Professional Documents

Culture Documents

Researchpaper Improvement of Efficiency and Thermal Withstanding Capacity of Single Phase Induction Motor Using Organic Nano Filler Mixed Enamel

Uploaded by

yoshimori91Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Researchpaper Improvement of Efficiency and Thermal Withstanding Capacity of Single Phase Induction Motor Using Organic Nano Filler Mixed Enamel

Uploaded by

yoshimori91Copyright:

Available Formats

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 1571

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

Improvement of Efficiency and Thermal

Withstanding Capacity of Single Phase Induction

Motor using organic Nano Filler Mixed Enamel

B.Guruprakash, R.vishnuprakash, E.Muthupandi, R.Balakumar, N.Vanaja, D.Edision selvaraj

Abstract - It has been found that the addition of nanofillers to the enamel can greatly improve the thermal, mechanical and electrical properties of

enamel. Al2O3 has been used as nano filler. The micro particles of Al2O3 were converted into nano particles with the help of ball mill. Scanning electron

microscope (SEM) has been used to augment the particle size of the nano powder. The nano filler was mixed with enamel by using ultrasonic vibrator.

The enamel filled with nano filler was coated on the windings of the single phase induction motor. The performance analysis of the single phase

induction motor was carried out by no load test, blocked rotor test and load test. Based on the calculations and result obtained by the above tests, the

efficiency of the induction motor coated with enamel filled with nano filler of Al2O3 was increased by 6% when compared to that of induction motor

coated with pure enamel. Heat run test was also performed on this motor to determine the total loss of energy dissipated as heat.

Index words Single Phase Induction motor, Enamel, Coating, Nano Filler, Load Test, Al2O3

I. INTRODUCTION

N recent days, a great deal of attention has been given

to the applications of nano fillers in the field of

electrical insulating materials. It has been noted that

the use of nano fillers to the enamel can greatly improve the

thermal, mechanical and electrical properties of it. Single

phase Induction motors are widely used in fans, centrifugal

pumps, blowers, lifts, washing machines, hair driers, toys

and so on. The efficiency of the induction motor depends

upon the enamel used. For motors, the enamel was used for

three purposes: impregnation, coating and adhesion. The

efficiency of the induction motor could be increased by

adding the nano fillers with the enamel which was used as

coating for the windings of the motor. In this paper, the

efficiency of the normal single phase induction motor and

Al2O3 nano filler added enamel coated with the single

phase induction motor was analyzed and the results were

compared with each other. Heat run tests were performed

on electric machines to determine the total loss of energy

dissipated as heat. It was a well-known fact that the

operating temperature of an electric machine has a very

strong relationship with the life duration of the insulation.

The enamel used for coating the machine windings were

organic in nature and were adversely affected by thermal

decomposition.

II. COATING OF THE NANO FILLER ADDED

ENAMEL TO THE WINDINGS OF THE

MOTOR

Five percentage of nano powder of Al2O3 was taken and it

was mixed with the enamel by using ultrasonic vibrator.

Then this enamel was coated on the windings of the single

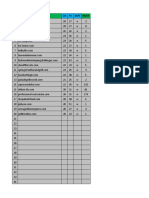

phase induction motor. The specifications of the single

phase induction motor were shown below in the table 1.

Table 1 Specificati ons of the Si ngl e phase induction motor

Power 0.5 HP

Speed 1470 rpm

Current 4 A

Voltage 220 V

Figure 1 Nanocomposit e f ill ed enamel coated i nducti on mot or

I

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 1572

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

III. EXPERIMENTAL ANALYSIS

A. PERFORMANCE ANALYSIS OF SINGLE

PHASE INDUCTION MOTOR DIRECT

LOADING METHOD

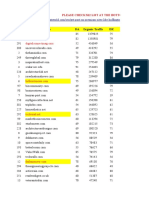

The load test was conducted as per the circuit diagram

shown in the figure 2 and the output power,current,

efficiency, powerfactor and speed of the induction

induction was measured. The maximum efficiency obtained

from an ordinary induction motor was 69%. The maximum

efficiency obtained from nano coated induction motor was

75%. The efficiency of the induction motor with and

without nanocoating was measured and their readings

were shown in the table 2.

Figure 2 circuit diagram f or load test on single phase i nducti on

motor

Table 2 Measurement of efficiency

Normal IM Nanocoated IM

current Efficiency Current efficiency

3.9 41.46 4 53.65

4 51.31 4.1 65.15

4.2 67.79 4.2 69.50

4.3 69.22 4.3 72.40

4.4 68.73 4.4 74.49

B. TEMPERATURE TEST

Heat run test was performed on electric machines to

determine the total loss of energy dissipated as heat. It

was a well-known fact that the operating temperature of

an electric machine has a very strong relationship with

the life duration of the insulation. Heat run tests were

conducted on this motor as per IEC 60851. The

temperature of the motor was measured under different

conditions and the readings were shown in the table 3.

Table 3 Measurement of t emperature

Time Normal motor Nano coated

motor

0 30 30

5 44 40

10 48 43

15 50 46

20 53 49

25 55 50

30 57 53

35 58 53

IV. CONCLUSIONS

The following observations were clear as per this study:

1. The efficiency of the induction motor was

increased by 6 % by adding nano filler of Al2O3

to the enamel used as the coating for the

windings of the single phase induction motor.

2. The addition of nano fillers to the enamel has

increased the temperature withstanding

capacity of the induction motor. Hence the life

time of the motor will be increased.

V. ACKNOWLEDGEMENT

This research project would not have been possible

without the support of many people. The authors wishes

to express their gratitude to the supervisor who was

abundantly helpful and offered invaluable assistance,

support and guidance. The author would also like to

convey thanks to the institute Mepco schlenk

engineering college and Faculty for providing the

laboratory facilities.

VI. REFERENCE

[1] Selvaraj, D. Edison. "Characterization of dielectric properties

of the enamel filled with carbon Nanotubes for the

frequency range of 50 Hz-5 MHz." International Journal of

Science and Engineering Applications 1.2 (2012): 102-106.

[2] Selvaraj, D. Edison, and C. Pugazhendhi Sugumaran.

"Comparative Analysis of Dielectric Properties of Enamel

Filled with Various Nanofillers such as ZrO2, Al2O3, CNT

and ZnO." International Journal of Science and Engineering

Applications 1.1 (2012): 51-55.

[3] Selvaraj, D. Edison. "Partial discharge characteristics of

enamel filled with micro and nano composite of SiO2 and

TiO2." International Journal of Science and Engineering

Applications 1.2 (2012): 95-101.

[4] D.Edisonselvaraj,B.Guruprakash,R.Vishnuprakash,R.Balaku

mar"Analysis of Efficiency, Thermal Withstanding Capacity

and Electromagnetic Interference of Three Phase Squirrel

Cage Induction Motor Coated with SiO2 & TiO2

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 1573

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

NanoCompositeFilledEnamel."International Journal of Science

and Engineering Applications 1.1 (2012): 17-21.

[5] Edison Selvaraj, D., C. Pugazhendhi Sugumaran, and A.

SivaPrakash. "Characterization of Electrical and Thermal

Properties of Enamel Filled with Carbon

Nanotubes." Proceedings of the Third International Conference

on Trends in Information, Telecommunication and Computing.

Springer New York.

[6] Barbara goricka ,Barbara czoeowska,Boleseaw

mazurek,Jadwiga zawadzka,Lech gorecki Varnishes modified

with nanoparticles for use in electrical insulation

Electrotechnical Institute, Division of Electro technology and

Materials Science M.Sklodowskiej-Curie 55/61, 50-369

Wroclaw, Poland

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Careers Puzzle GuideDocument2 pagesCareers Puzzle Guidepepac41425% (12)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 03 - SYNOPSIS - Garry CachoDocument11 pages03 - SYNOPSIS - Garry CachoSugar Ray0% (1)

- Custom HelmetDocument39 pagesCustom Helmetyoshimori91No ratings yet

- Premium Sites $12 List Checks Post Placement OpportunitiesDocument28 pagesPremium Sites $12 List Checks Post Placement Opportunitiesyoshimori91No ratings yet

- No Domain Da Pa W/N IndexDocument14 pagesNo Domain Da Pa W/N Indexyoshimori91No ratings yet

- Backlinks Service Guest Post List Sites January 2021Document7 pagesBacklinks Service Guest Post List Sites January 2021yoshimori91No ratings yet

- 2021 CretiveLinks Updated Sites List With TrafficDocument28 pages2021 CretiveLinks Updated Sites List With Trafficyoshimori91No ratings yet

- 99centarticles Link Buillding ReportDocument9 pages99centarticles Link Buillding Reportyoshimori91No ratings yet

- Affordable Predator Helmet GuideDocument12 pagesAffordable Predator Helmet Guideyoshimori91No ratings yet

- Desain Instalasi Listrik Bangunan Bertingkat (Studi Kasus: Pesantren Khoiru Ummah Sumedang)Document10 pagesDesain Instalasi Listrik Bangunan Bertingkat (Studi Kasus: Pesantren Khoiru Ummah Sumedang)Muhammad MuisNo ratings yet

- Keywords BHWDocument1,129 pagesKeywords BHWyoshimori91No ratings yet

- Acos 1Document4 pagesAcos 1yoshimori91No ratings yet

- 99centarticles Link Buillding ReportDocument9 pages99centarticles Link Buillding Reportyoshimori91No ratings yet

- Ubersuggest Speaker Al QuranDocument1 pageUbersuggest Speaker Al Quranyoshimori91No ratings yet

- Ubersuggest MukenaDocument4 pagesUbersuggest Mukenayoshimori91No ratings yet

- Ubersuggest BawangDocument2 pagesUbersuggest Bawangyoshimori91No ratings yet

- New Text DocumentDocument12 pagesNew Text Documentyoshimori91No ratings yet

- LinkDocument4 pagesLinkyoshimori91No ratings yet

- New Text DocumentDocument95 pagesNew Text Documentyoshimori91No ratings yet

- Motor 123987Document13 pagesMotor 123987Anbalagan MurugesanNo ratings yet

- New Text DocumentDocument48 pagesNew Text Documentyoshimori91No ratings yet

- Induction MotorsDocument14 pagesInduction MotorsAbdul RaheemNo ratings yet

- Test 1 For Checking KnowledgeDocument6 pagesTest 1 For Checking Knowledgeyoshimori91No ratings yet

- Performansi Parameter Motor Induksi Tiga Fasa Dengan Sumber Tegangan Dan Frekuensi VariabelDocument10 pagesPerformansi Parameter Motor Induksi Tiga Fasa Dengan Sumber Tegangan Dan Frekuensi VariabelAhmad Nur ArifinNo ratings yet

- KONTRIBUSI MOTIVASI DAN KEbiasaan BELAJAR TERHADAP HASIL BELAJAR MATA KULIAH LISTRIK DAN ELEKTRONIKADocument16 pagesKONTRIBUSI MOTIVASI DAN KEbiasaan BELAJAR TERHADAP HASIL BELAJAR MATA KULIAH LISTRIK DAN ELEKTRONIKAUmar Aron Al-bejoNo ratings yet

- DIGITUS DA-10287 Bluetooth Speaker ManualDocument7 pagesDIGITUS DA-10287 Bluetooth Speaker Manualbuns301No ratings yet

- ESD StrategicPlan2011Document44 pagesESD StrategicPlan2011Anonymous ftVjzUlWLNo ratings yet

- FO Components & SystemsDocument104 pagesFO Components & SystemsNikos Tsagkopoulos Anastasia DimakiNo ratings yet

- TPM Listing (Done Excel, Done CC)Document32 pagesTPM Listing (Done Excel, Done CC)CK AngNo ratings yet

- Role of Information Technology in Education System 170605100Document7 pagesRole of Information Technology in Education System 170605100farahdilafNo ratings yet

- Unit 2adtnotesDocument74 pagesUnit 2adtnotesJobi VijayNo ratings yet

- 8051 Microcontroller External Interrupt ProgrammingDocument28 pages8051 Microcontroller External Interrupt ProgrammingsharadaNo ratings yet

- Title Layout: SubtitleDocument12 pagesTitle Layout: Subtitleriska augustNo ratings yet

- ADVANCE STANDALONE Yamaha Z1 (EN) PDFDocument10 pagesADVANCE STANDALONE Yamaha Z1 (EN) PDFTechno TechNo ratings yet

- Syllabus - Mobile App Development Using FlutterDocument5 pagesSyllabus - Mobile App Development Using FlutterSagar KojuNo ratings yet

- MiCOM P132 - TechnicalDataSheetDocument44 pagesMiCOM P132 - TechnicalDataSheetcatalinccNo ratings yet

- 151820L (G) - 7M Manual de Servicio Montacargas HyundaiDocument247 pages151820L (G) - 7M Manual de Servicio Montacargas Hyundaihernando ramosNo ratings yet

- ATM Banking System (18192203029)Document4 pagesATM Banking System (18192203029)Md. Monir Hossain029321No ratings yet

- Digital IC Lab Manual by A.DARWIN JOSE RAJU, M.E., SMIEEEDocument8 pagesDigital IC Lab Manual by A.DARWIN JOSE RAJU, M.E., SMIEEEA.Darwin Jose RajuNo ratings yet

- Tomorrow I LL Learn PHP Global Variables. This Is A Bad Command: Del C: .Document5 pagesTomorrow I LL Learn PHP Global Variables. This Is A Bad Command: Del C: .harsh bathlqNo ratings yet

- OCIO - DBHIDS Data Governance Framework Implementation Plan v1Document62 pagesOCIO - DBHIDS Data Governance Framework Implementation Plan v1Jonatan Loaiza VegaNo ratings yet

- Introduction To Shell and Tube Heat Exchangers - Part01Document24 pagesIntroduction To Shell and Tube Heat Exchangers - Part01SergioRinconSolanoNo ratings yet

- Wonderware Training Course Catalog: February 2020 - Revision ADocument56 pagesWonderware Training Course Catalog: February 2020 - Revision AArturNo ratings yet

- (Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Document288 pages(Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Isabella Bianchin100% (2)

- Matrix ActionsDocument8 pagesMatrix ActionsmaszerkNo ratings yet

- Lma5473b - Us GL - Cyber and Data Limited Exclusion Endorsement 1Document2 pagesLma5473b - Us GL - Cyber and Data Limited Exclusion Endorsement 1Farrukh KhanNo ratings yet

- Resume For Broadcasting InternshipDocument7 pagesResume For Broadcasting Internshipbcrqs9hr100% (2)

- Manual L W26Document436 pagesManual L W26Taufan ArifNo ratings yet

- Fireman Lift NoteDocument3 pagesFireman Lift Notesoumya garaiNo ratings yet

- Manual: Training - Debugger BasicsDocument164 pagesManual: Training - Debugger BasicsSaagar KarandeNo ratings yet

- Online BankingDocument38 pagesOnline BankingROSHNI AZAMNo ratings yet

- Baumuller DSC Высокомоментные СерводвигателиDocument112 pagesBaumuller DSC Высокомоментные СерводвигателиNoks stNo ratings yet

- Computer Organization PDFDocument2 pagesComputer Organization PDFCREATIVE QUOTESNo ratings yet