Professional Documents

Culture Documents

Lecture 5M

Uploaded by

Manoj BallaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 5M

Uploaded by

Manoj BallaCopyright:

Available Formats

10/4/13

Lecture 5

Lecture 5

Developing Better Method:

With the present method or procedure for the job in mind, the application of critical analysis' highlights the essential part of

the job, for which alternative ways for its carrying out are developed .

When developing alternative ways for doing a task the following may be considered.

Where and how to use man' in the process?

What better work procedure be adopted?

What better equipment be used?

What better layout of work station, shop or factory be used?

In deciding whether a particular element of work (operation, inspection, or transportation) be carried out manually or with the

help of a device, method study engineer must be well aware of things which man cannot do or does in inferior fashion than

machine. Examples of such things are:

a.

b.

c.

d.

e.

f.

g.

h.

Exert large amount of force, as needed in metal cutting.

Exert force precisely or smoothly at a fixed rate as needed in metal forming.

Do high speed computations of complex nature.

Perform repetitive tasks without suffering from side effects like boredom, fatigue, etc.

Move at high speeds for hours together.

Carry out several tasks simultaneously.

Respond fast to frequently changing control signals.

Perform satisfactorily in an environment where conditions relating to cold, heat, noise, dampness, etc. are extreme.

In contrast, machines prove inferior generally when for carrying out a task it is necessary to

a.

b.

c.

d.

Think creatively or inductively

Learn

Generalize

Cope will unexpected events.

In most cases, the relative roles of man and machine vary from one extreme end in which entire process is manual to the

other extreme in which the process is completely mechanized with the presence of man only for monitoring, trouble

shooting, maintenance, and the like.

Man is readily available and extremely flexible tool, who has the capability of doing a large number and type of tasks with

learning and practice that is generally less expensive than the cost of creating devices for the same purpose. Man is

therefore considered a strong competitor for low, medium and even some high volume production tasks.

When an activity is decided to be carried out manually, the best work procedure is determined by considering the principles

of Motion Economy.

Equipped will the various alternative ways of carrying out essential elements of task, method study engineer has now to

choose the best alternative method. He decides upon the criteria, which may be additional fixed costs involved, running cost,

production rate, operator's fatigue, operator learning time, and the like. The weight to each criterion is fixed and performance

is predicted of each alternative with respect to each criteria. The one which gets the maximum points is selected for adoption

as a standard method.

Detailed specifications of this method are prepared with the description of procedure, workplace layout and

material/equipment to be used. This is important for

Communication of the proposed work method to those responsible for its approval

Communication of the proposed method to those concerned with its installation, for example instructors

nptel.iitm.ac.in/courses/Webcourse-contents/IIT-ROORKEE/INDUSTRIAL-ENGINERRING/part1/lecture5.htm#

1/2

10/4/13

Lecture 5

and supervisors who are actually responsible for instructions to operators and setting up the machinery and

work place layouts.

Official record of the work method.

Installation of Improved Method:

When the proposals of the improved method for a job are approved by the management of the company, the next step is to

put this method into practice. Installation of method requires necessary prior preparation for which the active support of

everyone concerned is very important.

The activities of the installation phase include:

1. Gaining acceptance of the change by the workers involved and their representatives. The method change may affect the

routine and paper work of wages, costs, planning, and even purchase department. It may require displacement of staff from

one section to another of the organisation. Adjustments of this type need to be carried out very carefully so that the least

possible hardship or inconvenience is caused.

2. Retraining the workers. The extent to which workers need retraining will depend on the nature of the job and the changes

involved. It is much more for those jobs which have a high degree of manual dexterity and where the workers have been

doing the work by traditional methods. The use of films demonstrating the advantages of new method as compared to

traditional one are often very useful in retraining the workers.

3. Arranging the requirements of the new method. This involves (i) arranging the necessary plant, tools and equipment at all the workplaces,

(ii) arranging building-up of necessary stocks of new raw materials, and running-down of old stocks,

(iii) checking up the availability and continuity of all supplies and services, and

(iv) arranging any clerical records which may be required for purposes of control and comparison.

4. Taking other necessary actions. These will depend upon situation to situation. For example, if changes in working hours

are involved, necessary instructions should be passed on to auxiliary services such as transport, canteen, water supply, etc.

If change in wages is involved, information concerning the date of installation must reach the costing department. Necessary

instructions should be passed on to every one concerned about the time table for the installation of the change in method.

5. Giving a trial run to the new method. It is important that all departments affected by the change are represented at the

rehearsal. It is often advantageous to conduct the rehearsal while the old method is still operating. It should usually take

place outside normal working hours; say at week-end or at holiday time so that there is no interference with normal

production. The suggestions for minor variations in the proposed method if they are worth while and cost effective should be

accepted and incorporated.

It is obvious that the method analyst has to be extra tactful and keep restraint throughout the period of installation. The

installation is considered complete when the new method starts running smoothly.

Follow-up:

The work of method study man is not complete with the installation of the improved method; the maintenance of the new

method in its specified form is also part of his activities. The main aim of maintenance of the new method is to ensure that

the workers do not slip back into old method, or introduce elements which are not part of the proposed method.

For effective maintenance it is important to define and specify the new method very clearly. An operator chart giving adequate

details of the tools, equipment, and workplace layout and operator-motion pattern is often helpful.

The workers have tendencey to drift away from the method laid down. The purpose of the method-maintenance is to check

this tendency. But if it is found that the change from the method specified is in fact an improvement which can be made in the

method, this should be officially incorporated.

Goto Home

nptel.iitm.ac.in/courses/Webcourse-contents/IIT-ROORKEE/INDUSTRIAL-ENGINERRING/part1/lecture5.htm#

2/2

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Weld Cracking PDFDocument5 pagesWeld Cracking PDFjuanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CSWIP Welding Inspection Plate Section PracticalDocument31 pagesCSWIP Welding Inspection Plate Section PracticalManoj Balla100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Welding Inspector Interview QuestionsDocument5 pagesWelding Inspector Interview QuestionsValli Raju91% (23)

- WeldingDocument34 pagesWeldingManoj BallaNo ratings yet

- UT Thickness ProcedureDocument8 pagesUT Thickness ProcedureManoj Balla100% (3)

- Ultrasonic Testing For LVL 1 & 2 Vol.2Document48 pagesUltrasonic Testing For LVL 1 & 2 Vol.2Mohd Nazirul Fahmi100% (2)

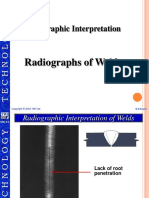

- Radiographic Interpretation: Radiographs of WeldsDocument22 pagesRadiographic Interpretation: Radiographs of WeldsManoj BallaNo ratings yet

- P&id NotesDocument17 pagesP&id NotesFitriana SarifahNo ratings yet

- Welded Steel PenstockDocument63 pagesWelded Steel PenstockIfnu Setyadi100% (1)

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFDocument11 pages3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- Fabrication Guide PDFDocument96 pagesFabrication Guide PDFbookpp100% (2)

- BS en 1711 (2000)Document24 pagesBS en 1711 (2000)Jindarat KasemsooksakulNo ratings yet

- Combined ChecklistDocument9 pagesCombined ChecklistKrishnaBanjareNo ratings yet

- Papers-1: Telegram To JoinDocument1 pagePapers-1: Telegram To JoinManoj BallaNo ratings yet

- Rail Track Material Catalogue Nov17Document44 pagesRail Track Material Catalogue Nov17Manoj BallaNo ratings yet

- Combined ChecklistDocument9 pagesCombined ChecklistKrishnaBanjareNo ratings yet

- International StandardDocument10 pagesInternational StandardManoj BallaNo ratings yet

- AsmeDocument11 pagesAsmeManoj BallaNo ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationRatnakumarChittoorNo ratings yet

- Pressure Shaft Installation Methodology PDFDocument8 pagesPressure Shaft Installation Methodology PDFRaj KumarNo ratings yet

- B4-28 - Appendix 7-8 - List of Codes, Standards and Specifications - A4E6E8Document14 pagesB4-28 - Appendix 7-8 - List of Codes, Standards and Specifications - A4E6E8Velpandian ManiNo ratings yet

- 13.march (GulfJobPaper - Com)Document6 pages13.march (GulfJobPaper - Com)Manoj BallaNo ratings yet

- API 510 Sample QuestionsDocument10 pagesAPI 510 Sample Questionsbichibtech1No ratings yet

- Especificaciones Tanques de AceroDocument6 pagesEspecificaciones Tanques de AcerojhobanybernalNo ratings yet

- API 510 Exam - 5C - Answer - KeyDocument1 pageAPI 510 Exam - 5C - Answer - KeyManoj BallaNo ratings yet

- 29 May Assignment Abroad TimesDocument2 pages29 May Assignment Abroad TimesManoj BallaNo ratings yet

- ASNT Level III MT Questions and Answers PDFDocument20 pagesASNT Level III MT Questions and Answers PDFManoj Balla100% (5)

- 19 P PDFDocument9 pages19 P PDFManoj BallaNo ratings yet