Professional Documents

Culture Documents

ENG7cranesgen Volvo Body Builder Cat Crane Mounting

Uploaded by

L.kolekarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENG7cranesgen Volvo Body Builder Cat Crane Mounting

Uploaded by

L.kolekarCopyright:

Available Formats

Body builder instructions

Volvo Truck Corporation

Gteborg, Sweden

Supersedes VBI Release 09 from 6.09.

Changes are marked with a bar (|) in the

margin.

Date

Group

Release

Page

2.10

95

10

1(13)

Crane and tail lifts

Cranes, general and design

FM, FH VERSION2

Contents

General, page 2

Stability, page 5

Installation, page 6

Helper frame, cab mounted crane, page 9

Helper frame design, rear mounted crane, page 11

Rear mounted crane, page 12

Crane mounted behind cab, page 12

Front mounted crane stabilizers, page 13

88963462

ENG40870

English

Printed in Sweden

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Cranes

General

Crane mounting on Volvo trucks should be verified by

calculating strength to the chassis frame.

Crane calculation programs for Rear mounted

crane and Back of cab mounted crane are available

through the Volvo body builder instruction site at

http://vbi.trucks.volvo.com. Click Calculation Tools in

the main menu and select a function.

Note: An FO number, chassis number or OM number is

required.

Further instructions are available when one of the above

numbers has been submitted (click on the question mark

(?).

CE marking

In addition to the procedures recommended in

body builder instruction, the EU Machinery Directive

89/392/EEC is also applicable. The complete vehicle

(crane and chassis) is considered to be one machine

in accordance with the directive. It should therefore

comply with these regulations and display the CE mark if

the vehicle is to used in an EU-directive member state.

Please refer to Body builder instructions CE marking

for details.

Assembly

A crane is normally mounted behind the cab or at the

rear end of the vehicles chassis. This section contains

installation instructions for both cab and rear mounted

cranes on the Volvo FM, FH and NH chassis. The

installation instructions cover cranes with a maximum

lifting capacity of up to 40 tm for cranes mounted behind

cab and a maximum lifting capacity of up to 25 tm for rear

mounted cranes. To install cranes with lifting capacity not

covered by these instructions, please contact the Volvo

importer.

A crane puts a large load on the chassis frame. The

frame often needs to be reinforced by a helper frame.

See also Front mounted crane stabilizers, page 13

T9007987

Page

2(13)

Volvo Truck Corporation

Body builder instructions

Crane stability test

The crane also affects the vehicles stability. The installer

of the crane is responsible for this, and must ensure that

the vehicle will not tip over when the crane is used for

lifting. The vehicle must be positioned on a flat surface.

Use the outrigger legs and make sure that they are placed

on firm ground. Block up the outrigger legs if necessary.

The Prohibit regulation function on the air suspension

should be activated, (only for airsuspended vehicles).

Tipping safety is achieved using the methods outlined in

Body builder instructions Tipper/Dumper installation.

Note: The installer of a crane or other lifting device is

responsible for the total stability of the vehicle under all

working conditions.

Date

2.10

Group

Release

95

10

Page

3(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Restrictions

Installing a crane directly onto the chassis frame is not

permitted. Wear plates must be used, unless strength

calculations reveal need for additional reinforcement

by helper frame.

A rear mounted crane on an air suspension vehicle

must have spring brakes on the front axle.

With back mounted crane, the lower flange must not

be cut to make clearance/taper end for under mounted

towing member or for any other purposes.

When installing a crane on an air suspended vehicle,

the added function Prohibit regulation and the

associated switch should be installed. Please refer to

Body builder instructions Vehicle electronics.

The following crane installations are not covered in this

section and therefore must not be carried out without

authorization from the Volvo importer.

Cranes with a maximum lifting capacity exceeding 40

tm for cranes mounted behind cab or exceeding 25 tm

for rear mounted cranes.

An axle load calculation must be made for large, cab

mounted cranes. This should guarantee that the legal

and technical requirements regarding the maximum

permitted front axle loading are complied with under all

working conditions.

T9006102

Page

4(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Page

5(13)

Stability

Note: The body builder installing the crane or other lifting

device is responsible for the total stability of the vehicle

under all working conditions.

Operational directions for a vehicle with air suspension during crane

operation

The trucks air suspension system is equipped with

a switch to control the "Prohibit regulation" function

(used to lock the air suspension when the support

legs are taking the load. Please refer to Body builder

instructions Vehicle electronics, VECU and BBM).

The truck must be secured by support legs if the front

axle is to be lifted off the ground when the crane is

operated.

The positioning of air suspension vehicles for the

deployment of outrigger legs should be as follows:

1 Switch from automatic to manual control level on the

electrical control box.

Do not switch back to automatic level control until the

crane operation has been completed.

2 Select the correct working height by manually adjusting

the air suspension with the control box.

3 Lower the support legs to the ground until they provide

stable support.

Deactivate the air suspended control by using the Prohibit

control function (please refer to Body builder instructions

Vehicle electronics).

CAUTION

Never disconnect the power when the crane is in

operation.

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Installation

General

The following points should be considered for all crane

installations.

A crane should always be installed on wear plates or

a helper frame.

The correct calculations should be made for both

unladen and fully laden axle vehicle.

Utilize the calculation programs, available in the Order

information section at http://vbi.trucks.volvo.com,

to calculate the correct helper frame strength: crane

imposed load or crane displacement.

Stability calculation.

Specify the PTO and oil system.

Stability test.

Wear plates

Wear plates are used to mount a crane when the chassis

frame does not need to be reinforced. Please refer to

Body builder instructions Attachments.

The plates should be of the same material as the

helper frames. Please refer to Body builder instructions

Attachments.

The plates should be made of L-profiles with a cross

section of 90 x 90 x 6 mm, and should be 160 mm longer

than the crane base (with 80 mm in front and 80 mm

behind the crane base).

Note: 6 mm is the minimum permitted thickness although

8 mm is recommended as most chassis components are

adapted to an 8 mm plate in the upper hole row.

T9007060

Attach the wear plates to the chassis frame using bolted

joints. The distance from the bottom edge to the top

flange and to the centre of the bolt holes in the side wall

of the plate, should be at least 60 mm.

Restriction

The crane must never be mounted directly to the chassis

frame.

T9006123

Page

6(13)

Volvo Truck Corporation

Body builder instructions

Helper frame

Cranes with a high lifting capacity require a helperframe.

The crane helperframe is used to reinforce a part of the

truck chassis frame only, or the whole chassis frame from

back of cab rearwards.

The helperframe should be attached to the chassis frame

so that no "bumping effect" between the helperframe and

chassis frame occurs whilst the crane is being operated

or driven. The helperframe and the attachments should

be designed to provide a stable platform for the crane but

should not interfere with the vehicles performance. This

is achieved by stiffening in the correct way.

In the case of special transports, with a minimized chassis

height or extremely heavy crane installation, the truck can

be specified with an extra long inner liner which is made

to special order. Please refer to Body builder instructions

Attachments.

When a rectangular profile is used, the helperframe

cross members must be made of similar profiles and

materials, i.e. of the same material as the lengthways

members of the helper frame.

If two pairs of outrigger legs are used it is important that

the chassis is torsionally rigid between them. This is

achieved by using square profiles, cross members, and/or

diagonal reinforcement braces in the helper frame. No

changes need to be made to the design of the helper

frame section, regardless of whether one or two pairs of

outrigger legs are used.

Fix the helper frame to the chassis frame with attachment

plates and driven bolt unions. Please refer to Body builder

instructions Attachments.

Attachment plates, hole spacing, welding and driven bolt

joints should be designed and implemented according to

Body builder instructions Attachments.

Date

2.10

Group

Release

95

10

Page

7(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

It is important that the chassis frame is not damaged or

deformed during installation.

The attachment plates should be positioned at a

relative distance of maximum 1000 mm apart.

There should also be an attachment plate at the

beginning and end of the helper frame.

Weld the attachment plates to the helper frame.

Alternatively the plates can be attached to the helper

frame with driven bolts. Please refer to Body builder

instructions Attachments.

Mount the attachment plates to the end-frame with

four driven bolts. Use M14 bolts or M16 bolts if the

pre-punched holes are used.

Driven M14 bolts should be drilled together to 13.7 mm

diameter and M16 to 15.8 mm diameter.

Driven bolt joints should be implemented. Please refer

to Body builder instructions Attachments.

T9006149

Mounting cranes using clamps is not recommended and

should be avoided if possible. If clamps are used, the

spacer element (A) must be placed between the flanges

in the chassis and helper frame.

T9006126

Page

8(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Helper frame, cab mounted crane

The helper frame should be positioned as far forward

as possible. For vehicles with short cabs a special

attachment plate is required at the front. Please refer to

Helper frame on vehicle with short cab L1EH1, page 10.

The helper frame should be attached with driven bolts.

Pleas refer to Body builder instructions Attachments.

If the helper frame is higher or lower than the sub-frame,

the top flange in the transition zone between them should

be at an inclination of 1:2. L is the reinforcement length

and can be found in both BOC crane calc (by activating

Required Wb) and the rear mounted crane calc.

T9008850

T9008849

Page

9(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Helper frame on vehicle with short cab L1EH1

Standard attachment plates cannot be used at the front

for cab mounted cranes on vehicles with short cab

L1EH1. A special 8 mm thick plate must be manufactured

instead. Please refer to the adjacent diagram.

Attach the plate via holes (A) and (B) on the chassis

frame.

Drill the holes if they are not already pre-punched.

Note: Under no circumstances must holes be drilled in

positions other than (A) and (B).

CAUTION

Do not damage the engine attachment.

In position (A), the engine attachment has pre-prepared

holes for M14 bolts.

Existing bolt joints on the engine attachment must not

be released or dismantled.

Co-drill holes in the attachment plate and chassis

frame for driven bolt joints.

Drill clearance holes (C) in the attachment plate for the

bolts to the engine attachment.

T9006314

Page

10(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Helper frame design, rear mounted crane

The helper frame should begin at least 3000 mm in front

of the first bogie axle.

On the rear section of the helper frame, the cross

members and end member should be of a similar design

to the chassis frame.

The helper frame should be reinforced by diagonal

bracing above the vehicle overhang, i.e. where the

crane is to be mounted. For a detailed description of

diagonal bracing, please refer to Body builder instruction

Customised overhang.

T9030156

To verify that the chassis frame will withstand forces and

moments caused by the crane mounted at the vehicles

rear overhang, utilise the rear mounted crane calculation

program, available in the Order information section at

http://vbi.trucks.volvo.com.

If, for the rear mounted crane installation, reinforcement

is required, an inner liner can be installed if the vehicle is

in order stage. Otherwise, the user can either select one

or more of the predefined reinforcement cross sections

the crane calculation program recommends, or define

another reinforcement in the Create section of the

calculation program.

T9030157

Basic technical data required to use the crane calculation

program is:

Total crane weight

Maximum dynamic crane moment

Required maximum crane lifting capacity

Distance between the crane support points

Chassis number or FO number

T9030249

For detailed requirements for running the Rear mounted

crane calculation program, please refer to the calculation

program help section.

T9008740

Page

11(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Rear mounted crane

A rear mounted crane is normally mounted on a bracket.

Weld the bracket to the helper frame, or use attachment

plates. The attachment plates are fitted to the chassis

frame with driven bolts. Driven bolt joints should be

implemented according to Body builder instructions

Attachments.

For this type of mounting, the Rear frame length

parameter in the Rear mounted crane calculation should

be prolonged by the distance the crane bracket extends

beyond the chassis frame.

T9006172

T9006308

Crane mounted behind cab

A crane behind the cab should be mounted so that the

maximum distance from the front reference hole to the

centre of the crane is 930 mm.

To verify that the chassis frame will withstand forces and

moments caused by the crane mounted at the vehicles

rear overhang, utilise the back of cab crane calculation

program, available in the Order information section at

http://vbi.trucks.volvo.com.

The calculation program can handle crane capacities up

to 40 tm. For larger back of cab crane mountings, please

contact the Volvo importer.

T9007988

Page

12(13)

Volvo Truck Corporation

Body builder instructions

Date

2.10

Group

Release

95

10

Front mounted crane stabilizers

If the intention is to mount crane front stabilizer(s) for

behind cab crane mounting, then the single crane front

stabilizer or the dual stabilizers together can be loaded

up to 13,5 ton as axial force. Although, a number of

demands should be taken into consideration to be able to

utilize this force capacity:

The applied crane moment used in the analysis must

be the maximum Mdyn1 (Crane Dynamic Moment).

The chassis frame must be at least FRAMEHIG,

FRAME88 with full inner liner underneath the crane

installation and to the chassis frame start end.

It is recommend that the vehicle is ordered with an

extended frame and inner liner as well as a front

mounted draw beam.

The front mounted draw beam must be used by the

body builder. If this is not possible, the new (locally

designed) front cross member, and its connection to

the chassis side frames, must be able to handle the

load from the crane stabilizer (single or double).

The cranes main supporting legs must be in contact

with the ground before using the front support legs.

The front support legs shall be mounted as close as

possible to the bumper and chassis side rails.

The input force must be pure axial force.

The helper frame should be mounted to the frame

rigidly.

It is not permitted to use the cranes main and front

support legs to lift the front axle completely off the

ground.

The helper frame start part should be tapered

according to the VBI.

The front stabilizer axial force must be static.

The crane installation must start directly behind the

cab, the helper frame starts a maximum of 50 mm

behind the cab.

Note: If Mdyn is not available, use the following

approximation:

The crane size in kN multiplied by 1,45 for a high

speed lifting system. For instance, Mdyn for crane

35 tm x 1,45 = 507 kNm. For a crane without a high

speed lifting system the factor is 1,3 instead of 1,45. For

instance Mdyn for crane 35 tm x 1,3 = 450 kNm.

1Mdyn

= (lifting moment + crane arm moment) x Fdyn (>1.40)

T9009336

Single and dual front crane stabilizers.

Page

13(13)

You might also like

- DAF Superstructures BodyBuilders - GuideDocument34 pagesDAF Superstructures BodyBuilders - GuideЮлия Дам100% (1)

- Podizna Osovina SAFDocument9 pagesPodizna Osovina SAFPavle StevanovicNo ratings yet

- MAN TGA Guidelines To Tting Bodies Manual - PDF Seroma Workshop 2020 PDFDocument167 pagesMAN TGA Guidelines To Tting Bodies Manual - PDF Seroma Workshop 2020 PDFTransport DepartmentNo ratings yet

- Spec 1 Vt2009bDocument5 pagesSpec 1 Vt2009bYasin Noer Huda PNo ratings yet

- MAN TGX26.440 6x2Document4 pagesMAN TGX26.440 6x2Abrar Hussain100% (1)

- Man Tga D2066 RadiatorDocument1 pageMan Tga D2066 RadiatorErsen ErdemNo ratings yet

- List of Spare Parts For BalerDocument6 pagesList of Spare Parts For Balerfariborz_136No ratings yet

- Contitech BeltCatalog2015Document476 pagesContitech BeltCatalog2015srinivas murthyNo ratings yet

- Terberg 2016.PDF - Pagespeed.ce - HeW2IPQc8cDocument98 pagesTerberg 2016.PDF - Pagespeed.ce - HeW2IPQc8cPaweł KorobajłoNo ratings yet

- DC 600 10588 To 11568Document28 pagesDC 600 10588 To 11568Jaime Arreola100% (1)

- 28m Truck-Mounted Pump ConcreteDocument2 pages28m Truck-Mounted Pump ConcreteDemçe Florjan100% (1)

- TGX 6x4 RigidDocument4 pagesTGX 6x4 RigidDorin PricopNo ratings yet

- Workshop Manual Mechanical Suspensions Series ECO Cargo W BW GW 35251401e - 01 PDFDocument40 pagesWorkshop Manual Mechanical Suspensions Series ECO Cargo W BW GW 35251401e - 01 PDFinformer techNo ratings yet

- BPW maintenance instructions for trailer axles and suspensionsDocument96 pagesBPW maintenance instructions for trailer axles and suspensionsIonut Valentin VladNo ratings yet

- Fitting WABCODocument88 pagesFitting WABCOTimon2005No ratings yet

- Superstructure Instructions Installation RigidDocument128 pagesSuperstructure Instructions Installation RigidЕвгений АксёновNo ratings yet

- 4D33 4D34T4 MT - 9Document1 page4D33 4D34T4 MT - 9wilmanesNo ratings yet

- HanDe Axle Company Profile, Products and Global StrategyDocument30 pagesHanDe Axle Company Profile, Products and Global StrategyliuNo ratings yet

- Volvo FHDocument7 pagesVolvo FHCristian ChiruNo ratings yet

- 8980 Epsilon UnlimitedDocument28 pages8980 Epsilon UnlimitedBOCHORIDISMEUROPARTSNo ratings yet

- Actros and Antos BrochureDocument29 pagesActros and Antos BrochureMinaSaeedNo ratings yet

- Volume 2-01 Truck SpecificationDocument2 pagesVolume 2-01 Truck SpecificationnurrahmatNo ratings yet

- Connecting Rod Bearings, Replace (All)Document5 pagesConnecting Rod Bearings, Replace (All)Hamilton MirandaNo ratings yet

- Spare Parts Catalog: 16 S 2323 TD Astra Veicoli Industriali Material Number: 1344.004.008Document66 pagesSpare Parts Catalog: 16 S 2323 TD Astra Veicoli Industriali Material Number: 1344.004.008Moe FellahNo ratings yet

- 89438353-Wiring Diagram, Led Tail Lamps (ENG)Document7 pages89438353-Wiring Diagram, Led Tail Lamps (ENG)Gerson FloresNo ratings yet

- Bär Original Spare PartsDocument52 pagesBär Original Spare PartsArians MarkitansNo ratings yet

- Group 1 - CabDocument324 pagesGroup 1 - CabEnoc ArenasNo ratings yet

- Gearbox, Mechanical - I Shift Generation DDocument55 pagesGearbox, Mechanical - I Shift Generation DMurniansyah AnsyahNo ratings yet

- China Heavy Equipments and Its SpecsDocument11 pagesChina Heavy Equipments and Its SpecsLuis Thethird BuotNo ratings yet

- Meritor / ROR DX175-DX225 Caliper Parts & Repair KitsDocument218 pagesMeritor / ROR DX175-DX225 Caliper Parts & Repair KitsAndrey MelnikNo ratings yet

- Manual PDFDocument28 pagesManual PDFNacer MalekNo ratings yet

- Brakes DanaDocument2 pagesBrakes DanaPdroGsus Abregú TerronesNo ratings yet

- Electrohydraulic Dual-Circuit Power Steering, FunctionDocument3 pagesElectrohydraulic Dual-Circuit Power Steering, FunctionAbi Jith100% (1)

- Parts Catalog of XML6112J14 Euro 4 (Peru)Document176 pagesParts Catalog of XML6112J14 Euro 4 (Peru)Miguel CardenasNo ratings yet

- TATRA T158-8P5R46 - 8x8 - 1-Way Tipper - ENDocument2 pagesTATRA T158-8P5R46 - 8x8 - 1-Way Tipper - ENMg diesel Mecatrônica diesel100% (1)

- D3 LCCDocument36 pagesD3 LCCstankovukanovicNo ratings yet

- Saf-Holland Design Handbook Intra En-DeDocument86 pagesSaf-Holland Design Handbook Intra En-DeneacsucristianNo ratings yet

- 16S-221 Iveco - AlemanDocument50 pages16S-221 Iveco - AlemanDanny Rodriguez Sanchez50% (2)

- Linde Service GuideDocument3 pagesLinde Service GuideLuis PaezNo ratings yet

- Front-End Cylinders: CatalogueDocument28 pagesFront-End Cylinders: CatalogueEdgardo GambandeNo ratings yet

- Section: L0 - Electric Al System Ref: 0 - 0.014.3360.4: Multifunction Control UnitDocument1 pageSection: L0 - Electric Al System Ref: 0 - 0.014.3360.4: Multifunction Control UnitEvaldas ŠtrapėlaNo ratings yet

- ILN2003A High-Voltage High-Current Darlington Transistor ArraysDocument8 pagesILN2003A High-Voltage High-Current Darlington Transistor ArraysAnonymous NSvuLOX10PNo ratings yet

- Spec GBDocument7 pagesSpec GBMohamed RaafatNo ratings yet

- ISRI Repair Manual 6500Document9 pagesISRI Repair Manual 6500Mehrdad Ghaffari Laleh100% (1)

- CE, PE, XE EngineDocument418 pagesCE, PE, XE Enginedzadza2100% (1)

- WABCO Technical Sheet 4324101020Document2 pagesWABCO Technical Sheet 4324101020DhinesuBaabu Anbu ThangaveluNo ratings yet

- Ebs 2012Document245 pagesEbs 2012GarryT2014No ratings yet

- ManDocument4 pagesManraduxcNo ratings yet

- TGS 26440 BLSDocument4 pagesTGS 26440 BLSjacob oommenNo ratings yet

- Headline Min. 24 - MAX. 36: Industrial Diesel Engine For Pump Drive ApplicationDocument3 pagesHeadline Min. 24 - MAX. 36: Industrial Diesel Engine For Pump Drive ApplicationIonut-alexandru IordacheNo ratings yet

- Jost 5th Wheel CatalogDocument44 pagesJost 5th Wheel CatalogmonokoeNo ratings yet

- 01 Intro Fifth Wheel Couplings and Mounting Plates eDocument7 pages01 Intro Fifth Wheel Couplings and Mounting Plates eAbrar HussainNo ratings yet

- SIBRE - General Catalogue Industrial BrakesDocument166 pagesSIBRE - General Catalogue Industrial BrakesRaul FloresNo ratings yet

- DAF OEM Silicone/Rubber HoseDocument9 pagesDAF OEM Silicone/Rubber Hose刘青No ratings yet

- JostDocument6 pagesJostAnonymous CJbaFnNo ratings yet

- MAN Truck ClutchDocument48 pagesMAN Truck ClutchAntnhe Bayu100% (1)

- Fontaine Instructions PDFDocument36 pagesFontaine Instructions PDFGonzalo SepulvedaNo ratings yet

- DEL DL500 Tail Lift Installation ManualDocument36 pagesDEL DL500 Tail Lift Installation ManualDuncan ReedNo ratings yet

- LT-103 3000instructions PDFDocument24 pagesLT-103 3000instructions PDFAndres AlvarezNo ratings yet

- Rigging Guide Part 3 0005Document33 pagesRigging Guide Part 3 0005amechmar5935No ratings yet

- Hydraulics The ReservoirDocument2 pagesHydraulics The ReservoirL.kolekarNo ratings yet

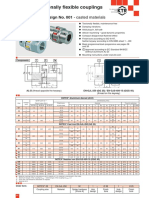

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Bep StandardDocument64 pagesBep StandardL.kolekarNo ratings yet

- Ipe 450Document2 pagesIpe 450L.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- List of Koc Standards & Specifications Applicable For JPF-4 & JPF-5 PDFDocument5 pagesList of Koc Standards & Specifications Applicable For JPF-4 & JPF-5 PDFL.kolekar25% (4)

- 108" CA Body and Other Optional Equipment ShownDocument2 pages108" CA Body and Other Optional Equipment ShownL.kolekarNo ratings yet

- CircuitDocument1 pageCircuitL.kolekarNo ratings yet

- 875c Series Api Dust Cap Data SheetDocument2 pages875c Series Api Dust Cap Data SheetL.kolekarNo ratings yet

- Storage TankDocument2 pagesStorage TankL.kolekarNo ratings yet

- KuwaitLaborLaw EnglishDocument51 pagesKuwaitLaborLaw EnglishL.kolekarNo ratings yet

- KTR 019 PDFDocument1 pageKTR 019 PDFL.kolekarNo ratings yet

- Revised Faq - 27.4.2021Document4 pagesRevised Faq - 27.4.2021L.kolekarNo ratings yet

- 2021 Calendar - India: January 2021 February 2021 March 2021Document1 page2021 Calendar - India: January 2021 February 2021 March 2021L.kolekarNo ratings yet

- Tank Shell Fit For Purpose Calculations: CA P H E S D TDocument5 pagesTank Shell Fit For Purpose Calculations: CA P H E S D TL.kolekarNo ratings yet

- Tozen Flex JTDocument16 pagesTozen Flex JTL.kolekarNo ratings yet

- MK Series User ManualDocument24 pagesMK Series User ManualL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Blackmer Parts List: T-Type Truck Pump Strainers FOR PUMP SIZES: 2, 2.5, 3Document2 pagesBlackmer Parts List: T-Type Truck Pump Strainers FOR PUMP SIZES: 2, 2.5, 3L.kolekarNo ratings yet

- Hot Product ValveDocument1 pageHot Product ValveL.kolekarNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Hampel PaintDocument2 pagesHampel PaintdaimaheshNo ratings yet

- Garbage CompactorDocument1 pageGarbage CompactorL.kolekarNo ratings yet

- JIS-G-3302 Specifications For GI PlatesDocument11 pagesJIS-G-3302 Specifications For GI PlatesL.kolekarNo ratings yet

- Extract of HEIL Old Manual Valve SectionsDocument10 pagesExtract of HEIL Old Manual Valve SectionsL.kolekar100% (1)

- Matl PropDocument1 pageMatl PropL.kolekarNo ratings yet

- TGH Pump Operating & Service ManualDocument39 pagesTGH Pump Operating & Service ManualL.kolekar100% (1)

- KATO SR250 25-Ton Crane Technical DataDocument9 pagesKATO SR250 25-Ton Crane Technical Datamk40% (5)

- Wmfun - E05 v0 - Wm-Im InterfaceDocument19 pagesWmfun - E05 v0 - Wm-Im Interfacechandra9000100% (1)

- Import of Vehicles: Taxpayer's Facilitation GuideDocument12 pagesImport of Vehicles: Taxpayer's Facilitation GuideSami Ur RehmanNo ratings yet

- Dynamic Speed GovernorDocument1 pageDynamic Speed GovernorBijil BajiNo ratings yet

- Standfast 43Document4 pagesStandfast 43Elison Farias OliveiraNo ratings yet

- Bmssa - Marc - S1 - Stud - M2 - Multiple Nuclei Theory - (Vidya, Likith, Renuka)Document12 pagesBmssa - Marc - S1 - Stud - M2 - Multiple Nuclei Theory - (Vidya, Likith, Renuka)YogeshNo ratings yet

- Pipeline InspectionDocument19 pagesPipeline InspectionsaeedalemveNo ratings yet

- Vermosa Presentation Material 04012019Document31 pagesVermosa Presentation Material 04012019Esther HerreraNo ratings yet

- Xtrail t32Document113 pagesXtrail t32mamatnamakuNo ratings yet

- HovercraftDocument15 pagesHovercraftpy9243No ratings yet

- Result Final Run - iXS GDC #5 Klinovec 2017Document8 pagesResult Final Run - iXS GDC #5 Klinovec 2017racementNo ratings yet

- A Manufacturer at Your Service: Rolls-RoyceDocument18 pagesA Manufacturer at Your Service: Rolls-RoyceManali PopatNo ratings yet

- 62-69 Engineer's Notebook DudaDocument5 pages62-69 Engineer's Notebook DudaMichael LagundinoNo ratings yet

- Ets 0505 SoalDocument19 pagesEts 0505 SoalkikinurasriNo ratings yet

- NTN FR PDFDocument292 pagesNTN FR PDFAnonymous 37PvyXCNo ratings yet

- VERCELES Thesis ProposalDocument21 pagesVERCELES Thesis ProposalPammy Evangelista Verceles100% (4)

- Regulation Test AnswersDocument9 pagesRegulation Test Answerskaitlyn bannisterNo ratings yet

- Rapid Risk Assessment Report For Pipeline From Jetty To BPCL Coastal Installation at HaldiaDocument69 pagesRapid Risk Assessment Report For Pipeline From Jetty To BPCL Coastal Installation at Haldiasachin nagavkarNo ratings yet

- Versatile Ringlock Scaffold SystemDocument9 pagesVersatile Ringlock Scaffold SystemJyles SirabNo ratings yet

- Congenbill1994 BLDocument2 pagesCongenbill1994 BLlarissasmith100% (3)

- Electronic Ticket Receipt 28AUG For SHEENA ANN BERNARDODocument4 pagesElectronic Ticket Receipt 28AUG For SHEENA ANN BERNARDOJENNY-ANN SORIANONo ratings yet

- Local Knowledge - Case Studies of Four Innovative PlacesDocument50 pagesLocal Knowledge - Case Studies of Four Innovative PlacesGiorgio BertiniNo ratings yet

- India Full Truckload Road Freight Transport Market 1676607714480Document82 pagesIndia Full Truckload Road Freight Transport Market 1676607714480Sidharth MaheshNo ratings yet

- Gas BallastDocument7 pagesGas BallastMiraNurhayaniNo ratings yet

- Vessel Database Listing in Certificate Order PDFDocument297 pagesVessel Database Listing in Certificate Order PDFraj_pegasusNo ratings yet

- Gencon 94Document4 pagesGencon 94Víctor Andrés AlarcónNo ratings yet

- 555 HondaDocument13 pages555 Hondaxtrmwrld100% (1)

- PhilippineAirlinesVSCA 1993 L-82619 DigestDocument1 pagePhilippineAirlinesVSCA 1993 L-82619 DigestChester BryanNo ratings yet

- Arni Sinaga - Tugas Descriptive 1Document4 pagesArni Sinaga - Tugas Descriptive 1Jefry Pasaribu GoratNo ratings yet

- Check ListDocument36 pagesCheck ListNitin GangwarNo ratings yet