Professional Documents

Culture Documents

Cal Dot Workshop Comments April 04

Uploaded by

prowagOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cal Dot Workshop Comments April 04

Uploaded by

prowagCopyright:

Available Formats

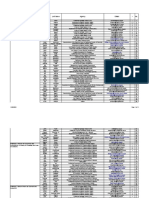

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Page 1 of 11 01/05/2010 01:39:45

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

THEME 2: MANAGING TRAFFIC IMPACTS

105 15 Transportation Management Plans

Effectiveness Studies, Contingency Plans, Local Impacts

Educate the public about our work. Have outreach programs.

Corridor TMPs when several projects occur concurrently. Itemize contingency plan equipment the contractor has to have available so that they can accurately bid the project. Have maintenance become part of Caltrans’ contingency plan. Use CHP

as part of contingency planning.

Special events, alternate routes. Maintain existing facilities or temporary relocation of existing facilities, such as ramp meters, during construction to keep traffic flowing. Communication with locals.

Involve CHP, local agencies, public in developing TMP. Using tow service to remove stalled vehicle in areas where no FSP. Use of call box for motorists to use. Motorist assistance.

Better a better job – go heavy on public awareness campaign to inform public on the project. Such as TV or newspaper advertisement, press conference.

Early planning is important, also include TMC and then partners sooner in planning, trailblazing alternate routes are very important. Regular checks of how the alternate route is flowing are very important as well. Good communication with city,

county, DOTs for when you direct traffic on their system.

Should provide information to emergency vehicle (fire department, police community).

Plan ahead and include provisions in the plans to maintain and operate any and all operational features (i.e., ramp meters, loop detectors, CCTV, fiber optics, etc.) through construction phase. If anything, these features are more critical in

managing traffic due to construction impacts.

Special events, such as college graduation days, sports events, traffic will be increased considerably. Solution: coordinate with local agencies, colleges to schedule work on different dates or not having lane closures on those event days.

It forces everyone to take a look at things beforehand (good).

Issues: we need to be better at construction/concurrence with stakeholder groups (construction, locals, etc.) on TMP mitigation measures.

Issues: enforcement/measuring TMP mitigation requirements in the field is not always done or a priority.

Accommodate bikes and peds in TMP – includes evaluating recommended detours.

Increase tools and staff available to develop TMPs. Incentive/disincentives increase contractor involvement/action. TMPs must be fully developed early in the planning process and revised as the scope changes. TMP training/classes required for

CT staff. TMP training for local agencies.

A plan is a necessary management tool. Plan should specify performance objectives (i.e., delay/vehicle, one accident per 100,000 vehicles entering work zone). Compare projects/districts on the execution of their plans.

Issue: too broad. Project/phase specific partnering.

Issues: resource intensive for small projects; how do you determine scope/intensity? Solution: scope based on project cost.

Along with all the data there needs to be a little input from people doing the work as to whether it is working or not working. Besides all the data, talk to the people in the field.

Public awareness prior to project so alternate routes can be taken.

Issue: understanding the TMP by all involved. Solution: education – from the laborer to management, everyone needs to know why we have TMPs and the importance of using it.

Need to consider the local’s congestion management system and incident response plan.

Issue: detours. Solution: allow detours to local streets.

Internal time limit on temporary signals. Involve AGC. Allowable delay is so short that we have trouble getting work completed. Close road for short period and get it done fast.

Better access to Caltrans information.

Obtain public feedback for the effectiveness of TMPs. Guide the local agencies on using state highways by creating detailed instructions, covering majority of scenarios.

How do you assist small projects in producing traffic management plans? Include all aspects of TMPs early and include all stakeholders.

Temporary pedestrian/bike route in construction area.

Alternate TMPs shall be designed for all projects requiring lane closures.

TMPs are designed for one project only, when several closures are grouped (projects in the same corridor) no individual TMP works. An integrated view of the projects is required.

More transit systems.

All items by themselves sound great, but they have to be interweaved to make it work. Like the Boston project – where lots of planning, sense, ownership and mainly continuity would be the key elements.

Increase focus on use of transit to provide a reasonable option to those who have to make trips. Need to investigate flexible transit, bus rapid transit facilities, and project financing.

Big picture: need cultural change within MPOs to support use of parallel local routes during partial closures. Less delay and shorter project duration will leave more money in the pot for real work.

Continue to warn (scare) public about potential delays. Mass transit needs to be promoted and more fully developed. Promote alternate work schedules to companies along the affected corridor.

Re-evaluate the proposed TMPs prior to starting construction to ensure that the said project TMP is coordinated with other projects starting concurrently along the same corridor.

Metrolink has a 4-free ride ticket opportunity that Caltrans can inform their customers about.

Beware using the “scare” technique – it becomes a “cry wolf” – lose credibility.

The more the public can be aware in advance of the closure the better the impact on traffic. Example – the ling lived pavement project in D7 at I-10 and SR-57 – the anticipated delay was huge while actually during construction the delay was

minimal due to public awareness.

Take advantage of project delays and driver inconvenience and promote transit alternatives.

Involve local CHP and maintenance when developing TMPs

Are they realistic? Can be too limiting to get work done. Match needs of project (exclude unneeded elements). Validation of lane closure charts

Address all work windows – traffic, weather, environmental, events, etc.

May need a corridor wide approach to handle more than one project on a route

When reflectors removed, and roadway realigned, glue pattern of existing reflectors (if not totally removed) will confuse drivers

Contractor doesn’t follow, should have a penalty; have locals help develop plan for buy in; politics drive TMPs instead of cost; end results are still about making money, not public travel impacts

Page 2 of 11 01/05/2010 01:39:45

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Most contractors do not want to consider contingency plans unless something happens and then they scramble to reroute, or they talk about it afterwards – we need to keep a checklist of things that go wrong

Involve public and local DOTs to get early buy in

Upfront coordination regarding detours, impacts and required/appropriate mitigation

Allows diversion/rerouting decision-making to occur early and long before encounter construction site

Issues: working cooperatively between all agencies, stakeholders, community, public media

Effective studies should be followed by implementation

Not only should the local impacts be taken into account/consideration, but also the impacts on businesses

Have design involvement, involvement of contractor, monitor and quantify effectiveness of TMP. Be flexible with 30-minute delay. Multiple work crews. More experience with A+B to give time to construct projects,

Need mechanism to construct TMP elements prior to major contract being awarded. Need to evaluate various TMP elements by an unbiased consultant. Commitment to implement TMP with money and personnel. Contractor involvement and

additional payment to contractor for this addition. RFP or bid item. Ability to specify number of shifts and/or crews on a project?

Fast response to incidents, not just TMP, but actual clean ups/removal of damages. So have plan/course of action.

Real time information and being flexible. Incentives for public transportation.

Page 3 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Special counts for accurate ADT.

Need accurate ADT, peak hour volume, early coordination among different functions.

Contractor review with recommendations.

Involve contractors in the beginning, during planning and design. Implement plan and also make changes as necessary during plan.

TMPs using current real time traffic information. Develop TMP plans early and update (living TMP). Involve contractors and other agencies – public. Implement the plan. Bus only lanes.

Coordinate traffic impact with all involved parties, locals, contractors, state.

Need flexible TMP when things don’t go as planned.

Discuss TMP with community meetings – involve motorists, not just the “community leaders”.

Implement TMP. Productivity also affects duration and type of material to use given different work windows.

Implementation of TMPs, contractor involvement with TMPs, community involvement with TMPs.

Implement TMP and review TMP prior to going out to contract – make sure all current TMP elements are included.

Coordinate with other agencies, particularly for special events.

Need to consider compensation for idle equipment and material.

Someone specifically assigned to monitoring of effectiveness of TMP with authority to make changes (implement contingency plans) when necessary.

Accurate traffic counts.

Seasonal impacts.

Keep on concentrating on creating good, thorough TMPs.

Identify best practices.

Have staff on site to ensure TMP strategies are carried out at work zones.

Implementing more requirements will only drive costs up.

Should be addressed as early as possible; updating as needed, even during construction. Involve all affected areas, road users/customers, etc.

Establish a construction traffic manager and project traffic manager to handle projects.

Creative incentive/working with contractor to verify workable hours. Detours/impacts on city streets, businesses. Establish at the preconstruction meeting alternate work hours/routes with the help of contractor/inspector. Involve maintenance in all

phases.

Establish checklist of impacted stakeholders and include railroads and RR approvals.

Plans need to show rail lines and how detoured around gates and flashers.

Coordinating with stakeholders – how soon? Impacts to local streets, roads, businesses, services. Getting information out. Better use of demand management. Being able to evaluate and adapt TMP as conditions change. Making sure TMPs

thoroughly cover bus/bike/ped, getting them reviewed by right people within CT.

Have all entities involved review plans – make comments. Make sure TMP makes sense for the project.

More notification to public through news media, radio station, and TV.

Input from DTM on management of traffic volume; more education on traffic volume with delay; still use TMP with delay counts.

Phasing of construction needs to be reanalyzed with the resident engineer and the contractor after the bid is awarded. Thus allowing alternative methods of construction.

Data collection of traffic volumes for day time and night time to aid in developing more effective TMPs for specific areas (including input from maintenance personnel). Not all work zones are the same.

Expand TMP and incorporate requests into project. Use delay count, demand management, etc. for better TMP.

Build in contingency plans to go into effect when predetermined criteria are met.

Interagency cooperation and communication. Standardized planning, these agencies contacted regardless.

Involve all outside customers once you involve outside agencies, the full effect of a closure becomes very clear. Effective contingency plans.

May change during planning process – may phase out funding and later determine it is needed, but no funds available.

Construction contingency plans.

Put a good plan together, but keep in mind that things will change and improve as the job progresses.

Strict enforcement of the plan.

Don’t be surprised to have to “re-do” many items of construction as soon as contractor is ready to go to work. Unfortunately, there are too many instances of erroneous quantity miscalculations. Too much emphasis is placed on rushing plans to be

“on time and under budget”.

TMP planning must begin at early design phase and not be done late in design. Need public involvement in TMP decisions. Must be willing to adjust TMP during construction. Must use CPM scheduling in TMP development along with traffic

modeling.

Need specific guidelines for when to use the tools available for TMPs. Need specific requirements for the contingency plans.

Effective staging plan; encourage carpool system to alleviate congestion; effective safety measures; stringent driving license tests.

I’m not this fits here but I believe there should be a certification process for companies who prepare traffic control plans. Currently, anyone can do it, but they should be certified as traffic control supervisors, have so many years of experience, etc.

and they should also pass a course through ATSSA.

TMPs should be incorporated with PDT.

Problems can be reduced and eliminated from well-prepared TMPs.

Can affect design, needs feedback loop on effectiveness, environmental discussion, must be project specific.

Each lane closure should have a plan regardless of maintenance or contractors (impact, contingency plan).

Performance based TMPs. Identify parameters (allowances) and allow contractor to develop plan within parameters with a standard for integrating instances that fall outside the allowances. Tie to incentive/disincentive based awards/penalties.

Utilize closeout meeting as the “look back” aspect of entire project development process.

Page 4 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Page 5 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

THEME 3: REDUCING WORKER EXPOSURE

80 21 Work Zone Visibility

Striping, Lighting, Innovative Devices

White overall for contractor.

Warning cones – warning workers of oncoming cars through work zone. White coveralls/reflectors/devices.

CCOs have been utilized for lighting around AC paving machines. This specialized lighting doesn’t cause any glare. District II can provide more information if requested, contact DII CTM.

Require all contractors as well as Caltrans to wear highly visible, retroreflective jump suits at night.

Improve lighting in work zone. Reduce glare so as not to induce accidents. Standardize lighting in construction zone.

Lighting that does not create any shadows. Currently, district II using light umbrella ($10k), usually done under CCO. White coveralls in night work with yellow or green reflective stripes.

Consideration for better worker/work zone lighting and better signage to make motorists more aware of work zone.

Wear proper safety gear; use standard signs and legends; improve equipment to understand signs; add more resources/tools to implement project.

Provide all field workers that drive state vehicles light packages that make the vehicles seen by drivers – similar to CHP.

Illuminate “road work” signs – don’t depend on reflectivity. Improve vest/hat color combinations (enforce “clean/new” vests at all work zones). Provide “night look” striped coveralls - summer and winter versions. Improve night time lighting

requirements for work zones – brighter, no glare to traffic. Return to “orange” truck equipment – visibility and recognition. Reevaluate board versus light stick.

As you add more “attention getter” devices, drivers will become complacent and eventually tone out them also, then when you really have a condition that warrants an “attention getter” application, it will be less effective.

Signs that are not alerting drivers to work or closure ahead – signs with LED lights to outline sign.

Bright lighting (day) of construction signs – something that will grab attention – a little shock factor.

Issue: complacency. Solution: flashing signs, light up lane change areas, clear signs.

Make sure contractor has signs that are visible, no old, run over, bent signs.

High visibility signs – too many a distraction. Improve work zone entrance visibility.

Look to the after market for development and clear red tape for suggested/approved methods.

Need better temporary reflective markers to last for 14 days.

Electronic message signs (EMS) should be out there on every construction site. Improve CMS quality so that the public can see better. Many times, the drivers can’t read them clearly, and they don’t take them seriously.

Technology is good already.

Red tape holds up changes.

Night and/or weekend full freeway and/or route closures will allow quick opening of entire freeways (i.e., I-10 after the North Ridge earthquake).

Temporary striping – paint versus tape

Ghost lines

Make sure specs cover upkeep

Using personal flasher

We know some things are better but it is hard to change standards; solution is to change colors so we get attention for new color

LED lights into night time cloth

Lights need to be properly located

Contractors usually try the cheapest and short term, not safest

Again, early, early warning to let some travelers avoid the work zone entirely

Strategic CMS placement

New kind of work lights.

Increase visibility of work zone and workers to traffic – signage, delineation, flaggers, MAZEEP.

Drive through the work zone. Look at it like you are the motorist.

Orange vests instead of lime vests. Advance warning signs. Provide barriers to prevent dirt during rain to come to pavement and clean up by crews.

Worker visibility/proximity awareness and warning within work zone. Protect from the heavy equipment. Look at lighting design first from driver’s perspective then workers. Localized lighting. Reduce visibility/glare issue, increase safety for all.

Training of workers in work zone safety by certified safety person prior to staring work. No training, no work.

Achieve OSHA lighting requirements while reducing glare to motoring public. Development of new devices that are practical and cost effective. Meet the need.

Advance signage, highly visible; work zone delineation; reflective highly visible uniforms.

Remove signs not needed, emphasize work zone somehow, work activities must be readily apparent, “soft” night time lighting.

Long extended zones giving public ample time to see and react. Lighted cones. Reduction of work dust and debris to increase visibility.

Coordination of work with input from TRFC, MTCE, and Construction – use PCMS and FCMS (if available).

Indirect worker lighting so as to not glare motorists’ visibility.

Reflectorize the tools.

Installing better products initially will allow for less maintenance in the long run (thermo/diamond grade signs, etc.).

If working, the more cover vehicles and lighting, the safer the situation and work zone.

All work equipment, down to the shovel, should be fluorescent or reflectorized.

Page 6 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Nighttime construction doesn’t have adequate lighting of work zone.

Specifications need to include automotive devices.

No database for capturing information.

Change specifications to higher sign sheeting specifications.

If work zones have thermoplastic, less return time for painting.

Diamond – replace every 10 years instead of 5.

Keep personnel out of the work zone.

Best bet to minimize exposure is to design for longer life and required maintenance.

More signs advising of construction ahead. More CMS signs used to advise of condition.

Use more workers to finish job faster; more lighting in work area; more equipment to work.

Recommend some of the devices involved in pilot programs throughout the state be shown to all Caltrans Districts to seek input/evaluation. Standardize lighting and signage devices throughout state and make them meaningful. Too many devices

on market.

Incorporate innovative devices into specifications and manuals.

Do not provide specifications for lighting. It is a subject that is debatable and job specific. The persons performing the work are the only ones who know how much light they need. Get the inspectors in the filed, need to be part of the work and learn

the work.

Install temporary, visible warning sign in advance place.

CHP officers need reflective clothing for night closures. Positioning lights so they will not hit oncoming traffic.

Work zone visibility should always include MAZEEP or COZEEP, especially when lane closures are involved.

Allow us to purchase safety garments from someone other than PIA, especially since they don’t have them available.

Need more training for workers and inspectors.

Clarity – Joe Blow recognition of desired action. Early warning recognition (taillights shouldn’t be first indication of work zone).

Improve monitoring, warning devices, workers’ alertness.

Wear reflective clothing/color code that is visible at night, foggy weather.

Set up cones and flags correctly to avoid confusion with guidance.

Implement standard lighting specification for night work. Require ANSI compliant high visibility garments.

Enforce existing standards, especially retroreflectivity of signs, striping, and temporary traffic control. Also, require 18” characters on PCMS on Caltrans right of way. Smaller signs are too difficult to read.

Clarify warning and construction signs. Mandatory safety apparel. Educate the public so signs are interpreted correctly.

Positive barrier requirements need to be expanded/developed for short-term work.

Night work lighting – enforce “no glare to traffic”. Make employees conform to “night garment and PPG”. Control the operation as far as replacement of delineators and devices (retroreflectivity) that have been damaged.

Class 3 high visibility clothing must happen soon.

Class 3 high reflective gear; change colors of work zone signs; more CMS boards for early warning.

Highly reflective vests and hard hats for construction workers (including operators).

Work zone visibility very important for drivers unfamiliar with the work zone. Advanced warning, CMS signs, etc.

Many work zones are lacking in signage and delineation and clearly communicating conditions to “average driver”. Review standard plans and augment, as needed, to ensure adequate safety, information, and detour provisions.

25 22 Short Term Work Zones – Safety

Combining Work Zones, Positive Barriers, Shield Distractions

Gawk screen makes more durable.

Issue: night work – what is active work area for CAI/OSHA required lighting (example – paving operation versus a replacement). Solution: department needs uniform policy.

Issue: retroreflective construction area signs being used over and over again. Solution: require new signs for each contractor.

How do we work with a contractor who had several different lane closures of 55 min. to do their work safely without putting in and taking out a complete lane closure each time?

There should be good delineators well ahead of work zone to guide the traffic for merging into work zone.

How to get vehicles/drivers to slow down? Temporary bumps with warning sign of temporary bumps. Temporary done at entrance of zone. Day lights on signage.

Issue: work zones stacked back to back with one PMCS required for each lane closure. Too many PMCS in too short an area. Solution: award rate, cooperation clauses, etc.

Issue: patching, retrieving hazards. Solution: use vehicle for protection. Use MAZEEP for patching assignments.

Issues: positive barriers costly to deploy. Time and money. Adequate planning for temporary work zones. Training for short term work zones. Solutions: temporary barriers, automated equipment, crash attenuators surrounding work zones, rolling

road blocks.

Continue to develop “quick barrier” types of worker protection. Portable “gawk screen” could improve traffic through accident and work zone.

Issues: hard barriers such as k-rail tend to be costly, restrict extra legal truck passage, and can limit/restrict construction equipment and material delivery in to work zone.

Encourage crewmember to insure closure signs are up and visible regularly.

Work zone safety should be priority.

Uniform traffic law to regulate speed through work zone.

Alarm systems, mandatory look outs.

Page 7 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

For shorter term work zones we need either movable barriers or at least two shadow trucks.

Automated equipment, safety of workers needs to be as valued as efficiency/cost savings.

Educate planners and designers (i.e., target audience).

Design user friendly portable barriers that maintenance will use. Better signage for motorists to identify taper start and end using arrows and text.

Consider providing full depth structural section on shoulders so they can handle traffic during future projects and in case of incidents. Also consider wider than minimum shoulders.

Have all emergency notification numbers for impacted agencies. Include flaggers trained in railroad safety.

Giving basic training in safety to workers who usually don’t go in the field. Such as for traffic counts, environmental studies, photographic work, bike surveys, traffic ops, etc.

Gang maintenance; work with construction; use MAZEEP to fill pothole in a day along with maintenance crews.

More barriers for public, not stopping to look at work.

Costs versus minimum standards. Safety of the public is more in jeopardy with some lousy utility company closures. How much time do the minimum standards take?

17 23 Automated Equipment – Short Term, High Exposure

Remotely Operated Equipment, Cost, Practicality

Develop automated equipment. Eliminate worker exposure by placing them inside automated equipment that will do the same job.

Temporary lighting when width of on-ramp and off-ramps are reduced to the point that there is no room for error and repetitive accidents occur.

Longitudinal buffer zone after the merging taper should be reflected.

How do we get around sole source requirements to get (new) products that work?

Safety is a culture – we need to change it to achieve it

Decision makers need to go for safety courses – maybe even back to college to safety 101 instead of economics 101, or take them out on the job site. Show them by example also. Safety can not be a biddable item, it needs to be fixed

Fully develop innovative equipment that has proven effective in concept and practice; build and use (example – drv @ AHMCT)

Streamline procurement procedures to allow sole source purchasing when a piece of innovative equipment proves to enhance productivity and safety (example – Aardvark (AHMCT))

Bureaucracy stops this process, prototype now sole source; solution is change sole source rule, rent instead of buying

Safety first – culture change

How can we get innovative equipment with existing purchasing requirements?

We have a process for acquiring innovative equipment, it is called “sole source” and the process is broken

Fix California “sole source” procurement so it takes three weeks or three months instead of three years

How do we get automated equipment from development to production

We and others have proven prototypes; to get to deployed or commercial systems, we all need to look at the big picture, including the possibility of incentives to get these technologies off the ground and reap the benefits.

“Selling” the public on need for road repair/construction.

Encourage use of new technology, traffic control equipment.

88 24 Design for Safety

Design for Low Maintenance to Keep Employees Off Road

CHP pull out.

Issue: high maintenance road. Solution: innovative roadway materials, long lasting.

Get maintenance involved during design process. Design for low maintenance.

Consideration also needed for designing the facility for low maintenance requirements over the life of the project, lower worker exposure.

Issue: costly, however there are some less costly designs for safety features that can have a significant impact on maintenance needs.

Issue: designs not always maintenance friendly. Solution: involve maintenance at design stage. Shoulders for low maintenance.

Issue: design it as maintenance friendly design – bean versus concrete rail. Solution: reduce failure, maintenance costs, and worker exposure by using the more costly item.

During project development, safety review should include CHP and maintenance personnel.

Change policy to address the proliferation of unnecessary guide and destination signs.

Lower maintenance paints – wider shoulders, lower maintenance foliage, superior road base materials and design.

Paved gore points; PCC barrier is MBGR; incorporate fixtures into sound walls (i.e., light built into walls, control cabinets); provide maintenance pullouts.

Eliminate permanent crash cushions; implement safety features, such as new warning devices, during construction in the design. Technology needs to come up for a faster setting PCC.

Maintenance pull out stations for maintenance workers to park safely. Design the shoulder wider (10’).

Landscaping needs to be based on maintainability factors.

TCP need to make sure the safety warning devices at crossings are not blocked.

Design shall consider maintenance equipment. For instance, a concrete channel design was based on hydraulic calculations to have the base at 6 feet, but maintenance requires having a minimum base width of 8 feet wide in order to have

machine cleaning. Of course this is not directly related to safety, but maintenance has to be out in the field to close the lane and manually clean up. It is safety too.

Design projects so they can be maintained safely. Litter no safety risk to maintenance personnel.

Page 8 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

We try to come up with safe designs and we are replacing MBG with barrier rail. How are they going to be repaired when they are hit by cars and trucks scrape them?

Long term materials; avoiding materials that have short duration (such as FSC in slab); use pre-cast slabs instead of PCC (longer duration).

Moveable barrier – in lieu of cones, moveable barriers pulled out by pickup trucks (new movable barriers system can be moved easily).

Design with safety in mind instead of cost

Look at cost saving now versus safety and maintenance cost

The Department should reiterate the importance of design for safety and enforce/encourage greater use of the program in spite of increased costs to do so

“Pay now or pay later” possibly with a maintenance worker’s life

Design for low maintenance to keep EEs off the road

We are not willing to spend enough money on the right design

We are picking cheap upfront cost versus cheap long term; solution – we need to talk as much as we can, it is a slow process. Conferences like this may be the right place to talk about them; it may get on agenda

Indoctrinate design for safety

Cost for improved system is not accepted

Refusal to use longer lasting construction techniques/materials due to high upfront cost (even though longer life, lower maintenance cost)

Again, use “full cost” cost/benefit to measure alternative construction techniques versus each other

Locate facility features to minimize maintenance worker exposure

Pavement in median/shoulders for veg. control

Concrete barrier vs. MBGR

Weed control under MBGR

Gore paving

Make it maintainable too

Don’t let cost limit your safety items/features

Relocating controller from traffic, moving signs next to turn outs, adding gates to landscape areas and sound walls.

Long life pavement, widen shoulders, detours to take traffic away from construction zone. Faster project reduces exposure to traffic. Longer cone tapers to reduce merging close to traffic.

Incorporate safety features in design.

Must involve designers. Communication before and during construction. Show/present bad designs and consequences. Trips to construction zones by designers.

On freeways we could do away with irrigation and plants that need maintenance if artificial plants and trees were used.

Design irrigation system to reduce maintenance and away from traveled way. Graffiti resistant surface for quick removal of writing.

Commit resources for innovative techniques in reducing worker exposure.

Now maintenance designs built into retroactive and new construction (quick replacement) – eliminate need. Utility location systems (i.e., irrigation, electrical, fiber). If you know where they are, you don’t damage and end up with another work zone.

Total road closure, use detours, design low maintenance or no maintenance, automated maintenance/irrigation.

Emphasize importance of safe design elements (advisory/mandatory). Safety should trump environmental impacts every time.

Adequate lane length to merge – no vegetation – vandalism during construction projects.

Move irrigation, use concrete barrier instead of guardrail or design low maintenance guardrail. Maintenance pull outs. Sometimes environment creates roadblock to safety – safety needs to be equal to efficiency (which costs money).

Anchorage on roadway for lightweight narrow barrier. Low maintenance roadside hardware. Reduce time maintenance workers spend on road.

D-4 has presentation on safety: long life pavement, concrete barrier, MVP.

Maintenance should be involved early in process.

Keep utilities underground, away from roads.

Build bumpers into bridge columns.

Design to the standard, and if not, need to address maintenance and safety of maintenance workers.

Early of involvement of maintenance in project design.

Maintenance to advocate and take lead in seeing that safety features are incorporated.

Width of shoulder and structural section.

Maintenance involvement for reviewing design for safety.

Rehabilitation and reconstruction for future traffic safety alternatives.

Review all design standards for WZTS revisions.

Consider clear span for future bridge designs.

Build the safety in (enough R/W) without building the aesthetics out of the project.

Fund more research and test projects to promote longer life pavements.

More rigorous design review by maintenance must be done.

Use of materials with longest possible life; improved maintenance methods/techniques that also have longest possible life.

Include industry in special provision composition to make traffic control requirements realistic.

Hold annual meetings for each District to have – design, construction, all contractors, maintenance, safety, meet to discuss issues that pertain to worker safety. Problem-solve and establish uniformity of processes.

“Lessons learned”. Design for field conditions. Do not reroute traffic in lanes with no railroad gates to keep traffic out of track areas. Include flaggers/law enforcement and railroad personnel (if needed).

Providing sufficient pull out areas to remove maintenance and other uses from edge of traveled way (pull outs in work zones also). Designing drainage easy to maintain, keep litter free.

Page 9 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Talk, learn from crews who work in field. Designers need to get out in field.

Use permanent barriers; lower the number of work zone designers needed to work in the field.

Design work with access considerations in mind (i.e., allow contractor or maintenance to place k-rail in one lane of traffic for a period of time to construct the work completely within a positive barrier zone, in lieu of nighttime work and closures).

Long life material is cheaper in the long run.

Provide guardrail for equipment in R/S and provide working pad for operation and maintenance.

A good product doesn’t require constant maintenance and lasts longer. Therefore, reducing the workers’ exposure to traffic. Let’s keep those things in mind in design stage.

Avoid sophisticated design (simple deign). Permanent structure that requires less time to repair or replace.

Safety should be considered before the design phase. The project design scope might need to be changed to ensure safety.

Modify with “CCO” if necessary to improve safety “priority goal”.

Improve design specifications, allocate resources, improve safety devices.

Utilize life cycle costing. Utilize other source for acquisition of safety equipment (not PIA).

Schedule maintenance work during non-congestion hours. Audit safety practices. Update the TCP specifications.

Issue: too much design based on budget and short term impacts. Solution: need to think about life cycle; a little more money upfront.

Early maintenance involvement in PID, PR. Cost effective methods of reducing repetitive tasks that expose workers, use resources, slow traffic. Life cycle focus – big picture.

Guideline for design for safety should be established. Project design team shall have the mandate to follow the guidelines. Guidelines shall include safety during construction and maintenance.

Designs must include capacity needs but should include safety considerations as just as important for maintaining and RR work later.

More input from workers in the field – design for safety in the project and stick with the cost. Educating employees of the reasons why the design was established.

56 25 Tools and Techniques for Safer Work Zones

Safer Speeds, Merging Aid, Reduce Gawking

Standardize the closure methodology. Make it simple and clear where motorist needs to turn. Often even I as an engineer, I have to think what the motorist is supposed to do. Simple arrow can make a difference.

Temporary rumble strip (mats).

Reduce speed limit at work zones.

Better dissemination of information regarding new approved devices to the field. Field personnel can help identify projects for these new devices can be applied to ongoing projects.

We need to develop temporary rumble strip to give driver tactile feedback to slow down or that they have entered the work zone.

Standardize signing. Prevent stark contrasts between northern and southern California. District 7 and district 11 have non-standard signing all over the place.

Develop more automated machines/equipment to avoid worker exposures to traffic. Reduce speed limit in work area.

Standardize and simplify traffic closure signing. Temporary rumble strips (mats). Reduced speed limit in work zone. Maintaining 10’ shoulders and MVP areas in future widening projects. Doubling fines enforced by COZEEP.

Rumble strips/speed zones when volumes are low and speeds are high. If implemented, needs to be standardized across the state. A public information campaign to alert motorists. Standard training for contractors. Caltrans and CHP. A course of

sorts. Currently anyone of the contractor’s side can close lanes. May close early or pick up late without knowing the consequences. They need to be educated.

No night work. K-rails between workers and autos.

Issue: speeding. Solution: use speed bumps/buttons, barriers – cones are not enough protection.

Issue: how to slow traffic down coming into work zone. Solution: radar signs, CMS boards, MAZEEP (proactive); monitor work zone to see how traffic is handling travel through work zone.

Issue: driver speeds too high. Solution: innovative striping - narrow lanes, closer strips, zigzag striping.

Issue: traffic slowing to look at job or accident. Solution: portable gawk screens about 40’ maximum in length to cover accident or job.

Change guidelines to recommend speed reduction and tie to highway patrol enforcement in MUTCD and Caltrans manual.

Get media support to reduce gawking at roadwork and accidents – cite increase accidents and delays. Try to change culture/society.

Enforce using k-rail screen or median barrier screen to enhance the work zone activity from obstructing drivers’ attention. Bottom line: isolating the work zone area form traffic is the major enhancement for improving the traffic flow and making

safer work zones.

Get the 2000 (leave alone the 2003) MUTCD accepted by the State of California – bureaucratic gridlock.

Speed limits should be implemented in work zones. Campaign to educate the public about double fines in work zones.

Educate the public through drivers’ education, etc.

Enforce speed zones – no matter the color of the MPH signs. Cameras?

Gang maintenance has more jobs done at the same time. In and out.

Solicit ideas from people in the field on increasing safety.

It is necessary to have better traffic control signs and more informative “instruction” signs on what to do or where to go.

Lowering speeds by narrowing roads and having law enforcement standing by will create a safer working environment.

We assume that blocking motorists view of an incident will make traffic flow smoother/faster, but barriers (e.g., k-rail) also cause motorists to slow down; need research/evaluation.

What does the research say about the types of collision and injuries – this will shape the potential solutions and benefits.

Conference focused on work zones – how does this problem differ from the maintenance work done on shoulders and in the median?

Training.

Use of quick drain water barrels.

Page 10 of 11 01/05/2010 01:39:46

Making Work Zones Work Better -- California Workshops

NOTE: IF YOU WANT TO SEE ALL

Summary of Index Cards… Suggestions/Comments COMMENTS FOR ALL AREAS,

"UNHIDE" THE HIDDEN ROWS --

April 27 & 29, 2004 Click on Format / Rows / Unhide.

Use less intrusive lights (design)

Use of vibrator mats prior to work zone.

Pre-meeting prior to start of work.

Proper tools and equipment.

AWIS to be re-evaluated/re-cost/worth of construction cost.

Physical barriers to cars entering the work zones are needed.

Crash energy absorption needed for short-term work zones.

Design R&R projects to make improvements to worker safety.

Continued and improved training.

Encouragement for innovation of equipment and techniques – incentives.

Better training for employees – get out as fast as one can without being unsafe.

I have seen on ADOT jobs the use of reduced speed zone at construction site and the zones are enforced. Having the traffic slow down – I think – makes them more aware.

Eliminate problem of sole sourcing. Training to pick up lane closures. Drop flares or bright objects on closures.

$1.00 surcharge on car registration to buy life insurance for highway workers. Legislation is required. This will get public attention to slow down at the core zone.

Driver education on work zones. Better taper instructions/guidelines. Pick up and placement specifications.

Set up a process so that new devices can be tested and easily incorporated into our specifications.

Require TMS trucks when placing/retrieving cones and anytime when working in a closed lane without positive separation.

New technology; improve presence of law enforcement; increase fines in work zones; improve protection devices; public education; coordination; proper monitoring; proper inspections.

Educate driver about work zones; impose some kind of penalty in the work zone.

Develop means to control speed through work zones. Drive education on driving through work zones.

Patrol “gawk boards” and damaged devices. Patrol signs and all devices. Don’t commingle devices.

Public safety awareness with content for learning.

Traffic school – when driver goes to school for reducing ticket, have drivers learn traffic control.

Necessary financial and technical support on education on safer work zones – techniques for implementing also inclusive.

All the tools/technique shall be added to the work zone to make the drivers and public aware and cautious to move through the work zone.

Improve standard plans and specifications relative to placement and removal of traffic control (i.e., order of removal for signage and cones, size of cone, trucks, etc.).

1,099

Page 11 of 11 01/05/2010 01:39:46

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cal - Dot - SHSP Safety Stakeholders TeamDocument11 pagesCal - Dot - SHSP Safety Stakeholders TeamprowagNo ratings yet

- Drip & Sprikler Irrigation SystemDocument21 pagesDrip & Sprikler Irrigation SystemBilal GandapurNo ratings yet

- Operation Manual For EWS - ADS 300-1607-Rev.3Document29 pagesOperation Manual For EWS - ADS 300-1607-Rev.3Firman100% (1)

- Pressurizes Irrigation JoinedDocument296 pagesPressurizes Irrigation Joinedmosne1100% (1)

- Water ManagementDocument6 pagesWater ManagementAgus Karsa YudhaNo ratings yet

- CatalogoDocument340 pagesCatalogoLalo Lawliet Betra100% (1)

- Vol. 3 Electrical and Mechanical SpecificationsDocument510 pagesVol. 3 Electrical and Mechanical Specificationshiima_3No ratings yet

- Multiple Choice - Exam - Irrigation - 09 - 10Document9 pagesMultiple Choice - Exam - Irrigation - 09 - 10Gemechu100% (2)

- Cal Dot Final Posters Summary VotesDocument1 pageCal Dot Final Posters Summary VotesprowagNo ratings yet

- Summary of Index Cards Top 10 Items & Key IssuesDocument1 pageSummary of Index Cards Top 10 Items & Key IssuesprowagNo ratings yet

- Transportation Improvements: San Francisco County Transportation AuthorityDocument14 pagesTransportation Improvements: San Francisco County Transportation AuthorityprowagNo ratings yet

- San Francisco County Transportation AuthorityDocument12 pagesSan Francisco County Transportation AuthorityprowagNo ratings yet

- MTC - Fhwa - Fy09 - Funding ObligationsDocument84 pagesMTC - Fhwa - Fy09 - Funding ObligationsprowagNo ratings yet

- Acronym Glossary: Appendix ADocument29 pagesAcronym Glossary: Appendix AprowagNo ratings yet

- CCSF - Mayor's Office On Disability - Accessisible Public Event ChecklistDocument8 pagesCCSF - Mayor's Office On Disability - Accessisible Public Event ChecklistprowagNo ratings yet

- San Francisco County Transportation AuthorityDocument20 pagesSan Francisco County Transportation AuthorityprowagNo ratings yet

- Countywide Transportation: Sanfranciscocountytransportationauthority JULY 2004Document13 pagesCountywide Transportation: Sanfranciscocountytransportationauthority JULY 2004prowagNo ratings yet

- CCSF - DPW - Bureau of Street-Use & Mapping - Notice of Intent - Contact List - Un-RedactedDocument8 pagesCCSF - DPW - Bureau of Street-Use & Mapping - Notice of Intent - Contact List - Un-RedactedprowagNo ratings yet

- Purpose of The Countywide Transportation Plan: San Francisco County Transportation AuthorityDocument12 pagesPurpose of The Countywide Transportation Plan: San Francisco County Transportation AuthorityprowagNo ratings yet

- Transportation System Needs & Opportunities: Starting With LandDocument18 pagesTransportation System Needs & Opportunities: Starting With LandprowagNo ratings yet

- Kirola VDocument1 pageKirola VprowagNo ratings yet

- SFPD 2009 - Organizational Chart - Airport BureauDocument3 pagesSFPD 2009 - Organizational Chart - Airport BureauprowagNo ratings yet

- SFPD 2009 - Organizational Charts - Field Operations BureauDocument3 pagesSFPD 2009 - Organizational Charts - Field Operations BureauprowagNo ratings yet

- SFPD 2009 - Organizational Chart - Investigations BureauDocument4 pagesSFPD 2009 - Organizational Chart - Investigations BureauprowagNo ratings yet

- City & County of San Francisco ADA Self-Evaluation Survey: Please List Your Department, Division & ProgramDocument30 pagesCity & County of San Francisco ADA Self-Evaluation Survey: Please List Your Department, Division & ProgramprowagNo ratings yet

- 2009/apr22mins - PDF: Download (48K) Print (5 Pages) Plain HTMLDocument1 page2009/apr22mins - PDF: Download (48K) Print (5 Pages) Plain HTMLprowagNo ratings yet

- SFPD 2009 - Organizational ChartDocument5 pagesSFPD 2009 - Organizational ChartprowagNo ratings yet

- Lighthouse For The Blind and Visually Impared - Annual Report - 2008 - Final VersionDocument20 pagesLighthouse For The Blind and Visually Impared - Annual Report - 2008 - Final VersionprowagNo ratings yet

- Thesis BamouniDocument51 pagesThesis BamouniCarlos RojasNo ratings yet

- Government of Balochistan Agriculture & Cooperatives DepartmentDocument1 pageGovernment of Balochistan Agriculture & Cooperatives DepartmentMuhammad SalehNo ratings yet

- Examples in 514Document5 pagesExamples in 514Ayodeji AdeyemiNo ratings yet

- MIP Guidelines PDFDocument68 pagesMIP Guidelines PDFdussanaveenNo ratings yet

- Manual Contrangulo Ti Max X SG20LDocument154 pagesManual Contrangulo Ti Max X SG20LANDRES RODRIGUEZNo ratings yet

- IFAS ST Augustine For FL LawnsDocument12 pagesIFAS ST Augustine For FL LawnsetggrelayNo ratings yet

- WH WC and Agri Allied WorksDocument30 pagesWH WC and Agri Allied WorksMohan KrishnaNo ratings yet

- The Range of Valves-DataDocument74 pagesThe Range of Valves-DataAsad KhudriNo ratings yet

- Wanaparthy Peddamandadi Peddamandadi GP INRM PlanDocument35 pagesWanaparthy Peddamandadi Peddamandadi GP INRM PlanSrajeshKNo ratings yet

- Soil Science Soil Water Conservation scqp26Document2 pagesSoil Science Soil Water Conservation scqp26Ankit SinghNo ratings yet

- Importance of Water ManagementDocument4 pagesImportance of Water ManagementKannan V KannanNo ratings yet

- 6+7fertilisation Low Cost DripDocument21 pages6+7fertilisation Low Cost DripArnab MondalNo ratings yet

- Iot Based Smart Farm1Document36 pagesIot Based Smart Farm1Hamza AliNo ratings yet

- Literature Review On Check DamDocument9 pagesLiterature Review On Check Damaflsodoam100% (1)

- Heavy Metals in Soils and Vegetables Irrigated With Urban Grey Waste Water in Fagge, Kano, NigeriaDocument10 pagesHeavy Metals in Soils and Vegetables Irrigated With Urban Grey Waste Water in Fagge, Kano, NigeriaijsretNo ratings yet

- Aem 403-Irrigation Engineering (3) UNIT-3: Dr. Anjitha Krishna P. R. Asst. Professor (Faculty of Agrl. Engg.) DEI, AgraDocument18 pagesAem 403-Irrigation Engineering (3) UNIT-3: Dr. Anjitha Krishna P. R. Asst. Professor (Faculty of Agrl. Engg.) DEI, AgraanjithakrishnaNo ratings yet

- DM Plan Raigonj Upazila Sirajgonj District - English Version-2014Document279 pagesDM Plan Raigonj Upazila Sirajgonj District - English Version-2014CDMP Bangladesh100% (1)

- DroughtcontingencyplanDocument15 pagesDroughtcontingencyplanapi-541632517No ratings yet

- Westernization of Asian Diets and The Transformation of Food Systems: Implications For Research and PolicyDocument18 pagesWesternization of Asian Diets and The Transformation of Food Systems: Implications For Research and PolicyJansher KhanNo ratings yet

- CDLF Catalogue GuomeipumpDocument7 pagesCDLF Catalogue Guomeipumpanon_6965157No ratings yet

- Polocy AnalaysisDocument23 pagesPolocy AnalaysisMelikteNo ratings yet

- Neo 70Document18 pagesNeo 70marrog0802No ratings yet

- Hawassa University Institute of TechnologyDocument14 pagesHawassa University Institute of TechnologybinyamNo ratings yet