Professional Documents

Culture Documents

Condensation calculations for building envelope

Uploaded by

lutfi awnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condensation calculations for building envelope

Uploaded by

lutfi awnCopyright:

Available Formats

Proj. No.

:D0052

Project No.

DESIGN CALCULATION

Sheet No.

SHEET

Mechanical & Industrial Department

D0052

CAIRO - EGYPT

Date

29-Nov-14

Computed by

1 of 2

Subject Condensation Calculation - Highest Relative Humidity

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

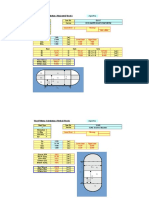

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Thermal

Resistivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.10

0.01

0.30

0.02

17.54

0.18

34.48

7.69

0.18

4.00

0.06

20.00

5.00

30.00

520.00

5.00

50.00

Hardboard

Plaster

The calculation is based on inside conditions of 24C and 50%rh

and outside conditions of 16C and 81%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

=

=

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1492.6-1473)/1.92E+10

Gt

1.02E-09 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 24 C & 50% rh

Pvo is the outside vapour pressure @ 16C and 81%rh

Gt is the total vapour resistence (N s/kg)

1 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - Highest Relative Humidity

Building Concourse 2 - Dubai International Airport

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

(24-16)/5.33

=

2

1.50 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

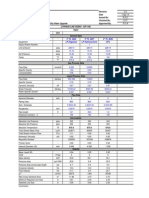

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

t1

t2

t3

t4

t5**

t6**

t7**

=

=

=

=

=

=

=

23.8

23.4

22

21.8

16.6

16.5

16.2

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

1490

2985

Pv3

=

1489

2985

Pv4

=

1484

2645

Pv5

=

1481

2645

pv6

=

1476

1938

pv7

=

1474

1938

pv8

=

1473

1818

Diffe Result*

rence

Pa

1495

1496

1161

1164

462

464

345

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 12.7 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

** Although the result is positivepressure difference,the difference is very low which indicates a risk

of condensation .

2 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

29-Nov-14

Computed by

1 of 2

Subject Condensation Calculation - Highest Dew Point Temperature

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Thermal

Resitivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Plaster Board

0.05

6.25

50.00

Ins. Fiberboard

0.05

1.00

0.10

0.01

0.30

0.02

17.54

0.18

34.48

7.69

0.18

4.00

0.06

20.00

5.00

30.00

520.00

5.00

50.00

Hardboard

Plaster

The calculation is based on inside conditions of 24C and 50%rh

and outside conditions of 30.5C and 70%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

=

=

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1492.6-2972)/1.92E+10

Gt

-7.71E-08 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 24C and 50%rh

3 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - Highest Dew Point Temperature

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 30.5C and 70%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

(24-30.5)/5.33

=

2

-1.22 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

24.1

24.5

25.6

25.8

30

30.1

30.3

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Pv2

=

1686

2985

Pv3

=

1763

3169

Pv4

=

2148

3363

Pv5

=

2379

3363

pv6

=

2780

4246

pv7

=

2895

4246

pv8

=

2972

4246

Differ

ence

Pa

1299

1406

1215

984

1466

1351

1274

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

4 of 22

Proj. No. :D0052

29-Nov-14

Computed by

MG

Approved by

MK

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

5 of 22

Proj. No. :D0052

29-Nov-14

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

6 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

29-Nov-14

Computed by

1 of 2

Subject Condensation Calculation - Highest Dry Bulb Temperature

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Resistivity

&Thermal

Conductivity is

assumed to be

similar to:

Assumed

Thickness

m

Thermal

Resistivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.10

0.01

0.30

0.02

17.54

0.18

34.48

7.69

0.18

4.00

0.06

20.00

5.00

30.00

520.00

5.00

50.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 46C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistance (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

=

=

5.33

(N s/kg)

where Rt is the total thermal resistance of the structure

mv

Pvi-Pvo

(1322-2928.3)/1.92E+10

Gt

-8.37E-08 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

7 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - Highest Dry Bulb Temperature

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 46C and 29%rh

Gt is the total vapour resistance (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-46/5.33

2

-4.50 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistance of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

22.5 Pv2

=

1531 Tables

2810

23.9 Pv3

=

1615

2985

27.9 Pv4

=

2033

3782

28.7 Pv5

=

2284

4008

44.2 pv6

=

2719

9110

44.6 pv7

=

2845

9593

45.4 pv8

=

2928

9593

Diffe Result*

rence

Pa

1279

1370

1749

1724

6391

6748

6665

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

8 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

29-Nov-14

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.1insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.10

0.01

0.30

0.02

17.54

0.18

34.48

7.69

0.18

4.00

0.06

20.00

5.00

30.00

520.00

5.00

50.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

=

=

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/1.92E+10

Gt

-6.47E-07 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

9 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - 80C (0.1insulation)

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-80/5.33

2

-10.9 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

Differ Result*

ence

Pa

t1

t2

t3

t4

t5

t6

t7

-130

-20

-877

-2133

28105

28836

31775

=

=

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

23.3 Pv2

=

2940 Tables

2810

26.7 Pv3

=

3587

3567

36.2 Pv4

=

6824

5947

38.2 Pv5

=

8765

6632

75.7 pv6

=

12131

40236

76.5 pv7

=

13102

41938

78.5 pv8

=

13749

45524

Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

10 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

29-Nov-14

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.15insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.15

0.01

0.30

0.02

17.54

0.18

34.48

7.69

0.18

4.00

0.06

20.00

5.00

30.00

520.00

5.00

50.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

2.07E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

=

=

7.06

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/2.07E+10

Gt

-6.00E-07 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

11 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - 80C (0.15insulation)

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-80/7.06

2

-8.2 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

Differ Result*

ence

Pa

t1

t2

t3

t4

t5

t6

t7

-13

-60

-1391

-3803

29690

28789

31775

=

=

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

23 Pv2

=

2823 Tables

2810

25.6 Pv3

=

3423

3363

32.8 Pv4

=

6425

5034

34.2 Pv5

=

9126

5323

76.7 pv6

=

12248

41938

77.4 pv7

=

13149

41938

78.8 pv8

=

13749

45524

Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

12 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

29-Nov-14

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.2insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.20

0.01

0.30

0.02

17.54

0.18

34.48

7.69

0.18

4.00

0.06

20.00

5.00

30.00

520.00

5.00

50.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

2.22E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

=

=

8.78

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/2.22E+10

Gt

-5.60E-07 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

13 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - 80C (0.2insulation)

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-80/8.78

2

-6.6 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

Differ Result*

ence

Pa

t1

t2

t3

t4

t5

t6

t7

89

-112

-1584

-4680

29588

30511

31775

=

=

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

22.8 Pv2

=

2721 Tables

2810

24.9 Pv3

=

3281

3169

30.6 Pv4

=

6080

4496

31.8 Pv5

=

9439

4759

77.4 pv6

=

12350

41938

77.9 pv7

=

13189

43700

79.1 pv8

=

13749

45524

No Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

14 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

29-Nov-14

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.1insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.10

0.01

0.00

0.00

17.54

0.18

34.48

7.69

0.00

0.00

0.06

20.00

5.00

30.00

520.00

0.00

0.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 70C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.67E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

=

=

5.07

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-9047)/1.67E+10

Gt

-4.63E-07 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

15 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - 70C (0.1insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-70/5.07

2

-9.5 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

Differ Result*

ence

Pa

t1

t2

t3

t4

t5

332

422

70

-695

20826

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

23.1 Pv2

=

2478 Tables

2810

26.1 Pv3

=

2941

3363

34.4 Pv4

=

5254

5324

36.1 Pv5

=

6642

5947

68.7 pv6

=

9047

29873

No Cond.

No Cond.

No Cond.

Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

16 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

29-Nov-14

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.15insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.15

0.01

0.00

0.00

17.54

0.18

34.48

7.69

0.00

0.00

0.06

20.00

5.00

30.00

520.00

0.00

0.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 70C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.82E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

=

=

6.80

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-9047)/1.82E+10

Gt

-4.24E-07 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

17 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Condensation Calculation - 70C (0.15insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-70/6.8

2

-7.1 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

Differ Result*

ence

Pa

t1

t2

t3

t4

t5

427

361

-434

-1806

20826

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

22.8 Pv2

=

2383 Tables

2810

25.1 Pv3

=

2808

3169

31.2 Pv4

=

4930

4496

32.5 Pv5

=

6840

5034

69 pv6

=

9047

29873

No Cond.

No Cond.

Cond.

Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

18 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

29-Nov-14

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

MG

Subject Critical Condensation Calculation - 60C (0.1insulation) (Ventilation Effect)

Checked by

Building Concourse 2 - Dubai International Airport

TZ

Approved by

MK

Data

Layer

Vaopur

Resistivety

&Thermal

Conductivety is

assumed to be

similar to:

Assumed

Thickness

m

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Ins. Fiberboard

0.05

1.00

0.10

0.01

0.00

0.00

17.54

0.18

34.48

7.69

0.00

0.00

0.06

20.00

5.00

30.00

520.00

0.00

0.00

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 60C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.67E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

=

=

5.07

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-5784)/1.67E+10

Gt

-2.67E-07 Kg/m2s

=

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 22C and 50%rh

19 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

D0052

Sheet No.

CAIRO - EGYPT

1 of 2

Subject Critical Condensation Calculation - 60C (0.1insulation) (Ventilation Effect)

Checked by

Building Concourse 2 - Dubai International Airport

TZ

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

Date

29-Nov-14

Computed by

MG

Approved by

MK

22-60/5.07

2

-7.5 W/m

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t 1 =t ai -qR si

Differ Result*

ence

Pa

t1

t2

t3

t4

t5

820

912

1166

639

13255

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

22.9 Pv2

=

1990 Tables

2810

25.2 Pv3

=

2257

3169

31.8 Pv4

=

3593

4759

33.2 Pv5

=

4395

5034

59 pv6

=

5784

19039

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

20 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

CAIRO - EGYPT

D0052

Sheet No.

1 of 2

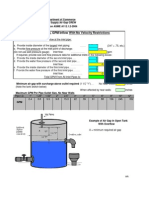

Subject Ventilation Air Required - Not To Exceed 60C

Building Concourse 2 - Dubai International Airport

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

Heat Gain To The Ventilated Air Gap:

Q = U A T

Where

Q is the heat gain to the ventilated air gap in W

U is the overall heat transfer coeffient in W/m2k

A is the area in m2

T is the temperature difference in Kelvin

Q = (3.85)(6.25)(353.15-333.15)

481

W

1642.62

=

BTU/hr

Ventilation air required:

Q = cfm(1.08)T

Where

Q is the heat gain to the ventilated air gap in BTU/hr

cfm is the required ventilation air

T is the temperature difference in Fahrenheit

1648.615 = cfm(1.08)(176-140)

cfm =

42

=

20 l/s

=

30 l/s

(For Safety)

Therefore ventilation air requird is 5 l/s for each 1 m2

Area through which air flow = 4*2.5*0.03/2

= 0.15 /2 = 0.075 m2

=

0.03/.075

0.4 m/s

80 ft/min

Velocity =

For air to enter

21 of 22

Proj. No. :D0052

Project No.

DESIGN CALCULATION

Mechanical & Industrial Department

CAIRO - EGYPT

Subject Ventilation Air Required - Not To Exceed 60C

Building Concourse 2 - Dubai International Airport

SHEET

D0052

Sheet No.

1 of 2

Checked by

TZ

Date

29-Nov-14

Computed by

MG

Approved by

MK

22 of 22

You might also like

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- BoilerCalcSteamPropDocument4 pagesBoilerCalcSteamPropMarc EdwardsNo ratings yet

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Reciprocating Compressor Performance Worksheeet USCDocument6 pagesReciprocating Compressor Performance Worksheeet USCTiano BaLajadiaNo ratings yet

- Plate Heat ExchangersDocument4 pagesPlate Heat Exchangersamini_mohiNo ratings yet

- Head Calculation Hydronic PipingDocument18 pagesHead Calculation Hydronic Pipingjomy_pj8106No ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- Pinch Analysis SpreadsheetDocument97 pagesPinch Analysis SpreadsheetuxahidNo ratings yet

- API 2000 guidance for inert gas blanketing of tanksDocument2 pagesAPI 2000 guidance for inert gas blanketing of tankssandeshNo ratings yet

- Flare Stack Radiation Intensity CalculationDocument21 pagesFlare Stack Radiation Intensity CalculationRafael ReyesNo ratings yet

- Pipe Heat Transfer CalculationsDocument12 pagesPipe Heat Transfer CalculationsmansourotaibiNo ratings yet

- Compressor SizeDocument3 pagesCompressor SizeSubhash KumarNo ratings yet

- Psychrometric ProcessesDocument9 pagesPsychrometric ProcessesArt JamesNo ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Ows Piping Size2BLDocument3 pagesOws Piping Size2BLreach_arindomNo ratings yet

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHNo ratings yet

- Mass flow rates and gas properties data tableDocument3 pagesMass flow rates and gas properties data tablemgkvprNo ratings yet

- Tank relief designDocument12 pagesTank relief designsachinumaryeNo ratings yet

- Bedok WRP velocity and pumping calculationsDocument3 pagesBedok WRP velocity and pumping calculationsPhyu Mar Thein Kyaw100% (1)

- Pressure Safety Valve Sizing Calculations Vapour or Gas ReliefDocument3 pagesPressure Safety Valve Sizing Calculations Vapour or Gas ReliefDhananjay NilkuteNo ratings yet

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaNo ratings yet

- Air Cooled Exchanger Specification for El Paso Exp West Cameron 62 A-Aux E132-2-36Document1 pageAir Cooled Exchanger Specification for El Paso Exp West Cameron 62 A-Aux E132-2-36Honey TiwariNo ratings yet

- Heater Lowers Methanol Temp from 95C to 40CDocument30 pagesHeater Lowers Methanol Temp from 95C to 40CHamdan ShdNo ratings yet

- 100 P 102Document33 pages100 P 102AJAY1381No ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2hwang2100% (1)

- HYSYS Excel Link Manipulate Oil ManagerDocument19 pagesHYSYS Excel Link Manipulate Oil ManagerEbby OnyekweNo ratings yet

- Process Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsDocument1 pageProcess Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsamitkrayNo ratings yet

- Gas Conditioning System Specification Sheet: Process InformationDocument3 pagesGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNo ratings yet

- CDA Data CollectionDocument2 pagesCDA Data Collectiondford8583No ratings yet

- Heat Exchanger Specification SheetDocument5 pagesHeat Exchanger Specification SheetNur Izzati KamrulnizamNo ratings yet

- Counter Current Heat Exchanger CarnahanDocument4 pagesCounter Current Heat Exchanger CarnahancymyNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Routine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsDocument3 pagesRoutine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsMohamed Sayed AbdoNo ratings yet

- Design Calculation Sheet: Chilled Water Secondary PumpsDocument2 pagesDesign Calculation Sheet: Chilled Water Secondary PumpsgerrydimayugaNo ratings yet

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaNo ratings yet

- Hydraulic calculation spreadsheet for single phase flowDocument16 pagesHydraulic calculation spreadsheet for single phase flowsamynatha PrasathNo ratings yet

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168No ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- TW6151A - Wake Freq CalcaDocument2 pagesTW6151A - Wake Freq Calcakkd3No ratings yet

- Vessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDocument4 pagesVessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDongwon ShinNo ratings yet

- Reference: Chapter 2 Spread Sheet Made By: Himanshu Parikh Vadodara, Gujarat, IndiaDocument5 pagesReference: Chapter 2 Spread Sheet Made By: Himanshu Parikh Vadodara, Gujarat, IndiaHimanshu ParikhNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocument7 pagesQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- All Sep CalcDocument22 pagesAll Sep Calcbharathscds100% (3)

- Cal. Dew PointDocument1 pageCal. Dew PointJuan Pablo ApazaNo ratings yet

- Compressibility Z FactorDocument14 pagesCompressibility Z FactorosbertodiazNo ratings yet

- Line Sizing - 2PHASEDocument11 pagesLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Can Length 6.875 6 Top: Input Data in Orange Area OnlyDocument13 pagesCan Length 6.875 6 Top: Input Data in Orange Area Onlyionutlaur86No ratings yet

- 2K Method Excess Head Loss in Pipe FittingsDocument8 pages2K Method Excess Head Loss in Pipe Fittingsjxd3261No ratings yet

- Condensation CalculationDocument40 pagesCondensation Calculationbinhjuki100% (2)

- Condensation Calculation for Dubai Airport BuildingDocument40 pagesCondensation Calculation for Dubai Airport Buildingwado11No ratings yet

- Condensation Calculation Design ReportDocument12 pagesCondensation Calculation Design ReportfebousNo ratings yet

- Insulation CalcDocument4 pagesInsulation Calcjacok22No ratings yet

- 220 KV Sag Tension Calculation - ThyottarDocument13 pages220 KV Sag Tension Calculation - Thyottarannuvyas100% (3)

- Liquid Pressure DropDocument8 pagesLiquid Pressure Droplutfi awnNo ratings yet

- E10 Blending Study Final ReportDocument107 pagesE10 Blending Study Final Reportlutfi awnNo ratings yet

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDocument11 pagesHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnNo ratings yet

- Air Compressor Tools APODocument7 pagesAir Compressor Tools APOlutfi awnNo ratings yet

- Air Compressor Curve ToolDocument14 pagesAir Compressor Curve Toollutfi awnNo ratings yet

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Document30 pagesLiquid and Gas Velocity Gas Compressibility and Renolds Number.lutfi awnNo ratings yet

- Bitumen Upgrading Shell Canada LimitedDocument301 pagesBitumen Upgrading Shell Canada Limitedlutfi awnNo ratings yet

- Hydraulic Calculations MKIIDocument8 pagesHydraulic Calculations MKIIlutfi awnNo ratings yet

- 2011 Chaudhuri U R Fundamentals of Petroleum and PetrochDocument33 pages2011 Chaudhuri U R Fundamentals of Petroleum and Petrochlutfi awnNo ratings yet

- Mixer Tank Jet Pumps Gea - tcm11 34889Document4 pagesMixer Tank Jet Pumps Gea - tcm11 34889Venodaren VelusamyNo ratings yet

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanNo ratings yet

- 04 Jet Mixing Design ApplicationsDocument6 pages04 Jet Mixing Design Applicationslutfi awnNo ratings yet

- Lubricating Oils: Test Methods Test MethodsDocument32 pagesLubricating Oils: Test Methods Test MethodsCorina StanculescuNo ratings yet

- Astm D 86Document8 pagesAstm D 86lutfi awnNo ratings yet

- Energy conversion factors and density ranges for petroleum productsDocument2 pagesEnergy conversion factors and density ranges for petroleum productslutfi awnNo ratings yet

- Conversion of Milligrams Per Cubic Meter To PPMDocument2 pagesConversion of Milligrams Per Cubic Meter To PPMlutfi awnNo ratings yet

- Plumbing H 2 Osu Pair Gap CalculatorDocument9 pagesPlumbing H 2 Osu Pair Gap Calculatorlutfi awnNo ratings yet

- Gas TurbDocument10 pagesGas Turblutfi awnNo ratings yet

- Calculation ExampelDocument21 pagesCalculation Exampellutfi awnNo ratings yet

- Water Demand Calculation 1Document2 pagesWater Demand Calculation 1lutfi awnNo ratings yet

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnNo ratings yet

- Fonds Bombes - Surface MouilleeDocument3 pagesFonds Bombes - Surface MouilleesegunoyesNo ratings yet

- Valve Sizing Worksheet InstructionsDocument11 pagesValve Sizing Worksheet Instructionslutfi awnNo ratings yet

- H2S RiskDocument6 pagesH2S Risklutfi awnNo ratings yet

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationlutfi awn100% (1)

- Line sizing for gas flow from PCV to flare headerDocument2 pagesLine sizing for gas flow from PCV to flare headerlutfi awnNo ratings yet

- GOR Vs GVFDocument8 pagesGOR Vs GVFlutfi awnNo ratings yet

- Centrifugalcompressorpower Si UnitsDocument4 pagesCentrifugalcompressorpower Si UnitsJoshi DhvanitNo ratings yet

- PumpDocument31 pagesPumpkajale_shrikant2325No ratings yet

- Gas ReservesDocument8 pagesGas Reserveslutfi awnNo ratings yet

- Calculate Size of Ventilation FanDocument3 pagesCalculate Size of Ventilation Fanhusnainyasir100% (2)

- Upc 2021Document495 pagesUpc 2021mohammad ali100% (3)

- Msds Polyanionic Cellulose PacDocument4 pagesMsds Polyanionic Cellulose PacWANGYUSHENG Kima Chemical Co LtdNo ratings yet

- NFPA 101 Handbook 2018 44Document1 pageNFPA 101 Handbook 2018 44sundarayya giscoNo ratings yet

- Ufc 3 410 01Document88 pagesUfc 3 410 01Andrei LunguNo ratings yet

- Des Champ - Heatpipe (Catalog)Document20 pagesDes Champ - Heatpipe (Catalog)picnarukNo ratings yet

- Designing HVAC System With and Without Heat Recovery Wheel Using ECO FRESH Enthalpy WheelDocument4 pagesDesigning HVAC System With and Without Heat Recovery Wheel Using ECO FRESH Enthalpy WheelZain ShariffNo ratings yet

- Mine 422 SyllabusDocument4 pagesMine 422 Syllabusgirmay kasayeNo ratings yet

- Nabl 102 PDFDocument74 pagesNabl 102 PDFRajat JainNo ratings yet

- Catalog Fatade Ventilate Etem PDFDocument110 pagesCatalog Fatade Ventilate Etem PDFLucian BumbaceaNo ratings yet

- Summer Internship ReportDocument77 pagesSummer Internship ReportNicole RobinsonNo ratings yet

- 861-868 Series MsdsDocument2 pages861-868 Series MsdsMangesh MohiteNo ratings yet

- Anesthesia SystemDocument6 pagesAnesthesia SystemYoussry Elsayed MohamedNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- TDS - Hardtop XP - English (Uk) - Azad Jotun Ras TanuraDocument4 pagesTDS - Hardtop XP - English (Uk) - Azad Jotun Ras TanuraAzadAhmadNo ratings yet

- Risk Assessment Form Entry Into Enclosed Spaces 0119Document9 pagesRisk Assessment Form Entry Into Enclosed Spaces 0119Thurdsuk NoinijNo ratings yet

- Design and Development of Hybrid Native Chicken Egg Incubating Machine For Poultry Industry in Concepcion, Batangas CityDocument10 pagesDesign and Development of Hybrid Native Chicken Egg Incubating Machine For Poultry Industry in Concepcion, Batangas CitygimNo ratings yet

- Johnson Controls J06Document124 pagesJohnson Controls J06Geovanni Sanchez TrejoNo ratings yet

- Hotel StandardsDocument12 pagesHotel StandardsCiara AnneNo ratings yet

- Roldan, MC (400 Questions)Document68 pagesRoldan, MC (400 Questions)Couline Castillo Roldan - DinoyNo ratings yet

- YORK® 50 Ton To 65 Ton, YPAL Design Level F, Single Packaged Rooftop Units, Installation, Operation, and Maintenance ManualDocument164 pagesYORK® 50 Ton To 65 Ton, YPAL Design Level F, Single Packaged Rooftop Units, Installation, Operation, and Maintenance ManualMaqbool MNo ratings yet

- German Air Supply Standards in Operating TheatresDocument24 pagesGerman Air Supply Standards in Operating TheatresYury LorenzNo ratings yet

- AIr Quality in Bone Marrow Transplant UnitsDocument6 pagesAIr Quality in Bone Marrow Transplant UnitsA MNo ratings yet

- Iaq PDFDocument228 pagesIaq PDFUmi PhamNo ratings yet

- MSDS Novec 72FL LOXDocument8 pagesMSDS Novec 72FL LOXsshaffer_9No ratings yet

- Ashrae Standard For GymDocument2 pagesAshrae Standard For GymignatiadiskNo ratings yet

- Facadetectonics2014boake RevDocument24 pagesFacadetectonics2014boake RevstomakosNo ratings yet

- Saudi Aramco Inspection Checklist: Battery Room HVAC Requirements SAIC-K-4046 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Battery Room HVAC Requirements SAIC-K-4046 HvacshahzadaNo ratings yet

- Architectural Ideas For The New NormalDocument4 pagesArchitectural Ideas For The New NormalChi De LeonNo ratings yet

- Emission ControlDocument26 pagesEmission ControllogammicNo ratings yet