Professional Documents

Culture Documents

Us 4207797

Uploaded by

fghdfjerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 4207797

Uploaded by

fghdfjerCopyright:

Available Formats

I

United States Patent [19]

[11]

4,207,797

Gyiirik

[45]

Jun. 17, 1980

[54] MAGAZINE FOR AN AUTOMATIC WEAPON

[76] Inventor Joseph J Gy?rik, 3043 15th St

'

'

N_W_

gton DC 20009

longitudinal magazine axis and extending parallel

thereto. Each storage chamber is adapted to receive

[21] APPL No.1 41,471

cartridges in an end-to-end contacting series. The maga

zine further has a loading arrangement for providing

access to the storage chambers at a rear end of the

[22] Filed;

magazine:

separate folllozer sfprings arranged to extiend

into eac storage 0 am er or urging t e cartri ges

E58}

May 22, 1979

laccliz

0: ............................................

'''' '

'

..

e 42/37 39

[56]

24 33 35

D 3'3 B 33BA 34:

References Cited

U;S_ PATENT DOCUMENTS

_

igggg?

122;;

gate

therein

arranged

towardsatathe

front

front

endend

of the

of the

magazine;

magazine;

a and a

feeding arrangement for advancing the cartridges from

the storage chambers to the feeding gate. The feeding

arrangement has a feeding wheel which is mounted at

the front end of the magazine for rotation about the

magazine axis and which is divided into feeding cham

..................................... ..

be. each repeatedly communicating with each storage

""""""""""""""""""" "

chamber upon rotation of the feeding wheel for receiv

FOREIGN PATENT DOCUMENTS

6994 of 1888 United Kingdom ........................ .. 42/6

Primary Examiner-Stephen C. Bentley

ing a cartridge therefrom. The feeding gate successively

mmuhicates with the feeding chambers as the feeding

wheel rotates for sequentially receiving cartridges

Attorney, Agent, or FirmSpencer & Kaye

therefrom. A manually windable power spring is con

nected with the feeding wheel for exerting a torque

[57]

thereon.

ABSTRACT

A magazine for an automatic weapon has a plurality of

storage chambers arranged in a circular array about a

7 Claims, 8 Drawing Figures

ill

WA.

muggy-glutamate! u..v_

29

- "I"!

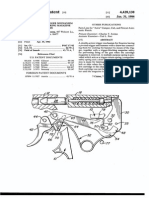

Patent

Jun. 17, 1980

Sheet 1 of 2

I/)lh1,2%};i.\

g}!

26

El?!

FIG.

I

36

FIG

2

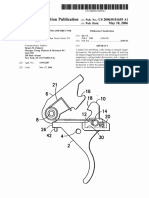

US. Patent

Jun. 17, 1980

Sheet 2 of2

4,207,797

FIG.4

FIG. 5

FIG. 3

FIG. 8

FIG]

4,207,797

wheel for exerting a torque thereon and an arrangement

for winding the feeding spring.

MAGAZINE FOR AN AUTOMATIC WEAPON

It is an advantage of the magazine according to the

invention that, by virtue of the arrangement of the car

BACKGROUND OF THE INVENTION

This invention relates to a magazine for an automatic 5 tridges in independent series, a malfunctioning or break

down in one series will not necessarily mean the inter

weapon, particularly a small weapon, such as a subma

ruption of the ?ring of the weapon.

chine gun.

It is a further advantage of the magazine according to

Generally, the magazines may be of the drum type or

the box type. It is generally a disadvantage of drum- 10 the invention that it is adapted for insertion into a posi

tion in which it is at least approximately parallel to the

type magazines that they are bulky, they are dif?cult to

barrel and is situated underneath the bolt of the weapon.

load and they generally cannot be attached or detached

with ease. Further, ?ring from a lying position is un

BRIEF DESCRIPTION OF THE DRAWINGS

comfortable due to the particular location of the drum

FIG. 1 is a side elevational view of a preferred em

magazine on the weapon. More recently, the box-type

magazines have been more frequently used. In this type

of magazine the ?ring comfort has been improved with

the lateral arrangement of the magazine. This, however,

is disadvantageous because of the signi?cant additional

dimension taken up by the weapon. In the known Hill

submachine gun, the length dimension of the box-type

magazine is parallel to the barrel and the magazine,

which is disposable, is arranged above the bolt.

bodiment of the invention.

FIG. 2 is an axial sectional view of the preferred

embodiment'taken along line II-II of FIG. 6.

FIG. 3 is a sectional view taken along line III-III of

FIG. 1.

FIG. 4 is an axial sectional view of a detail of the

structure shown in FIG. 2 depicting the components in

a different operational position.

The invention more particularly relates to a box-type

magazine whose longitudinal axis is parallel to the bar

rel.

It is a further general disadvantage of known maga

zines for automatic weapons that the cartridges are

arranged in the magazine in a single series so that a

malfunctioning or jamming within the magazine is

likely to interrupt altogether the feed of cartridges to

the feeding gate of the magazine, thus preventing the

weapon from ?ring.

25

FIG. 5 is an end view as seen in the direction of ar

rows V-V of FIG. 4.

FIG. 6 is an end view as seen in the direction of ar

rows VI-VI of FIG. 1.

FIG. 7 is a sectional view taken along line VII-VII

of FIG. 1.

FIG. 8 is a schematic view of a submachine gun in

corporating the invention.

DESCRIPTION OF THE PREFERRED

EMBODIMENT

Turning now to FIGS. 1, 2 and 3, the magazine gen

It is an object of the invention to provide an im 35 erally indicated at 1 has a cylindrical body 2 which has

proved box-type magazine for an automatic weapon

a longitudinal axis A. Within the body 2 there are pro

such as a submachine gun which is of improved reliabil

vided a plurality of axially parallel channels which are

ity, which permits a comfortable ?ring from a lying

SUMMARY OF THE INVENTION

position or from cover, which in no way hinders motion

through dif?cult terrain, such as bushy areas, and which

has an increased capacity without a corresponding in

crease in dimensions.

These objects and others to become apparent as the

arranged in an even circumferential distribution about

the axis A. In the illustrated example there are shown

six channels 3-8, respectively. The channels 3, 4, 5, 6

and 7 constitute storage chambers in which cartridges 9

are received in an end-to-end relationship. The channel

8 accommodates a spring-loaded positioning device to

tion, according to which, brie?y stated, the magazine 45 be described later. It is noted that in practice the num

ber of the storage chambers may be nine, each having a

for an automatic weapon has a plurality of storage

speci?cation progresses, are accomplished by the inven

chambers arranged in a circular array about a longitudi

nal magazine axis and extending parallel thereto; each

storage chamber is adapted to receive cartridges in an

end-to-end contacting series. The magazine further has

a loading mechanism for providing access to the storage

chambers at the rear end of the magazine; separate

follower springs arranged to extend into each storage

chamber for urging the cartridges therein towards the

front end of the magazine; a feeding gate arranged at the

front end of the magazine; and a feeding mechanism for

advancing the cartridges from the storage chambers to

the feeding gate. The feeding mechanism includes a

feeding wheel mounted at the front end of the magazine

for rotation about the magazine axis with respect to the

storage chambers. The feeding wheel is divided into

feeding chambers, each repeatedly communicating with

capacity of nine cartridges.

Also referring to FIGS. 4, 5 and 6, at the rear end of

the cylindrical body 2, there is, coaxially with the axis

A, rotationally mounted a loading head 10. Within the

loading head 10 there are provided ?ve spring cham

bers 11-15 and a cylindrical loading port 16. The spring

chambers 11-15 are closed at one end by the radial rear

terminal wall 10a of the loading head 10, while the

loading port 16 is open at both ends. The spring cham

bers 11-15 and the loading port 16 are, when viewed

together, so arranged radially with respect to the axis A

and have such an angular circumferential distribution

that upon rotation of the loading head 10, the compo

nents 11-16 are brought into respective alignment with

the channels 3-8 arranged in the cylindrical body 2. To

provide for a positive successive alignment of these

components, a positioning device of the click-type is

accommodated in the channel 8 of the body 2. The

each storage chamber upon rotation of the feeding

wheel for receiving a cartridge therefrom. The feeding

gate successively communicates with the feeding cham 65 positioning device comprises a positioning plug 17

urged outwardly from the body 2 in the direction of the

bers upon rotation of the feeding wheel for sequentially

loading head 10 by means of a positioning spring 18.

receiving cartridges therefrom. The feeding mechanism

The external terminus of the positioning plug 17 is re

further has a feeding spring connected with the feeding

4,207,797

ceived in the open end of that one of the respective

components 11-16 which is momentarily in alignment

with the positioning device 17, 18. In this manner the

loading head 10 is immobilized in a position in which

with each component 3-8 in the body 2 there is in align

ment a component 11-16 provided in the loading head

10. The immobilizing force of the positioning spring 18

can be overcome upon exerting a manual torque on the

loading head 10 to rotate it into a subsequent aligned

position as will be discussed in greater detail later.

Each spring chamber 11-15 carries a follower coil

spring 19 which engages, at one end, the inner face of

the rear wall 10a of the loading head 10. At its other

end, each follower spring 19 carries a follower plunger

?guration as illustrated in FIG. 2 for clearing two

pickup blades 34 (only one shown in FIG. 7) attached to

the inner wall of the feed housing 28 in the vicinity of

the feeding gate 33, on either side of the vanes 31. The

purpose of the pickup blades 34 is to guide the cartridge

into the feeding gate 33 from the respective feeding

chamber 32 as the latter moves past the feeding gate 33.

On the shaft 30 there is further rotatably mounted a

feeding spring drum 35 in which there is arranged a

power spring 36. At its inner end, the power spring 36

is af?xed to a hub portion of the feeding wheel 29,

whereas its outer end is secured to an inner wall of the

feeding spring drum 35.

When the feeding wheel 29 is blocked in its rotation

20, which is adapted to engage the outermost cartridge 15 by a cartridge dwelling in the feeding gate 33 as will be

in the respective aligned storage chambers 3-7, thus

described later, a manual rotation of the feeding spring

exerting a forwardly urging force on each series of

drum 35 will cause winding of the power spring 36 as a,

cartridges situated in the*respective storage chambers

result of the relative rotation between the feeding spring

3-7. The follower springs 18 are so designed that in the

drum 35 and the feeding wheel 29. A one-way brake

fully compressed state they are, together with the entire 20 assembly (not shown) cooperating with the feeding

length of the respective follower plunger 20, fully re

spring drum 35 and the feeding wheel 29 ensures that

ceived in the respective spring chamber 11-15 as will be

the feeding spring drum 35 can be rotated only unidirec

described later.

tionally in the sense of winding the power spring 36.

The tubular body 2 further has a central axial space

Thus, when the feeding wheel 29 is blocked and the

21 in which there is longitudinally displaceably and 25 feeding spring drum 35 has been rotated through a pre

rotatably supported an arming rod 22. During normal

determined number of turns and then released, the feed

operation of the magazine, the arming rod 22 is in its

ing spring 36 exerts a torque on the feeding wheel 29. It

position as illustrated in FIG. 2.

To the arming rod 22, at the rear terminus thereof as

is thus seen that as long as there is no cartridge in the

22 is manually displaced towards its pulled-out position

magazine 1 has at both ends axially projecting holding

pins 37 (as seen in FIGS. 1 and 2) which cooperate with

feeding gate 33, the feeding wheel 29 is free to rotate

viewed in FIG. 2, there is secured a radially oriented,

under the force of the power spring 36.

manually engageable arming lever 23 which in its nor

FIG. 8 shows the magazine 1 in place in the auto

mal position, as shown in FIGS. 2 and 6, closes off the

matic weapon, such as a submachine gun. As seen, the

loading port 16 from the outside.

longitudinal magazine axis is generally parallel to the ,

To the front terminus of the arming rod 22 there is

barrel of the weapon and the magazine is situated below

secured an arming disc 24 which, when the arming rod 35 the barrel and between the grip and the butt plate. The

as shown in FIG. 4, it carries with it all the follower

plungers 20 by virtue of engagement with respective

respective holes or depressions in the weapon to hold

lugs 25 attached to each follower plunger 20 and pro

the magazine 1 in place. One of the depressions may be

jecting into the central space 21. Detent pins 26 are 40 provided in a manually engageable leaf-spring member

secured to the arming rod 22 at a distance from the

38 which, when pushed rearwardly, releases the maga

arming disc 24. The detent pins 26, as the arming rod 22

zine 1 from the weapon.

is pulled against the force of the follower springs 19,

In the description which follows, the operation of the

pass through slots 27 provided in the rear wall 10a of

above-described magazine will be set forth.

the loading head 10 and thereafter upon rotating the 45 The operation of the magazine may be divided into a

arming rod 22 about 90, the detent pins 26 are brought

loading phase in which the magazine is charged with

out of alignment with the slots 27 and into alignment

the cartridges and an emptying phase during which the

with the depressions 27a provided in the wall 10a of the

cartridges are fed into the ?ring weapon.

loading head 10. Then, after releasing the pull-back

For loading the magazine, the latter is lifted out of the

lever 23, the springs 19, via the lugs 25 and the arming

weapon and, as the ?rst step, a cartridge is manually

disc 24, urge the detent pins 26 into the depressions 27a.

placed from the outside directly into the feeding gate 33

In this manner the arming rod 22 can be immobilized in

for thus preventing rotation of the feeding wheel 29 as

its pulled-out position as shown in FIGS. 4 and 5.

may be observed in FIG. 7. Then, the power spring 36

Turning now in particular to FIGS. 1, 2 and 7, to the

front end of the tubular body 2 there is affixed a feed

is wound by turning the feeding spring drum 35 through

housing 28 in coaxial relationship with respect to the

axis A. Withing the feed housing 28 there is accommo

dated a feeding wheel 29 which is rotatably supported

tion the assembly formed of the feeding spring drum 35,

several turns and then releasing the same. In this posi

the power spring 36 and the feeding wheel 29 is immobi

lized and a torque is exerted on the feeding wheel 29 by

on a shaft 30 secured to the tubular body 2 in coaxial

the power spring 36, whereby a feeding vane 31 abuts

relationship with the axis A. The feeding wheel 29 has 60 the cartridge positioned in the gate 33.

six radially extending uniformly distributed feeding

Next, the arming lever 23 of the arming rod 22 is

vanes 31; each two adjoining feeding vanes 31 de?ne,

manually grasped and the arming rod 22 is pulled out.

between themselves, a feeding chamber 32 which at its

During its motion towards the right (as viewed in FIG.

outside, is bounded by a wall portion of the feed hous

2), the arming disc 24, by virtue of the lugs 25 entrains

ing 28. The feed housing 28 has an aperture through 65 the follower plungers 20, causing a compression of the

which a cartridge may pass from the feeding chambers

follower springs 19. In the ?nal phase of the outward

into a feeding gate 33 of conventional structure. Each

pull of the arming rod 22, as the detent pins 26 have

feeding vane 31 has a radially outwardly tapering con

passed the respective slots 27, all the follower springs

4,207,797

19, together with their associated follower plungers 20,

ber division closer to the feeding gate 33. It is thus seen

have been pulled back in their entirety into the respec

that as the feeding wheel 29 comes to a rest after the

tive spring chambers 11-15 of the loading head 10. In

?rst cartridge has been advanced by the feeding wheel

this position of the follower springs 19, the loading head

29 into the feeding gate 33, no re?ll of any of the feeding

10 is free to be rotated with respect to the tubular body 5 chambers 32 from the storage chambers 3-7 has yet

2. As it has been described earlier in connection with

taken place.

FIG. 4, the arming rod 22 is immobilized in the armed

As the second cartridge is removed by the bolt from

state of the follower springs 19 by bringing the detent

the feeding gate 33, the feeding wheel 29 rotates again,

pins 26, by means of a 90 turn of the arming rod 22, out

advancing a new cartridge into the feeding gate 33. At

of alignment with the slots 27 and allowing the detent

the same time, the ?rst empty feeding chamber 32 ar

pins 26 to rest in the depressions 27a of the loading head

rives into alignment with the storage chamber 7. Thus,

wall 100. Since now the arming lever 23 is removed

the leading cartridge in the storage chamber 7 is ad

from the loading head 10, the loading port 16 of the

vanced, by the follower spring 19, into the empty feed

loading head 10 is accessible from the outside. The

ing chamber 32. Since the other four feeding chambers

loading port 16 in the loading head 10 is brought into 15 32 are still loaded, no charging from the other storage

alignment with a ?rst one of the storage chambers 3-7

chambers 3-6 takes place at this time.

(by a manual rotation of the loading head 10) where

The above-described stepwise operation, that is, the

upon the cartridges are fed consecutively into the stor

re?lling of an empty feeding chamber from the storage

age chamber in an orientation as shown in FIG. 2. The

chamber 7 takes place until the storage chamber 7 is

leading cartridge assumes its ?nal position in the respec 20 emptied and the lug 25 of the follower plunger 20 is

tive aligned feeding chamber 32 of the feeding wheel

pressed by the follower spring 19 against the arming

29. After the first storage chamber is ?lled, the loading

disc 24. In this manner the follower plunger 20 is pre

head 10 is rotated until, as indicated by the click of

vented from being advanced by the follower spring 19

the positioning device 17, 18, the loading port 16 is

into the momentarily aligned feeding chamber 32. Since

brought into alignment with the following storage 25 thereafter

the empty feeding chamber is no longer re

chamber. This loading operation is continued until all

plenished

from

the storage chamber 7, it arrives in an

?ve storage chambers 3-7 are charged with cartridges.

empty state into alignment with the next storage cham

Thereafter, the arming rod 22 is manually slightly

ber 6. Thus, now the loading of the feeding chambers 32

pulled back and rotated to bring the detent pins 26 into

alignment with the slots 27 and then the arming rod 22 30 occurs solely from the storage chamber 6 until the stor

age chamber 6 has expended the last cartridge.

is shifted from its pulled position shown in FIG. 4 into

In the above-described manner, all the storage cham

its normal position shown in FIG. 2. The loading phase

bers

7-3 which remain stationary during operation are

is now completed: all the storage chambers 3-7 are

consecutively emptied.

?lled with cartridges which are urged towards the front

end of the magazine by the respective follower springs 35 Should in any of the storage chambers 3-7 jamming

occur, the charging of the feeding chambers 32 may

19 and further, a torque is exerted on the feeding wheel

continue from the other storage chambers and thus the

29 which, however, is prevented from rotating due to

jamming or other malfunction in one storage chamber

the presence of a cartridge in the feeding gate 33.

does not halt the operation of the magazine, as long as

Subsequently, the loaded magazine 1 is placed into

the weapon and thus it assumes a position as illustrated 40 at least one other loaded storage chamber is still present.

The magazine will be empty as the last cartridgein FIG. 8.

which was the last in the series accommodated in the

Turning now to the emptying phase, as the weapon is

storage chamber 3-is removed from the feeding gate

?red, the bolt (not shown) of the weapon moves for

33 by the bolt of the weapon.

ward and in a conventional manner pushes the cartridge

It is to be understood that the above description of

in a forward direction out of the feeding gate 33 in the 45

the preferred embodiments is susceptible to modi?ca

axial direction into the barrel of the weapon.

tions, changes and adaptations, and the same are in

Referring now in particular to FIG. 7, as the car

tended to be comprehended within the meaning and

tridge 9 has left the feeding gate 33, the feeding wheel

range of equivalents of the appended claims.

29 is free to rotate and, as a result, a subsequent feeding

chamber 32 of the feeding wheel 29 is brought immedi 50 What is claimed is:

1. A magazine for an automatic weapon comprising

ately underneath the feeding gate 33. During this mo

in combination:

tion the trailing vane 31 bounding the last-named feed

ing chamber 32 displaces, with the cooperation of the

pickup blades 34, the cartridge upwardly into position

within the feeding gate 33. Thus, in this manner, a new 55

(a) means de?ning a plurality of stationary storage

chambers arranged in a circular array about a lon

gitudinal magazine axis and extending parallel

cartridge is ready for removal from the feeding gate 33

by the bolt of the weapon for ?ring the next shot. Thus,

thereto; each said storage chamber being adapted

as illustrated in FIG. 7, at the moment the feeding wheel

29 assumes its new position, one of the feeding cham

series;

(b) loading means for providing access to said storage

bers 32, namely the chamber which previously was

underneath the feeding gate 33, is empty. This empty

chamber 32 in the position shown in FIG. 7, is now in

(0) separate follower springs arranged to extend into

each storage chamber for urging the cartridges

alignment with the channel 8 which is not a storage

chamber, but which, at its right-hand end, accommo

dates the positioning device 17, 18 as described before. 65

Apart from the round advanced into the feeding gate

33, each cartridge originally positioned in its respective

feeding chamber 32 has been rotated one feeding cham

to receive cartridges in an end-to-end contacting

_

chambers at a rear. end of the magazine;

therein towards a front end of the magazine;

(d) a feeding gate arranged at said front end of the

magazine; and

(e) feeding means for advancing the cartridges from

said storage chambers to said feeding gate; said

feeding means including

4,207,797

4. A magazine as de?ned in claim 3, wherein said

arming means comprises an arming rod arranged sustan

(l) a feeding wheel mounted at said front end of the

magazine for rotation about said axis with re

tially in alignment with said axis; spring-engaging

spect to said storage chambers; said feeding

means secured to said arming rod for at least indirectly

wheel being divided into feeding chambers, each

repeatedly communicating with each said stor

engaging said follower springs; said arming rod having

a normal position in which it is substantially in its en

age chamber upon rotation of said feeding wheel

for receiving a cartridge therefrom; said feeding

tirety within the confines of the magazine and a pulled

out position in which a substantial part thereof projects

gate being arranged to successively communi

beyond said loading head externally of the magazine;

cate with said feeding chambers upon rotation of

said pulled-out position constituting said arming posi

said feeding wheel for sequentially receiving

tion; and means for maintaining said arming lever in said

pulled-out position while cartridges are introduced into

cartridges therefrom;

(2) a power spring connected with said feeding

said storage chambers through said loading port.

wheel for exerting a torque thereon; and

5. A magazine as defined in claim 4, wherein said

(3) means for manually winding said power spring. 15 arming means further comprises an arming lever at

2. A magazine as de?ned in claim 1, wherein the

tached to said arming rod and situated externally of said

loading head; said arming lever being in engagement

number of said feeding chambers is greater by one than

with said loading head and covering said loading port

the number of said storage chambers.

when said arming rod is in its said normal position; said

3. A magazine as de?ned in claim 2, wherein said

arming lever being spaced from said loading head and

uncovering said loading port when said arming rod is in

loading means comprises a loading head mounted at

said rear end of the magazine for rotation about said axis

its pulled-out position.

with respect to said storage chambers; said loading head

6. A magazine as defined in claim 4, further compris

including a plurality of spring chambers and a loading

ing follower plungers, one mounted at an end of each

port arranged in a circular array about said axis; the

follower spring for engaging the trailing cartridge

number of said spring chambers equalling the number of 25 said

in the end-to-end contacting series in the respective

said storage chambers; each said spring chamber receiv

storage chamber and further wherein said spring-engag

ing a separate one of said follower springs; further com

ing means comprises an arming disc attached to said

prising a manually engageable arming means movable

arming rod and arranged for abutting a portion of each

said follower plunger for moving said follower plungers

with said arming disc when said arming rod is moved

from said normal position into said pulled-out position.

into an arming position for compressing simultaneously

all said follower springs fully into the respective spring

chambers for permitting manual rotation of said loading

head with respect to said storage chambers to bring said

7. A magazine as defined in claim 6, wherein said

loading port consecutively into alignment with said

storage chambers for introducing cartridges thereinto

through said loading port.

portion of each said follower plunger comprises a lug

35 projecting into the traveling path of said arming disc.

#

50

SS

65

You might also like

- CMMG Banshee Owner ManualDocument24 pagesCMMG Banshee Owner ManualDerek LoGiudice100% (1)

- Instruction-Manual CZ 805 BREN enDocument25 pagesInstruction-Manual CZ 805 BREN enRazza Willi60% (5)

- Ajax Model Engineer 1947Document4 pagesAjax Model Engineer 1947Stewart RunnallsNo ratings yet

- Parkerizing 200: Technical BulletinDocument6 pagesParkerizing 200: Technical BulletinJony RahmanNo ratings yet

- Orca Docs V5.3Document25 pagesOrca Docs V5.3camlasutriNo ratings yet

- ChicopeerfDocument15 pagesChicopeerfRomG78No ratings yet

- Car Maintainer, Group B: Passbooks Study GuideFrom EverandCar Maintainer, Group B: Passbooks Study GuideNo ratings yet

- Basic Markmanship Pistol Manipulation Malfunction Drills and Range CommunicationsDocument16 pagesBasic Markmanship Pistol Manipulation Malfunction Drills and Range CommunicationsRuby Jane Sintin PenaNo ratings yet

- Ruger P85 ManualDocument32 pagesRuger P85 ManualGene Herman0% (1)

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Post 6 38604 Reifgraber AutoDocument14 pagesPost 6 38604 Reifgraber AutoAoolf ManNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Tel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Document4 pagesTel - Escope Mounting FDR Guns.: N0. 69 - , 248. V ' Patented Lan. I4, - 902Radim KadlecNo ratings yet

- NAA .32 ACP专利 PDFDocument8 pagesNAA .32 ACP专利 PDFJin SongNo ratings yet

- Mannlicher Pistol PatentDocument10 pagesMannlicher Pistol PatentAndrew NicolleNo ratings yet

- Manuale CZ200Document11 pagesManuale CZ200gatto61No ratings yet

- Us 20060101695Document11 pagesUs 20060101695galak12001100% (1)

- Tap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadDocument1 pageTap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadPliskinAJNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- Mossberg Brownie Barrel PDFDocument1 pageMossberg Brownie Barrel PDFCarlos sandoval100% (2)

- AKT020 Rivet Jaws InstructionsDocument12 pagesAKT020 Rivet Jaws InstructionsDale WadeNo ratings yet

- Pressure Air GunDocument7 pagesPressure Air GunyuehanNo ratings yet

- FN 98 Mauser Model 98 Rifle Operators ManualDocument28 pagesFN 98 Mauser Model 98 Rifle Operators ManualAdam Ward100% (1)

- GG2 Operator's ManualDocument30 pagesGG2 Operator's ManualWerner Patric WengNo ratings yet

- Ruger 22-45 Parts PicturesDocument4 pagesRuger 22-45 Parts Picturesapi-3840428No ratings yet

- Making and Using Reamers: Part 1Document50 pagesMaking and Using Reamers: Part 1angelines123No ratings yet

- Electrode Properties EdmDocument6 pagesElectrode Properties Edmomer21No ratings yet

- UZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Document60 pagesUZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Ricardo C TorresNo ratings yet

- Report Gundriling AAMAstakhovDocument27 pagesReport Gundriling AAMAstakhovGyörgy Murvai100% (1)

- Page 18Document1 pagePage 18frank1615100% (2)

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- VZ 58 Shell DeflectorDocument15 pagesVZ 58 Shell DeflectoromikamiNo ratings yet

- AR Module Trigger System: JARD, IncDocument4 pagesAR Module Trigger System: JARD, IncJames McEwenNo ratings yet

- How To Make A Babbitting MandrelDocument1 pageHow To Make A Babbitting MandrelJason BowmanNo ratings yet

- Product Instructions - Trigger Guard Rivet Drilling Jig Instructions PDFDocument3 pagesProduct Instructions - Trigger Guard Rivet Drilling Jig Instructions PDFFrank MeekerNo ratings yet

- FN FAL Gas Block Conversion InfoDocument2 pagesFN FAL Gas Block Conversion InfoAdam HemsleyNo ratings yet

- Hamilton Rifle ConstructionDocument5 pagesHamilton Rifle Constructionposchul2003No ratings yet

- Dell 2145cn Service Manual PDFDocument208 pagesDell 2145cn Service Manual PDFMārtiņš DreijersNo ratings yet

- Technical Details For Adjusting The Bam b50 51Document57 pagesTechnical Details For Adjusting The Bam b50 51jamman6969No ratings yet

- Mossberg Brownie Grip Frame-1Document1 pageMossberg Brownie Grip Frame-1angel123100% (2)

- 192 Office/Tech:: Shotgun IndexDocument16 pages192 Office/Tech:: Shotgun IndexStan BrittsanNo ratings yet

- Semiautomatic Rifle SharacDocument3 pagesSemiautomatic Rifle SharacOlegValNo ratings yet

- 180 Misc .DXFDocument392 pages180 Misc .DXFNester Tovar0% (1)

- Bolt Action 1Document10 pagesBolt Action 1lucamorlandoNo ratings yet

- M1 Garand Barrel Replacement  " New BarrelDocument35 pagesM1 Garand Barrel Replacement  " New BarrelToschanoNo ratings yet

- Patented Nov. I3, 900.: A. V0N Zeke A. K. RédlDocument3 pagesPatented Nov. I3, 900.: A. V0N Zeke A. K. Rédlcll1968No ratings yet

- Tap & Drill Chart W - Decimal Inch & MetricDocument10 pagesTap & Drill Chart W - Decimal Inch & MetricGanesh NatarajanNo ratings yet

- Patented May 28, 1912.: Air 4. - GentsDocument12 pagesPatented May 28, 1912.: Air 4. - GentsСлэйтер Строительная компанияNo ratings yet

- 870 Detent Staking PunchDocument1 page870 Detent Staking PunchZardoz10900% (1)

- AutoSpeed - DIY Digital AnemometerDocument4 pagesAutoSpeed - DIY Digital Anemometerarjuna1210No ratings yet

- AMT LightningDocument9 pagesAMT LightningJustinNo ratings yet

- MD Profiler Instruction ManualDocument11 pagesMD Profiler Instruction ManualTatiana Trenogina100% (1)

- Surface Grinder ManualDocument11 pagesSurface Grinder ManualRandyWilsonNo ratings yet

- Dormer Reamer Tolerances PDFDocument12 pagesDormer Reamer Tolerances PDFHenrique MarquesNo ratings yet

- Rebuild ManualDocument55 pagesRebuild Manualaccujack0% (1)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- United States Patent (191: Sullivan Et A1Document21 pagesUnited States Patent (191: Sullivan Et A1fghdfjerNo ratings yet

- Unlted States Patent (19) (11) Patent Number: 5,335,579Document8 pagesUnlted States Patent (19) (11) Patent Number: 5,335,579fghdfjerNo ratings yet

- United States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993Document13 pagesUnited States Patent (191 (11) Patent Number: 5,259,288: Vatsvog (45) Date of Patent: Nov. 9, 1993fghdfjerNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007Document26 pagesUnited States Patent: (12) (10) Patent N0.: US 7,213,519 B2 Wiley Et Al. (45) Date of Patent: May 8, 2007fghdfjerNo ratings yet

- Kwa Operator's Manual - Km4, Sr10, Km4 RisDocument20 pagesKwa Operator's Manual - Km4, Sr10, Km4 RisMarc LaBarberaNo ratings yet

- Golden Boy Web ManualDocument12 pagesGolden Boy Web ManualDaleen HealyNo ratings yet

- 1911manual 5Document64 pages1911manual 5jackNo ratings yet

- Henry Pump Action - H003T RiflesDocument11 pagesHenry Pump Action - H003T RiflesMaster ChiefNo ratings yet

- United United: States Statespatent Patent Patent PatentDocument21 pagesUnited United: States Statespatent Patent Patent Patentliequieze oilgavaragNo ratings yet

- Instruction Manual CZ 455Document18 pagesInstruction Manual CZ 455huzunNo ratings yet

- Item Fucntion Potential Failure Mode Potential Effects of Failure Potential Cause of Failure Current Design ControlsDocument2 pagesItem Fucntion Potential Failure Mode Potential Effects of Failure Potential Cause of Failure Current Design ControlsMk ReddyNo ratings yet

- CZ Mod. 58: Instruction ManualDocument31 pagesCZ Mod. 58: Instruction ManualToni TursićNo ratings yet

- Izh 43 2004Document26 pagesIzh 43 2004grugnirNo ratings yet

- Cemte C Rifle ManualDocument46 pagesCemte C Rifle Manualholescreek100% (1)

- Mini 14 ManualDocument48 pagesMini 14 ManualCarlos CainNo ratings yet

- WFRP 4E Modified Fumbles and MiscastsDocument7 pagesWFRP 4E Modified Fumbles and MiscastsVinie CastroNo ratings yet

- tm9-1005-212-25 1919a41Document101 pagestm9-1005-212-25 1919a41pavefeguyNo ratings yet

- B58A1 Feral Animal Aerial Shooting Team SLRDocument52 pagesB58A1 Feral Animal Aerial Shooting Team SLRgreaternorthroad8820No ratings yet

- 2002 US Army M-2 50 CAL 381p PDFDocument381 pages2002 US Army M-2 50 CAL 381p PDFKostasVoulgaridis0% (1)

- Instruction ManualDocument16 pagesInstruction ManualAmerico Toledo0% (1)

- St200f Service Manual Eng 120224Document73 pagesSt200f Service Manual Eng 120224Jose David MarchanteNo ratings yet

- STG 43 ManualDocument23 pagesSTG 43 ManualDavid NashNo ratings yet

- Laugo Alien User Manual en Full Kit 2021 9Document24 pagesLaugo Alien User Manual en Full Kit 2021 9Los Bly4tos100% (1)

- ArmaliteDocument91 pagesArmaliteBen Drusoy100% (1)

- Combat PistolDocument84 pagesCombat Pistolfalcoxm100% (1)

- Instruction ManualDocument16 pagesInstruction ManualTavo AcdiNo ratings yet

- CZ 511Document15 pagesCZ 511ProfConoNo ratings yet

- Ruger Mark III Autoloading Pistol ManualDocument44 pagesRuger Mark III Autoloading Pistol ManualPlainNormalGuy2100% (2)

- Terasaki Instruction Manual 21B ACBDocument91 pagesTerasaki Instruction Manual 21B ACBanipchin100% (1)

- Swiss K31 K11 Manual PDFDocument81 pagesSwiss K31 K11 Manual PDFbjmooseNo ratings yet