Professional Documents

Culture Documents

Anchor Bolt Design Spreadsheet Calculations

Uploaded by

Hector AguanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor Bolt Design Spreadsheet Calculations

Uploaded by

Hector AguanaCopyright:

Available Formats

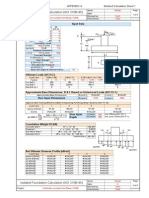

PIP STE05121

January 2003

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

PIP

Company

Project # PIP STE05121

Project

Example 1

Name

Date

12/12/2002

Checked by

Check Date

7/10/2003

LOADING CONDITIONS

Total Sheets

DESIGN CONSIDERATIONS

Note: Calculations are per ACI 318-02 Appendix D.

Ductility required?

Nu and Vu were factored using factors from ACI 318-02?

Tension

116

Specified concrete strength (psi) = f'c =

Factored shear load (kips) = Vu =

Cracking

modification

factor,Y 7

Is there a built-up grout pad?

ANCHOR DATA, EMBEDMENT, AND THICKNESS OF MEMBER

Anchor material type =

Adequate reinforcement provided to resist shear loads in anchors?

21.00 = hef ECCENTRICITY

60.00 = h

Eccentricity of tensile force on group of tensile anchors (in.)

2

eN' =

0

4

Eccentricity of shear force on group of anchors (in.)

(Note ev' must be less than s perpendicular to shear)

eV'=

0

CONCRETE FAILURE AREAS

Do you want to manually input the value of An?

Note: Units for An and Av are sq. in.

no

c1

NU

200

An=

3906

2000

Av=

2790

SHEAR

Spacing, in.

Edge Distance, in.

c1 = 32.00 c3 = 46.00

s1 =

0.00

c1 = 30.00

c2 = 28.00

s2 =

6.00

c2 = 28.00

c4 = 28.00

Spacing, in.

s2 =

c4 = 28.00

VU (parallel)

c1

c1 s1 c3

INTERACTION OF TENSILE AND SHEAR FORCES

fNn = 116.6 kips >= Nu = 116.0 kips

fVn = 75.6 kips >= Vu = 0.0 kips

Nu/(fNn) + Vu/(fVn) =

0.99 + 0.00 = 0.99 <=1.2

VU

h or 1.5c1

VU (perpendicular)

VU

c1

c4

RESULTS

OK

116.60

Process Industry Practices

6.00

c1 = edge distance in direction of Vn (perp.)

35o

Breakout cone for tension

Breakout cone for shear

SUMMARY OF RESULTS

DUCTILITY

Tensile ductility not required by user input

Shear ductility not required by user input

no

Av =

TENSION

Edge Distance, in.

c2 s2 c4

1.5c1

1.5c1

35o

(0=single anchor)

EDGE DISTANCES AND SPACING

An =

Do you want to manually input the value of Av?

hef

3000

Adequate supplementary reinf. provided to resist tension loads in anchors?

Nominal anchor diameter (in.) =

Effective anchor embedment depth (in.) = hef

Thickness of member in which anchor is anchored, (in.) = h

Number of anchors in tension = n(tension) =

Number of anchors in shear = n(shear) =

1.5hef

Shear

Intermediate or high seismic risk?

Factored tensile load (kips) = Nu =

1.5hef

Sheet Number

c2 s2 c4

Subject

s2

c2

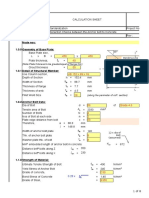

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

PIP STE05121

January 2003

Output

PIP

Company

1 of 1

Sheet

Project # PIP STE05121

Project

Example 1

Subject

Date 12/12/2002

Name

Check Date 7/10/2003

Checked by

BOLT PARAMETERS

Grade

Size

do

F1554 Gr 36

1 3/4 in.

1.750 in.

LOAD CONDITIONS

Load Conditions

Tensile Load\, Nu

Shear Load, Vu

fy

fut

Ase

Ab

36 ksi hef

58 ksi n(tension)

1.900 sq. in. n(shear)

4.144 sq. in.

21.00 in.

2

4

REINFORCEMENT

Section 9.2

116.0 kips Reinforcement NOT designed to carry tensile load

0.0 kips Reinforcement NOT designed to carry shear load

DESIGN CONSIDERATIONS

Ducitlity NOT req'd for tension

Ducitlity NOT req'd for shear

Low seismic risk

Eccentricities

eN' = 0.00 in.

DESIGN FOR TENSION

Ns

Steel Strength

Concrete breakout

strength of anchor(s)

Ncb or Ncbg

Pullout strength of

anchors (s)

nNpn

Concrete sideface

blowout strenght of

headed anchor(s)

Concrete Strength, f'c

3000 psi

Cracking Modification Factor, Y7

Grout Pad

eV' = 0.00 in.

1.4

DESIGN FOR SHEAR

220.4 kips Steel Strength

Concrete breakout strength of

anchor(s), Perpendicular to

166.6 kips edge

Vs

211.6 kips

Vcb or Vcbg

108.0 kips

Vcp

333.2 kips

Concrete pryout strength of

278.5 kips anchor(s)

Nsb or Nsbg

(governing)

NA

EDGE DISTANCES, SPACINGS,

FAILURE AREAS

c2 s2 c4

c1 s1 c3

SUMMARY OF RESULTS

TENSION

Steel Capacity

165.3 kips

Tension

Shear

Concrete Capacity

116.6 kips

c1

32.00 in.

30.00 in.

Tensile ductility not required by user input

c2

28.00 in.

28.00 in.

SHEAR

c3

46.00 in.

c4

28.00 in.

s1

0.00 in.

s2

6.00 in.

An or Av

Steel Capacity

28.00 in.

Process Industry Practices

137.5 kips

75.6 kips

Shear ductility not required by user input

6.00 in.

3906.0 sq. in. 2790.0 sq. in.

Calculated

Concrete Capacity

Calculated

INTERACTION OF TENSILE AND SHEAR FORCES

= fNn*

116.6 kips

>= Nu = 116.0 kips

= fVn*

75.6 kips

>= Vu = 0.0 kips

Nu/(fNn*) + Vu/(fVn*) =

0.99 + 0.00 <= 1.2

OK

*Multiplied by 0.75 if intermediate or high seismic area

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

PIP STE05121

January 2003

c3

Direction of load

c2

s 2 c4

c1 s1

Notes:

1. Determinations concerning fitness for purpose and particular matters or application of the Practice

to particular project or engineering situations should not be made solely on information contained in

these materials. All Practices or guidelines are intended to be consistent with applicable laws and

regulations including OSHA requirements. To the extent these Practices or guidelines should

conflict with OSHA or other applicable laws or regulations, such laws or regulations must be

followed. Consult an appropriate professional before applying or acting on any material contained

in or suggested by the Practice.

2. This spreadsheet has been developed utilizing ACI 318-02 Appendix D and PIP STE05121 . It will

give shear and tensile capacities of an anchor or anchor group and the concrete around the anchor

or anchor group. It will also let the user know if the anchor configuration is ductile (refer to PIP

STE05121 , section 6). The user needs to use this spreadsheet in combination with ACI 318-02

Appendix D and PIP STE05121 . This spreadsheet merely saves the user time in laborious

calculations but is no substitute for the engineers expertise.

3. The spreadsheet works for any number of bolts in tension and/or shear.

4. For 1, 2, or 4 bolts in a rectangular pattern, this spreadsheet will calculate An and Av. For other

numbers of bolts and bolt patterns, the user needs to calculate and input An and Av.

5. For tensile loads, if the user has 1, 2, or 4 bolts in a rectangular pattern, the user should provide c 1

through c4 and s1 and s2. For 1 bolt, s1 and s2 should be input as 0 (zero). For 2 bolts, either s1 or

s2 should be input as 0. Note: Only the bolts in tension shall be considered. If there are bolts in

shear only, ignore them.

6. For shear loads c1, c2, c4 and s2 are required inputs. c1 could be different for shear than for

tension. Note: Only the bolts in shear shall be considered. If there are bolts in tension only ignore

them. If there is only one bolt (or 2 bolts in line of load), s2 = 0.

7. If the user is using rebar to resist either tensile or shear loads applied to the anchor, this needs to

be indicated in the spreadsheet. The rebar needs to develop the required strength in accordance

with ACI 318 . See Section 7 of PIP STE05121 .

8. If reinforcement is provided to resist tension, then the concrete breakout strength of the anchor in

tension will not be used in checking the anchor size. Furthermore, if a ductile material is specified

for the anchor, the anchor is automatically ductile in tension.

9. If reinforcement is provided to resist shear, then the concrete breakout strength of the anchor in

shear and the concrete pryout strength of the anchor in shear will not be used in checking the

anchor size. Furthermore, if a ductile material is specified for the anchor, the anchor is

automatically ductile in shear.

Process Industry Practices

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

Selected Bolt:

do = 1.750 in.

hef = 21.0 in.

PIP STE05121

January 2003

Calculations

1 3/4 in.

Ase = 1.900 sq. in.

Abrg = 4.144 sq. in.

F1554 Gr 36

fy = 36 ksi

fut = 58 ksi

No. of Bolts

nt(tension) = 2

nv(shear) = 4

Note: Figures in parenthesis and in red refer to equations or paragraphs in ACI 318-02 , Appendix D.

Ns = nAsefut (fut < 1.9fy and fut < 125 ksi) = 220.4 kips

Steel Strength in Tension:

1. Concrete breakout strength of anchor in tension:

hef(max) = 21.0 in.

Use hef = 21.0 in.

AN(calc) = 3906.0 sq. in.

Use AN = 3906.0 sq. in.

Y1 = [1/(1 + 2eN'/3hef) <= 1] = 1.00

Y2 = 0.967

cmin = 28.0 in.

Y3 = 1.25

(D-3)

(D.5.2.3)

ANo = 9hef2 = 3969.0 sq. in.

(D-9)

(D-10 or D-11)

Nb = 140.1 kips

(D.5.2.6)

(D-7 or D-8)

Ncb or Ncbg = (AN/ANo)Y1Y2Y3Nb = 166.6 kips

(D-4 or D-5)

2. Pullout strength of anchor in tension:

Y4 = 1.4

Np = Abrg8f'c = 99.5 kips

(D.5.3.6)

For n bolts, nNpn = nY4Np = 278.5 kips

3. Concrete side-face blowout strength of headed anchor in tension:

c2 = 28.0 in.

c = 32.0 in.

Side-face blowout strength does not apply.

Nsb = 160c(Abrg)0.5(f'c)0.5 = NA

(D-15)

Side blowout group effects do not apply.

Nsbg = (1+so/6c)Nsb = NA

(D-16)

Nsb or Nsbg (governing) = NA

(D-13)

(D-12)

c2/c = 1.14

Nsb (modified) = NA

so =

Steel Strength of Fastener in Shear:

Vs = nAse(0.6 fut)*(0.8 if there is a grout pad) = 211.6 kips

1. Concrete breakout strength of anchor in shear:

Av(calc) = 2790.0 sq. in.

Use Av = 2790.0 sq. in.

Avo = 4.5c12 = 4050.0 sq. in.

AV (max) = nAVo = 16200.0 sq. in. (D.6.2.1)

Use min Av = 2790.0 sq. in.

l = min (8do and hef) = 14.0 in.

(D.0 - Notation for l)

c1 (max) = 30.0 in.

Process Industry Practices

(D-6)

(D.6.2.4)

Use c1 = 30.00 in.

Sheet 4 of 10

(D-18 & D.6.1.3)

(D-22)

(D.5.4.1)

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

Vb = 7(l/do)0.2(do)0.5(f'c)0.5(c1)1.5 = 126.3 kips

Y5 = 1/(1 + 2eV'/3c1) <= 1 = 1

(D-23)

(D-25)

Y6 = [0.7+0.3(c2/(1.5c1) if c2 < 1.5c1, 1.0 if c2 >= 1.5c1] = 0.887

Y7 = 1.4

(D.6.2.7)

Vcb or Vcbg = (AV/AVo)Y5Y6Y7Vb = 108.0 kips

243.7 kips

2. Concrete pryout strength of anchor in shear:

kcp = 2

(D.6.3.1)

Vcp = kcpNcb = 333.2 kips

PIP STE05121

January 2003

Calculations

(D-26 [Errata] or D-27)

(D-20 or D-21) Shear perpendicular to edge

(D-20 or D-21) Shear parallel to edge

Ncb = 166.6 kips

<------- Applies

<-------- NA

(D-4)

(D-28)

Summary of Results:

f for concrete = 0.70

f for steel = 0.75

Tension:

(D.4.4)

Steel capacity = fNn[*0.75 if inter. or high seismic risk] = 165.3 kips

(D.3.3)

Concrete capacity = fNn[*0.75 if inter. or high seismic risk] = 116.6 kips

(D.3.3)

Governing mode of concrete failure: Concrete breakout strength of anchor in tension

f for concrete = 0.70

f for steel = 0.65

(D.4.4)

Steel capacity = fVn[*0.75 if inter. or high seismic risk] = 137.5 kips

Conc. capacity = fVn[*0.75 if inter. or high seismic risk] = 75.6 kips

Governing mode of concrete failure: Concrete breakout strength of anchor in shear

Ductility Req'd?

Tension

0

Shear:

Interaction of tensile and shear forces:

fNn = 116.6 kips

0.2fNn = 23.3 kips

Nu = 116.0 kips

Nu/(fNn) = 0.99

Applicable equation = (D-1)

Process Industry Practices

(D.3.3)

(D.3.3)

(D.7)

fVn = 75.6 kips

0.2fVn = 15.1 kips

Vu = 0.0 kips

Vu/(fVn) = 0.00

116.60

OK

Sheet 5 of 10

Shear

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

Calculations

Supplementary Calculations

Calculation for An and cmax

input

If < 1.5 hef, 1, else 0

Find cmax

Edge distance (c1) =

32

Edge distance (c2) =

28

28

Edge distance (c3) =

46

Edge distance (c4) =

28

28

Total sides < 1.5 hef =

cmax* =

Anchor spacing (s1) =

28

0

Anchor spacing (s2) =

6

* For pedestals with edge distances on 3 sides less than 1.5hef, cmax is the largest edge distance of those 3 sides. For pedestals with

4 sides less than 1.5hef, cmax is the second largest edge distance less than 1.5hef. It has been determined that the calculated capacity

of the concrete will decrease by as much as 40% even though AN is being increased if all 4 edge distances are being used. ACI has

been contacted about this problem and is working toward revising this portion of the code. The PIP CSA Function Teaam has agreed

that this meets the intent of the code and is conservative.

Calculate for Av and c1(max)

input

If < 1.5 c1, 1, else 0

Edge distance (c1) =

30

Edge distance (c2) =

28

Edge distance (c4) =

28

Total sides < 1.5 c1 =

Anchor spacing (s2) =

Process Industry Practices

Sheet 6 of 10

PIP STE05121

January 2003

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

Anchor Material Type

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Minimum

Size

A307-Type A

A307-Type C

A36

F1554 Gr 36

F1554 Gr 55

F1554 Gr 105

A 193 Gr B7

A 193 Gr B7

A 193 Gr B7

2.51

4.01

A354 Gr BC

A354 Gr BD

A449

A449

A449

1.01

1.51

1 A307, Type A, Fu = 60

2 A307-Type C, Fu = 58

3 A36, Fu = 58

4 F1554 Gr 36

PIP STE05121

January 2003

Tables

Maximum

Size

4

4

8

2

2

2

2.5

4

7

4

4

1

1.5

3

Fy

ksi

0

36

36

36

55

105

105

95

75

109

130

92

81

58

Fut

ksi

60

58

58

58

75

125

125

115

100

125

150

120

105

90

Ductile?

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

5 F1554 Gr 55

6 F1554 Gr 105

7 A193 Gr B7

8 A354 Gr BC

9 A354 Gr BD

10

10 A449

Row = 4

User's answer =

fy = 36

fut = 58

Ductile anchor bolt mat'l

14

do =

Bolt Type Used: 4

Adequate Reinforcement Provided to Resist Tension Loads in Anchors?

Yes

2 = no

MUST CHECK CONCRETE for ....

1. Concrete breakout strength of anchor (concrete cone)

2. Pullout strength of anchor

3. Concrete side-face blowout strength of headed anchor

The anchor is NOT automatically DUCTILE for tension and

phi factor (D.4.4) = 0.70.

1.75 inch

Adequate Reinforcement Provided to Resist Shear Loads in Anchors?

1

2

3

4

5

6

7

Bolt Diameter: 10

do

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

0.500

0.625

0.750

0.875

1.000

1.125

1.250

Process Industry Practices

Ase

0.142

0.226

0.334

0.462

0.606

0.763

0.969

Abrg*

0.467

0.671

0.911

1.188

1.501

1.851

2.237

hef,min

6.0

7.5

9.0

10.5

12.0

13.5

15.0

User's answer =

2 = no

MUST CHECK ....

1. Concrete breakout strength of anchor (concrete cone)

2. Concrete pryout strength of anchor (backside of anchor)

The anchor is NOT automatically DUCTILE for shear and

phi factor (D.4.4) = 0.70.

Sheet 7 of 10

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

8

9

10

11

12

13

14

15

16

1 3/8

1 1/2

1 3/4

2

2 1/4

2 1/2

2 3/4

3

4

1.375

1.500

1.750

2.000

2.250

2.500

2.750

3.000

4.000

* Heavy Hex

Ductility Required for

Tension?

PIP STE05121

January 2003

Tables

1.160

1.410

1.900

2.500

3.250

4.000

4.930

5.970

11.080

2.659

3.118

4.144

5.316

6.633

8.095

9.703

11.456

19.923

16.5

18.0

21.0

24.0

27.0

30.0

33.0

36.0

48.0

1 Yes

2 No

Concrete Failure Modes

1 Concrete breakout strength of anchor in tension

2 Pullout strength of fastener in tension

1

Perpendicular or

1

parallel to edge?

perpendicular to edge

(D.6.2.1 (a), (b), or (c)) parallel to edge

Intermediate or High

Seismic Risk?

Built-up Grout Pad? 1

1 Yes

2 No

Load Combinations per

ACI .....(D 4.4) 1 Section 9.2

(D 4.5) 2 Appendix C

Ductility Required for

Shear?

1 Yes

2 No

2

1 Yes

2 No

Y7 : 4

1

1.0 1.0 - No edge reinf or edge reinf rebar < #4

2

1.2 1.2 - Edge reinf rebar >= #4

3

1.4 1.4 - Edge reinf rebar >=#4 + stirrups @ <= 4 in.

4

1.4 1.4 - Located in region where there isn't cracking at service loads (f t < fr)

Capacity (kips)

166.6

1

Applicable Interaction Equation

fNn >= Nu

278.5

2

1 (D-1)

3 Concrete side-face blowout strength of anchor in tension

4 Concrete breakout strength of anchor in shear

5 Concrete pryout strength of anchor in shear

NA

2 (D-2)

fVn >= Vu

108.0

333.2

4

5

3 (D-29)

Nu/(fNn) + Vu/(fVn) <= 1.2

Use Equation 1

Governing Tension Concrete Capacity = 166.6 kips

Concrete Failure Mode for Tension = 1

Governing Shear Concrete Capacity = 108.0 kips

Concrete Failure Mode for Shear = 4

Process Industry Practices

Manual 2

1 Yes

2 No

Sheet 8 of 10

Manual Av 2

1 Yes

2 No

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

A brg

A No

AN

A se

A Vo

AV

c

c1

Glossary

PIP STE05121

January 2003

bearing area of the head of stud or anchor bolt, in.2

projected concrete failure area of one anchor, for calculation of strength in tension, when not

limited by edge distance

projected concrete failure area of an anchor or group of anchors, for calculation of strength in

tension

effective cross-sectional area of anchor, in.2

projected concrete failure area of one anchor, for calculation of strength in shear, when not limited

by corner influences, spacing, or member thickness

Projected concrete failure area of an anchor or group of anchors, for calculation of strength in

shear

distance from center of an anchor shaft to the edge of concrete, in.

distance from center of an anchor shaft to the edge of concrete in one direction, in. Where shear

force is applied to anchor, c1 is in the direction of the shear force. For tension, c1 is the minimum

edge distance.

c2

distance from center of an anchor shaft to the edge of concrete in the direction orthogonal to c 1, in.

c max

c min

do

du

e N'

the largest of the edge distances that are less than or equal to 1.5hef, in. (used only for the case of

3 or 4 edges).

the smallest of the edge distances that are less than or equal to 1.5hef, in.

shaft diameter of anchor bolt, in.

diameter of head of stud or anchor bolt or equivalent diameter of effective perimeter of an added

plate or washer at the head of the anchor, in.

e V'

eccentricity of normal force on a group of anchors; the distance between the resultant tension load

on a group of anchors and the centroid of the group of anchors loaded in tension, in.

eccentricity of shear force on a group of anchors; the distance between the point of shear force

application and the centroid of the group of anchors resisting shear in the direction of the applied

shear, in.

f' c

specified compressive strength of concrete, psi

f ct

specified tensile strength of concrete, psi

fr

modulus of rupture of concrete, psi

ft

calculated tensile stress in a region of a member, psi

fy

specified yield strength of anchor steel, psi

f ut

specified tensile strength of anchor steel, psi

thickness of member in which an anchor is anchored measured parallel to anchor axis, in.

h

h ef

k

k cp

l

n

Nb

effective anchor embedment depth, in.

coefficient for basic concrete breakout strength in tension

coefficient for pryout strength

load bearing length of anchor for shear, not to exceed 8do, in.; hef for anchors with a constant

stiffness over the full length of the embedded section, such as headed studs.

number of anchors in a group

basic concrete breakout strength in tension of a single anchor in cracked concrete, lb.

N cb

nominal concrete breakout strength in tension of a single anchor, lb.

N cbg

nominal concrete breakout strength in tension of a group of anchors, lb.

Nn

nominal strength in tension, lb.

Np

pullout strength in tension of a single anchor in cracked concrete, lb.

N pn

nominal pullout strength in tension of a single anchor, lb.

Process Industry Practices

Page 9 of 10

Anchor Bolt Design Spreadsheet

Revision 2, November 2003

Glossary

N sb

side-face blowout strength of a single anchor, lb.

N sbg

side-face blowout strength of a group of anchors, lb.

Ns

nominal strength of a single anchor in tension as governed by the steel strength, lb.

Nu

factored tensile load, lb.

anchor center-to-center spacing, in.

s

so

t

Vb

spacing of the outer anchors along the edge in a group, in.

thickness of washer or plate, in.

basic concrete breakout strength in shear of a single anchor in cracked concrete, lb.

V cb

nominal concrete breakout strength in shear of a single anchor, lb.

V cbg

nominal concrete breakout strength in shear of a group of anchors, lb.

Vn

nominal strength in shear, lb.

Vp

pullout strength in shear of a single anchor in cracked concrete, lb.

V pn

nominal pullout strength in shear of a single anchor, lb.

V sb

side-face blowout strength of a single anchor, lb.

V sbg

side-face blowout strength of a group of anchors, lb.

Vs

nominal strength of a single anchor in shear as governed by the steel strength, lb.

Vu

factored tensile load, lb.

strength reduction factor

modification factor, for strength in tension, to account for anchor groups loaded eccentrically

modification factor, for strength in tension, to account for edge distances smaller than 1.5hef

f

Y1

Y2

Y3

Y4

Y5

Y6

Y7

modification factor, for strength in tension, to account for cracking

modification factor, for pullout strength, to account for cracking

modification factor, for strength in shear, to account for anchor groups loaded eccentrically

modification factor, for strength in shear, to account for edge distances smaller than 1.5hef

modification factor, for strength in shear, to account for cracking

Process Industry Practices

Page 10 of 10

PIP STE05121

January 2003

You might also like

- Anchor Bolt DesignDocument60 pagesAnchor Bolt DesignS.s. LeeNo ratings yet

- Anchor Bolt DesignDocument6 pagesAnchor Bolt DesignFian ArdiyanaNo ratings yet

- 1030 - Embedded Plate Design - 4 - S7.00Document9 pages1030 - Embedded Plate Design - 4 - S7.00rajedmaglinte100% (2)

- Base Plate Design-1 - J BoltDocument41 pagesBase Plate Design-1 - J BoltGautam PaulNo ratings yet

- Concrete Anchor Bolt Design CalculationDocument10 pagesConcrete Anchor Bolt Design Calculationraghu_mn100% (5)

- Anchor Bolt CalculationDocument17 pagesAnchor Bolt CalculationSrinivasa Rao Venkumahanthi100% (6)

- Baseplate Design Input DataDocument166 pagesBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Vertical Vessel Circular Pattern Anchor Bolt Design - ACI 318-14Document4 pagesVertical Vessel Circular Pattern Anchor Bolt Design - ACI 318-14dovi01No ratings yet

- Calculation Sheet: Anchor Bolt Design Combined Tension and Shear Code AbbreviationDocument1 pageCalculation Sheet: Anchor Bolt Design Combined Tension and Shear Code AbbreviationNoppolNorasriNo ratings yet

- Axially Loaded RC Column DesignDocument17 pagesAxially Loaded RC Column DesignBert EngNo ratings yet

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- Anchor BoltDocument8 pagesAnchor Boltazwan50% (2)

- Anchor Bolt DesignDocument1 pageAnchor Bolt DesignpawanNo ratings yet

- Design Base Plate for Platform 1 ColumnDocument93 pagesDesign Base Plate for Platform 1 ColumnAnand.5No ratings yet

- Anchor Bolt Design (ACI318)Document5 pagesAnchor Bolt Design (ACI318)Ashraful AlamNo ratings yet

- Moving Wheel Loads AnalysisDocument3 pagesMoving Wheel Loads AnalysisAnibal Via EnNo ratings yet

- Ankeri SI JediniceDocument30 pagesAnkeri SI Jedinicepperic13No ratings yet

- Baseplate Design AiscDocument20 pagesBaseplate Design AiscShamim Ahsan ZuberyNo ratings yet

- Anchor Bolt DesignDocument18 pagesAnchor Bolt Designbhaskardharani78% (9)

- Design of Anchorage To Concrete Using ACI 318 08 CSA A23.3 04 CodeDocument155 pagesDesign of Anchorage To Concrete Using ACI 318 08 CSA A23.3 04 Codeajay100% (1)

- Anchor BoltDocument22 pagesAnchor BoltIrwan RamdaniNo ratings yet

- Isolated Foundation Calculation (ACI 318M-95) : Input DataDocument5 pagesIsolated Foundation Calculation (ACI 318M-95) : Input DataJuan CarlosNo ratings yet

- Literature Review of Coconut Coir in Polymer CompositesDocument17 pagesLiterature Review of Coconut Coir in Polymer CompositesFaruq Luqman60% (5)

- Base Plate DesignDocument118 pagesBase Plate Designsanjay singhNo ratings yet

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- Excel Anchor Bolt Calculator-1Document2 pagesExcel Anchor Bolt Calculator-1teesk200350% (2)

- Anchor Bolt & Base Plate DesignDocument6 pagesAnchor Bolt & Base Plate DesignAzeem Suddal100% (1)

- Design of Headed Concrete AnchorDocument121 pagesDesign of Headed Concrete AnchorkalpanaadhiNo ratings yet

- Design of Anchor Bolt - Rev.ADocument8 pagesDesign of Anchor Bolt - Rev.AcivilaskarNo ratings yet

- "Anchor Bolt (318-08) " - Embedment Strength Per ACI 318-08 Appendix DDocument11 pages"Anchor Bolt (318-08) " - Embedment Strength Per ACI 318-08 Appendix DMian M KhurramNo ratings yet

- Anchorbolt R1Document12 pagesAnchorbolt R1Matheus HenrichNo ratings yet

- Circular Base PlateDocument4 pagesCircular Base PlateErnesto Feliciano Basurto Galvez100% (1)

- JCP Product Distribution Base Plate DesignDocument22 pagesJCP Product Distribution Base Plate DesignEmil Parangue100% (1)

- A Bolts Aci318 05Document6 pagesA Bolts Aci318 05RnD2013No ratings yet

- Fastener Connection To Structure - ExampleDocument12 pagesFastener Connection To Structure - ExamplekingdbmNo ratings yet

- Notes On Anchor Bolt Design (ACI 318-08 APP D)Document6 pagesNotes On Anchor Bolt Design (ACI 318-08 APP D)Kai LeeNo ratings yet

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Base Plate With Moment & Axial CompressionDocument2 pagesBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- Anchor Reinforcement AnalysisDocument10 pagesAnchor Reinforcement AnalysisTarek AbulailNo ratings yet

- 2013.01.09 - ACI Appendix D - Updates For ACI 318-11Document68 pages2013.01.09 - ACI Appendix D - Updates For ACI 318-11UALU333No ratings yet

- Anchor BoltDocument15 pagesAnchor BoltRyan Wiratama67% (3)

- CivilBay Structural Engineering Spreadsheet Tutorial on Anchorage DesignDocument153 pagesCivilBay Structural Engineering Spreadsheet Tutorial on Anchorage Designhatot100% (1)

- Super Composite ColumnDocument2 pagesSuper Composite ColumnCheng Por EngNo ratings yet

- Anchorbolt (318 08)Document26 pagesAnchorbolt (318 08)Anonymous 9MDGo2jNo ratings yet

- Design of Base PlateDocument4 pagesDesign of Base PlatesanggythaNo ratings yet

- Rectangular Concrete Beam Analysis in ExcelDocument16 pagesRectangular Concrete Beam Analysis in ExcelAli Syaputra100% (1)

- AISC2005 Anchor Bolt Version22042015 FixDocument8 pagesAISC2005 Anchor Bolt Version22042015 FixThuyTranNo ratings yet

- Broadway Ledger AnglesDocument8 pagesBroadway Ledger AnglesxpertsteelNo ratings yet

- Mathcad - AB DesignDocument5 pagesMathcad - AB Designrmartinson8No ratings yet

- Anchor Bolt Design For Tension and ShearDocument7 pagesAnchor Bolt Design For Tension and ShearJohn BuntalesNo ratings yet

- Anchor BoltDocument7 pagesAnchor Boltmarcoav1No ratings yet

- ASME B31.3 Pre Heat & PWHT PDFDocument4 pagesASME B31.3 Pre Heat & PWHT PDFGANGADHAR SAHUNo ratings yet

- Shotcrete Support Load CalculationsDocument6 pagesShotcrete Support Load Calculationsanon_160157252No ratings yet

- Anchor Bolt Strength Calculation per ACI 318-05 Appendix DDocument7 pagesAnchor Bolt Strength Calculation per ACI 318-05 Appendix DGunawan NamakuNo ratings yet

- Moment ConnectionsDocument15 pagesMoment ConnectionsHector Aguana100% (1)

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNo ratings yet

- Beam Column Base Plate DesignDocument10 pagesBeam Column Base Plate DesignSPUD1100% (3)

- Anchor Embedment - Pa2Document8 pagesAnchor Embedment - Pa2joeilaganNo ratings yet

- Basic Design Parameters:: Loads: 1Document5 pagesBasic Design Parameters:: Loads: 1Fandy SipataNo ratings yet

- Optimized Title for Screw Fastening Design Problems DocumentDocument42 pagesOptimized Title for Screw Fastening Design Problems DocumentrenebbNo ratings yet

- "EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionDocument18 pages"EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionIhab SorourNo ratings yet

- Cobble Design - Sample NewDocument2 pagesCobble Design - Sample NewBekele AmanNo ratings yet

- Concrete Anchorage Special RequirementsDocument2 pagesConcrete Anchorage Special RequirementsSatyanarayana JayantiNo ratings yet

- Shear Strength CalculationDocument4 pagesShear Strength CalculationAnil kumar RNo ratings yet

- .Document77 pages.Hector AguanaNo ratings yet

- Nuevo Documento de TextoDocument15 pagesNuevo Documento de TextoHector AguanaNo ratings yet

- Product KeyDocument635 pagesProduct KeyHector AguanaNo ratings yet

- Product KeyDocument636 pagesProduct KeyHector AguanaNo ratings yet

- Product KeyDocument637 pagesProduct KeyHector AguanaNo ratings yet

- Product KeyDocument640 pagesProduct KeyHector AguanaNo ratings yet

- SAFE Users GuideDocument62 pagesSAFE Users GuideMonica Maria OquendoNo ratings yet

- HSS Dimensions and Section Properties BrochureDocument28 pagesHSS Dimensions and Section Properties BrochureHector AguanaNo ratings yet

- Vigas Continuas, Singer y PytelDocument39 pagesVigas Continuas, Singer y PytelHector AguanaNo ratings yet

- SAFE Users GuideDocument62 pagesSAFE Users GuideMonica Maria OquendoNo ratings yet

- Concrete Strength by Brick ChipsDocument10 pagesConcrete Strength by Brick ChipsHamayet RaselNo ratings yet

- Nylon-A Material Introduction and Overview For BiomedicalDocument16 pagesNylon-A Material Introduction and Overview For BiomedicalTHILLAI NADESH SNo ratings yet

- Hiten Kadu 6.1Document104 pagesHiten Kadu 6.1Pranjal DograNo ratings yet

- Answers Sheet (II) - MergedDocument44 pagesAnswers Sheet (II) - Mergedmarwankh305No ratings yet

- BD 5610Document177 pagesBD 5610David PriceNo ratings yet

- ChemistryDocument4 pagesChemistryManish SainiNo ratings yet

- Effect of Dielectric Fluids on Surface Integrity in EDMDocument185 pagesEffect of Dielectric Fluids on Surface Integrity in EDMshahadNo ratings yet

- Electrical BEE Latest 2022 2023 Quantum Series (Searchable)Document116 pagesElectrical BEE Latest 2022 2023 Quantum Series (Searchable)ritamlyrisNo ratings yet

- Caracterizacao PluronicDocument15 pagesCaracterizacao PluronicThiago Nunes VianaNo ratings yet

- Physics 7B Thermal Equilibrium and Ideal Gas DiscussionDocument5 pagesPhysics 7B Thermal Equilibrium and Ideal Gas DiscussionNorphinNo ratings yet

- Simple Stresses and StrainsDocument6 pagesSimple Stresses and StrainsNwankwo EmmanuelNo ratings yet

- Mse 113 - 2009Document6 pagesMse 113 - 2009maftahokNo ratings yet

- Fetter Ch6r PDFDocument11 pagesFetter Ch6r PDFAbdul SalamNo ratings yet

- Lightweight Car Body TechnologiesDocument12 pagesLightweight Car Body TechnologiesS P Suganthi GaneshNo ratings yet

- Lec4. Practical Applications of Bernoulli Equation By. Engr - Wendhel Q.LDocument5 pagesLec4. Practical Applications of Bernoulli Equation By. Engr - Wendhel Q.Ljames PrincipeNo ratings yet

- Viscose Fibres With New Functional QualitiesDocument6 pagesViscose Fibres With New Functional Qualitiesahmed samirNo ratings yet

- 10th Class Physics Guess Paper 2023Document24 pages10th Class Physics Guess Paper 2023Farhatullah MuhammadNo ratings yet

- Refresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Document10 pagesRefresh Refresh (Dynamic - Bypass - Reload) Click Here If You Are Not Automatically Redirected. For Assistance, Contact Your Network Support Team.Kelvin LimNo ratings yet

- Shape Optimization of Welded Plate Heat Exchangers Based On GreyDocument9 pagesShape Optimization of Welded Plate Heat Exchangers Based On GreySandro Chuqui PorteroNo ratings yet

- Heat Tech PresentationDocument49 pagesHeat Tech Presentationquality.sarthakautoNo ratings yet

- Homework Chapter 22 Solutions Including Key Problems 22.5, 22.7, 22.11, 22.25, 22.27Document16 pagesHomework Chapter 22 Solutions Including Key Problems 22.5, 22.7, 22.11, 22.25, 22.27bidinNo ratings yet

- High Temp Furnace Bottom Loading Ceramics MetalsDocument4 pagesHigh Temp Furnace Bottom Loading Ceramics MetalsDekanat FizfakNo ratings yet

- Exam 1 Sp23Document11 pagesExam 1 Sp23Mike TederNo ratings yet

- Quiz 1 - SolutionDocument2 pagesQuiz 1 - Solutionhimadrisahu88No ratings yet

- Reversible and Irreversible ProcesesDocument12 pagesReversible and Irreversible ProcesesFarouk BassaNo ratings yet

- Thermodynamic Relation IntroDocument4 pagesThermodynamic Relation IntromahendranNo ratings yet