Professional Documents

Culture Documents

Dimetcote 9 PDS AI

Uploaded by

Amer Y KCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimetcote 9 PDS AI

Uploaded by

Amer Y KCopyright:

Available Formats

December 2013

Revision of October 2013

DESCRIPTION Inorganic Zinc Silicate Primer

PRINCIPAL CHARACTERISTICS >85% zinc in dry film

Provides outstanding corrosion resistance

Abrasion resistant

Resistant to dry film temperatures of up to 750F

Recommended for ISO 12944 C5I and C5M Conditions

COLOR AND GLOSS Green

Flat

BASIC DATA

Volume solids 63% 3% (based on applied film, including porosity)

VOC* 4.1 lbs/gal (491 g/L)

* For compliance with regulations which require < 420 g/L, Dimetcote 9VOC can be specified interchangeably.

For compliance with regulations which require <340 g/L, Dimetcote 9H can be specified interchangeably.

Recommended

Dry film thickness (per coat) 2 - 4 mils (50-100 microns)

* Applications up to 6 mils are acceptable with random spot readings up to 8 mils. For high temperature

applications, a maximum of 3 mils is allowed.

Theoretical Spread Rate @ 1 mil dft 1,011 ft

2

/gal

@ 3 mils dft 337 ft

2

/gal

Components 2 (liquid, zinc powder)

Dry Temperature Resistance Continuous 750F

Color will drift at elevated temperatures.

Shelf Life Liquid 9 months from date of manufacture when stored indoors in the original unopened

container. Storage temperature should be 40-100F and in dry conditions.

Powder 24 months from date of manufacture when stored indoors in the original

unopened container.

SURFACE PREPARATION Coating performance is proportional to the degree of surface preparation.

Steel Abrasive blast to SSPC SP-6 or higher with a 1.5-3.0 mil surface profile. Higher

surface profiles up to 5 mils are acceptable, but the product must be applied in a

thickness great enough to achieve a minimum of 2.5 mils dry film thickness.

Apply Dimetcote 9 as soon as possible to prevent the blasted surface from rusting.

Keep moisture, oil, grease, or other organic matter off surface before coating.

For touch up and repair, power tool cleaning in accordance with SSPC SP-11 is

acceptable.

ENVIRONMENTAL CONDITIONS

Ambient temperatures 0F to 120F (-18C to 49C)

Surface temperature must be at least 5F above the dew point temperature.

Material temperatures 40F to 90F (10C to 32C)

Relative humidity 50% minimum

* Work area can be artificially humidified by atomized water spray and/or ponding water under the coated

structures. After the film is dry-to-touch, a fine mist may be applied over the coating to expedite curing in low

humidity environments.

Surface temperature 0F to 130F (-18C to 54C)

Surface temperature must be at least 5F above the dew point temperature.

General air quality Area should be sheltered from airborne particulates and pollutants. Ensure good

ventilation during application and curing. Provide shelter to prevent wind from affecting

spray patterns.

DIMETCOTE

9

page 1/3

INSTRUCTIONS FOR USE

Mixing 77 parts liquid :: 23 parts powder by volume.

Pre-mix base component with a pneumatic air mixer at moderate speeds to homogenize

the container. Add powder component slowly under agitation until fully mixed. Strain the

mixture from one container to another through a 30 mesh filter/strainer to remove any

undispersed lumps.

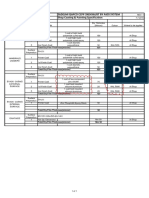

Pot life*

* Maintain agitation throughout application to prevent settling of the zinc. Protect product from moisture

contamination

Airless spray Standard airless spray equipment, 30:1 pump or larger, 0.019 0.023, reversible fluid

tip recommended

Air spray Thin up to 10%, dedicated equipment for inorganic zinc is highly recommend, standard

conventional equipment, 0.070 fluid orifice. A moisture and oil trap in the main line is

recommended. Separate regulators for air and fluid pressure are recommended. Use an

agitated pressure pot. Limit fluid hose length to 50 feet.

Brush & roll Use a high quality natural bristle. Brush application is only recommended for small

touch up and/or repair areas. Roller application is not recommended.

Repair When dry though, measure the dry film thickness. If film thickness is lower than

specified, additional material can be applied up 24 hours from the previous application.

Thin the second coat with Amercoat 101 thinner or Amercoat 930 thinner. Ensure any

dry spray is removed.

For aged inorganic zinc coatings, spot blast rusted areas in accordance with the surface

preparation instructions before touching up with Dimetcote 9. When blasting is not

practical, Amercoat 68HS or Dimetcote 302H may be used for repair.

Thinner Amercoat 65 (xylene), Amercoat 101 (recommended for > 60F), Amercoat 930 (recom-

mended for applications > 80F or when dry spray is a problem)

Cleaning solvent Amercoat 12 Cleaner or Amercoat 65 thinner (xylene)

Primers Direct to metal

Topcoats PSX 700, Amerlock 2/400, Amercoat 385, Amercoat 370, others

A mist coat / full coat application technique is required when topcoating to prevent

application bubbling. Ensure dry spray is removed from the surface.

Product can be un-topcoated in certain applications.

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES Dimetcote 9 @ 3 mils dft and 50% relative humidity

* A MEK rub resistance rating of 4 or higher, indicates the film has cured sufficiently for topcoating.

** Surface must be power washed as needed to remove all surface contaminants including zinc salts. Surface

must be clean and dry.

PRODUCT QUALIFICATIONS SSPC Paint 20, Type IC , Level 1

RCSC Class B Slip Coefficient for High Strength Bolted Connections

Zinc Dust meets ASTM D520 Type 2 standards

AASHTO M300

Nuclear Qualified version available

DIMETCOTE 9

page 2/3

Temperature 70F

Dimetcote 9 8 hours

32F 50F 70F 90F

Dry to handle 2 hours 1 hour 30 minutes 20 minutes

Dry to overcoat* 48 hours 36 hours 24 hours 18 hours

Full Cure 4 days 72 hours 46 hours 36 hours

page 3/3

DIMETCOTE 9

AVAILABILITY

Packaging Available in 1-gallon and 5-gallon kits

Product codes DI9-A Liquid component

DI9-P Zinc Powder component

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

WARRANTY STATEMENT

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in

effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the product.

THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES,

UNDER STATUTE ORARISING OTHERWISE IN LAW, FROMA COURSE OF DEALING OR USAGE OF TRADE, INCLUDING

WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FORA PARTICULAR PURPOSE OR USE, ARE DISCLAIMED

BY PPG.

Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed

defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the delivery

of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein

shall bar Buyer from recovery under this warranty.

LIMITATION OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF

ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT.

The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to be reliable.

PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of the PPG product, whether in technical documentation,

or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it

is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that

Buyer has done so, as its sole discretion and risk.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or

the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment,

changes in procedures of use, or extrapolation of data may cause unsatisfactory results.

This sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to

using the product.

Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

Dimetcote is a registered trademark of PPG Industries Ohio, Inc.

You might also like

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- D4060.37296 - Taber Abraser TestDocument6 pagesD4060.37296 - Taber Abraser TestJeremyNo ratings yet

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Astm D4260-88 PDFDocument2 pagesAstm D4260-88 PDFdang2172014No ratings yet

- D4940 15 (Reapproved 2020) REDDocument3 pagesD4940 15 (Reapproved 2020) REDcarlos_k1555alejo100% (1)

- C240Document4 pagesC240BeymerBustamanteMejía100% (1)

- D3806Document5 pagesD3806Mohamed FaragNo ratings yet

- ASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsDocument4 pagesASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsArmaghan ShiekhNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- Astm D4417Document3 pagesAstm D4417claudiaNo ratings yet

- Wet-to-Dry Hiding Change: Standard Test Method ForDocument5 pagesWet-to-Dry Hiding Change: Standard Test Method ForShaker QaidiNo ratings yet

- Isobond: SBR Bonding AdmixtureDocument3 pagesIsobond: SBR Bonding AdmixtureHussain MarzooqNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- Astm D1148 - 13Document4 pagesAstm D1148 - 13faroukNo ratings yet

- 2 Astm D6943Document16 pages2 Astm D6943Boris CardenasNo ratings yet

- CCL GS-11 Paints Coatings Stains Sealers (2015)Document26 pagesCCL GS-11 Paints Coatings Stains Sealers (2015)Duk UquillasNo ratings yet

- ASTM D897.20934 Propiedades Ténsiles en Uniones AdhesivasDocument3 pagesASTM D897.20934 Propiedades Ténsiles en Uniones Adhesivasamgoyesv17No ratings yet

- Adhesion Characteristics of Protective Coatings for Nuclear Power PlantsDocument8 pagesAdhesion Characteristics of Protective Coatings for Nuclear Power PlantsHaidarHussaini100% (1)

- AstmDocument4 pagesAstmmohamed abd eldayemNo ratings yet

- 672CDocument3 pages672CJGD123No ratings yet

- Astm D 660 - 93 (2019)Document9 pagesAstm D 660 - 93 (2019)Sur VaniNo ratings yet

- HEMPEL'S VINYL ESTER GF 35910 Product Data SheetDocument2 pagesHEMPEL'S VINYL ESTER GF 35910 Product Data SheetEngTamerNo ratings yet

- ASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and ReagentsDocument2 pagesASTM D 3023 - 98 Determination of Resistance of Factory-Applied Coatings On Wood Products To Stains and Reagentsalin2005No ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- Power PlantDocument34 pagesPower Plantmiguel0581No ratings yet

- Astm D714Document5 pagesAstm D714Boris AguilarNo ratings yet

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceDocument3 pagesFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- SoniCell ASTM E85 Fire TestDocument10 pagesSoniCell ASTM E85 Fire TestAvs CrNo ratings yet

- Epoxy Polyamide Paint SpecificationDocument5 pagesEpoxy Polyamide Paint SpecificationMaria Clara100% (1)

- Nuclear Containment FailuresDocument10 pagesNuclear Containment FailuresskdonaldsNo ratings yet

- Astm and Iso Vocs in Coatings - Method Comparison MatrixDocument2 pagesAstm and Iso Vocs in Coatings - Method Comparison MatrixShaik ShahNo ratings yet

- Astm D 1654-05 PDFDocument4 pagesAstm D 1654-05 PDFharpreet singhNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- Auramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeDocument2 pagesAuramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeVipin Kumar Parashar100% (1)

- Astm D-4214Document4 pagesAstm D-4214Ahmad RoyaniNo ratings yet

- SSPC Protective Coatings InspectorDocument731 pagesSSPC Protective Coatings InspectorTeymur RegenmaisterNo ratings yet

- D 6412 - D 6412m - 99 Rdy0mtivrdy0mtjnDocument4 pagesD 6412 - D 6412m - 99 Rdy0mtivrdy0mtjnMarceloNo ratings yet

- Amine Blush+Bloom Explained - Dow BulletinDocument5 pagesAmine Blush+Bloom Explained - Dow BulletinPhilip La Trobe100% (2)

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- The Tale of The Tape ASTM D3359Document3 pagesThe Tale of The Tape ASTM D3359lthyaguNo ratings yet

- D358 PDFDocument3 pagesD358 PDFChandraditya Iman FirmanshaNo ratings yet

- Technical Data Sheet: Stolevell Thinplast FinishDocument3 pagesTechnical Data Sheet: Stolevell Thinplast FinishAnthony Al Lakiss0% (1)

- Section 07810 Applied FireproofingDocument4 pagesSection 07810 Applied FireproofingMØhãmmed ØwięsNo ratings yet

- Roof GuardDocument2 pagesRoof Guardpravi3434No ratings yet

- Beginners Guide To CorrosionDocument10 pagesBeginners Guide To Corrosionshamu081No ratings yet

- ASTM D 823 - 95 Practicas Estandar para Producir Peliculas...Document8 pagesASTM D 823 - 95 Practicas Estandar para Producir Peliculas...María Alejandra Gutiérrez GutiNo ratings yet

- ASTM D 714 - 87 R00 Standard Test Method For Evaluating Degree of Blistering of Paints PDFDocument5 pagesASTM D 714 - 87 R00 Standard Test Method For Evaluating Degree of Blistering of Paints PDFAlfredoNo ratings yet

- Evaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForDocument4 pagesEvaluating Degree of Flaking (Scaling) of Exterior Paints: Standard Test Method ForSudharsanNo ratings yet

- ASTM D 280-01 Standard Test Methods For Hygroscopic MoistureDocument2 pagesASTM D 280-01 Standard Test Methods For Hygroscopic Moisturealexander_suarez_19No ratings yet

- Defend 740Document2 pagesDefend 740Mohamed NouzerNo ratings yet

- SSPC Paint 18Document5 pagesSSPC Paint 18anoopkumarNo ratings yet

- Astm D 3274 PDFDocument4 pagesAstm D 3274 PDFSwaminathan Balasubramanian BNo ratings yet

- ASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodDocument9 pagesASTM D2228 04 - Standard Test Method For Rubber Property-Relative Abrasion Resistance by Pico Abrader MethodAndre Rodriguez Spirim100% (1)

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroNo ratings yet

- Density, Absorption, and Voids in Hardened Concrete: Standard Test Method ForDocument3 pagesDensity, Absorption, and Voids in Hardened Concrete: Standard Test Method ForMohamed BelmokaddemNo ratings yet

- Sika Fibre 2011 - PDSDocument4 pagesSika Fibre 2011 - PDSIbnu SenaNo ratings yet

- Exxsol D40 SDSDocument10 pagesExxsol D40 SDSKim Chuan OngNo ratings yet

- Astm C868-02 PDFDocument4 pagesAstm C868-02 PDFIan HsuNo ratings yet

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsideNo ratings yet

- Awwa C208-17Document32 pagesAwwa C208-17Pablo DM100% (1)

- Daikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFDocument2 pagesDaikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFAmer Y KNo ratings yet

- Advance Steel AttributesDocument2 pagesAdvance Steel AttributesAmer Y KNo ratings yet

- CO2Document2 pagesCO2Amer Y KNo ratings yet

- Daikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFDocument2 pagesDaikin Constant Volume With Reheat Systems AppGuide AG31-023 LR PDFAmer Y KNo ratings yet

- Key 2Document17 pagesKey 2Amer Y KNo ratings yet

- TANK-01 Layout1Document1 pageTANK-01 Layout1Amer Y KNo ratings yet

- Key 2Document17 pagesKey 2Amer Y KNo ratings yet

- Key 2Document18 pagesKey 2Amer Y KNo ratings yet

- KeyDocument18 pagesKeyAmer Y KNo ratings yet

- Structural Steel Painting DFT Inspection Record (Beams) : Readings ( )Document5 pagesStructural Steel Painting DFT Inspection Record (Beams) : Readings ( )Amer Y KNo ratings yet

- Sadelmi Qapco CCPP 3Xhaust By Pass System Shop Coating & Painting SpecificationDocument1 pageSadelmi Qapco CCPP 3Xhaust By Pass System Shop Coating & Painting SpecificationAmer Y KNo ratings yet

- 1 Software / Instruction Manuals: A. Communications & NetworkingDocument2 pages1 Software / Instruction Manuals: A. Communications & NetworkingAmer Y KNo ratings yet

- Diesel CoolerDocument1 pageDiesel CoolerAmer Y KNo ratings yet

- Monokote MK 6s 17Document2 pagesMonokote MK 6s 17Amer Y KNo ratings yet

- 1 Software / Instruction Manuals: A. Communications & NetworkingDocument2 pages1 Software / Instruction Manuals: A. Communications & NetworkingAmer Y KNo ratings yet

- Advance Steel AttributesDocument2 pagesAdvance Steel AttributesAmer Y KNo ratings yet

- GASOLINE STORAGE TANK INSPECTION AND TEST PLANDocument1 pageGASOLINE STORAGE TANK INSPECTION AND TEST PLANAmer Y KNo ratings yet

- TCV Modification PlanDocument1 pageTCV Modification PlanAmer Y KNo ratings yet

- Silicone SealantDocument2 pagesSilicone SealantAmer Y KNo ratings yet

- UL Certificate of Compliance MK6s 05-02-16Document1 pageUL Certificate of Compliance MK6s 05-02-16Amer Y KNo ratings yet

- Petrochemical Grade Cementitious Fireproofing Product InformationDocument2 pagesPetrochemical Grade Cementitious Fireproofing Product InformationAmer Y KNo ratings yet

- ASME B16.4 Example 1Document8 pagesASME B16.4 Example 1Amer Y KNo ratings yet

- Avikote AV 650-5 PDFDocument2 pagesAvikote AV 650-5 PDFAmer Y KNo ratings yet

- Zamil Airconditioning Delivery - 9-8-2015Document3 pagesZamil Airconditioning Delivery - 9-8-2015Amer Y KNo ratings yet

- Gantt Project Planner1Document1 pageGantt Project Planner1Amer Y KNo ratings yet

- Pipe Identification ModelDocument1 pagePipe Identification ModelAmer Y KNo ratings yet

- Avikote AV 650-5Document2 pagesAvikote AV 650-5Amer Y KNo ratings yet

- NFPA Fire Code ListDocument8 pagesNFPA Fire Code ListAnindito NurprabowoNo ratings yet

- Demeclocycline Effective for Treating SIADHDocument4 pagesDemeclocycline Effective for Treating SIADHSally TareqNo ratings yet

- Testing and Adjusting 12GDocument5 pagesTesting and Adjusting 12GJuan GonzalezNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationHazama HexNo ratings yet

- EP820 User Guide (V100R003C00 - 05) (PDF) - ENDocument47 pagesEP820 User Guide (V100R003C00 - 05) (PDF) - ENchineaNo ratings yet

- 2219 & 2219 Clad PDFDocument22 pages2219 & 2219 Clad PDF孙俊磊No ratings yet

- Prioritizing Seaweed Value Chain ImprovementsDocument10 pagesPrioritizing Seaweed Value Chain ImprovementsRosas PagtooNo ratings yet

- Diseases of The Kidney andDocument12 pagesDiseases of The Kidney andI. C. StraussmanNo ratings yet

- Signs and SymptomsDocument2 pagesSigns and SymptomsKristine GurimbaoNo ratings yet

- Commuter Students and Involvement Theory: Rowan Digital WorksDocument67 pagesCommuter Students and Involvement Theory: Rowan Digital WorksDark LegendNo ratings yet

- ARSA 2010 International Conference Proceeding - Volume IIDocument540 pagesARSA 2010 International Conference Proceeding - Volume IICholnapa AnukulNo ratings yet

- MR Safe Conditional PDFDocument4 pagesMR Safe Conditional PDFAKSNo ratings yet

- Service Manual: For Hyundai Heavy Industries Co.,LtdDocument27 pagesService Manual: For Hyundai Heavy Industries Co.,LtdDmitry100% (1)

- Opioids For Chronic Pain ManagementDocument45 pagesOpioids For Chronic Pain ManagementaartiNo ratings yet

- Death Certificate: Shaheed Monsur Ali Medical College HospitalDocument3 pagesDeath Certificate: Shaheed Monsur Ali Medical College HospitalBokul80% (5)

- APA Style Guide For StudentsDocument18 pagesAPA Style Guide For StudentsTeacher Jorge Omar NievesNo ratings yet

- MHWirth PileTopDrillRigs Brochure Web2Document12 pagesMHWirth PileTopDrillRigs Brochure Web2geobyun100% (1)

- Class 8 Physics 3Document16 pagesClass 8 Physics 3Akhil ChintalapalliNo ratings yet

- FP02BDocument3 pagesFP02BRazak JeyNo ratings yet

- Railway Recruitment Board Level-1 Exam DetailsDocument2 pagesRailway Recruitment Board Level-1 Exam Detailsrajesh naikNo ratings yet

- SerieventilacionDocument37 pagesSerieventilacionCaexvenNo ratings yet

- Sensation As If by Roberts PDFDocument369 pagesSensation As If by Roberts PDFNauman Khan100% (1)

- Yuken pvr50 FF 45 Raa 3180 Hydraulic Vane PumpDocument4 pagesYuken pvr50 FF 45 Raa 3180 Hydraulic Vane Pumpnelson nadarNo ratings yet

- X1jet MX Manual PDFDocument97 pagesX1jet MX Manual PDFrithik srivastavaNo ratings yet

- Autorefractometro GRK 7000Document82 pagesAutorefractometro GRK 7000Wilson CepedaNo ratings yet

- Brochure FinalDocument14 pagesBrochure FinalRajesh BadheNo ratings yet

- American Institute of Timber Construction: AITC 405-2005Document8 pagesAmerican Institute of Timber Construction: AITC 405-2005jerchiNo ratings yet

- Notes Micro FinanceDocument9 pagesNotes Micro Financesofty1980No ratings yet

- Hawaii Hotel Performance by WeekDocument1 pageHawaii Hotel Performance by WeekHonolulu Star-AdvertiserNo ratings yet

- Installation and Operation Manual: SCR DC Motor ControlDocument32 pagesInstallation and Operation Manual: SCR DC Motor ControlAndres GarcíaNo ratings yet

- LPT22Document3 pagesLPT22Leonardo Vinicio Olarte CarrilloNo ratings yet