Professional Documents

Culture Documents

Bentley - Navada Vibration Tester

Uploaded by

kamran719Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bentley - Navada Vibration Tester

Uploaded by

kamran719Copyright:

Available Formats

The attached material is copyrighted by and will remain the property of the individual manufacturers.

Technical Diagnostic Services is providing this information at no charge as a service to our customers.

This Specification Data Sheet

brought to you by:

15825 Trinity Blvd.

Fort Worth, Texas 76155

817/465-9494

equipment@technicaldiagnostic.com

www.technicaldiagnostic.com

www.test-equipment-rental.com

BNC Part Number 141580-01 Page 1 of 2

Revision NC, July 1999

Specifications and Ordering Information

TK3-2 Calibration Instrument

Description

The TK3-2 Calibration Instrument simulates shaft vibration and position for

calibrating Bently Nevada monitors. It verifies the operating condition of the

monitor readouts as well as the condition of the proximity transducer system.

A properly calibrated system means that the monitor readings and transducer

inputs are accurate.

A spindle micrometer is used to check the transducer system and position

monitor calibration. A probe mounting adapter provided with the TK3-2 holds

the probe while the target is moved toward or away from the probe tip in

calibrated increments. The output from the Proximitor Sensor is recorded

using a voltmeter.

Vibration monitors are calibrated using the motor-driven wobble plate. A

swing-arm holder is located over the wobble plate to hold the proximity probe

in place. The holder and probe are adjusted to a position where the desired

amount of mechanical vibration is found. The vibration is then measured

using a dial micrometer which is supplied with the unit (no oscilloscope is

needed).

A vibration monitor's reading can then be compared to the known mechanical

vibration signal input. The mechanical vibration signal from the TK3-2 can

range from 50 to 254 m (2 to 10 mils) peak-to-peak.

Specifications

Inputs

Power

Electric: 95 - 125 Vac, 50/60 Hz, 1A minimum.

190 - 250 Vac, 50/60 Hz, 1A minimum.

Air: 90 psi (6.2 bar) maximum.

Wobulator Range

Vibration Amplitude

Range:

50 m to 254 m (2 to 10 mils) peak-to-peak.

Maximum Speed

Electric: 0 to 10,000 cpm 2,500 cpm.

Air: 0 to 5,000 cpm 1,000 cpm.

R

BNC Part Number 141580-01 Page 2 of 2

Revision NC, July 1999

Spindle Micrometer

Range:

0 - 25.4 mm (0 - 1000 mils).

Target Button and

Wobble Plate:

AISI 4140 Alloy Steel.

Note: Contact your nearest Bently Nevada

Sales Professional for details on special

target and wobble plate materials.

Physical

Size

Height: 215 mm (8.5 in)

Width: 184 mm (7.25 in)

Depth: 285 mm (11.25 in)

Weight: 5.9 kg (13 lb)

Ordering Information

Electric Driven TK3-2

14700-AXX

Option Descriptions

A: Scale Units 0 1 English

0 2 Metric

Air Driven TK3-2

14680-AXX

Option Descriptions

A: Scale Units 0 1 English

0 2 Metric

Accessories

107360-01 REBAM Verification Kit:

This kit allows you to verify correct

operation of the 3300 REBAM

Transducer System.

Kit includes:

1 High resolution digital micrometer

1 Adaptive spacer

1 AISI E52100 steel target button

to simulate the outer ring of a

rolling element bearing.

1999 Bently Nevada Corporation

used in this document are registered marks of Bently Nevada Corporation

Diagram

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Detection and Measurement of Partial Discharge (Corona) Pulses in Evaluation of Insulation SystemsDocument10 pagesDetection and Measurement of Partial Discharge (Corona) Pulses in Evaluation of Insulation Systemskamran719No ratings yet

- Common PQ Issues TransientsDocument6 pagesCommon PQ Issues Transientskamran719No ratings yet

- ATP MCA Analysis Manual 2008 Rev BDocument116 pagesATP MCA Analysis Manual 2008 Rev Bkamran719No ratings yet

- MCA User Manual Ver 1.3.1Document63 pagesMCA User Manual Ver 1.3.1kamran719No ratings yet

- ATP MCA Analysis Manual AT5Document78 pagesATP MCA Analysis Manual AT5kamran719No ratings yet

- Conductor Resistance MTO106 An enDocument6 pagesConductor Resistance MTO106 An enkamran719No ratings yet

- Application Note: Enabling Additional ChannelsDocument2 pagesApplication Note: Enabling Additional Channelskamran719No ratings yet

- Application Note Application Note Application Note Application NoteDocument2 pagesApplication Note Application Note Application Note Application Notekamran719No ratings yet

- Power Factor Testing Nov2005Document5 pagesPower Factor Testing Nov2005power_generator2007No ratings yet

- Application Note: MPQ1000 Common ConnectionsDocument14 pagesApplication Note: MPQ1000 Common Connectionskamran719No ratings yet

- Common PQ Issues TransientsDocument6 pagesCommon PQ Issues Transientskamran719No ratings yet

- Tandelta BasicsDocument48 pagesTandelta Basicskamran719No ratings yet

- TanDelta Diagnostics - Guidelines V4 03.2013Document19 pagesTanDelta Diagnostics - Guidelines V4 03.2013kamran719No ratings yet

- Artigo Fator de PotênciaDocument4 pagesArtigo Fator de PotênciaDiego FaenelloNo ratings yet

- Doble Test ProceduresDocument21 pagesDoble Test ProceduresRamKumarNo ratings yet

- Doble Power Factor Theory - Training - BrusettiDocument76 pagesDoble Power Factor Theory - Training - Brusettikamran719100% (2)

- Doble Test ProceduresDocument21 pagesDoble Test ProceduresRamKumarNo ratings yet

- Tandelta BasicsDocument48 pagesTandelta Basicskamran719No ratings yet

- Power Factor Insulation DiagnosisDocument60 pagesPower Factor Insulation Diagnosiscountershadow_14No ratings yet

- EM-300 Motor Driver ModuleDocument1 pageEM-300 Motor Driver Modulekamran719No ratings yet

- HFO Separator2Document236 pagesHFO Separator2kamran719No ratings yet

- Tandelta BasicsDocument48 pagesTandelta Basicskamran719No ratings yet

- KINAX 3W2 Transducer For 2GT1022Document7 pagesKINAX 3W2 Transducer For 2GT1022kamran719No ratings yet

- Operating Instructions: Vegacom 557 Siemens 3964 and 3964 R Procedure With RK 512Document44 pagesOperating Instructions: Vegacom 557 Siemens 3964 and 3964 R Procedure With RK 512kamran719No ratings yet

- EXTER T70 MAEN772E EnglishDocument25 pagesEXTER T70 MAEN772E Englishkamran719No ratings yet

- SPM-D2-10/YB Synchronizing Unit: ManualDocument51 pagesSPM-D2-10/YB Synchronizing Unit: Manualrodruren01No ratings yet

- 4-Pin Plug WIKADocument4 pages4-Pin Plug WIKAkamran719No ratings yet

- Acuvim II Profibus Modules Users Manual v1.10Document36 pagesAcuvim II Profibus Modules Users Manual v1.10kamran719No ratings yet

- Acuvim II User's Manual v1.61Document264 pagesAcuvim II User's Manual v1.61kamran719No ratings yet

- Acuvim II Quick Setup Guide (1040E3103)Document12 pagesAcuvim II Quick Setup Guide (1040E3103)kamran719No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Data Loss PreventionDocument20 pagesData Loss Preventiondeepak4315No ratings yet

- Piccadilly Circus BusDocument1 pagePiccadilly Circus Busmeylota2No ratings yet

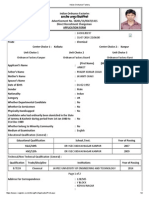

- Indian Ordnance FactoryDocument2 pagesIndian Ordnance FactoryAniket ChakiNo ratings yet

- ADAMDocument12 pagesADAMreyNo ratings yet

- Ad CVDocument2 pagesAd CVzahid latifNo ratings yet

- Consolidated Digests - Part 2Document314 pagesConsolidated Digests - Part 2Neil Patrick Pepito ErmacNo ratings yet

- Final Exam - Comprehensive - 10.24.16Document5 pagesFinal Exam - Comprehensive - 10.24.16YamateNo ratings yet

- Datasheet HFS60Document3 pagesDatasheet HFS60RajeswaranNo ratings yet

- FranchisingDocument38 pagesFranchisingprasadmahajan26100% (1)

- Fashion Designing Sample Question Paper1Document3 pagesFashion Designing Sample Question Paper1Aditi VermaNo ratings yet

- 11.traders Virtual Mag OTA July 2011 WebDocument68 pages11.traders Virtual Mag OTA July 2011 WebAde CollinsNo ratings yet

- Cattle Feed Close Tenders in BikanerDocument9 pagesCattle Feed Close Tenders in BikanerCodm DutyNo ratings yet

- Print Design Business Model CanvasDocument3 pagesPrint Design Business Model CanvasMusic Da LifeNo ratings yet

- 5-Benefits at A GlanceDocument2 pages5-Benefits at A GlanceBlackBunny103No ratings yet

- Compose Testing CheatsheetDocument1 pageCompose Testing CheatsheetEstampados SIn ApellidoNo ratings yet

- Choosing The Right HF Welding Process For Api Large Pipe MillsDocument5 pagesChoosing The Right HF Welding Process For Api Large Pipe MillsNia KurniaNo ratings yet

- Tech Bee JavaDocument57 pagesTech Bee JavaA KarthikNo ratings yet

- Review of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)Document12 pagesReview of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)RHIAN B.No ratings yet

- Influence of Intellectual Capital in The Organizational InnovationDocument8 pagesInfluence of Intellectual Capital in The Organizational InnovationsopingiNo ratings yet

- IM0973567 Orlaco EMOS Photonview Configuration EN A01 MailDocument14 pagesIM0973567 Orlaco EMOS Photonview Configuration EN A01 Maildumass27No ratings yet

- Lab ManualDocument15 pagesLab ManualsamyukthabaswaNo ratings yet

- Polyhouse Gerbera CultivationDocument5 pagesPolyhouse Gerbera CultivationArvindVPawar100% (2)

- Important Questions Mba-Ii Sem Organisational BehaviourDocument24 pagesImportant Questions Mba-Ii Sem Organisational Behaviourvikas__ccNo ratings yet

- Mine Gases (Part 1)Document15 pagesMine Gases (Part 1)Melford LapnawanNo ratings yet

- CH7Document34 pagesCH7Abdul AzizNo ratings yet

- On Fracture MechanicsDocument81 pagesOn Fracture MechanicsDEEPAK100% (1)

- BancassuranceDocument41 pagesBancassuranceanand_lamaniNo ratings yet

- Mysuru Royal Institute of Technology. Mandya: Question Bank-1Document2 pagesMysuru Royal Institute of Technology. Mandya: Question Bank-1chaitragowda213_4732No ratings yet

- Sarah Williams CVDocument2 pagesSarah Williams CVsarahcwilliamsNo ratings yet

- Lecture Notes (Financial Economics)Document136 pagesLecture Notes (Financial Economics)americus_smile7474100% (2)