Professional Documents

Culture Documents

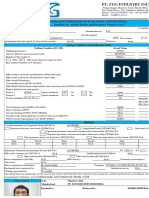

161 Gmaw Zug Asme (Beni Kantona 3g) WPQ

Uploaded by

Muhammad Fitransyah Syamsuar PutraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

161 Gmaw Zug Asme (Beni Kantona 3g) WPQ

Uploaded by

Muhammad Fitransyah Syamsuar PutraCopyright:

Available Formats

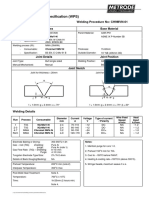

IC.

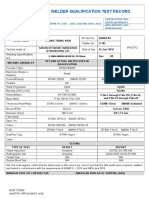

161/GMAW/ZUG/ASME

Welder's Name

Identification of WPS followed Test coupon Production weld

Specification and type/grade or UNS of base metal(s) Thickness

Welding process(es)

Type (ie. Manual, semi-automatic) used

Backing (with/ without)

Plate Pipe (enter diameter if pipe or tube)

Base metal P- Number to P- Number

Filler metal or electrode specification(s) (SFA) (info only)

Filler metal or electrode classification(s) (info only)

Filler metal F-Number(s)

Consumable insert (GTAW or PAW)

Filler Metal Product Form (solid/metal or flux cored/powder) (GTAW or PAW)

Deposit thickness for each process

Process 1 : GMAW 3 layers minimum Yes No

Process 2 : 3 layers minimum Yes No

Position qualified (2G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode (spray/globular or pulse to shot circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN)

Visual Examination of Completed Weld (QW-302.4)

Transverse face and root bends [QW462.3(a)] Longitudinal bends [QW-462.3(b)] Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)

Pipe specimen, macro test for fusion [QW-462.5(b)] Plate specimen, macro test for fusion [QW-462.5(e)]

Type

N/A

Alternative Volumetric Examination Result (QW-191) RT or UT (check one)

Fillet weld - fracture test (QW-181.2)

Fillet weld in plate [QW-462.4(b)] Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184) Fillet size(in.) Concavity/convexity(in.)

Other tests N/A

Film or specimens evaluated by Mr. Abdul Djalal Company PT ZUG I.I (159 WQT/V/ZII/QC-RT/2013)

Mechanical tests conducted by N/A

Welding supervised by Mr. Andika

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of ASME BOILER AND PRESSURE VESSEL CODE.

Date : May 28, 2013

Manufacturer : PT. ZUG INDUSTRY INDONESIA

Prepared by, Reviewed by,

Test Description

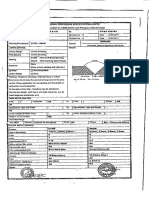

WELDING PERFORMANCE QUALIFICATIONS (WPQ)

(Section IX, ASME Boiler and Pressure Vessel Code)

Mr. Beni Kantona Identification no. Z 74

018/WPS/GMAW R.0

A 36 12 mm

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

SFA 5.18 None

GMAW GMAW

MANUAL MANUAL

Without With or Without

Plate Min 2 in. (73 mm) O.D.

P. No.1 to P. No.1 P-No. 1 through P-No.15F, P-No.34,

and P-No.41 through P-No. 49

ER 70S-6 None

F 6 All F6

N.A N.A

N.A N.A

12 mm max. 13.2 mm

None None

3G Plate & Pipe Over 24 in (610 mm) OD = F, V

Uphill Uphill

Pipe 24 in. (610 mm) OD = F

Fillet : Plate & Pipe = F, H, V

N.A N.A

None None

Short Circuting Short Circuting

N.A N.A

RESULTS

ACCEPTED

Result Type Result Type Result

N/A Length and percent of defects N/A

N/A N/A N/A

Laboratory test no. N/A

Photo Welder

Muh. Fitransyah. S.P

QA/QC Manager Welding Engineer

Wiyanto

N/A N/A N/A N/A N/A

ACCEPTED

PT. ZUG INDUSTRY INDONESIA

Pergudangan Miami Jl. Rawa Melati Blok A. No.5

Kel. Tegal Alur - Kec. Kalideres Jakarta. Barat 11820

Phone : (62) 21-55952077 Fax : (62) 21-55951873

Email : zug@cbn.net.id

Photo Welder

Production weld

Test Description

WELDING PERFORMANCE QUALIFICATIONS (WPQ)

(Section IX, ASME Boiler and Pressure Vessel Code)

Z 74

12 mm

Testing Conditions and Qualification Limits

Range Qualified

None

GMAW

MANUAL

With or Without

Min 2 in. (73 mm) O.D.

P-No. 1 through P-No.15F, P-No.34,

and P-No.41 through P-No. 49

None

All F6

N.A

N.A

max. 13.2 mm

None

Plate & Pipe Over 24 in (610 mm) OD = F, V

Uphill

Pipe 24 in. (610 mm) OD = F

Fillet : Plate & Pipe = F, H, V

N.A

None

Short Circuting

N.A

RESULTS

Result

N/A

N/A

N/A

N/A

PT. ZUG INDUSTRY INDONESIA

You might also like

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- Welder Qualification Test Certificate for Mohan ReddyDocument2 pagesWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- Conceptual Cost Estimating Manual - John S. PageDocument350 pagesConceptual Cost Estimating Manual - John S. PageiponputraNo ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WELDER QUAL TEST REPORTDocument1 pageWELDER QUAL TEST REPORTtantri.hellyanti100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Lifting Lug Calculation G1-5Document3 pagesLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- PQR-AFPL-GTAWDocument7 pagesPQR-AFPL-GTAWBala SingamNo ratings yet

- Pwps Asme Gtaw & SmawDocument2 pagesPwps Asme Gtaw & SmawMuhammad Fitransyah Syamsuar Putra100% (1)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- DS58 - (1975) Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of 3 To 9 Percent Chromium-Molybdenum Steels PDFDocument222 pagesDS58 - (1975) Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of 3 To 9 Percent Chromium-Molybdenum Steels PDFJacques StrappeNo ratings yet

- WPS PQR-03Document12 pagesWPS PQR-03Ranjan KumarNo ratings yet

- PT. VISTA BANGUN UTAMA Welder QualificationDocument1 pagePT. VISTA BANGUN UTAMA Welder QualificationHaryanto RNo ratings yet

- BS en 10016-3-1995 (1999)Document10 pagesBS en 10016-3-1995 (1999)Martijn GrootNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- Jis StandardDocument40 pagesJis Standardkeerthivasan_mrv0% (1)

- All Private Mining IndustriesDocument18 pagesAll Private Mining IndustriespathodiaNo ratings yet

- Saudi Kayan Olefins Project Welding Procedure Qualification RecordDocument13 pagesSaudi Kayan Olefins Project Welding Procedure Qualification RecordMuhammedShafeeq50% (2)

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- 327101-C-BOD-0001, Rev.01 PDFDocument54 pages327101-C-BOD-0001, Rev.01 PDFGokulprabhuNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Stamp Charging TechnologyDocument6 pagesStamp Charging Technologypramod_try100% (1)

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- PT. ZUG INDUSTRY WELDING QUALIFICATIONDocument4 pagesPT. ZUG INDUSTRY WELDING QUALIFICATIONMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- BS en 10085-2001Document30 pagesBS en 10085-2001Martijn GrootNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- PT Montis Energy Welding Procedure SpecificationDocument4 pagesPT Montis Energy Welding Procedure SpecificationMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Qualified Welder List Valid Until - 03-12-2019Document2 pagesQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- PolymerDocument30 pagesPolymerBarang TeknikNo ratings yet

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Mechanical Test 1Document21 pagesMechanical Test 1Manoranjan sharmaNo ratings yet

- Welder qualification test recordDocument3 pagesWelder qualification test recordTuTuy AnNo ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- PT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTDocument4 pagesPT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Welder Operators Qualification TestDocument2 pagesWelder Operators Qualification Testlokifarad100% (1)

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- RFI-3458 - Daily Fit Up Inspection Report-OKDocument24 pagesRFI-3458 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportmohd as shahiddin jafriNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- Program K3 2023Document2 pagesProgram K3 2023Muhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Employee Hours Worked Last Three YearsDocument1 pageEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Tanda TerimaDocument2 pagesTanda TerimaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Laporan PiketDocument12 pagesLaporan PiketMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Hydrostatic Water Filling Test ProcedureDocument1 pageHydrostatic Water Filling Test ProcedureMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Program K3 2023Document2 pagesProgram K3 2023Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Vii CertificateDocument1 pageVii CertificateMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Transmittal FormDocument90 pagesTransmittal FormMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Fit-Up Inspection ReportDocument1 pageFit-Up Inspection ReportMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- III EngineeringDocument1 pageIII EngineeringMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Manufacturing Data Record IndexDocument2 pagesManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT BridonDocument1 pagePT BridonMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT BridonDocument1 pagePT BridonMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Transmittal FormDocument90 pagesTransmittal FormMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Design Intermittent WeldingDocument5 pagesDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Method Statement For Prediction Weld Shrinkage On StructuralDocument4 pagesMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT PrysmianDocument1 pagePT PrysmianMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PT DjabesmenDocument1 pagePT DjabesmenMuhammad Fitransyah Syamsuar PutraNo ratings yet

- CSDCDocument2 pagesCSDCMuhammad Fitransyah Syamsuar PutraNo ratings yet

- JSL Indian Railways Specific GradesDocument43 pagesJSL Indian Railways Specific GradesNagarajan GNo ratings yet

- B. Tech.: Printed Pages: 3Document3 pagesB. Tech.: Printed Pages: 3arugeetNo ratings yet

- Common EtchantsDocument3 pagesCommon EtchantsValeria Reyes VilchezNo ratings yet

- HTTP WWW Pressbolt Com Astm A193 b7, b7m, b8, b8m, b16, A320 l7, l7m, l43 Studbolts HTMLDocument2 pagesHTTP WWW Pressbolt Com Astm A193 b7, b7m, b8, b8m, b16, A320 l7, l7m, l43 Studbolts HTMLMashudi FikriNo ratings yet

- Hilti - RE500 V3 and HAS U - EngDocument14 pagesHilti - RE500 V3 and HAS U - EngDawn NguyenNo ratings yet

- Welding and Reinforcement PDFDocument9 pagesWelding and Reinforcement PDFScottBuchholzNo ratings yet

- 011 Besi BajaDocument34 pages011 Besi BajaMFA nounNo ratings yet

- Caster Technology Consulting enDocument8 pagesCaster Technology Consulting enOmar TahaNo ratings yet

- Electrical Construction ProcedureDocument12 pagesElectrical Construction ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- WeldedBridgeCode ACS 2 15Document1 pageWeldedBridgeCode ACS 2 15MAYMODERN STEELNo ratings yet

- Bamboo Reinforced Concrete Septic Tank DesignDocument19 pagesBamboo Reinforced Concrete Septic Tank DesignVaibhav DawkareNo ratings yet

- Abrasives: 钢铁行业 Steel Industry 磨轧辊砂轮 Roller grinding wheelDocument7 pagesAbrasives: 钢铁行业 Steel Industry 磨轧辊砂轮 Roller grinding wheeldingjiahaoNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- Mms Unit IIIDocument3 pagesMms Unit IIIAdula RajasekharNo ratings yet

- Steel Alloy Testing Pro No. 1599 GuideDocument14 pagesSteel Alloy Testing Pro No. 1599 GuideOm PrakashNo ratings yet

- Leading in Loading Technology with Minimal CAPEX & OPEXDocument50 pagesLeading in Loading Technology with Minimal CAPEX & OPEXPeter StanleyNo ratings yet

- Fe Si MGDocument34 pagesFe Si MGamitkkambleNo ratings yet

- Turcont Catalogue EnglishDocument23 pagesTurcont Catalogue EnglishHusain EbrahimNo ratings yet

- Pneumatic Actuators Parts & MaterialsDocument4 pagesPneumatic Actuators Parts & MaterialscvfNo ratings yet