Professional Documents

Culture Documents

SCA2008-39-Comparison of High - Low Salinity Water - Oil Relative Permeability

Uploaded by

tsanshine0 ratings0% found this document useful (0 votes)

43 views12 pagesConference Paper

Original Title

SCA2008-39-Comparison of High_Low Salinity Water_Oil Relative Permeability

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentConference Paper

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views12 pagesSCA2008-39-Comparison of High - Low Salinity Water - Oil Relative Permeability

Uploaded by

tsanshineConference Paper

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

SCA2008-39 1/12

COMPARISON OF HIGH/LOW SALINITY WATER/OIL

RELATIVE PERMEABILITY

Kevin Webb, Arnaud Lager, Cliff Black

BP Exploration

This paper was prepared for presentation at the International Symposium of the

Society of Core Analysts held in Abu Dhabi, UAE 29 October-2 November, 2008

ABSTRACT

There is much published data in the literature showing that waterflood recovery is

dependent on the composition, especially the salinity, of the injection brine. Some of this

published data have shown the characteristics of coreflood tests at reduced conditions with

dead crude and brines. Relatively few have discussed tests performed at reservoir

conditions with live fluids.

This paper describes characteristics of full reservoir condition waterfloods with live crude

oil and brines (both high and low salinity) on reservoir plug samples from many global oil

producing basins. Experimental procedures and reservoir condition waterflood

characteristics are presented in this paper from both secondary (low salinity injection into a

plug sample at initial water saturation (Swi)) and tertiary injection (low salinity injection

into samples which have already seen high salinity injection). This simulates both low

salinity injections in new waterfloods and also in mature waterfloods.

Fully interpreted reservoir condition water/oil relative permeability are also presented.

High and low salinity relative permeability data measured on the same reservoir rock types

are compared from similar Swi values. The characteristics of injecting low salinity brines

after high salinity waterfloods are also discussed.

INTRODUCTION

Waterflooding is one of the most used enhanced oil recovery technique. Until recently it

has been viewed exclusively as a physical process for maintaining pressure and sweeping

oil to producing wells unless scaling or souring potential was present.

In the 90s, J adhunandan and Morrow [1995] and Yildiz and Morrow [1996] published

papers on the influence of brine composition on oil recovery which started to change the

industrys view on how waterflooding works and how it could be optimised. Since then a

number of papers have been published investigating this phenomena and growing evidence

from the laboratory [Lager et al 2006, Webb et al 2005], field single well tests [McGuire et

al 2005, Webb et al 2004, Seccombe et al 2008], and through to reservoir scale evidence

[Lager et al 2008], are supporting the technology. Reservoir simulation of the process has

also been published by J erauld et al [2006]. Generally oil recovery is increased

SCA2008-39 2/12

significantly, up to 50%, by injecting brines of salinity <4000 ppm opposed to sea water or

higher salinity produced waters.

Most of the published corefloods have been performed at reduced conditions, mainly with

dead oils and brines, with the objective of improving mechanistic understanding behind the

measured increased recovery(for instance Yildiz et al, [1996], Tang et al, [1999]). Webb et

al [2005] published reservoir condition oil production data but did not discuss relative

permeability. Therefore no data has been reported that could be used for reservoir

simulation. This paper therefore presents fully interpreted water/oil relative permeability

derived at reservoir conditions.

The success of any EOR technique is the ability to release significant volumes of oil, after

secondary recovery scheme, rapidly and at low cost. Most of the reduced condition

waterfloods in the literature have suggested that the oil produced by low salinity

waterflooding would not develop into an oil bank but would be produced as a long

drainage process at high fractional flow of water. This could result in the technology being

uneconomical due to the long period of time and the large amount of water which would be

required. This paper will show characteristics of oil production for many different

reservoirs, at different initial water saturations, measured at full reservoir conditions which

suggest very different characteristics, making low salinity waterflood a potential

economical EOR technique.

This paper describes the design, execution, analyses and interpretation of full reservoir

condition tests on reservoir rock/oil, comparing high and low salinity waterflood tests with

live oil and brine. Water/oil relative permeability data obtained on a number of reservoirs

from around the world, from different Swi values (Figure 1), are compared to show the

speed of response of tertiary production that is achieved during the LoSal

TM

EOR

technology process.

EXPERIMENTAL PROCEDURES

Description of Equipment

These studies utilised coreflood facilities which operate at full reservoir conditions, up to

150

o

C and 10000 psi, (Figure 2). Equipment utilises in-situ saturation monitoring by

gamma ray and uses live fluids both for ageing and fluid flow (Figure 3). Volumetric

production is measured at full reservoir conditions with an in-line separator, and

saturations at the end of the flood are confirmed by performing aqueous dispersions with a

doped phase.

Reservoir Systems

The relative permeability studies presented have been selected on the basis of showing the

impact of low salinity on many of the producing basins across the world (Figure 1). The

characteristics of rocks are therefore very different, ranging from relatively clean (low clay

content) rocks, to rocks which have many minerals other than quartz. Crude oils also have

SCA2008-39 3/12

very different characteristics (acid/base numbers, SARA analyses etc). Connate brine

salinities vary from~15,000ppm to ~200,000 ppm. Likewise temperature and pressure of

the tested reservoirs vary considerably from ~60

o

C to ~130

o

C and ~2500psi to ~7500 psi.

Description of Procedures

Core Preparation.

Plug samples, nominally 3" long by 1.1/2" in diameter were used for these studies.

All samples used for this study were restored i.e. samples were cleaned to as water wet

condition as possible by miscible solvents. After cleaning, samples were saturated with

the simulated formation water (both samples for high and low salinity corefloods) by

flowing under a back pressure. After ca. 10 pore volumes of brine throughput, samples

were removed from the hydrostatic coreholders and initial water saturations set up using

the procedures described below.

Acquisition of Initial Water Saturations.

It was essential that plug samples had representative Swi values which were matched to the

height above the oil water contact in the reservoir. For these cleaned plug samples, initial

water saturations were achieved by porous plate de-saturation, using strongly non wetting

gas (nitrogen). Once these initial water saturations were acquired, the samples were loaded

into hydrostatic coreholders and saturated by flowing refined oil under back pressure.

In-situ saturation monitoring was used to provide distributed saturation data to aid

interpretation of experimental results. This technique was based on the linear attenuation

of -rays. Each source/detector pair viewed a slice of core 4 mm wide. A linear

relationship between the log of counts (transmitted flux) and water saturation existed.

Therefore, by employing careful calibration procedures for each source/detector assembly,

fluid saturations were calculated. A number of these assemblies were mounted along the

core plug samples so that water saturation was monitored at fixed positions versus

time/throughput during the waterfloods.

Two sets of calibration data were collected for each source/detector pair at the end of each

waterflood. 100% brine saturation calibrations were recorded at the end of the cleaning

stage. 100% oil saturation calibrations were measured with the core 100% saturated with

live crude oil.

In these experiments it was necessary to replace chloride ions in the simulated formation

brine with iodide ions so that the contrast between the aqueous and oleic phases was

increased. This reduced the noise to signal ratio, and improved the accuracy of the

calculated in-situ saturations. The molarity of the doped brine was kept the same as the

un-doped brine to ensure that no adverse rock/fluid interactions occurred, although a

maximum of 50 g/l of sodium iodide was not exceeded in any test.

SCA2008-39 4/12

Ageing Process.

Samples were loaded into reservoir condition coreholders and slowly raised in pressure

and temperature to reservoir conditions. Reservoir temperatures varied from 60

o

C to

125

o

C.

The refined oil was miscibly displaced at full reservoir conditions by live crude oil to

constant gas/oil ratio via a slug of toluene to ensure that no asphaltene was precipitated

due to an incompatibility between the live oil and the refined oil. When the differential

pressure was stable, the live crude oil viscosity and effective permeability to live crude oil

were measured. All samples were aged in live crude oil for two to three weeks. During

the ageing period the crude oil was replaced every few days. A minimum of 3 pore

volumes were injected and a sufficient amount was used to achieve a constant pressure

drop across the sample and a constant gas oil ratio.

Waterflooding Procedures.

Unsteady state waterfloods were carried out on the sample at full reservoir conditions

using in-situ saturation monitoring (Figure 3). In-situ saturations were used to provide

data on the oil distributions which developed during the course of the waterflood. Swi for

both high and low salinity samples was initiated following on from saturating with the

simulated formation brine. Injection brines were simulated formation brine for high

salinity waterfloods (salinity 15,000 ppm to >200,000 ppm), and low salinity brine (<5000

ppm) for the low salinity corefloods. All brines, both high and low salinity, used for the

waterflood tests, were pre-equilibrated with separator gas at the reservoir pore pressure to

ensure no gas transfer from oil to water phases

Low rate waterfloods were carried out on the restored state samples at a typical reservoir

advancement rate (1 foot per day, typically corresponding to 4 cm

3

/hour in the laboratory).

During the injection of the brine, oil production, pressure drop and in-situ saturation data

were continuously monitored. Oil production was recorded at full reservoir conditions in

an ultrasonic separator. This had the advantage of directly measuring oil production at

reservoir conditions. Errors associated with using formation volume factors to correct oil

production data were therefore avoided.

For the high salinity secondary waterfloods, tertiary injection of low salinity brine was

injected after >10 pore volumes throughput of the high salinity brine.

At the end of the waterflood test sequence and after the plugs were cleaned to Sw=1,

miscible dispersions using doped and undoped brine were performed at relatively low rates

to determine the aqueous pore volumes at the end of the waterflood process and fully brine

saturated, by two independent means, (density and concentration profile from the

measured gamma attenuation). In this way a number of independent means of measuring

low salinity benefit were performed (mass balance, in-situ saturation during waterflood,

dispersion tests).

SCA2008-39 5/12

Coreflood Analyses and Interpretation.

Laboratory production and differential pressure were initially analysed using the J ohnson

Bossler Naumann technique [1959]. This however assumes that there are no impacts of

capillary pressure on waterflood characteristics. This rarely is the case. Therefore further

interpretation is required to remove the impact of capillary pressure on the relative

permeability data. In the corefloods discussed here, imbibition capillary pressure was

derived from the dynamic waterflood in-situ saturation and differential pressure data

measured during the waterflood.

The starting point for the data interpretation was to confirm that the J BN data sets were

consistent with the pressure and production data measured in the laboratory. This was

performed by including the laboratory measured data and the J BN relative permeability

data into an input file which was run through the 1D coreflood simulator 'PAWS' [Carr et

al 1983]. The next stage in the interpretation process was to include imbibition capillary

pressure data, and modify the relative permeability data in the PAWS input file. Imbibition

capillary pressure was derived from waterflood displacement data and the measured in-situ

saturation data.

The PAWS simulator was run, and the simulated production and pressure profiles

compared against those generated during the experiment. If poor agreement was obtained

then the relative permeability to oil and water were modified until good agreement was

observed. Once good agreement was obtained, simulated in-saturation profiles at the end

of the waterflood were checked against the in-situ saturation profiles which developed in

the laboratory.

SECONDARY WATERFLOOD CHARACTERISTICS

Many reservoir condition secondary recovery injections of low salinity brine, performed in

BPs laboratories, have now been completed. All reservoir condition waterfloods, when a

comparison has been able to be made, have shown incremental recovery, both in dry oil

and reduction in remaining oil saturation, after waterflood. An example of oil production

vs. throughput for a high salinity and low salinity secondary displacements, are given in

Figure 4 for a 200,000 ppm salinity reservoir system. These characteristics are similar to

those that are seen in any salinity, whether lower or higher.

Many waterfloods have been performed comparing high and low salinity injection waters.

Swi values ranged from 0.05 to >0.25 (Figure 5); A range of wettabilities are therefore

likely to have been investigated (although these were not measured explicitly). All have

shown similar characteristics. When compared with the high salinity curves, the low

salinity curves can be seen to have similar mobilities, but are shifted in saturation,

generally by the change in saturation observed for the low salinity benefit. This indicates

that dry oil production is increased (the first point reported in unsteady state waterfloods is

the shock front saturation). This shift in the dry oil production appears to be similar to the

reduction in residual oil saturation between the high and low salinity waterfloods. The low

SCA2008-39 6/12

salinity benefit is therefore seen as a shift in fractional flow behaviour, manifest by a shift

in relative permeability behaviour.

Incremental dry oil recovery shows the mechanism to be kinetically quick (consistent with

the double layer/multiple ion exchange theory [Lager et al, 2006], and importantly from a

reservoir perspective, increasing the amount of oil produced during the phase of production

plateau. Ranges in incremental oil were measured from 5% to 40% based on high salinity

recoveries (Table 1).

One of the concerns with low salinity waterflooding is one of detrimental rock/fluid

interactions, causing reduction in permeability and therefore reducing injectivity into a

reservoir. In all cases, the end point relative permeability to water appears to be similar

after high and low salinity (Figure 5). Also the shape of the water relative permeability

(increasing) curve indicates that there is no material damage to the sample due to fines

migration or clay swelling for these samples.

TERTIARY WATERFLOOD CHARACTERISTICS

The majority of the reservoir condition waterfloods performed by BPs laboratory,

comparing high and low salinity in secondary injection, have also been compared after

tertiary ( low salinity brine has been injected after multiple pore volumes of high salinity

brine). Example oil production profiles are given in Figure 10 and Figure 11 and show that

the increased production does not appear to be dependent on salinity of the resident phase

prior to low salinity injection. Once again low salinity injection was seen to improve oil

recovery in all cases where the comparison was made.

For most EOR processes to be economical in the field, it is essential that oil is produced

quickly. The characteristics of these reservoir condition corefloods, performed by BP, are

very different to some of the previously reported tests performed at reduced conditions by

non BP laboratories.

During tertiary core flood tests, differential pressure during the high salinity and low

salinity injections were continuously monitored. Summary end point relative permeability

data for example data sets are given in Table 2. These data represent data sets that are near

the extremes of initial water saturations seen. The permeability after low salinity is similar

to that measured after high salinity injection. It should be pointed out that although only

three corefloods are reported here, similar characteristics have been seen in all reservoir

condition corefloods performed by BP, where tertiary low salinity benefits have been

measured. This indicates, at least for the reservoir systems tested, that no adverse

rock/fluid interaction is observed with the low salinity brine. Also several systems had

high salinity injected after the low salinity injection. Again the effective permeabilities

were similar to the low salinity values.

SCA2008-39 7/12

CONCLUSION

1. Reservoir condition waterfloods have proven that low salinity waterfloods improve

waterflood characteristics previously seen in reduced condition experiments-

Incremental benefits range from ~5-40% over a wide range of reservoir systems

(rock, fluid, saturation, temperature and pressure).

2. The additional low salinity recovery is produced as dry oil for secondary floods and

results in a reduction in residual oil saturation.

3. Generally end point water relative permeability data do not vary significantly

between high and low salinity waterfloods, in secondary or tertiary modes.

4. Tertiary waterflood characteristics observed at reservoir conditions are materially

different to those measured at reduced conditions.

ACKNOWLEDGEMENTS

The authors wish to thank BP for permission to publish this paper

REFERENCES

1. Carr, A.H. and Christie, M.A.: "Controlling Numerical Diffusion in Reservoir

Simulation using Flux Corrected Transport", SPE 2235 (1983)

2. J adhunandan, P. and Morrow, N.R.: Effect of Wettability on Waterflood

Recovery for Crude Oil/Brine/Rock Systems, SPE RE (1995) 10, 40-46.

3. J erauld, G R, Lin C Y, Webb K J , Seccombe J C, Modeling Low-Salinity

Waterflooding SPE 102239, presented at the SPEATC San Antonio 2006.

4. J ohnson, E.F., Bossler, D.P. and Naumann, V.O.: "Calculation of Relative

Permeability from Displacement Experiments", Trans. AIME (1959) 216, 370.

5. Lager, A., Webb, K.J ., Black, C.J .J ., Singleton, M., Sorbie, K.S. Low Salinity Oil

Recovery- An Experimental Investigation. International symposium of the society

of core analysts. 2006. Trondheim.

6. Lager, A., Webb, K.J ., Collins, I.R. and Richmond, D.M., " LoSal Enhanced

Oil Recovery: Evidence of Enhanced Oil Recovery at the Reservoir Scale", SPE

113976 presented at the SPE/DOE Symposium on Improved Oil Recovery, 20-23

April 2008, Tulsa, Oklahoma, USA

7. Mcguire, P., Chatham, J .R., Paskvan, F.K., Sommer. D.M., Carini, F.H. Low

salinity oil recovery: an exciting opportunity for Alaska's North Slope. SPE 93903

2005.

8. Nicholls, C.I. and Heaviside, J .: "Gamma Ray Absorption Techniques Improve

Analysis of Core Displacement Tests", SPE 14421 (1985).

9. Seccombe, J .C., Lager, A., Webb, K. J ., J erauld, G., and Fueg, E., "Improving

Wateflood Recovery: LoSal EOR Field Evaluation", SPE 113480 presented at

the SPE/DOE Symposium on Improved Oil Recovery, 20-23 April 2008, Tulsa,

Oklahoma, USA

10. Tang, G.-Q. and N.R. Morrow, Influence of brine composition and fines migration

on crude oil brine rock interactions and oil recovery Journal of petroleum science

& engineering, 1999. 24: p. 99-111.

SCA2008-39 8/12

11. Webb, K.J ., C.J .J . Black, and H. Al-J eel, Low salinity oil recovery - log inject

log SPE 89379 2004.

12. Webb, K.J ., C.J .J . Black, and I.J . Edmonds. Low salinity oil recovery - the role of

reservoir condition corefloods. Presented at the EAGE conference Budapest,

Hungary 2005.

13. Yildiz, H.O. and N.R. Morrow, Effect of brine composition on recovery

waterflooding of Moutray crude oil. Petroleum science & engineering, 1996. 14:

p. 159-168.

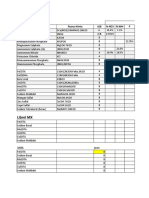

Table 1: Summary of Coreflood Results

Table 2: Examples of Summary Relative Permeability after high and low salinity

Reservoir

Keo @

Swi Swi

Sor

high Sal

krw

high Sal

Sor low

Sal

krw low

Sal

A 1140 0.05 0.351 0.14 0.3 0.153

B 650 0.145 0.289 0.23 0.214 0.32

C 325 0.212 0.21 0.128 0.15 0.19

Field Sor High Sor Low % WF

Meas

A 0.33 0.25 16

B 0.32 0.24 14

B 0.21 0.13 11

C 0.23 0.19 8

C 0.23 0.19 8

D 0.25 0.13 21

E 0.33 0.12 39

F 0.2 0.1 20

G 0.26 0.23 7

G 0.18 0.13

9

G 0.19 0.12

11

G 0.23 0.2 5

A 9

A 8

B 0.28 0.2 13

B 0.28 0.15 22

C 0.27 0.23 7

C 0.2 11

A 0.125 0.077 6

A 0.33 0.3 5

A 0.2 0.1 13

A 0.2 0.18 ~5

B 0.27 0.2 10

B 0.27 0.22 8

A 0.47 0.43 8

C 0.31 0.26 8

C 0.31 0.28 4

A 0.26 0.18 12

A 0.26 0.22 7

SCA2008-39 9/12

Figure 1: Global reach of LoSal

TM

EOR Technology Relative Permeability Evaluations

Figure 2: Typical Reservoir Condition

Figure 3: Schematic of In-situ Saturation Monitoring Equipment

0

10

20

30

40

50

60

70

1st Qtr 2nd Qtr 3rd Qtr 4th Qtr

East

West

North

Coreholder Collimator Minature

NaI

Detector

Gamma

Ray Source

Lead

Collimator

Cross-Section of GASM Apparatus

0

20

40

60

80

100

1st

Qtr

2nd

Qtr

3rd

Qtr

4th

Qtr

East

West

North

Inlet

Outlet

dP

NaI

Detectors

Gamma Source

dP

PLUG

In-Situ Saturation Monitoring Schematic

0

10

20

30

40

50

60

70

1st Qtr 2nd Qtr 3rd Qtr 4th Qtr

East

West

North

Coreholder Collimator Minature

NaI

Detector

Gamma

Ray Source

Lead

Collimator

Cross-Section of GASM Apparatus

0

20

40

60

80

100

1st

Qtr

2nd

Qtr

3rd

Qtr

4th

Qtr

East

West

North

Inlet

Outlet

dP

NaI

Detectors

Gamma Source

dP

PLUG

In-Situ Saturation Monitoring Schematic

SCA2008-39 10/12

Figure 4: Secondary Production Profiles

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir A

0.0001

0.001

0.01

0.1

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir A

Figure 5: Water/Oil Relative Permeability Swi<0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir B

0.00001

0.0001

0.001

0.01

0.1

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir B

Figure 6: Water/Oil Relative Permeability Swi 0.1-0.17

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 2 4 6 8 10 12

Water Throughput (Pore Volumes)

O

i

l

P

r

o

d

u

c

t

i

o

n

(

T

o

t

a

l

P

o

r

e

V

o

l

u

m

e

)

200,000 ppm High Salinity Brine

2,000 ppm Low Salinity Brine

SCA2008-39 11/12

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

wHigh Salinity

LowSalinity

Reservoir C

Reservoir D

Reservoir E

0.0001

0.001

0.01

0.1

1

0 0.2 0.4 0.6 0.8 1

Sw

k

r

o

,

k

r

wHigh Salinity

LowSalinity

Reservoir C

Reservoir D

Reservoir E

Figure 7: Water/Oil Relative Permeability Swi 0.18-0.2

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir F

Reservoir G

Reservoir H

0.0001

0.001

0.01

0.1

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir F

Reservoir G

Reservoir H

Figure 8: Water/Oil Relative Permeability Swi 0.2-0.25

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir I

Reservoir J

0.0001

0.001

0.01

0.1

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sw

k

r

o

,

k

r

w

High Salinity

LowSalinity

Reservoir I

Reservoir J

Figure 9: Water/Oil Relative Permeability Swi >0.25

SCA2008-39 12/12

Figure 10: Tertiary Production from High and low Salinity Connate Brines

Figure 11: Tertiary Production from High and low Salinity Connate Brines

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 2 4 6 8 10 12 14 16 18 20

Water Throughput (Pore Volume)

O

i

l

P

r

o

d

u

c

t

i

o

n

(

T

o

t

a

l

P

o

r

e

V

o

l

u

m

e

)

200,000 ppmHigh Salinity 2,000 ppmLow Salinity Brine

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 5 10 15 20 25 30

Water Throughput (Pore Volumes)

O

i

l

P

r

o

d

u

c

t

i

o

n

(

T

o

t

a

l

P

o

r

e

V

o

l

u

m

e

High Salinity Low Salinity

0.535 PV

0.61 PV

15000 ppm 1500 ppm

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 5 10 15 20 25 30

Water Throughput (Pore Volumes)

O

i

l

P

r

o

d

u

c

t

i

o

n

(

T

o

t

a

l

P

o

r

e

V

o

l

u

m

e

High Salinity Low Salinity

0.535 PV

0.61 PV

15000 ppm 1500 ppm

You might also like

- Masters in Sustainable System 2016Document26 pagesMasters in Sustainable System 2016tsanshineNo ratings yet

- Revised Paper Based Test PDFDocument2 pagesRevised Paper Based Test PDFtsanshineNo ratings yet

- LSW With PolymerDocument24 pagesLSW With PolymertsanshineNo ratings yet

- Lecture - 8 Lab Measurement of Crude Oil PropertiesDocument9 pagesLecture - 8 Lab Measurement of Crude Oil PropertiestsanshineNo ratings yet

- Modern French Grammar A Practical Guide PDFDocument387 pagesModern French Grammar A Practical Guide PDFtsanshineNo ratings yet

- TutorialDocument208 pagesTutorialJohnnyNo ratings yet

- Petrel Basic Training For FDPDocument46 pagesPetrel Basic Training For FDPtsanshine100% (7)

- Fundamentals of Formation Testing - SchlumbergerDocument270 pagesFundamentals of Formation Testing - Schlumbergertsanshine100% (3)

- Eclipse Manual 2012.1Document1 pageEclipse Manual 2012.1tsanshineNo ratings yet

- Petex GAP Product-Info Sep2015Document4 pagesPetex GAP Product-Info Sep2015tsanshineNo ratings yet

- New Insights Into The Removal of Calcium SulfateDocument10 pagesNew Insights Into The Removal of Calcium SulfatetsanshineNo ratings yet

- FDP UtpDocument549 pagesFDP Utptsanshine86% (7)

- Ichthys Gas Field Development Project, Blaydin Point: Assessment Report 65Document126 pagesIchthys Gas Field Development Project, Blaydin Point: Assessment Report 65tsanshine100% (1)

- Annual ReportDocument192 pagesAnnual ReporttsanshineNo ratings yet

- Details of ProjectDocument3 pagesDetails of ProjecttsanshineNo ratings yet

- Dua - Grief & SorrowDocument5 pagesDua - Grief & SorrowtsanshineNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Coordination ChemistryDocument43 pagesCoordination ChemistryvictorNo ratings yet

- Science Checkpoint Revision Y8Document16 pagesScience Checkpoint Revision Y8Mark ZuckerburgNo ratings yet

- Nu-Calgon Product Bulletin: Bio-Fresh CDDocument2 pagesNu-Calgon Product Bulletin: Bio-Fresh CDAudi eko susatyoNo ratings yet

- 715 1Document155 pages715 1Aniculaesi MirceaNo ratings yet

- Pocket Handbook For VI & Weld DiscontinuitiesDocument17 pagesPocket Handbook For VI & Weld Discontinuitiesixotee100% (2)

- Construction Fibre Concreate Fibre Recron 3sDocument7 pagesConstruction Fibre Concreate Fibre Recron 3sAbhishek JoshiNo ratings yet

- Great DesignomicsDocument95 pagesGreat DesignomicsChristopher Allen VarsoviaNo ratings yet

- United States Patent (10) Patent No.: US 7,806,945 B2: The To In... TDocument21 pagesUnited States Patent (10) Patent No.: US 7,806,945 B2: The To In... TesiNo ratings yet

- Inner Earth May Hold More Water Than The SeasDocument2 pagesInner Earth May Hold More Water Than The SeasManuel TPNo ratings yet

- Asme A13 - 1Document13 pagesAsme A13 - 1Jaroslaw KoniecznyNo ratings yet

- Vitra WCDocument160 pagesVitra WCcothacoNo ratings yet

- Chem Lab 1 Itlog AssignmentDocument2 pagesChem Lab 1 Itlog Assignmentfamigo451No ratings yet

- 4013 Stability TestingDocument5 pages4013 Stability TestingtghonsNo ratings yet

- Applications Assignment 2Document7 pagesApplications Assignment 2Chrystal BrownNo ratings yet

- 4200 459 D62 18139 Code 4 Rev 7Document4 pages4200 459 D62 18139 Code 4 Rev 7rcpuram01No ratings yet

- Product Data Sheet Metco 9MBM / 9MBH Plasma Spray GunDocument4 pagesProduct Data Sheet Metco 9MBM / 9MBH Plasma Spray GunMuhammad ZulfaqarNo ratings yet

- Excel Meracik Nutrisi Bandung 11 Feb 2018Document30 pagesExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNo ratings yet

- A2H Actuator CatalogDocument6 pagesA2H Actuator CatalogahnafNo ratings yet

- Enzymes NPDocument25 pagesEnzymes NPBharatShethNo ratings yet

- Profil Farmakikinetik Pantoprazole InjeksiDocument17 pagesProfil Farmakikinetik Pantoprazole InjeksitikaNo ratings yet

- Additives in Australian FoodsDocument11 pagesAdditives in Australian FoodsSarah AnnesleyNo ratings yet

- B1e 004 PDFDocument40 pagesB1e 004 PDFNguyễn Xuân ĐiệpNo ratings yet

- Grundfosliterature-836 - (PG 10,24-25)Document226 pagesGrundfosliterature-836 - (PG 10,24-25)anggun100% (1)

- Inspeccion Visual de Treminales Crimpeado PDFDocument2 pagesInspeccion Visual de Treminales Crimpeado PDFCarlos ChirinosNo ratings yet

- Project Work Chem1Document15 pagesProject Work Chem1UMESH BIKRAM SHAHNo ratings yet

- 2 Manuale D Uso GB 03 12 CE C-0104Document33 pages2 Manuale D Uso GB 03 12 CE C-0104vtechelectricNo ratings yet

- Heterogeneous Azeotropic Distillation Column DesignDocument67 pagesHeterogeneous Azeotropic Distillation Column Designvenkatesh801100% (1)

- LDH SLDocument4 pagesLDH SLLUIS DANIEL VAZQUEZ RAMIREZNo ratings yet

- Eco Hopper GBDocument8 pagesEco Hopper GBArmand SpiderHerpNo ratings yet

- Swing Arm Calculation and Analysis JournalDocument5 pagesSwing Arm Calculation and Analysis JournalBálají SèlvakümárNo ratings yet