Professional Documents

Culture Documents

United States Patent (191: Larsson Et Al

Uploaded by

arses20026695Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent (191: Larsson Et Al

Uploaded by

arses20026695Copyright:

Available Formats

United States Patent [191

[111

Larsson et al.

[45]

[54-] GAS DISTRIBUTION DEVICE FOR THE

3,803,723

SUPPLY OF A PROCESSING GAS TO AN

499847

Belgium ................................... .. 55/260

2/1962

55/260

55/260

France ............................. ..

[57]

Denmark ........................... .. 3640/78

[51]

Int. Cl.2 ............................................ .. B01D 47/16

[52]

US. Cl. ...................................... .. 55/260; 55/226;

55/230; 159/4 B; 159/4 S; 261/79 A; 261/88;

261/89; 261/118

Field of Search .................. .. 261/78 A, 96, 79 A,

261/88, 109, 89, 118; 55/226, 230, 260,

442-445, 459 R, 459 C; 159/4 R, 4 B, 4 S

References Cited

55/260

ABSTRACT

A processing gas is supplied to the atomizing zone

around an atomizing device arranged centrally in an

atomizing chamber through a conical guide duct com

municating with a horizontal spiral supply duct through

an annular mouth. A uniform gas distribution with re

spect to ?ow direction and velocity is obtained by

means of guide vanes arranged with a Small angular

spacing in the mouth and comprising two succeeding

vane sets, in which the vanes of one set are shaped to

de?ect the tangential gas stream in the spiral duct to a

flow direction, for which the radial velocity component

considerably exceeds the tangential component,

Us PATENT DOCUMENTS

619 6 6 934 B _

l

3,373,095

Lamm et al. .................. .. 159/4 B X

Primary ExaminerRichard L. Chiesa

Attorney, Agent, or Firm-Sughrue, Rothwell, Mion,

Zinn and Macpeak

A/S Niro Atomizer, Soborg,

[21] Appl. No.: 63,884

[22] Filed:

Aug. 3, 1979

[30]

Foreign Application Priority Data

[56]

3/1951

1289817

Denmark

[58]

Oct. 14, 1980

70827 l/l970 Fed. Rep. of Germany

80661 3/1971 Fed. Rep. of Germany

Denmark

Aug. 17, 1978 [DK]

4,227,896

FOREIGN PATENT DOCUMENTS

ATOMIZING CHAMBER

[75] Inventors: Finn H. Larsson, Tastrup; Christian

Schwartzbach, Malov, both of

[73] Assignee:

4/1974

>

5 226

whereas each vane of the other set positioned at the

opening of the mouth towards the conical guide duct

l/1963 nlgibgtiteg et a. ................. " 53230

projects into the space between neighboring vanes of

3112239

11/1963

Andermai't' ' ' ' ' ' ' ' ' '

3:175:340

3/1965

Schulze

3,596,885

8/1971

Stone

3,789,582

2/ 1974

Graybill ........................... .. 55/260 X

._

' ' ' ' ' "159/4 B

"""

. . .. .. .

. . . . . ..

/79 A X

the ?rst set and extends substantlally parallel to tangen

tial planes to said vanes at their internal edges.

55/260 X

2 Claims, 3 Drawing Figures

17

._

1&1

";

//

I20

/0

Ma

I00

/4b

/0b

/2b

6'

__..__t

U.S. Patent

Oct. 14, 1980

Sheet 1 of 3'

I20

/0

/40 I00

4,227,896

F76.

/

US. Patent

Oct. 14, 1980

Sheet 2 of 3

4,227,896

U.S. Patent

Oct. 14, 1980

Sheet 3 of 3

4,227,896

4,227,896

jGAS DISTRIBUTION DEVICE FOR THE SUPPLY

OF A PROCESSING GAS TO AN ATOMIZING

CHAMBER

'

The invention relates to a gas distribution device for

supplying a processing gas to an atomizing zone around

an atomizing device arranged centrally in an atomizing

chamber, said processing gas being conducted from a

horizontal spiral supply duct through an annular mouth

extending in rotational symmetry around the axis of the

chamber into the space between two conical guide

walls extending around and above the atomizing device,

guide vanes being provided in said mouth for imparting

a change of direction to the gas stream from a mainly

From the speci?cations of Belgian Pat. No. 499,847

and GDR (German Democratic Republic) Pat. No.

80,661, it is known to conduct gas either from an annu

lar supply duct directly into an atomizing chamber or

from a spiral supply duct into a conical guide duct com

municating therewith by means of adjustable guide

vanes arranged in the annular month between the sup

ply duct and the atomizing chamber or the conical duct,

respectively. However, in these prior art constructions,

the gas distribution has been relatively casual, and no

unambiguous directional guiding of the supplied gas

into a downwards directed stream with a certain rota~

tion in the conical guide duct has been obtained due to

the rather complex and critical adjustment of the indi

vidual dampers and a relatively great angular spacing

purely tangential ?ow in the spiral duct into a rotating

flow with a smaller tangential velocity component in

the space between the conical guide walls.

By atomizing chambers is herein to be understood

thereof.

It is the object of the invention to provide a gas distri

bution device, by means of which an optimum and with

drying, cooling and absorption, in which a liquid which

internal opening of the mouth towards the conical guide

respect to rotational symmetry, uniform distribution of

processing chambers for different processes, such as 20 the processing gas supplied in the spiral duct at the

duct is obtained at a considerably lower pressure drop

across the mouth, and by which there is furthermore

obtained already at this place an unambiguous direc

- as a rotating atomizer wheel arranged centrally in the

25 tional guiding of the gas stream into a downwards di~

normally mainly cylindrical chamber.

rected spiral path with a relatively low rotational com

The atomized material leaves the atomizing device in

ponent in the conical guide duct.

may be a homogenous substance, a solution or a suspen

sion, is atomized by means of an atomizing device such

mainly horizontal radial directions out into an atomiz

ing zone. In the processes in question, one or the other

In order to achieve this, a gas distribution device

according to the invention is characterized in that the

kind of a processing gas is most frequently supplied to 30 guide vanes are arranged in the mouth with a small

this atomizing zone for achieving a desired result. In a

angular spacing and comprise two succeeding sets of

' drying process, for example, a heated drying gas which

stationary guide vanes, in which the guide vanes of one

may be atmospheric air or an inactive gas may be sup

set positioned at the external opening of the mouth

plied. In other processes, gases may be supplied which

towards the spiral duct are shaped to deflect the gas

perform other physical or chemical reactions with the 35 stream to a ?ow direction, for which the radial velocity

atomized liquid.

For obtaining a distribution of the supplied process

ing gas around the atomizing device which in respect of

component considerably exceeds the tangential velocity

component, whereas each vane of the other vane set

positioned at the internal opening of the mouth towards

the space between the conical guide walls projects into

the space between the internal portions of neighbouring

rotational symmetry is as uniform as possible, use is

most frequently made of a distribution device of the 40

above mentioned kind, in which the gas is conducted

vanes of the ?rst vane set and extends substantially

from the horizontal spiral supply duct which is posi

parallel to tangential planes to these vanes at the inter

tioned at a higher level than the atomizing device

through said mouth into the conical duct formed by the

nal edges thereof.

space between the conical guide walls, the annular

arranged in this manner with closely positioned guide

mouth of said conical duct being positioned in a hori

zontal plane immediately overlying the atomizing zone.

vanes, such an equalization of the velocity distribution

in the space between each pair of neighbouring vanes in

Through the use of two guide vane sets shaped and

In order to obtain uniformity of the gas distribution

the one direction-changing vane set is obtained that

throughout the length of the internal opening of the

throughout the internal opening of the mouth towards

mouth towards the conical duct, there has been used in

the constructions hitherto known a relatively high

working pressure in the spiral duct in combination with

a plate grid in the form, for example, of a perforated

obtained substantially without any observable velocity

plate arranged in the mouth, said grid having caused a

relatively high pressure drop, such as disclosed in

French Patent Speci?cation No. 1,289,817. Since such

plate grids do not per se exert any essential directional

effect on the gas, a desired ?ow direction with a down

the conical guide duct, a uniform gas distribution is

variations. In addition, the vanes of the other vane set

positioned towards the conical duct exert such a direc

tional effect on the gas streams passing through the ?rst

vane set that at any place at the internal opening of the

mouth towards the conical guide duct, a well de?ned

flow direction forming a relatively small angle with a

radial plane in the gas distribution device is obtained, so

wards directed rotating movement could subsequently

that the entire amount of gas is conducted into the con

be imparted to the amount of gas supplied into the coni 60 cial guide duct as a spiral stream with a strong radial

cal duct by means of guide vanes arranged in the coni

and, thus, downwards directed velocity component and

a relatively smaller rotational component.

cal duct. Likewise, it is known to divide the conical

Subsequently, a further changeof direction, possibly

guide ducts for vproducing two gas streams passing

through the atomizing zone with different directions,

after division into two partial streams, may be imparted

" suchas an internalmainly axially downwards directed

65 to this gas stream by means of guide vanes in the conical

'Yannular'streariifand any external spirally downwards

duct. The pronounced uniform distribution along the

internal side of the mouth of the gas stream entering into

"directed gas streamwith a relatively high rotational

component.

the conical duct with respect to ?ow direction as well

4,227,896

as velocity facilitates the adjustment and regulation of

subsequent guide vanes and, thus, the achievement of a

rotational symmetrically uniform gas supply to the at

omizing zone, whereby the atomized material is sub

jected to a considerably more uniform in?uence from

the processing gas than in the gas distribution devices

hitherto known.

As a result of theuse of stationary guide vanes, the

guide vanes per se may form distance members, so that

separate stay or supporting means in the mouth may be 0

dispensed with.

In the following, the invention will be further ex

plained with reference to the accompanying drawings,

in which

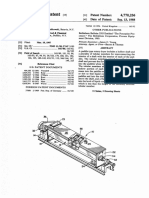

FIG. 1 is a simpli?ed vertical sectional view of an

embodiment of a gas distribution device according to

the invention,

FIG. 2 is a horizontal sectional view along the line

II~II in FIG. 1, and

FIG. 3 is a perspective view, for illustrating the guide

vanes in the embodiment shown in FIGS. 1 and 2.

In FIGS. 1 and 2 a rotating atomizing device, such as

an atomizer wheel, is shown at 1, which device is pre

supposed to be arranged centrally in the upper part of

an atomizing chamber, of which only the underside of

the chamber ceiling is indicated at 2.

ducing the above mentioned internal stream of process

ing gas.

'

For each of the two streams of processing gas, the

?ow direction is determined by guide vanes, as shown

at 140 and 14b in the ducts 10a and 10b.

For obtaining an optimum and, with respect to rota

tional symmetry, uniform distribution of the processing

gas conducted from the spiral supply duct 8 into the

conical guide duct 10, there are arranged in the mouth

9, according to the invention, two succeeding sets of

stationary guide vanes 15 and 16, respectively, in which

the vanes in one vane set positioned at the opening of

the mouth 9 towards the spiral duct 8 are shaped to

de?ect the gas stream from the purely tangential ?ow

shown by an arrow 17 in the duct 8 to a flow direction

shown by arrows18, for which the radial velocity com

ponent inwards to the axis of the gas distribution device

considerably exceeds the tangential velocity compo

nent, whereas each of the vanes 16 in the other vane set

at the internal opening of the mouth 9 towards the coni

cal guide duct 10 projects into the space between the

internal portions of neighbouring vanes in the ?rst vane

set and extends substantially parallel to tangential planes

to these vanes at their internal edges, i.e. parallel to the

direction to which the gas stream has been de?ected by

these neighbouring vanes.

form of homogenous substance, a solution or a suspen

In the embodiment shown in the drawings, each vane

15 has a bend form composed of two substantially plane

portions 15a and 15b, but these vanes may also have a

more uniformly curved cross sectional shape which can

provide the desired de?ection of the gas stream in the

sion in a manner not further illustrated.

To the atomizing zone of the chamber which is situ

duct 8. The vanes 16 are shown as ?at guide vanes, but

should only extend substantially parallel to the vane

ated radially around the atomizing device 1, there shall

be supplied by means of a gas distribution device ac

cording to the invention a processing gas adapted to the

process, such as drying, cooling or absorption, to which

the supplied material is to be subjected after atomization

by means of the atomizing device 1. In a drying process,

parts 15b, so as to stabilize the gas streams to the direc

atmospheric air.

de?ection will be suitable that the gas streams leave the

The atomizing device 1 is positioned at the bottom of

a conical skirt 3 surrounding the lower part of drive

means, not shown, for the atomizing device, through

which skirt the liquid to be atomized is supplied in the

tions to which they have been de?ected by the vanes 15.

The magnitude of the de?ection angle may vary

somewhat according to the kind of processing gas and

the supply velocity thereof and with a consideration to

the desired progress of the ?nal gas streams through the

the processing gas may consist, for example, of heated 40 atomizing zone. For many applications, such a strong

In many cases, the processing gas is caused to pass

through the atomizing chamber in two separate streams,

vanes 16 under an angle of 15, for example, with axial

planes in the mouth since, thereby, a gas supply is ob

tained at the upper end of the conical guide duct 10 with

i.e. an internal stream supplied to the atomizing zone

from above with a strong downwards directed move 45 a suitably low, but well de?ned rotation.

The detailed construction of the vanes 15 and 16 may

ment, as shown by arrows 4 and 5, and an external

be as shown in the perspective view in FIG. 3. In order

stream carried through the chamber at a greater dis

to obtain the desired gas distributing and directional

tance from the atomizing device 1, as shown by arrows

6 and 7, and with a strong rotational component.

The processing gas is supplied from a fan device, not

shown, through a spiral supply duct 8 arranged above

the ceiling 2 of the atomizing chamber, said supply duct

communicating through an endless annular mouth 9

with a conical guide duct 10. This guide duct 10 is

restricted to one side by an internal conical guide wall

11, the lower end of which is connected to the skirt 3

and, in the example illustrated, in which two separate

streams of processing gas are to be produced, the duct

10 is divided, by means of two external conical guide

walls 120 and 12b spaced differently from the guide wall

11 and overlapping each other on a small portion only

at the underside of the chamber ceiling 2, into an exter

nal channel 10a opening at the underside of the chamber

ceiling 2 for producing the above mentioned external

stream of processing gas, and an internal channel 10b to

which only a part of the amount of gaspassing through

the duct 10a is supplied and which opens some distance

below the underside of the chamber ceiling 2 for pro

guiding effect, it is essential that the vanes 15 and 16 in

the two vane sets are positioned at a small angular spac

ing in the mouth 9, preferably such that the spacing of

neighbouring vanes is smaller than the radial extension

of the mouth 9 between the internal opening of the duct

8 and the inlet opening to the conical guide duct 10.

The vanes may be manufactured by simple stamping

and folding or bending of vane members of a plate mate

rial, such as steel, which is resistant to the possibly

corroding in?uences from the processing gas.

What is claimed is:

1. A gas distribution device for supplying a process

ing gas to an atomizing zone around an atomizing de

vice arranged centrally in an atomizing chamber, com

prising a horizontal spiral supply duct for said process

ing gas, said duct having an annular mouth extending in

rotational symmetryaround the axis of the chamber,

and two conical guide walls extending around and

above the atomizing device, said guide walls limiting a

space communicating with said mouth, guide vanes

4,227,896

6

tangential velocity component, the other vane set being

positioned at the internal opening of the mouth towards

the space between the conical guide walls, and each

being provided in said mouth for imparting a change of

direction to the gas stream from a mainly purely tangen

tial flow in the spiral duct into a rotating ?ow with a

smaller tangential velocity component in the space be

tween the conical guide walls, wherein the improve

mouth with a small angular spacing and comprise two

vane of said other vane set projecting into the space

between the internal portions of neighbouring vanes of

the ?rst vane set and extending substantially parallel to

tangential planes to these vanes at the internal edges

succeeding sets of stationary guide vanes, the guide

thereof.

ment comprises that the guide vanes are arranged in the

vanes of one set being positioned at the external opening

2. A gas distribution device as claimed in claim 1,

wherein the spacing of the vanes is smaller than the

radial extension of the mouth.

of the mouth towards the spiral duct and being shaped

to deflect the gas stream to a flow direction, for which

the radial velocity component considerably exceeds the

II

15

20

25

30

35

40

45

55

60

65

It

1i

I!

You might also like

- Lab Report For Venturi MeterDocument9 pagesLab Report For Venturi MeterRichard Puni89% (44)

- Inlet Nozzles MomentumDocument9 pagesInlet Nozzles Momentum404FileNotFoundNo ratings yet

- Basic Electricity Final ExamDocument9 pagesBasic Electricity Final ExamrockerfxNo ratings yet

- Torque Vs Tension Interpretation Instructions Rev 6Document25 pagesTorque Vs Tension Interpretation Instructions Rev 6Kurt Kandora MontroneNo ratings yet

- European Patent Application: Duct Transition ArrangementDocument20 pagesEuropean Patent Application: Duct Transition ArrangementhbookNo ratings yet

- Us4589264 PDFDocument6 pagesUs4589264 PDFRodrigoPomaNo ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- United States PatentDocument5 pagesUnited States PatentPraveen SinghNo ratings yet

- Pipe Expansion and Support - International Site For Spirax SarcoDocument8 pagesPipe Expansion and Support - International Site For Spirax SarcoSandi ApriandiNo ratings yet

- Pipe Expansion and Support - International Site For Spirax SarcoDocument8 pagesPipe Expansion and Support - International Site For Spirax SarcoVenkatesh NatlaNo ratings yet

- Patent for ambient air vaporizer with dissimilar materials couplingDocument12 pagesPatent for ambient air vaporizer with dissimilar materials couplingJaime Ocampo SalgadoNo ratings yet

- Venturi Scrubbers: Lesson 3Document14 pagesVenturi Scrubbers: Lesson 3AdhitomoWirawan100% (1)

- Surface Condenser Eng2Document5 pagesSurface Condenser Eng2MuhammadFikriNo ratings yet

- Condensers: J. M. McnaughtDocument6 pagesCondensers: J. M. McnaughtLTE002No ratings yet

- Centrifugal CompressorDocument7 pagesCentrifugal Compressorrohan112358No ratings yet

- United States Patent (191: Allum Et Al. (11) Patent NumberDocument12 pagesUnited States Patent (191: Allum Et Al. (11) Patent NumberdnddownloaderNo ratings yet

- 364 June 1386Document9 pages364 June 1386MaheshNo ratings yet

- Login Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationDocument8 pagesLogin Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationFilipNo ratings yet

- Nozzle - WikipediaDocument5 pagesNozzle - WikipediaPye PhyoNo ratings yet

- Controlling Jet Flow with NozzlesDocument53 pagesControlling Jet Flow with NozzlesVasanth AradhyaNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument6 pagesUnited States Patent (191: (11) Patent Number: (45) Date of PatentmhdmkNo ratings yet

- Selection of Reboiler Type Design ProceduresDocument0 pagesSelection of Reboiler Type Design ProcedurestpchoNo ratings yet

- Rotating double shell heat exchange drumDocument5 pagesRotating double shell heat exchange drumaegosmithNo ratings yet

- Steam Nozzle FundamentalsDocument20 pagesSteam Nozzle Fundamentalsamarparimi50% (4)

- WWW Spiraxsarco Com Resources Steam Engineering Tutorials ST 3Document12 pagesWWW Spiraxsarco Com Resources Steam Engineering Tutorials ST 3Mashudi FikriNo ratings yet

- Support LocationsDocument12 pagesSupport LocationsdasubhaiNo ratings yet

- Dollhopf Matthew J 200407 MSIEDocument36 pagesDollhopf Matthew J 200407 MSIEАндрей АндреевNo ratings yet

- Spe 174521 MSDocument17 pagesSpe 174521 MSDavid MontoyaNo ratings yet

- Mud Gas Separator SizingDocument10 pagesMud Gas Separator Sizingermaniez100% (2)

- Sonic BoomDocument6 pagesSonic BoomSaifAdamz'sNo ratings yet

- FLOW METER DEMONSTATION ReportDocument15 pagesFLOW METER DEMONSTATION ReportAbenezer TasewNo ratings yet

- Concentric Tubing Completion System for Communicating Fluids Between a Surface Structure and Subsea WellboreDocument21 pagesConcentric Tubing Completion System for Communicating Fluids Between a Surface Structure and Subsea Wellboredaniel_iosif_glNo ratings yet

- De Laval NozzleDocument6 pagesDe Laval Nozzlethiago sousaNo ratings yet

- Rotary Dryer Steam Distribution SystemDocument7 pagesRotary Dryer Steam Distribution SystemDouglas TondelloNo ratings yet

- Lecture 32 33Document7 pagesLecture 32 33Naga Varshini MeenakshisundaramNo ratings yet

- Efficiency Analysis of An Aerospike Nozzle: Dipak J. Choudhari, Uday V. AsolekarDocument5 pagesEfficiency Analysis of An Aerospike Nozzle: Dipak J. Choudhari, Uday V. AsolekarAswith R ShenoyNo ratings yet

- Us 2409624Document6 pagesUs 2409624Giovanni BlancoNo ratings yet

- Shock Tunnel Design and Flow VisualizationDocument21 pagesShock Tunnel Design and Flow VisualizationrashidatalatNo ratings yet

- A Computational Model of A Power Plant Steam Condenser: R. P. RoyDocument11 pagesA Computational Model of A Power Plant Steam Condenser: R. P. RoyAhmed HelmyNo ratings yet

- Description: (OCR Text May Contain Errors)Document3 pagesDescription: (OCR Text May Contain Errors)SachinNo ratings yet

- Heat Exchanger Design for Distillation Column Energy RecoveryDocument22 pagesHeat Exchanger Design for Distillation Column Energy Recoverykirandevi1981No ratings yet

- Studyof60horsepo00evan PDFDocument86 pagesStudyof60horsepo00evan PDFDaniel InostrozaNo ratings yet

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocument10 pagesEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNo ratings yet

- Steam EjectorDocument4 pagesSteam Ejectorjlcheefei9258No ratings yet

- Introduccion - Calculo de Una PlacaDocument8 pagesIntroduccion - Calculo de Una PlacamontanovillarroelfabiolalourdeNo ratings yet

- Valva MechanismDocument38 pagesValva MechanismAnkitSingh100% (1)

- Hughes' tapered sonic pressure wave generatorDocument3 pagesHughes' tapered sonic pressure wave generatorSaeedAkbarzadehNo ratings yet

- Article CFB Studies On The Operation of Loop Seal in Circulating Fluidized Bed Boilers-3Document1 pageArticle CFB Studies On The Operation of Loop Seal in Circulating Fluidized Bed Boilers-3nguyenhuutan91No ratings yet

- Biblio 1Document6 pagesBiblio 1Miguel Ángel Sevilla SánchezNo ratings yet

- Compressor Horsepower: Gas Distribution and ControlDocument3 pagesCompressor Horsepower: Gas Distribution and ControlRahmat AbdullahNo ratings yet

- Review CombustionDocument21 pagesReview CombustionSuresh Balaji VedarethinamNo ratings yet

- Synopsis - VenrurimeterDocument14 pagesSynopsis - VenrurimeterSunil GuptaNo ratings yet

- Frederick Terry's Lab Report Fluid Dynamics - AsdDocument19 pagesFrederick Terry's Lab Report Fluid Dynamics - AsdFreddie TerryNo ratings yet

- Heat Transfer Enhancement Broken V-BafflesDocument25 pagesHeat Transfer Enhancement Broken V-Bafflesabu1987No ratings yet

- Pressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsDocument9 pagesPressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsJoseph Alexander BorgNo ratings yet

- CondenserDocument21 pagesCondenserAshraf Zoubi100% (4)

- Relative Density Report 2nd SemDocument14 pagesRelative Density Report 2nd SemFasakin Akinwole50% (2)

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- The Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827From EverandThe Mirror of Literature, Amusement, and Instruction Volume 10, No. 287, December 15, 1827No ratings yet

- Us 4226603Document7 pagesUs 4226603arses20026695No ratings yet

- Preparation of Peracetic Acid From Acetic Acid and Hydrogen Peroxide Experimentation and ModelingDocument7 pagesPreparation of Peracetic Acid From Acetic Acid and Hydrogen Peroxide Experimentation and Modelingarses20026695100% (1)

- Blowing AgentsDocument35 pagesBlowing Agentsarses20026695No ratings yet

- Us 8157249Document7 pagesUs 8157249arses20026695No ratings yet

- Spray DrierDocument10 pagesSpray DrierSandi ApriandiNo ratings yet

- DryerDocument80 pagesDryerAaron Paulo Bernardo100% (2)

- A Primer On Spray Drying Chemical Engineering Nov09Document7 pagesA Primer On Spray Drying Chemical Engineering Nov09Hikmah Triana HadiNo ratings yet

- Spray Drying Lithium IonDocument7 pagesSpray Drying Lithium Ionarses20026695No ratings yet

- Urea Dryer Specs and FeaturesDocument2 pagesUrea Dryer Specs and Featuresarses20026695No ratings yet

- Eraprene RB 6570TDocument2 pagesEraprene RB 6570Tarses20026695No ratings yet

- Artigo 1Document7 pagesArtigo 1Rafael AmaranteNo ratings yet

- Libro de Gasógeno de La FAODocument139 pagesLibro de Gasógeno de La FAOpobrecitogasificadorNo ratings yet

- Goeyens Et Al 199b PDFDocument4 pagesGoeyens Et Al 199b PDFarses20026695No ratings yet

- Perchlorine AnalysisDocument1 pagePerchlorine Analysisarses20026695No ratings yet

- 1 s2.0 000925099185152N MainDocument17 pages1 s2.0 000925099185152N Mainarses20026695No ratings yet

- Heat PipeDocument19 pagesHeat Pipearses20026695No ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Reynolds NumberDocument15 pagesReynolds NumberZzPumpkingNo ratings yet

- Phase Diagrams: Lecture 2 (Manufacturing Technology)Document21 pagesPhase Diagrams: Lecture 2 (Manufacturing Technology)Ayush BhadauriaNo ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 1 2021-2022Document36 pagesIM BSCE 3 - Hydraulics 1 Chapter 1 2021-2022acurvz2005No ratings yet

- Experiment 3.Document6 pagesExperiment 3.tracyymendozaNo ratings yet

- R7222301 Mass Transfer & SeparationDocument2 pagesR7222301 Mass Transfer & SeparationsivabharathamurthyNo ratings yet

- Lect 17Document26 pagesLect 17vatsalp3No ratings yet

- What Is A Circuit BreakerDocument18 pagesWhat Is A Circuit Breakersrinu247No ratings yet

- EDC Formula Notes - PDF 65Document8 pagesEDC Formula Notes - PDF 65VenkatGollaNo ratings yet

- Physics Paper IDocument13 pagesPhysics Paper IJalaja RajNo ratings yet

- Essay HIRFDocument2 pagesEssay HIRFHamdan Merchant100% (2)

- Specimen Paper Unit 6993 01 Additional Mathematics Advanced LevelDocument16 pagesSpecimen Paper Unit 6993 01 Additional Mathematics Advanced LevelIshuWaryNo ratings yet

- EDTA Titrations: Metal Chelate ComplexesDocument35 pagesEDTA Titrations: Metal Chelate ComplexesalphhabetaNo ratings yet

- Advertisement: Magnetic CurrentDocument6 pagesAdvertisement: Magnetic Currentstormrunner002No ratings yet

- Quantum Bhabna Safalyagatha 0Document226 pagesQuantum Bhabna Safalyagatha 0mamunngsNo ratings yet

- Mould Fluxes in The Steel Continuous Casting ProcessDocument30 pagesMould Fluxes in The Steel Continuous Casting ProcessUgur KayaNo ratings yet

- Slab On GradeDocument56 pagesSlab On GradeTere Mota DondéNo ratings yet

- Introduction To CATIA V5: Release 16 (A Hands-On Tutorial Approach)Document33 pagesIntroduction To CATIA V5: Release 16 (A Hands-On Tutorial Approach)Vinoth KumarNo ratings yet

- MANU PPT - PPTX 2Document13 pagesMANU PPT - PPTX 2Karan JoshiNo ratings yet

- MORRIS JR., J. W. Overview of Dislocation Plasticity.Document36 pagesMORRIS JR., J. W. Overview of Dislocation Plasticity.Vitor Scarabeli BarbosaNo ratings yet

- Exercise HighwayDocument7 pagesExercise HighwayOmar AbdelnabyNo ratings yet

- Double Layer LecturesDocument38 pagesDouble Layer LecturesKhaled AbeedNo ratings yet

- Hydrogen Spectral LinesDocument17 pagesHydrogen Spectral LinesarnoldNo ratings yet

- Solutions CH 13Document27 pagesSolutions CH 13Prinka AriessaNo ratings yet

- ICSE 2017 Chemistry Science Sample Paper 2 PDFDocument7 pagesICSE 2017 Chemistry Science Sample Paper 2 PDFPrabhat BhatNo ratings yet

- MCQ in Thermodynamics 000ANSDocument33 pagesMCQ in Thermodynamics 000ANSSANKAR VNo ratings yet

- Reasons Xii ChemistryDocument4 pagesReasons Xii ChemistryManahil PariNo ratings yet

- Tension Test ReportDocument7 pagesTension Test Reportzgts100% (1)

- Exp 2. AbstractDocument5 pagesExp 2. AbstractBrev Candare50% (2)