PDFMujibur Khan100% (1)

- Efficient Use of Secondary Nutrients for Higher Crop YieldsDocument18 pagesEfficient Use of Secondary Nutrients for Higher Crop YieldsMessiNo ratings yet

- General Microbiology Laboratory Manual: Biology 490Document83 pagesGeneral Microbiology Laboratory Manual: Biology 490Ibnul MubarokNo ratings yet

- Reason For Processing Farm ProduceDocument2 pagesReason For Processing Farm ProduceIsraelNo ratings yet

- ACC 721 - PlantationDocument45 pagesACC 721 - PlantationNur Hidayah100% (1)

- KATALOG Fertigation 2010 PDFDocument44 pagesKATALOG Fertigation 2010 PDFsanitermNo ratings yet

- Grodan Report How To Use Crop SteeringDocument3 pagesGrodan Report How To Use Crop SteeringalnuteNo ratings yet

- The Effects of Tillage Practice On Yam ProductionDocument33 pagesThe Effects of Tillage Practice On Yam ProductionJoshua Bature SamboNo ratings yet

- IFOAM Training MAnualDocument243 pagesIFOAM Training MAnualSampathkumar TharmarNo ratings yet

- Prospects of Biofertilizers by Raj VakilDocument16 pagesProspects of Biofertilizers by Raj VakilRaj VakilNo ratings yet

- Complete Guide On New Borewell Drilling AtoZDocument6 pagesComplete Guide On New Borewell Drilling AtoZJOHN MASEFIELD100% (1)

- Field Tomato Production Guide 2016 PDFDocument6 pagesField Tomato Production Guide 2016 PDFJonathan de JongNo ratings yet

- Rakesh PPT On Drip IrrigationDocument10 pagesRakesh PPT On Drip IrrigationMalleshamNo ratings yet

- COMPARISON BETWEEN TRADITIONAL AND MODERN AGRICULTUREDocument4 pagesCOMPARISON BETWEEN TRADITIONAL AND MODERN AGRICULTURENoraishah IsaNo ratings yet

- Rubber ProductonDocument12 pagesRubber ProductonHannah JamesNo ratings yet

- Palm Oil Mill by ProductDocument14 pagesPalm Oil Mill by ProductSulaiman FairusNo ratings yet

- FertirrigacionDocument111 pagesFertirrigacionAngel_Scribd1No ratings yet

- Intercultural Operations PDFDocument1 pageIntercultural Operations PDFsam100% (1)

- MLVSS/MLSS Ratio GuideDocument7 pagesMLVSS/MLSS Ratio GuidecassindromeNo ratings yet

- Potential Use of Hydroponics As An Alternative Way of Growing Sweet PotatoesDocument16 pagesPotential Use of Hydroponics As An Alternative Way of Growing Sweet PotatoesJohnny Robert English100% (1)

- How To Make A Mini Forest With Miyawaki MethodDocument7 pagesHow To Make A Mini Forest With Miyawaki MethodLuís Palma RodriguesNo ratings yet

- Lettuce Cultivation Guide 2018Document5 pagesLettuce Cultivation Guide 2018amarNo ratings yet

- Agricultural engineering variables affecting hydroponic grass production 1647-1666Document1 pageAgricultural engineering variables affecting hydroponic grass production 1647-1666pipestressNo ratings yet

- AGR558 Lab Drip Irrigation SystemDocument3 pagesAGR558 Lab Drip Irrigation SystemNoor Syazwan NasirNo ratings yet

- Smart Irrigation SystemDocument15 pagesSmart Irrigation SystemraginiNo ratings yet

- FERTIGATIONDocument96 pagesFERTIGATIONNohaAbdulWarthNo ratings yet

- Entrepreneurship Organico (Slides)Document25 pagesEntrepreneurship Organico (Slides)Arslan TariqNo ratings yet

- AGR524 CalibrationDocument7 pagesAGR524 CalibrationMuhammad Aliuddin BakarNo ratings yet

- Pineapple Drying Using A New Solar Hybrid Dryer: SciencedirectDocument9 pagesPineapple Drying Using A New Solar Hybrid Dryer: SciencedirectJKLSDNo ratings yet

- Horticulturae 03 00037 v2Document20 pagesHorticulturae 03 00037 v2TuấnAnhTrầnNo ratings yet

- Fertigation - of - Vegetable PDFDocument48 pagesFertigation - of - Vegetable PDFYowan SolomunNo ratings yet

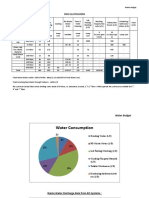

- Water consumption and waste analysisDocument6 pagesWater consumption and waste analysisNaveen MathurNo ratings yet

- Port City Project ECBADocument61 pagesPort City Project ECBAVijaykanth ViveNo ratings yet

- RWS PDFDocument6 pagesRWS PDFAnand NanduNo ratings yet

- Control Water Levels with RAF 10 Float ValveDocument2 pagesControl Water Levels with RAF 10 Float Valvevelikimag87No ratings yet

- CO2-ZnO Patch by Heather Bryant - Plasma Health Patches DRAFTDocument7 pagesCO2-ZnO Patch by Heather Bryant - Plasma Health Patches DRAFTMany Hands 4 Peace100% (2)

- Technical Installation Guide Above Below Ground DrainageDocument44 pagesTechnical Installation Guide Above Below Ground DrainageChamara Chinthaka RanasingheNo ratings yet

- Permeable Pavers - A Sustainable Alternative for Driveways and Parking AreasDocument9 pagesPermeable Pavers - A Sustainable Alternative for Driveways and Parking Areas7d5b3373No ratings yet

- Abstractions From Precipitation PDFDocument30 pagesAbstractions From Precipitation PDFSeshu NagaNo ratings yet

- 7 Template For SDA ReportsDocument16 pages7 Template For SDA ReportsfastreturnNo ratings yet

- Skil High-Pressure Washer 0760Document104 pagesSkil High-Pressure Washer 0760Pintér GézaNo ratings yet

- Report On The Heritage City ProjectDocument23 pagesReport On The Heritage City ProjectL'express Maurice100% (2)

- Meghna PVC LTD (Pet Division) QAC Department Shift Chemist Log BookDocument5 pagesMeghna PVC LTD (Pet Division) QAC Department Shift Chemist Log Bookswapon kumar shillNo ratings yet

- BiogasDocument12 pagesBiogasAna AnawatiNo ratings yet

- 2012 Stoler Weeks Fink JWASHDocument18 pages2012 Stoler Weeks Fink JWASHMensah ElishaNo ratings yet

- Catálogo Vontron - CompletoDocument57 pagesCatálogo Vontron - CompletomarianaNo ratings yet

- Surface Water Collection: UnitsDocument19 pagesSurface Water Collection: UnitsLabib AbdallahNo ratings yet

- Product Assessment Report - K-Othrine SC 25 Family PublicDocument142 pagesProduct Assessment Report - K-Othrine SC 25 Family PublicwibowoNo ratings yet

- Multi-Media Filters Rev 01Document76 pagesMulti-Media Filters Rev 01Flavia Zanette100% (1)

- ReferencesDocument5 pagesReferencesMazzel May PacatanNo ratings yet

- TDS Brushbond India5Document2 pagesTDS Brushbond India5SK Emran AliNo ratings yet

- Arsenic in Groundwater: Testing Pollution Mechanisms For Sedimentary Aquifers in BangladeshDocument9 pagesArsenic in Groundwater: Testing Pollution Mechanisms For Sedimentary Aquifers in BangladeshDiego Alex Cahuaya MamaniNo ratings yet

- Weldability of Aluminium Alloys GuideDocument3 pagesWeldability of Aluminium Alloys Guidebrijesh kinkhabNo ratings yet

- LakeSacramento Book PDFDocument152 pagesLakeSacramento Book PDFFickleNo ratings yet

- Hydrogeological Processes in Karst TerranesDocument422 pagesHydrogeological Processes in Karst TerranesAbdullah Cem Koç100% (1)

- Arpit PorwalDocument14 pagesArpit PorwalMalav PatelNo ratings yet

- Solar Water DistllatorDocument3 pagesSolar Water DistllatorJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Aeration Types of AeratorsDocument2 pagesAeration Types of AeratorsMichael Asmith UniqueNo ratings yet

- Daikin VRV Product Line UpDocument112 pagesDaikin VRV Product Line Upshubham ahireNo ratings yet

- Cambridge IGCSE™: Geography 0460/13 October/November 2020Document17 pagesCambridge IGCSE™: Geography 0460/13 October/November 2020Miguel Oubiña SánchezNo ratings yet

- Sambhar LakeDocument3 pagesSambhar LakeAditya BhandariNo ratings yet