Professional Documents

Culture Documents

01 Supplier Pre-Qualification Assessment

Uploaded by

Chinh Lê ĐìnhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Supplier Pre-Qualification Assessment

Uploaded by

Chinh Lê ĐìnhCopyright:

Available Formats

Audit No.

/Year:

Supplier Pre-Qualification Assessment

Audit Date:

Company:

Address:

Process(es):

Products:

Total no. of employees:

Employees in Quality dept.:

Main customer(s):

Quality Certifications:

Assessment reason:

ISO 9001 certif. number

ISO/TS 16949 certif. number

ISO 14001 certif. number

Expiration:

Expiration:

Expiration:

Certif. no:

Certif. no:

Certif. no:

Other certification available

Expiration:

Certif. no:

Initial Audit for New Supplier

Follow up

Other:

Name

Title

Name

Title

KSS Auditor(s):

Supplier

Participants:

Assessment Summary:

This audit

Previous audit

503

Total Potential Score

Total Actual Score

Number of Improvement Items:

0.00%

Overall Audit Score

Corrective Action Due Date:

Assessment Passed?

Yes

No

(see comments below)

Corrective Action Required ?

Yes

No

Total Pages:

Improvement

Areas:

Best Practice

Areas:

*

**

Yes - signed

Contractual Partner

Simple/medium complexity parts

KSS Quality First Manual acknowledgment:

Partnership:

Complexity of product:

Supplier Management Acknowledgement

Supplier Engineering Manager:

Supplier Manufacturing Manager:

Supplier Quality Manager:

Supplier General Manager

Report no. 1038929 Rev. 01

KSS Auditors

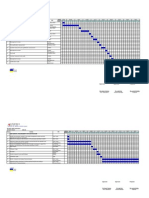

Supplier Pre-Qualification Assessment

Scoring Summary

Potential Score

Total Score

Actual Score

Overall

1.0 Management

27

0.00%

2.0 Waste Reduction

29

0.00%

3.0 Internal Auditing

29

0.00%

4.0 Customer PPAP

29

0.00%

20

0.00%

Criteria

5.0

Corrective / Preventive

Action

6.0 Engineering / Testing

41

0.00%

7.0 Program Management

21

0.00%

8.0 Procurement & Supplier Management

22

0.00%

9.0 Tooling / Machine

59

0.00%

10.0 Receiving Inspection

46

0.00%

11.0 Process Control / Traceability

108

0.00%

12.0 Measurement & Calibration

39

0.00%

13.0 Employee Orientation / Training

24

0.00%

14.0 Document Control / Records Management

0.00%

Total Score (%)

503

0.00%

**

**

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment scoring summary

1

100%

80%

60%

40%

20%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

1.0 - Management

Deployment / Execution

Criteria

Weight

1.0

Score

(0 or 1)

Result

Management Review

1.1

Formal Management Review process exists, is conducted semi-annually (at a minimum), and covers

all elements of the Quality Systems Manual applicable to the facility.

1.2

Key Measureables are defined, measured, tracked and action plans in place as needed.

1.3

Supplier PPM and on time delivery is tracked and a reporting system in place.

1.4

Customer PPM and on time delivery is tracked, and action plan in place as needed.

1.5

English Speaking ability of key person and key function.

Housekeeping & Working Condition

1.6

Housekeeping (offices, plant, labs warehouse, outside building, yard trailers).

1.7

Working conditions (Such as safety, health and environment, enough light for visual checks, noise

inspection in quiet areas)

Total Potential Score

27

Actual Score

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

0%

Supplier Pre-Qualification Assessment

2.0 - Waste Reduction

Deployment / Execution

Criteria

2.0

Weight

Score

(0 or 1)

Result

Waste Reduction

2.1 Scrap Analysis and Reduction process.

2.2

Formal, real time review, analysis champion and corrective action process for scrap - trends

positive. Pareto analysis for scrap with detailed and timely action plans for top pareto issues.

2.3

Downtime analysis and reduction process, Planned and Unplanned maintenance activities

documented?

2.4

Formal, real time review, analysis champion and corrective action process for downtime -trends

positive. Pareto analysis for downtime with detailed and timely action plans for top pareto issues.

2.5 Downtime and Scrap issues are fed back to PM process.

2.6 Cost of Quality (COQ) Process. Pareto analysis of each element.

2.7 Detailed and timely action plans for top COQ pareto issues for each element.

Total Potential Score

29

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

3.0 - Internal Auditing

Deployment / Execution

Criteria

3.0

3.1

Weight

Score

(0 or 1)

Result

Internal Auditing

12 month Internal Quality System Audit schedule covering all clauses of TS 16949:2002 or ISO

9001:2000 as applies.

3.4 All processes and products subjected to regular internal audits. (Layered Audits)

3.5 Housekeeping / 5S process included in internal audits of all areas / facilities.

3.6 Records of audits maintained including objective evidence.

3.7 Findings reviewed with responsible department managers.

3.2 Audits conducted by qualified auditors. Auditors do not check their own work.

3.3

3.8

Management practices layered audits to insure continued compliance to the common business

systems and process controls at their facility.

Corrective actions in place in a timely manner with management sign off approval. Corrective

actions address issue/concern.

3.9 Follow-up / reassessment of action plan completion / effectiveness and verification

Total Potential Score

29

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

4.0 - Customer PPAP

Deployment / Execution

Criteria

4.0

4.1

Weight

Score

(0 or 1)

Result

Customer PPAP process

All information contained in PPAP meets AIAG standards (current revision / released / approved

documents, print ballooned, product picture) and customer specific requirements.

4.2 Material composition submitted into IMDS database

4.3 All issues are resolved prior to submission of any PPAP to the Customer

4.4 PPAP Review Checklist and Sign-off Process (prior to customer submission)

4.5 PPAP approval required prior to first shipment (any saleable vehicle builds)

4.6

PV build design level. Component sources / revision levels / lot numbers required - subsequent

changes re-PPAP'ed and PV'ed

4.7 Control of Appearance Approval Report (AAR) for PPAP.

4.8

Run at Rate process. Run at rate performed and documented. Run at rate includes all serial stations

and tools.

4.9

Run at Rates achieve the quoted capacities and quality requirements. Action plans in place as

required.

Total Potential Score

29

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

5.0 - Corrective / Preventive Action

Deployment / Execution

Criteria

5.0

Weight

Score

(0 or 1)

Result

Corrective & Preventive Action

5.1

All customer concerns are tracked, addressed and verified for internal and external closure.

Responses submitted on time and accepted the first time.

5.2

Process/product issues systematically analyzed with team approach for structured problem solving,

utilizing 5-Why, 8D or other required problem solving formats.

5.3

Repeat concerns are evaluated for management action and problem solving process improvement.

CAR kept on file and verified for internal and external closure.

5.4

Corrective actions for concerns are addressed across similar products, processes and implemented

as applicable

5.5

Both formal and informal customer and supplier concerns are addressed. In process concerns are

tracked and verified for closure.

5.6

Formal continuous improvement program in place with project log and action item register with

target and completion dates identified.

Total Potential Score

20

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

6.0 - Engineering / Testing

Deployment / Execution

Criteria

6.0

Weight

Score

(0 or 1)

Result

DFMEA Management

6.1 DFMEA's are cross functionally reviewed and approved prior to release

6.2 DFMEA's are released into document control initially and following all revisions

6.3 All "hard" or "control level" revisions to products require DFMEA update and release to the new level

Test plan development and approval process (internal and customer); is manufacturing feasibility

6.5 assessed on the basis of the requirements established for the product and process, on a crossfunctional level?

6.6 Build level and component suppliers / lot numbers are documented for DV and PV builds

6.7 PV build must be 100% production components (PPAP'ed) and off production processes and tools.

6.4

DFMEA RPN reduction actions are documented and completed where applicable - DFMEA is updated

to reflect completion of all RPN reduction actions.

DV / PV Reporting System

6.8

Delta DV /PV all changes after initial full DV / PV. Team agrees on modified plan if full DV / PV is not

necessary

6.9

Corrective and preventive action system for testing, including issue resolution and formal closure - for

all DV / PV / Cert tests. Corrective actions completed within time requirements

6.11 Post launch Design Change validation, approval and implementation process

6.12 All effected areas notified of change

6.13 Date of first production run with the change recorded.

6.10 All component design changes implemented via KSS SREA or approved by other customer.

Engineering Change Notice System

Total Potential Score

41

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

7.0 - Program Management

Deployment / Execution

Criteria

7.0

7.1

Weight

Score

(0 or 1)

Result

Customer Side Program Management

Product launch process in place with established phases for completion and check sheets for

tracking.

7.2 Metrics tracked (% pass on original date, % red programs, attendance) Actions taken

7.3 Evidence books complete with retention controlled.

7.4 Lessons learned recorded and records retained.

7.5 Detailed program timing plans exist, are updated regularly and distributed to all involved persons

7.6 Regular Program Team Meetings held to track and update development / launch timing plans

7.7 Program delay / risk escalation and recovery process

Supplier Side Program Management

7.8

Supplier product launch process reviewed and tracked for timing; are the necessary resources

planned and available for the development of the project and are changes highlighted?

7.9 Action items registers with follow-up for quality and timing issues.

Total Potential Score

21

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

8.0 - Procurement & Supplier Management

Deployment / Execution

Criteria

8.0

Weight

Score

(0 or 1)

Result

Supplier Selection Process

8.1 All suppliers must pass initial on-site Quality Systems survey before sourcing.

8.2 All suppliers are ISO 9001:2000 or TS 16949:2002 certified or have customer waiver.

8.3 Supplier Directory (Supplier status: Approved / Business Hold / Desource, quarterly updates)

8.5 Dimensional verification of supplier data for CC / SC's

8.6 Follow-up system for rejected or interim approved PPAP's

8.7 PPAP Date Determination & Communication Process

8.8 Supplier Run @ Rate process (risk determination, witnessed / self certify status)

8.9 Supplier Run @ Rate status tracking, follow-up and resolution process

Supplier PPAP process

8.4

Supplier PPAP process (review checklist, all PPAP elements addressed, no marked prints, 100%

compliance or approved SREA, no statements of conformance without raw data).

Supplier Performance Tracking

8.10 Supplier ratings distribution to supply base.

Total Potential Score

22

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

9.0 - Tooling / Machine

Deployment / Execution

Criteria

9.0

Weight

Score

(0 or 1)

Result

Preventive Maintenance / Tooling

9.1 Tooling Preventive Maintenance (PM) schedule available, Tooling work orders show PM is current.

9.2 Tool tracking system with tool number, location, usage, capability and rev.

9.4 Tooling reactive maintenance tracked for feedback for predictive maintenance.

9.5 Tooling design / construction standards.

9.6 Tool build / approval tracking.

9.7 Customer owned tools have clear identification.

Equipment PM (Preventive Maintenance) schedule available. Equipment work orders show

equipment PM is current.

9.9 Equipment tracking system available with equipment number, location, usage, capability and rev.

9.13 Equipment systematically requalified after maintenance / breakdowns

9.14 Maintenance / breakdowns documented and tied to lot traceability records.

9.15 Part related equipment marked with part number / engineering level.

9.16 Maintenance trouble log exist and posted at the machinery.

9.17 Machine control characteristics tracked / controlled at each machine.

9.18 Documented set-up / changeover Work Instructions exist.

9.19 Unreleased or unapproved equipment / tools identified and appropriately stored.

9.3

9.8

9.10

Tooling spare parts and perishable tools inventory list available and maintained including spare part

location and reorder points.

Equipment spare parts inventory list available and maintained including spare part location and

reorder points.

9.11 Equipment reactive maintenance tracked for feedback for predictive maintenance.

9.12

Supplier change / tool move planning, validation & customer approval (supplier and KSS and tooling

audit initiated changes).

Total Potential Score

59

Total Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

10.0 - Receiving Inspection

Deployment / Execution

Criteria

10.0

Weight

Score

(0 or 1)

Result

Receiving Inspection

10.1 Receiving Inspection process (all direct material for PV and production are in scope)

10.2 Verification of current PPAP Approval for supplier and revision being received

10.3 Revision level inspected to is revision level ordered

10.4 CC / SC's checked at a minimum

10.5 Is all incoming raw material has the supplier self-inspection certifications?

10.6 For heat treated parts each box is verified for correct hardness. Dock-to-stock not allowed.

10.7 Plant component issue feedback to Receiving Inspection criteria

10.9 Inspection Results Recorded, not just Pass / Fail or Accept / Reject

10.10 All rejected material is identified and moved to a quarantine area

10.8

10.11

Control Plan & Inspection Records Sheet available. Are incoming goods inspected systematically

according to their specification and according to the control plan ?

If any Dock-to-Stock Program defined, the part must be PPAP approved at current revision, no

Open NCR's, acceptable history, QA Mgr. approval, component criticality considered

Material Review Board (MRB) Process (corrective action responsibility determination, material

10.12 disposition). MRB Process includes QNs/NCRs dispositioned within 48 hours with follow-up and

closure tracking.

10.13

All supplier concerns are tracked, addressed, Corrective Action Report(s) kept on file and verified

for closure.

10.14 Supplier delivery issue resolution process (corrective action, follow-up and closure)

Total Potential Score

46

Actual Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

11.0 - Process Control / Traceability

Deployment / Execution

Criteria

Weight

11.0

Score

(0 or 1)

Result

Core Documents

11.1 APQP documents cross linked by operation sequence and operation number.

11.2 PFMEA is updated for all process and design changes.

11.3 PFMEA being updated to include findings from internal quality as well as customer complaints.

11.4 PFMEA and Control Plan understood to be living documents & updated timely & appropriately.

11.5 PFMEA includes all processes from receiving to shipping.

11.6 RPN's reduction actions are noted and RPN's reduced accordingly.

11.7 PFMEA's are cross functionally reviewed and approved prior to release.

11.8 Control Plans are complete and followed at all times.

Control plans reviewed and updated as appropriate when any of the following occurs: product or

11.10 process changes, processes are found to be unstable or non-capable, inspection method, frequency

is revised.

11.11 Process exists for the application of Statistical Methods, reaction plans and improvement

11.12 CP and PFMEA contain all CC/SC shown on the drawing and spec.

11.13 SPC used on all CC/SC's or equivalent where possible.

11.14 Action take when Ppk<1.67, Cpk<1.33?

11.15 Review process for capability indices and improvement program tracking

11.9

Control Plans include Prototype, Pre-Launch and Production control requirements, as required by

the customer.

Mistake Proofing Process

11.16 Poke Yoke line control sample verification process (each shift at a minimum)

11.17

Are procedures clear, used correctly & test parts available to check and verify functioning of errorproofing?

11.18

Is error-proofing adequate and implemented/ working according to the PFMEA and process control

plan?

11.20 First pieces verification is required after shift start-up, order changes, maintenance.

11.21 Is there an effective First Piece Sample measurement process?

First Piece / Last Piece Inspection and Launch Containment

11.19

11.22

Report no. 1038929 Rev. 01

First Piece / Last Piece Inspection check sheet used with actual data recorded and sign off approval

to begin production.

Launch Containment process. For new program launch an Early Production Containment is in place

and being followed.

Supplier Pre-Qualification Assessment

11.0 - Process Control / Traceability

Deployment / Execution

Criteria

Weight

Score

(0 or 1)

Result

Management of Nonconformances at the Line

11.23

Clear identification and segregation of non-conforming and suspect material as well as control to

prevent misuse.

11.24

Scrap / Rejected Material is identified at all times. Use of the rework or scrap containers understood

and documented for the operators.

11.25 Supervisor or Quality (not operators) control keys, remove defects from process and clear faults.

11.26 Scrap is removed from line every shift at a minimum.

11.27 Rejected Material is identified and moved to quarantine area immediately.

11.30 Operators are responsible for the quality of their work.

11.31 Operators have the authority to shut down lines in the event of nonconforming parts.

11.32 Work In Process minimized. If operations are not bottlenecks, one piece flow being utilized.

Backward Traceability: Lot Traceability System provides traceability from finished product lot

11.33 number / serial number to all process quality data, component / sub-assembly lot numbers and

component raw material lot numbers. Verify system by auditing a random component lot.

Forward Traceability: Lot Traceability System provides traceability from component lot number to all

11.34 sub-assembly and finished assembly lot / serial numbers produced, shipped and where / when

shipped. Verify system by auditing a random component lot.

11.35

First in First Out system used for shipping and for dispersing materials to production. Items used out

of sequence must have documentation to show reason used out of sequence.

11.36

Shelf life tracking includes checking shelf life expiration dates prior to production and also checking

shelf life of inventory on an established schedule.

11.28

Procedures for rework clear and followed. Customer Approval Required. Reverification of parts

through production process when rework is needed.

Operator Control

11.29

Detailed operator Instructions and Visual Aids exist, are visible and followed by all operators.

Operators instructions reflect PFMEA and control plan.

Lot Traceability / Shelf Life Tracking

Total Potential Score

108

Total Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

12.0 Measurement & Calibration

Deployment / Execution

Criteria

12.0

Weight

Score

(0 or 1)

Result

Measurement & Calibration

12.1

Supplier has Metrology capability in house.

12.2

Supplier has the required equipment (CMM, Optical Comparator, Micro vu, etc) to properly check the

features on the parts we wish to source to them?

12.3

Supplier has required expertise in house. (understand GD&T, ability to program and operate CMM,

etc.)

12.4

Calibration control system exists for all gages (including manual gages)

12.5

All measuring devices have an unique identifying number and an inventory log is maintained.

12.6

Calibration frequencies are established and measuring devices reviewed are current.

12.7

Gages / Test Equipment / Standards are calibrated and the calibration data recorded.

12.8

Calibration instructions are controlled and in use.

12.9

Gage R and R studies are performed for the measuring devices, with acceptible results.

Outsourced calibrations are performed by accredited laboratories. Calibrations requested to be

performed by the accredited laboratories fall within the scope of the outside labs certification.

Total Potential Score

39

Total Score

12.10 Master rejects and boundary samples included in calibration system.

12.11

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

13.0 - Employee Orientation / Training

Deployment / Execution

Criteria

13.0

Weight

Score

(0 or 1)

Result

Employee Orientation and Training

13.1 Job descriptions for all positions.

13.2 Required skill levels identified.

13.3 Comprehensive training program for employees by job classification.

13.4 Training of production operators prior to performing production operations.

13.5 Temporary employees trained the same as permanent employees.

13.6 Effectiveness of training is periodically reviewed and includes all employees / job functions

13.7 Skills matrix available for operators.

13.8

On line operator has required skills to perform job based on skill matrix and can demonstrate job

knowledge.

Total Potential Score

24

Total Score

0%

Instructions: Assign score of 1 or 0 in Light Blue colored column.

Score should be assessed based on 100% implementation of all aspects of each question.

Report no. 1038929 Rev. 01

Supplier Pre-Qualification Assessment

14.0 - Document Control / Records Management

Deployment / Execution

Criteria

Weight

Score

(0 or 1)

Result

14.0 Document Control / Records Management Process

14.1 Document Control / Records Management process followed

14.2 Change Communication / Review / Signoff process

14.3 Distribution Process for revised documents.

14.4 Obsolete Documentation Removal Process.

14.5 Engineering change implementation, customer approval process followed

Report no. 1038929 Rev. 01

Total Potential Score

Total Score

0%

You might also like

- Spyder Active Sports Case AnalysisDocument2 pagesSpyder Active Sports Case AnalysisSrikanth Kumar Konduri100% (3)

- A Review On Julie's Manufactring SDN BHD - Chika OgbuehiDocument8 pagesA Review On Julie's Manufactring SDN BHD - Chika OgbuehiChika100% (2)

- F Control of Non - Conforming Product ProcedureDocument3 pagesF Control of Non - Conforming Product ProcedureNgonidzashe Zvarevashe100% (1)

- Supplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDDocument6 pagesSupplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDPratik KarekarNo ratings yet

- Supplier Audit Check SheetDocument33 pagesSupplier Audit Check SheetMotive PostNo ratings yet

- QMS DeliverablesDocument9 pagesQMS DeliverablessteveNo ratings yet

- Supplier Pre Qualification Procedure PDFDocument5 pagesSupplier Pre Qualification Procedure PDFnorlieNo ratings yet

- Vendor Qualification ProcedureDocument2 pagesVendor Qualification ProcedurePrem Goel80% (10)

- Internal Audit Checksheet EMS-OHSASDocument32 pagesInternal Audit Checksheet EMS-OHSASRambir KaushikNo ratings yet

- GM 1927-30 QSB Audit Master - Final011811Document16 pagesGM 1927-30 QSB Audit Master - Final011811Mohammad GadNo ratings yet

- Process Verification Audit ChecklistDocument5 pagesProcess Verification Audit Checklistriki3xNo ratings yet

- ProQC ExampleReport TS16949 Audit PDFDocument39 pagesProQC ExampleReport TS16949 Audit PDFpandajayNo ratings yet

- Summer Internship Project ReportDocument32 pagesSummer Internship Project ReportAbhilasha Singh33% (3)

- A Guide To Preparing For Sales and TradiDocument4 pagesA Guide To Preparing For Sales and TradiBrenda WijayaNo ratings yet

- Effectiveness of The QMSDocument33 pagesEffectiveness of The QMSvavvavNo ratings yet

- Supplier AuditDocument37 pagesSupplier Auditjacksodb100% (1)

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaNo ratings yet

- Supplier Assessment ChecklistDocument2 pagesSupplier Assessment ChecklistCOLONEL ZIKRIA100% (1)

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUNo ratings yet

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- Supplier Process Audit Checklist TemplateDocument8 pagesSupplier Process Audit Checklist TemplateYang LishengNo ratings yet

- Process InteractionsDocument1 pageProcess Interactionscao thanh quocNo ratings yet

- Iso 9001 Toolkit File ListDocument3 pagesIso 9001 Toolkit File ListEl KhanNo ratings yet

- Self Audit Checklist PresentationDocument20 pagesSelf Audit Checklist Presentationnashwan mustafaNo ratings yet

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- Master List of Records 1Document2 pagesMaster List of Records 1Anonymous i3lI9MNo ratings yet

- Quality & Industrial Performance: Supply Chain ManagementDocument50 pagesQuality & Industrial Performance: Supply Chain Managementshivashankar hrNo ratings yet

- MFG Procedure ManualDocument46 pagesMFG Procedure ManualAdinanNo ratings yet

- Turtle Diagram & Its Usage in ISO 9001Document4 pagesTurtle Diagram & Its Usage in ISO 9001Gopalakrishnan100% (1)

- F-PUR-04 Supplier Evaluation FormDocument1 pageF-PUR-04 Supplier Evaluation FormBhavin SukhadiyaNo ratings yet

- QPR 13 Rev-01 Purchase DeptDocument7 pagesQPR 13 Rev-01 Purchase DeptrajshakeeNo ratings yet

- PPAP FundamentalsDocument21 pagesPPAP FundamentalsRajdeep SinghNo ratings yet

- Management Review Meeting ChecklistDocument1 pageManagement Review Meeting ChecklistGaruda84No ratings yet

- Iso 9001 Activity Plan '05Document3 pagesIso 9001 Activity Plan '05jvenrqzNo ratings yet

- CS-P07 - Sales & Marketing Proceduce BackupDocument6 pagesCS-P07 - Sales & Marketing Proceduce BackupIdrus Ismail100% (1)

- Supplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLDocument38 pagesSupplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLsrkadaliNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Excel Tool Prozessaudit VDA 6.3 2010 enDocument29 pagesExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenNo ratings yet

- Supplier Audit ChecklistDocument28 pagesSupplier Audit Checklist88No1FanNo ratings yet

- Supplier Audit Checklist NewDocument7 pagesSupplier Audit Checklist NewsigmasundarNo ratings yet

- CS-P03-HR Recruitment TrainingDocument5 pagesCS-P03-HR Recruitment TrainingIdrus IsmailNo ratings yet

- Supplier Audit ChecklistDocument20 pagesSupplier Audit ChecklistSteven Singleton100% (1)

- Procedure 01 - Control of Documents and RecordsDocument6 pagesProcedure 01 - Control of Documents and Recordssuhara hussainNo ratings yet

- Design Process TurtleDocument2 pagesDesign Process TurtleBAlaNo ratings yet

- Iso IATF 16949 Upgrade Planner and Delta ChecklistDocument14 pagesIso IATF 16949 Upgrade Planner and Delta ChecklistHomero Januncio100% (1)

- Procedure For Control of RecordsDocument3 pagesProcedure For Control of Recordsmatrixmaze50% (2)

- Foreign Vendor Assessment Program PDFDocument13 pagesForeign Vendor Assessment Program PDFAbdhel X-MetaNo ratings yet

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocument16 pagesQC 080000-2005 (2nd Ed) IECQ-HSPMISO VintecomNo ratings yet

- Setting KPIs and Quality ObjectivesDocument48 pagesSetting KPIs and Quality ObjectivesSharaf AgeedNo ratings yet

- Audit Check List (ISO 9001)Document12 pagesAudit Check List (ISO 9001)morshed_mahamud7055No ratings yet

- Adverse Event Log TemplateDocument2 pagesAdverse Event Log TemplateLore LopezNo ratings yet

- Supplier QADocument41 pagesSupplier QAMoraru CiprianNo ratings yet

- KPI ExamplesDocument2 pagesKPI Exampleshrhvdy100% (1)

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 pagesMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanNo ratings yet

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- CS P09 Project ManagementDocument4 pagesCS P09 Project ManagementIdrus IsmailNo ratings yet

- 0606 Supplier Evaluation FormDocument4 pages0606 Supplier Evaluation FormSmitesh VangalwarNo ratings yet

- Procedure - Control of NC ProductDocument4 pagesProcedure - Control of NC ProductAdriana BracamonteNo ratings yet

- ISO 9001 - 2015 - 2020 - October - Management Review - Last DayDocument59 pagesISO 9001 - 2015 - 2020 - October - Management Review - Last DayMatt Andrew Baquiano100% (1)

- ISO 9001 - 2008 ChecksheetDocument14 pagesISO 9001 - 2008 ChecksheetSachin KumbharNo ratings yet

- Supplier Evaluation - SourcingDocument43 pagesSupplier Evaluation - SourcingBalaji ShindeNo ratings yet

- QMS Audit Check SheetDocument7 pagesQMS Audit Check Sheetaboo2uNo ratings yet

- QMS Audit Check SheetDocument7 pagesQMS Audit Check Sheetaboo2uNo ratings yet

- Project Evaluation Plan TemplateDocument8 pagesProject Evaluation Plan TemplateChinh Lê ĐìnhNo ratings yet

- Third Party Regulation Mapping MatrixDocument54 pagesThird Party Regulation Mapping MatrixChinh Lê ĐìnhNo ratings yet

- BP Op Entpr S4hanax Usv1 Prerequisites Matrix en UsDocument20 pagesBP Op Entpr S4hanax Usv1 Prerequisites Matrix en UsChinh Lê ĐìnhNo ratings yet

- 201702fraud Responsibility MatrixDocument4 pages201702fraud Responsibility MatrixChinh Lê ĐìnhNo ratings yet

- Fraud Policy Decision MatrixDocument15 pagesFraud Policy Decision MatrixChinh Lê ĐìnhNo ratings yet

- Control MatrixDocument1 pageControl MatrixChinh Lê ĐìnhNo ratings yet

- Risk Assessment MatrixDocument19 pagesRisk Assessment MatrixChinh Lê ĐìnhNo ratings yet

- 201602AP Internal Controls 101Document7 pages201602AP Internal Controls 101Chinh Lê ĐìnhNo ratings yet

- Requirements Traceability Matrix Template GuidelinesDocument5 pagesRequirements Traceability Matrix Template GuidelinesChinh Lê ĐìnhNo ratings yet

- Need: 0 Needless 1 Nice To Have 2 Desireable 4 Mandatory. RankDocument2 pagesNeed: 0 Needless 1 Nice To Have 2 Desireable 4 Mandatory. RankChinh Lê ĐìnhNo ratings yet

- It Audit Risk MatrixDocument16 pagesIt Audit Risk MatrixChinh Lê ĐìnhNo ratings yet

- 201607COSO ICF C3 Cont - Act Payroll Calculating Salaries WagesDocument5 pages201607COSO ICF C3 Cont - Act Payroll Calculating Salaries WagesChinh Lê ĐìnhNo ratings yet

- Managing Key Business ProcessesDocument12 pagesManaging Key Business ProcessesMNo ratings yet

- Assistant Manager - CSR (Mumbai)Document2 pagesAssistant Manager - CSR (Mumbai)Kumar GauravNo ratings yet

- BNI Bank StatementDocument1 pageBNI Bank Statementelisio.silvaNo ratings yet

- Kotler Mm15e Inppt 10Document20 pagesKotler Mm15e Inppt 10Wildan BagusNo ratings yet

- Assignment For First Sem CMDocument4 pagesAssignment For First Sem CMnishant khadkaNo ratings yet

- Functional RequirementDocument6 pagesFunctional RequirementmanishNo ratings yet

- Iso 45001Document106 pagesIso 45001Black Gold100% (2)

- Details FM DATADocument212 pagesDetails FM DATAAbhishek MishraNo ratings yet

- Affect of Branding On Consumer Purchase Decision: Research ProjectDocument7 pagesAffect of Branding On Consumer Purchase Decision: Research ProjectPooja RawatNo ratings yet

- Assignment 2 - Termination of EmploymentDocument5 pagesAssignment 2 - Termination of EmploymentAraceli Gloria-FranciscoNo ratings yet

- Ledger - Ajanta Shoes (India) Private LimitedDocument10 pagesLedger - Ajanta Shoes (India) Private LimitedSuraj MehtaNo ratings yet

- ICAEW - Accounting 2020 - Chap 2Document56 pagesICAEW - Accounting 2020 - Chap 2TRIEN DINH TIENNo ratings yet

- Equicapita Update - Thomas Syvret Joins Investment TeamDocument1 pageEquicapita Update - Thomas Syvret Joins Investment TeamEquicapita Income TrustNo ratings yet

- BUAD 807 SummaryDocument6 pagesBUAD 807 SummaryZainab Ibrahim100% (1)

- Sharda dss10 PPT 04Document38 pagesSharda dss10 PPT 04Abdulmajeed AlshehriNo ratings yet

- AP.3404 Audit of Cash and Cash EquivalentsDocument5 pagesAP.3404 Audit of Cash and Cash EquivalentsMonica GarciaNo ratings yet

- Actividad de Aprendizaje 12 Evidencia 4 Questionnaire HR VocabularyDocument12 pagesActividad de Aprendizaje 12 Evidencia 4 Questionnaire HR VocabularyJhonJaLopezNo ratings yet

- Compensation Management at Tata Consultancy Services LTDDocument4 pagesCompensation Management at Tata Consultancy Services LTDNishaant S Prasad0% (2)

- Respected Recruiting Manager: MOBILE: 0563699037Document5 pagesRespected Recruiting Manager: MOBILE: 0563699037Mahboob Ali Khan100% (2)

- XYZ Investing INC. Trial BalanceDocument3 pagesXYZ Investing INC. Trial BalanceLeika Gay Soriano OlarteNo ratings yet

- E3 Operating AuditingDocument21 pagesE3 Operating AuditingPaupauNo ratings yet

- PPT, Final Report, Kshitij Negi, C-41Document12 pagesPPT, Final Report, Kshitij Negi, C-41Kshitij NegiNo ratings yet

- Marketing Strategy of NestléDocument27 pagesMarketing Strategy of Nestléshami00992No ratings yet

- Para BankingDocument57 pagesPara BankingAjyPri100% (1)

- Seeing The World Differently Litigation AriDocument4 pagesSeeing The World Differently Litigation AriTC 15 SPEAKER 2No ratings yet

- MKT624 - Final Term Quiz Master File SolvedDocument69 pagesMKT624 - Final Term Quiz Master File SolvedAzeem AhmadNo ratings yet