Professional Documents

Culture Documents

Test 1 For Checking Knowledge

Uploaded by

yoshimori91Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test 1 For Checking Knowledge

Uploaded by

yoshimori91Copyright:

Available Formats

Test 1 for checking knowledge

1. Why only three-phase induction motor fins wide applicability in industry as well

as farm sector?

2. In what way the performance of an induction motor is affected by the choice of

specific magnetic loading?

3. What is crawling?

4. What is cogging?

. !ow a slow speed induction motor has inherently poor p.f.?

". Why the length of air gap in induction motor is kept minimum possible whereas in

a #$ machine it is larger?

%. Why does an induction motor designed with higher specific electric loading has

smaller o&er load capacity?

'. (he air gap of a polyphase induction motor is kept small to

)a* reduce the possibility of crawling

)b* reduce the noise

)c* reduce the magneti+ing current

)d* obtain high starting tor,ue.

-. . three-phase s,uirrel cage induction motor finds wide applicability in industry

and farm sector because of

)a* its high starting tor,ue

)b* its high power factor

)c* its robust construction and &ery little maintenance

)e* its wide range of speed control.

1/. #ie cast rotor is e0tensi&ely used in making three-phase cage induction motor

because

)a*it gi&es ,uiet operation

)b*it is economical and ease in mass production

)c*it impro&es the starting tor,ue

)d*it a&oids the problem of harmonics.

Test 2 for checking knowledge

1. Why is the harmonic leakage flu0 in s,uirrel-cage induction motor +ero?

2. !ow the o&erload capacity of an induction motor is higher if higher magnetic

loading is used?

3. !ow the o&erload capacity of an induction motor is lower if higher magnetic

loading is used?

4. What is done to reduce tooth pulsation losses in an induction motor?

. When a three-phase induction motor is designed with higher &alue of 1

a&

it will

gi&e

)a* better full load power factor

)b* a higher starting tor,ue

)c* higher full load efficiency

)d* higher o&er load capacity.

". .n increase in number of poles of an induction motor results in of an induction

motor

)a* decrease in ma0imum p.f.

)b* increase in ma0imum p.f.

)c* no change in ma0imum p.f.

)d* can not be predicted.

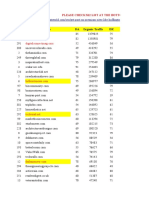

%. . -h.p. 4// 23 4-pole / !+ induction motor ha&ing 3" slots in the stator and 4/

slots in the rotor may crawl synchronously at

)a* / rpm

)b* 1/ rpm

)c* 2// rpm

)d* %/ rpm.

'. In case of induction motors the a&erage &alue of air gap flu0 density 1

a&

taken is

)a* 1.2 to 1. (esla

)b* /.% to 1./ (esla

)c* /.3 to /." (esla

)d* /.1 to /.2 (esla.

-. 4arger &alues of air gap flu0 density is taken while designing induction motors of

)a* larger output

)b* larger bore diameter

)c* both )a* and )b* abo&e

)d* none of the abo&e.

(est 5 3 for checking knowledge

1. Why die-cast aluminium rotor bars are commonly employed compared to copper

bars?

2. !ow the si+e and hence cost of machine decreases if increased &alue of specific

loading s are used?

3. Why is the unbalanced magnetic pull high when the machine is designed with a

small air gap?

4. Why a great ma6ority of induction motors are made with s,uirrel cage rotors?

. Why the frames of totally enclosed machines are pro&ided with a0ial fins?

". 4arger &alues of air gap flu0 density is taken while designing induction motors of

)a* higher &oltages

)b* lower &oltages

)c* higher speeds

)d* both )b* and )c* abo&e.

%. . 3.% kW cage induction motor of 1/// rpm has a p.f. of /.%". . % kW cage

induction motor of 1/// rpm can be e0pected to ha&e a p.f. of

)a* /.'"

)b* /.%"

)c* /.%2

)d* /.%/.

'. . % kW %/ rpm induction motor has a p.f. of /.'4. . % kW 1// rpm

induction motor can ha&e a p.f. of

)a* /.%'

)b* /.'2

)c* /.'4

)d* /.-1.

1/. .n induction motor of %. kW 1/// rpm has an efficiency of '27. .n induction

motor of % kW with the same rpm can ha&e an efficiency of

)a* '/7

)b* '7

)c* -17

)d* -%7.

(est 5 1. Main dimensions of a rotating machines

1. (he diameter of a rotor of a 4 kW3 / !+3 two-pole induction motor is

-' mm and the length is '2 mm. .ssume 17 rated slip and calculate the machine

constant and the a&erage tangential stress.

2. Why the length of air gap in induction motor is kept minimum possible

whereas in a #$ machine it is larger?

3. What is a suitable air gap for a 11/ kW3 si0-pole3 hea&y-duty induction

motor?

4. . salient-pole synchronous machine with a no-load sinusoidal air 8gap

flu0 density has a stator linear current density of . 9 "/ k.:m3 an air-gap flu0

density amplitude of 1 ( and a pole pitch of /. m. ;ind a suitable air gap for the

machine.

(est 5 2. Design of magnetic circuits

1. .n induction motor has an air gap /.' mm. (he stator slot opening is b

1

9 3 mm3

the rotor slots are closed and the stator slot pitc

h

is 1/ mm. the rotor magnetic

circuit is manufactured from high-,uality electrical steel with low eddy current

losses. $alculate the $arter-factor-corrected air gap of the machine. !ow deep is

the flu0 density dip at a slot opening if the rotor eddy currents do not affect the

dip? !ow much three-phase stator current is needed to magneti+e the air gap to /.-

( fundamental peak flu0 density? (he number of stator turns in series is 1//3 the

number of pole pairs is p 9 23 and the number of slots per pole and phase is , 9 3.

(he winding is a full-pitch one.

2. In a four-pole machine3 the outer diameter /. m3 the stator air gap diameter is /.3

m3 the machine stator core length is /.3 m and the air gap is 1 mm. (he peak &alue

of the fundamental air-gal flu0 density is o.- (. (he stator yoke height is /./ m.

$alculate the stator yoke magnetic &oltage.

3. (he sum of magnetic &oltages in half of the magnetic circuit of a four-pole

induction motor is 1// .. (here are 1// turns in series per stator winding and the

fundamental winding factor is /.-2. $alculate the no-load stator current.

(est 5 3. Design process and properties of rotating electric machines

1. $alculate the magnetic &oltage and / !+ losses of an induction motor stator of

height /./2 m with a constant width /./1 m and slot pitch /./2 m when the air-

gap flu0 ma0imum density is /.' (. (he stator lamination space factor is /.-%. (he

length of the stator stack is /.1 m.

2. $haracteristics of an induction machine.

3. $ommutation.

(est 5 1 for design pro6ect maintaining )graded test*

1. What is the most important consideration in determining the length of air <gap of

an induction motor?

2. Why closed type slots are often used for small induction motors?

3. When a three-phase induction motor is designed with higher &alue of 1

a&

it will

gi&e

)e* better full load power factor

)f* a higher starting tor,ue

)g* higher full load efficiency

)h* higher o&er load capacity.

4. .n induction motor of 1'. kW at %/ rpm has an efficiency of '7. .n induction

motor of 1'. kW at 1// rpm can ha&e an efficiency of

)a* ''7

)b* '7

)c* '27

)d* '/7.

. In the design of induction motor to incorporate feature of good o&er all design what

should be the ratio of core length of pole-pitch )4:=*

)a* 1./

)b* 1.//

)c* /.'/

)d* 1./ to 2.//.

". In the design of induction motor to incorporate the design feature of minimum cost

what should be the ratio of core length of pole-pitch )4:=*

)a* /.'/

)b* 1.//

)c* 1.2

)d* 1./ to 2.//.

%. In the design of induction motor to incorporate the design feature of good

efficiency what should be the ratio of core length of pole-pitch )4:=*

)a* 1./ to 2.//

)b* 1.//

)c* 1./

)d* 1.2.

(est 5 2 for design pro6ect maintaining )graded test*

What type of slots gi&e ,uiet operation?

1. What is the parameter other than ratio of rotor current limits which decides the

number of resistance sections of a slip-ring induction motor starter?

2. Why stator and rotor slots are not made e,ual in an induction motor?

3. Why for larger si+ed induction motors3 the stator cores are made of segmental

laminations?

4. Why the stator of three-phase s,uirrel cage induction motor is normally connected

in delta?

. In an induction motor the slots per pole per phase are most normally taken as

)a* three or less

)b* more than fi&e

)c* less than three

)d* three to fi&e.

". >ormally semi-enclosed slots are used in an induction motor

)a* reduced cost

)b* dropped-in coils can be used

)c* reduced &alue of magneti+ing current

)d* none of the abo&e.

%. Which type of slots are normally used in induction motors

)a* open

)b* semi-enclosed

)c* closed

)d* round.

'. In induction motors the mean &alue of flu0 density in the stator tooth to lie

between

)a* /.3 to /." (esla

)b* 2.1 to 2.4 (esla

)c* 1.3 to 1.% (esla

)d* /.- to 1.1 (esla.

-. Which of the following ,uantity is affected by the leakage reactance of an

induction motor?

)a* starting current

)b* starting tor,ue

)c* ma0imum tor,ue

)d* all the abo&e.

1/. Which of the following induction motor is cheaper?

)a* s,uirrel cage induction motor

)b* wound rotor induction motor

)c* double cage induction motor.

(est 5 3 for design pro6ect maintaining )graded test*

1. Why the frames of medium and large induction motor are fabricated?

2. Why the s,uirrel-cage rotor is prepared skewed?

3. !ow the power factor of an induction motor becomes poor by selecting higher

&alue of specific magnetic loading?

4. What is the most important consideration in selecting the number of rotor slots of

an induction motor in relation to the number of stator slots?

. What is the relation between rotor copper losses and full load slip?

". . great ma6ority of induction motors are made with s,uirrel cage rotors because of

its high efficiency.

%. (he frames of totally enclosed machines are pro&ided with a0ial fins to impro&e

cooling.

'. (he power factor is the most important consideration in determining the length of

air gap of an induction motor.

-. #ie-cast aluminium rotor bars are commonly employed compared to copper bars.

1/. (he length of air gap in an induction motor is kept minimum possible.

11. (he length of air gap in an induction motor is small to increase the starting tor,ue.

12. (he length of air gap in an induction motor is small to increase the magneti+ing

current.

13. (he magneti+ing current in an induction motor has to be small to impro&e the

power factor.

14. (o limit the magneti+ing current in an induction motor higher specific magnetic

loading is used.

1. ?emi-closed slots gi&e low tooth pulsation losses but noisy operation.

1". ?emi-closed slots gi&e low tooth pulsation losses and ,uiet operation.

1%. 4arge air gap length in an induction motor reduced noise le&el and impro&ed

cooling.

You might also like

- Submersible Pump Moter Core Design PDFDocument7 pagesSubmersible Pump Moter Core Design PDFIjabiNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Chapter 4 and 5 QuastionDocument10 pagesChapter 4 and 5 Quastionbekabeki829No ratings yet

- Emd-I AssignmentDocument6 pagesEmd-I Assignmentayan PatelNo ratings yet

- Design and Analysis of A Premium Efficiency (Ie3) Induction MotorDocument6 pagesDesign and Analysis of A Premium Efficiency (Ie3) Induction MotoresatjournalsNo ratings yet

- Unit - V Three Phase Induction Motor DesignDocument14 pagesUnit - V Three Phase Induction Motor DesignPrema ElizabethNo ratings yet

- Inductionmotor DesignDocument31 pagesInductionmotor Designbilalbaig97No ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Short Type Questions of Three Phase Induction Motor - 01.04.2020Document5 pagesShort Type Questions of Three Phase Induction Motor - 01.04.2020Amit DebnathNo ratings yet

- E2063 Teknologi Elektrik 2 UNIT7Document36 pagesE2063 Teknologi Elektrik 2 UNIT7dbu2952No ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Acharya Institute of Technology Department of Electrical and Electronics Engineering Bengaluru 560107Document3 pagesAcharya Institute of Technology Department of Electrical and Electronics Engineering Bengaluru 560107RAVIKIRAN CNo ratings yet

- Chapter ThreeDocument67 pagesChapter Threeetayhailu80% (5)

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Electric Machine Design (Module-4)Document24 pagesElectric Machine Design (Module-4)karumNo ratings yet

- Semi-Active Suspension Control Design for VehiclesFrom EverandSemi-Active Suspension Control Design for VehiclesRating: 5 out of 5 stars5/5 (1)

- Induction Motor Design PDFDocument46 pagesInduction Motor Design PDFdiptiNo ratings yet

- Question About MachinnesDocument3 pagesQuestion About MachinnesJoshua HicksNo ratings yet

- EE 1403 DESIGN OF ELECTRICAL APPARATUS Question BankDocument4 pagesEE 1403 DESIGN OF ELECTRICAL APPARATUS Question BankBavi ThraaNo ratings yet

- AssignmentDocument3 pagesAssignmentVikash TiwariNo ratings yet

- 3 Phase Induction MotorDocument48 pages3 Phase Induction Motormsd183wkNo ratings yet

- Chapter 3 Phase Induction MachinesDocument101 pagesChapter 3 Phase Induction Machineskelemyas ayalewNo ratings yet

- Motor ImanDocument4 pagesMotor ImanBALTAZARMARTINNo ratings yet

- EMD II UNIT 2 Design of Wound RotorDocument52 pagesEMD II UNIT 2 Design of Wound RotorAmit kumarNo ratings yet

- Ee8002 - Dem - Question Bank - Unit4Document4 pagesEe8002 - Dem - Question Bank - Unit4DEVINo ratings yet

- Chapter ThreeDocument64 pagesChapter ThreeTheødřøš ÄbNo ratings yet

- Unit-IV-Induction MotorsDocument57 pagesUnit-IV-Induction MotorssujithNo ratings yet

- Selection of Induction Motors Part 3Document6 pagesSelection of Induction Motors Part 3adau100% (1)

- A Comparative Study On Performance of 3KW InductioDocument7 pagesA Comparative Study On Performance of 3KW InductioAtanuMajiNo ratings yet

- Module 3. Design of 3 Phase Induction MotorDocument43 pagesModule 3. Design of 3 Phase Induction MotorVivek Pawar83% (6)

- R07-SUPPLY-DecemberJanuary 2014-15 - Design of Machine Members - IIDocument2 pagesR07-SUPPLY-DecemberJanuary 2014-15 - Design of Machine Members - IIPraveen KumarNo ratings yet

- Single Phase Induction Motor ThesisDocument7 pagesSingle Phase Induction Motor Thesisadrianawilsonpaterson100% (2)

- Brushed Direct-Current Motors: 5.1 Review of Motor TheoryDocument32 pagesBrushed Direct-Current Motors: 5.1 Review of Motor TheoryEvren SoydanNo ratings yet

- Current Circuit Short Ideal Current G MagnetizinDocument2 pagesCurrent Circuit Short Ideal Current G MagnetizinTechno madNo ratings yet

- ConfPaperEPE 2007 PDFDocument9 pagesConfPaperEPE 2007 PDFSelva KumarNo ratings yet

- Modeling and Simulation of Three Phase Induction Machine Using Written Pole TechnologyDocument7 pagesModeling and Simulation of Three Phase Induction Machine Using Written Pole TechnologyJOHN MINKHANTNo ratings yet

- C1201042329 PDFDocument7 pagesC1201042329 PDFJOHN MINKHANTNo ratings yet

- A.C. Motors: Figure 5a - Exploded View of A.C. 3-Phase Induction MotorDocument6 pagesA.C. Motors: Figure 5a - Exploded View of A.C. 3-Phase Induction MotorJB 1922No ratings yet

- Machine Design: 1 - I N T R Od U C T I OnDocument45 pagesMachine Design: 1 - I N T R Od U C T I Onr.anushyaNo ratings yet

- GRP No.1 El-P-MachineryDocument12 pagesGRP No.1 El-P-MachineryYasin OmaryNo ratings yet

- Ee2403-Special Electrical Machines Unit I - Synchronous Reluctance Motor Synchronous Reluctance Motor ConstructionDocument8 pagesEe2403-Special Electrical Machines Unit I - Synchronous Reluctance Motor Synchronous Reluctance Motor ConstructionVijaya KumarNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsMitesh GandhiNo ratings yet

- 3 Phase ImDocument43 pages3 Phase Imvibhash kumar dwivediNo ratings yet

- Efficiency Improvement of Squirrel Project ReportDocument31 pagesEfficiency Improvement of Squirrel Project ReportDular PatelNo ratings yet

- A Three-Phase Induction Motor ProblemDocument26 pagesA Three-Phase Induction Motor ProblemmehmetNo ratings yet

- BobiSoft Short Description 2017Document12 pagesBobiSoft Short Description 2017Masum uddin mondolNo ratings yet

- A Three-Phase Induction Motor ProblemDocument26 pagesA Three-Phase Induction Motor Problemowen674s100% (2)

- Assignment Sheet No. 1 Subject Name: Special Electrical Machines Subject Code: REE-064Document2 pagesAssignment Sheet No. 1 Subject Name: Special Electrical Machines Subject Code: REE-064Vikash TiwariNo ratings yet

- Pathfinder Motor HandbookDocument83 pagesPathfinder Motor Handbookchristianyankel100% (3)

- 3 Phase Induction Motor Speed Control Using PIC PDFDocument18 pages3 Phase Induction Motor Speed Control Using PIC PDFAmmar Al-Kindy100% (2)

- Espinosa, Vincent, F. JANUARY 7, 2017 ME - 2Y2-3 Ratings:: Assignment No. 1M ELEC. 325 Ac MotorDocument6 pagesEspinosa, Vincent, F. JANUARY 7, 2017 ME - 2Y2-3 Ratings:: Assignment No. 1M ELEC. 325 Ac MotorFroilan EspinosaNo ratings yet

- Fadriquel 2208 Laboratory Report 2Document7 pagesFadriquel 2208 Laboratory Report 2Kent Orriele FadriquelNo ratings yet

- Seminar Paper2Document8 pagesSeminar Paper2Disha NayarNo ratings yet

- 2021 CretiveLinks Updated Sites List With TrafficDocument28 pages2021 CretiveLinks Updated Sites List With Trafficyoshimori91No ratings yet

- 2021 CretiveLinks Updated Sites List With TrafficDocument28 pages2021 CretiveLinks Updated Sites List With Trafficyoshimori91No ratings yet

- Predator HelmetDocument12 pagesPredator Helmetyoshimori91No ratings yet

- Keywords BHWDocument1,129 pagesKeywords BHWyoshimori91No ratings yet

- Different Type of Generator ExcitersDocument3 pagesDifferent Type of Generator Excitersjipix78No ratings yet

- TVH - Brushes For Forklift PDFDocument326 pagesTVH - Brushes For Forklift PDFpiojezior100% (1)

- Experiment No. 1 and 2 PDFDocument14 pagesExperiment No. 1 and 2 PDFJoshua LlamasNo ratings yet

- Lecture 08 Ideal and Real TransformerDocument26 pagesLecture 08 Ideal and Real TransformerSyed AfzalNo ratings yet

- Working Principle of Three Phase Induction MotorDocument6 pagesWorking Principle of Three Phase Induction MotorAvinash Kanaujiya100% (1)

- Qleous Blumei Fadrigon - Final Examination (E&m)Document1 pageQleous Blumei Fadrigon - Final Examination (E&m)Jersey Ann Reign A. GabinNo ratings yet

- Question Bank of PC EE 401Document7 pagesQuestion Bank of PC EE 401Isabella SwanNo ratings yet

- TransformerDocument25 pagesTransformerTHE PIVOTALNo ratings yet

- Tut 3Document3 pagesTut 3mohanrajgupta1950% (2)

- G9 1 Induction Gen Report Lab K EditDocument194 pagesG9 1 Induction Gen Report Lab K EditGame PlayNo ratings yet

- Ee8401 - em Ii - Question Bank - Unit2Document4 pagesEe8401 - em Ii - Question Bank - Unit2DEVINo ratings yet

- Transformers Project FileDocument13 pagesTransformers Project FiledikshaNo ratings yet

- Linear Solenoid Actuator FINAL 3 PPDocument3 pagesLinear Solenoid Actuator FINAL 3 PPJean GrandeNo ratings yet

- Lecture 10 - DC Motors and DrivesDocument83 pagesLecture 10 - DC Motors and DrivesSaad Murad GorayaNo ratings yet

- Grand Assignment IDocument3 pagesGrand Assignment ISheri Abhishek ReddyNo ratings yet

- EM-I Lab Viva Questions Updated OnDocument6 pagesEM-I Lab Viva Questions Updated OnNagamohan BilluNo ratings yet

- Indt 103 Course ScheduleDocument4 pagesIndt 103 Course Scheduleapi-245222092No ratings yet

- Chapter2-1 - Overview of DC MachinesDocument40 pagesChapter2-1 - Overview of DC MachinesTabi4every175% (4)

- Motor Wiring Diagram: D.C. Motor ConnectionsDocument1 pageMotor Wiring Diagram: D.C. Motor Connectionsczds6594No ratings yet

- LT CT SpecificationsDocument12 pagesLT CT SpecificationsRehan SadiqNo ratings yet

- Typical 400kV TRF (HV) Bay View (GIS MODULE)Document1 pageTypical 400kV TRF (HV) Bay View (GIS MODULE)Amarjit KulkarniNo ratings yet

- Ignition Coils TypesDocument27 pagesIgnition Coils TypesMohamed EssamNo ratings yet

- Grundfosliterature 5874Document232 pagesGrundfosliterature 5874Nikola VeleskiNo ratings yet

- Induced Voltage in A Three Phase Generator VDocument43 pagesInduced Voltage in A Three Phase Generator VPao Castillon100% (1)

- Electrical Machines TutorialsDocument6 pagesElectrical Machines TutorialsAllegro Presto ModeratoNo ratings yet

- DC M&T Lecture Notes - 0Document121 pagesDC M&T Lecture Notes - 0syulmnmd100% (1)

- Electrical Machineghvhvs2tuts2013!14!1Document8 pagesElectrical Machineghvhvs2tuts2013!14!1Utkarsh Verma100% (1)

- Analisa Kandungan Harmonisa Pada Motor Ac 3 Phasa 0,12 KW Terkendali Inverter 3 PhasaDocument7 pagesAnalisa Kandungan Harmonisa Pada Motor Ac 3 Phasa 0,12 KW Terkendali Inverter 3 PhasaMochammad IrfanNo ratings yet

- Sigma Institute of Engineering Department of Electrical Engineering Bakrol, VadodaraDocument11 pagesSigma Institute of Engineering Department of Electrical Engineering Bakrol, VadodaraBhavik PrajapatiNo ratings yet

- Medical PhysicsDocument10 pagesMedical PhysicsZuhaib AhmedNo ratings yet

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...From EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsFrom EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNo ratings yet

- Power System Control and ProtectionFrom EverandPower System Control and ProtectionB. Don RussellRating: 4 out of 5 stars4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (10)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- Build Your Own Electronics WorkshopFrom EverandBuild Your Own Electronics WorkshopRating: 3.5 out of 5 stars3.5/5 (3)

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldFrom EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldRating: 4 out of 5 stars4/5 (87)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)