Professional Documents

Culture Documents

MaterialUniverse Hybrids Composites, Foams, Honeycombs, Natural Materials Composites Polymer Epoxy Matrix Carbon Fiber

Uploaded by

Pedro Martins0 ratings0% found this document useful (0 votes)

43 views3 pagesMaterialUniverse

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMaterialUniverse

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views3 pagesMaterialUniverse Hybrids Composites, Foams, Honeycombs, Natural Materials Composites Polymer Epoxy Matrix Carbon Fiber

Uploaded by

Pedro MartinsMaterialUniverse

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Page 1 of 3

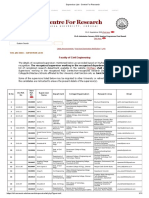

Epoxy SMC (carbon fiber)

Values marked * are estimates.

No warranty is given for the accuracy of this data

Identification

Designation

Epoxy (Carbon Fiber, SMC)

Tradenames

Carboform; Ferropreg EP; Fiberdux; Fiberite; Scotchply

General Properties

Density 1.4e3 - 1.7e3 kg/m^3

Price * 18.6 - 20.5 EUR/kg

Composition overview

Composition (summary)

Epoxy + C filler

Base Polymer

Polymer class Thermoset plastic

Polymer type EP

Polymer type full name Epoxy resin

% filler (by weight) * 15 - 50 %

Filler type Carbon fiber

Composition detail (polymers and natural materials)

Polymer * 50 - 85 %

Carbon (fiber) * 15 - 50 %

Mechanical properties

Young's modulus 69 - 150 GPa

Compressive modulus * 69 - 150 GPa

Flexural modulus 33.5 - 35.2 GPa

Shear modulus * 27.8 - 60.5 GPa

Bulk modulus * 63.4 - 66.6 GPa

Poisson's ratio 0.219 - 0.266

Shape factor 22

Yield strength (elastic limit) * 221 - 276 MPa

Tensile strength 276 - 345 MPa

Compressive strength 207 - 276 MPa

Flexural strength (modulus of rupture) 517 - 655 MPa

Elongation 0.5 - 2 % strain

Hardness - Vickers * 66.2 - 82.8 HV

Hardness - Rockwell R * 130 - 135

Fatigue strength at 10^7 cycles * 109 - 142 MPa

Fracture toughness * 25.8 - 38.3 MPa.m^0.5

Mechanical loss coefficient (tan delta) * 0.0012 - 0.00206

Impact properties

Impact strength, notched 23 C * 79 - 110 kJ/m^2

Thermal properties

Glass temperature * 67 - 167 C

Heat deflection temperature 0.45MPa * 286 - 343 C

Heat deflection temperature 1.8MPa 261 - 316 C

Maximum service temperature 166 - 184 C

Minimum service temperature * -123 - -73 C

Thermal conductivity 5.8 - 6.3 W/m.C

Specific heat capacity * 1.29e3 - 1.34e3 J/kg.C

Thermal expansion coefficient 5.29 - 5.51 strain/C

Page 2 of 3

Epoxy SMC (carbon fiber)

Values marked * are estimates.

No warranty is given for the accuracy of this data

Processing properties

Linear mold shrinkage 0.091 - 0.11 %

Molding pressure range 3.44 - 13.8 MPa

Electrical properties

Electrical resistivity * 100 - 1e6 ohm.cm

Galvanic potential 0.14 - 0.22 V

Optical properties

Transparency Opaque

Absorption, permeability

Water absorption @ 24 hrs 1.45 - 1.76 %

Durability: flammability

Flammability Self-extinguishing

Durability: fluids and sunlight

Water (fresh) Excellent

Water (salt) Excellent

Weak acids Acceptable

Strong acids Unacceptable

Weak alkalis Limited use

Strong alkalis Excellent

Organic solvents Limited use

UV radiation (sunlight) Good

Oxidation at 500C Unacceptable

Primary material production: energy, CO2 and water

Embodied energy, primary production * 358 - 396 MJ/kg

CO2 footprint, primary production * 23.5 - 26 kg/kg

Water usage * 660 - 730 l/kg

Material processing: energy

Compression molding energy * 3.33 - 3.68 MJ/kg

Material processing: CO2 footprint

Compression molding CO2 * 0.266 - 0.294 kg/kg

Material recycling: energy, CO2 and recycle fraction

Recycle

Recycle fraction in current supply 0.1 %

Downcycle

Combust for energy recovery

Heat of combustion (net) * 30.2 - 31.8 MJ/kg

Combustion CO2 * 2.59 - 2.72 kg/kg

Landfill

Biodegrade

A renewable resource?

Notes

Typical uses

Lightweight structural members in aerospace, ground transport and sporting goods; springs; pressure vessels

Links

ProcessUniverse

Page 3 of 3

Epoxy SMC (carbon fiber)

Values marked * are estimates.

No warranty is given for the accuracy of this data

Producers

Reference

Shape

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Mariner 2 Press KitDocument37 pagesMariner 2 Press KitBob AndrepontNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- M.A Education New MCQs Sustainable DevelopmentDocument67 pagesM.A Education New MCQs Sustainable DevelopmentSaqlain Kaleem100% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Super: NormalDocument20 pagesSuper: NormalPedro Martins100% (1)

- Asnt RT L1, 2 & 3Document80 pagesAsnt RT L1, 2 & 3jasminnee92% (12)

- Techno-Economic Modelling and Cost Functions of CO Capture ProcessesDocument11 pagesTechno-Economic Modelling and Cost Functions of CO Capture ProcessesAlex MarkNo ratings yet

- TUTORIAL 5 - Modeling Radiation and Natural Convection - 12 Juni 2014Document50 pagesTUTORIAL 5 - Modeling Radiation and Natural Convection - 12 Juni 2014Nadia HandayaniNo ratings yet

- Augmenting Kitchen Appliances With A Shared Context Using Knowledge About Daily EventsDocument3 pagesAugmenting Kitchen Appliances With A Shared Context Using Knowledge About Daily EventsPedro MartinsNo ratings yet

- Chamaecyparis Lawsoniana PesquisaDocument1 pageChamaecyparis Lawsoniana PesquisaPedro MartinsNo ratings yet

- Excel TabelaDocument1 pageExcel TabelaPedro MartinsNo ratings yet

- Uji MarshallDocument10 pagesUji MarshallNovo EkaNo ratings yet

- Thermodynamics Tutorial MaesoDocument58 pagesThermodynamics Tutorial MaesoCalvin LabialNo ratings yet

- Intro To BiomesDocument5 pagesIntro To Biomesapi-235669157No ratings yet

- Factors Causing Slope FailuresDocument2 pagesFactors Causing Slope FailuresAqir SyamilNo ratings yet

- Course OutlineDocument3 pagesCourse OutlinehekiNo ratings yet

- Lightning and Surge Protection For Rooftop Photovoltaic Systems - EE PublishersDocument14 pagesLightning and Surge Protection For Rooftop Photovoltaic Systems - EE Publishersabin k rajuNo ratings yet

- Revision (UNIT 4 & 5)Document10 pagesRevision (UNIT 4 & 5)WKQNo ratings yet

- Structural and Thermal Analysis of Magnesium Based Brake Friction MaterialDocument13 pagesStructural and Thermal Analysis of Magnesium Based Brake Friction MaterialIJRASETPublicationsNo ratings yet

- LSC 54Document4 pagesLSC 54pankaj tyagiNo ratings yet

- BriquetteDocument2 pagesBriquetteArbie SantosNo ratings yet

- Plastic Marine PollutionDocument3 pagesPlastic Marine PollutionDivine Grace CabungcagNo ratings yet

- Activity On Evidences of Plate MovementsDocument7 pagesActivity On Evidences of Plate Movementscally manaloNo ratings yet

- 1 1 AP Homework Answer Key-1Document3 pages1 1 AP Homework Answer Key-1Kaitlyn CabreraNo ratings yet

- RS10-PHYSICAL Air FilterDocument21 pagesRS10-PHYSICAL Air FilterRalph David AbellaNo ratings yet

- Climate Change - EssayDocument3 pagesClimate Change - Essaymimi yusofNo ratings yet

- Engineering Properties of Soil and Rock ChapterDocument38 pagesEngineering Properties of Soil and Rock ChapterjonaspdNo ratings yet

- Dielektrik, Ohmik Dan IrDocument4 pagesDielektrik, Ohmik Dan IrAswin PrasetiyoNo ratings yet

- Anna Univ CivilDocument11 pagesAnna Univ CivilKvaibala PNo ratings yet

- Physics Question BankDocument20 pagesPhysics Question BankJoshNo ratings yet

- Transition of Hindu Environmental EthicsDocument11 pagesTransition of Hindu Environmental Ethicskritika MahatoNo ratings yet

- Soil Density and Porosity NotesDocument5 pagesSoil Density and Porosity NotesThomas SmithNo ratings yet

- Room Acoustic Comfort™ ASM Architects LongDocument15 pagesRoom Acoustic Comfort™ ASM Architects LongCristiana FaurNo ratings yet

- Supercritical CO2 A Green SolventDocument4 pagesSupercritical CO2 A Green SolventLisbeth Roos RoosNo ratings yet

- 1 Soil ConservationDocument23 pages1 Soil ConservationShivangi SrivastavaNo ratings yet

- ASME Stress Tables Carbon Steel Max Allowable StressDocument167 pagesASME Stress Tables Carbon Steel Max Allowable StressVictorNo ratings yet