Professional Documents

Culture Documents

PTC Motor Starters: 8EA Series

Uploaded by

cloviscfsjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC Motor Starters: 8EA Series

Uploaded by

cloviscfsjCopyright:

Available Formats

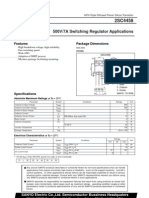

Product Bulletin

PTC Motor Starters

8EA Series

Features

Solid-state PTC motor starter

Designed for use with most split phase, capacitor run and/or start, fractional h.p. hermetic compressors

Available for all single phase voltage applications

Low power dissipation

Easy installation

Electrically (EMI) noise free

Operating noise free

Approved for use with explosive proof applications

High reliability with no moving parts

Product Overview

The Sensata Technologies 8EA motor

starter, a low-cost alternative to

electro-mechanical relays, performs

the PTC (positive temperature

coefficient) solid-state starter function. The 8EA is suitable for

compressors used in refrigerators,

freezers, water coolers,

de-humidifiers, vending machines

and similar refrigeration applications. It plugs directly onto the

compressor terminal pins, and is

frequently used with the 4TM

plug-on motor protector.

Technical Features

Utilizes PTC pill materials to

energize / de-energize motor

start windings

Provides inherent start

winding protection

Optimal packaging approach

improves efficiency

Used in 120V or 240V

applications

Provides lowest power

consumption in industry

Wide spectrum of resistance

ranges available

Quality and Performance

PTC pills 100% electrically

tested twice

High reliability with no moving

parts

500K cycles min. at max.

rated condition

Dissipates less than 2 watts

under normal operating

conditions

UL and CUL Recognized

Component: File SA3745

IEC Cert. number: US/4312/UL

Demko Cert. number: 129508-1

CCEE number: CH003840-99

ENEC 2018218.01

Exploded View

Cover

Pin

Connector

Convenience

Fits within most existing

terminal fences

Highly legible part coding

One rating will potentially

service entire compressor

voltage series

Mounts directly to the

compressor terminal pins

Compatible with world class

4TM motor protection

PTC Pill

Base

Male

Quick Connect

Terminals

PTC Pill Spring

Electrical Component Assembly Process

Compressor Housing

Terminal Fence

4TM Protector

8EA Motor Starter

Compressor

Electrical Cover

Bale Strap

Wire Leads to 8EA

Wire Lead to 4TM

Assembly Process

Description

The illustration above depicts the

assembly of the 8EA onto the

compressor. The 4TM motor protector is plugged onto the common

pin. The 8EA plugs onto the

remaining 2 pins. Female flag connectors are connected, and the

electrical cover encloses the entire

assembly.

Dimensional Drawings (mm)

(11.7)

(32)

8EA Coding System

(23.5)

8EA XXX ......................Sensata Product number

XXXX ............................Customer part number optional

06H9R ..........................Date Code (Typical)

Mexico ........................Country of Origin (Typical)

(25)

(25)

Wiring Diagrams

Terminal Configurations

For use with CSCR

or CSIR motor

Run Winding

R

Compressor

terminal

For use with RSIR

or RSCR motor

Run Winding

8EA

1

Compressor

terminal

PTCR

Overload

(Motor Protector)

Run

Capacitor

(Optional)

L1

S

Start

Winding

8EA

S

Start

Winding

PTCR

Run

Capacitor

(Optional)

Overload

(Motor Protector)

L2

L1

PTC Performance

Terminal Numbers

3

2

4

Device

8EAXXC1

8EAXXC2

8EAXXC3

8EAXXC4

8EAXXC5

M

M

M

M

M

M

M

M

M

M

M

M = 1/4"Male Quick Connect Terminal

For other configurations contact Sensata

L2

8EA PTC Motor Starter Design Chart

When power is first applied to the compressor via

the 8EA, the PTC pill is in low resistance state.

Independent Variable

Current flows through the PTC pill to the start

windings, causing a beneficial phase angle shift

Resistance

P

between start and main windings, and resulting in T Mass

C

an increase in the starting torque.

R

Device Property

Switch

Time

Power

Max.

Voltage

Cool

Rate

Switch Temperature

General trends are shown for changes in the PTCR element specifications and the

corresponding 8EA device properties.

Common Electrical Rating

R/T Curve

Rmax

8EA

Series

Log resistance

V1

V2

V2>V1

2Ro

Ro

Switch Temp.

50

100

150

200

Temperature Celcius

250

14CX

15CX

16CX

17CX

18CX

19CX

20CX

Application

Voltage

VmaxImax

120

120

120

240

240

240

240

For other ratings contact Sensata.

180

200

200

300

355

300

400

/

/

/

/

/

/

/

12

12

10

7

6

8

5

Heat

Nominal

Resistance Capacity

(Ohms)

MCP

4.720%

6.820%

1020%

2220%

3320%

520%

4720%

1.40

1.40

1.40

1.40

1.40

1.40

1.40

8EA PTC Motor Starter Application Procedure

Glossary

Step 1: Assemble Data Required for New Applicaions

R0

Example

R0 Resistance ..............................5.0 Ohms

Max. Volt (Vmax).......................... 162 VAC

Max. Current (In Rush)..............8 Amp

Switch Time of Motor ..................

>0.5 Sec @ 8 Amp

Ambient 25oC

Measured resistance value at 25oC Max.

voltage of 2.0 volts.

Cooldown Time Time required for the PTC resistance to

return to two times the initial value (2R0)

Temperature obtained with a resistance

Curie Point

value of two times (2R0) the minimum

(Switch Temp.)

resistance value (R0)

Vmax

Reset Time ..................................<80 Sec @ Nom. Volt

Ambient 25oC

Maximum operating voltage which may be

applied across the PTC continuously at the

ambient temperature specified and in a

steady high resistance state.

Vr

Test Requirements .......................250K Cycles @ Max.

Operational Conditions

Application rated supplied voltage/

120 or 240 VAC (below Vmax)

Iss

Steady state current remaining at maximum

operating voltage.

Imax

Maximum operating current.

Motor Type ...................................RSCR

300 Hrs. @

Max. Volt +10%

Step 2: Select PTC pill based on resistance and maximum

operating conditions.

(See electrical rating on previous page).

Step 3: Select 8EA physical configuration based on motor

type. (See terminal configurations on previous page).

Step 4: Switch Time Calculation

The amount of time required for PTC to switch into its

high resistance state can be approximated as follows:

Equation

C (T -T )

Time (Sec) = M P 2 S A

IR

MCP = Heat Capacity

(Watt-Sec/oC)

Ts = Switch Temperature(oC)

Example

R = 5 Ohms (R=5x.8=4)

I = 8 Amps

Ts = 120oC

TA = 25oC

C = 1.60

TA = Ambient Temperature(oC) M P

1.60 (95)

I = Inrush Current (Amps-Rms)

Time (Sec) = (82) (4)

Switch Time = 0.59 Sec.

R = Initial Device Resistance

Under Voltage

(Use R 0 x 0.8)

Theoretical Calculated PTC Switch Time

Should Be Time Required to Start Motor

For further information write or call:

Sensata Technologies

529 Pleasant Street

Attleboro, Massachusetts 02703-0964

Phone: (508) 236-3800

website: www.sensata.com

Application Notes

1. The surface and terminals of the 8EA device can reach

high temperatures under normal running conditons.

Any material in contact with the 8EA and its terminals,

including wire and quick-connect receptacle plastic

insulation, should have a minimum temperature rating

(RTI) of 105oC. Adequate spacing should be provided

to insulate lower-rated materials from this heat source.

2. The 8EA device should be protected from potential

sources of liquid, such as the evaporator tray and

water connections.

3. Certain materials, such as chlorine (Cl) containing

gases, can degrade the characteristics of the 8EA

device. The 8EA device should not be exposed to

sulphur (S) or chlorine (Cl) containing gases, and

must be kept away from materials that can generate

them. In particular, avoid the use of polyvinyl chloride

(PVC) insulation in contact with the 8EA terminals.

4. The 8EA device is designed to be used in conjunction

with an electrical cover.

Important Notice: Sensata Technologies reserves the right to make changes to, or to discontinue, any product

or service identified in this publication without notice. Before placing orders, users should obtain the latest

version of the relevant information to verify that the information being relied upon is current.

Sensata Technologies assumes no responsibility for customers product designs or applications. Users must

determine the suitability of the Sensata device described in this publication for their application, including the

level of reliability required. Many factors beyond Sensatas control can affect the use and performance of a

Sensata product in a particular application, including the conditions under which the product is used and the

time and environmental conditions in which the product is expected to perform. As these factors are uniquely

within the users knowledge and control, it is essential that the user evaluate the Sensata product to

determine whether it is fit for a particular purpose and suitable for the users application.

Sensata Technologies products are sold subject to Sensatas Terms and Conditions of Sale which can be

found at www.sensata.com/terms.htm

MCCS017D

Printed in U.S.A., Reprinted 03/2011

You might also like

- SCR c106Document4 pagesSCR c106Francisco PedrozaNo ratings yet

- Reverse Blocking Triode Thyristors: Semiconductor Technical DataDocument4 pagesReverse Blocking Triode Thyristors: Semiconductor Technical DataAlejandro Lar RodNo ratings yet

- RTI PTC Thermistor CatalogDocument20 pagesRTI PTC Thermistor Cataloghenrycervantes4No ratings yet

- Template Manual Abb Ret 670 v1.1 Enu Tu2.22 v1.000Document18 pagesTemplate Manual Abb Ret 670 v1.1 Enu Tu2.22 v1.000m_dh87129100% (1)

- ATS48 CatalogueDocument48 pagesATS48 CatalogueUrsula JohnsonNo ratings yet

- Carrier 38ap 4pdDocument106 pagesCarrier 38ap 4pdMaritza SolorzanoNo ratings yet

- Sivacon 8PT-Busbar Rear-Technical CatalogueDocument69 pagesSivacon 8PT-Busbar Rear-Technical CatalogueLaurentiu CatalinNo ratings yet

- Surface Mount Power Package: Semiconductor Technical DataDocument4 pagesSurface Mount Power Package: Semiconductor Technical DataHarish Kumar MNo ratings yet

- PC1616 PC1832 PC1864 V4 2 Installation Manual enDocument68 pagesPC1616 PC1832 PC1864 V4 2 Installation Manual enScarlat MadalinNo ratings yet

- Siemens Motor - Control - CentersDocument80 pagesSiemens Motor - Control - Centersmarf123No ratings yet

- Smartgen 6100seriesDocument31 pagesSmartgen 6100seriesbdthinh100% (2)

- AN6780Document6 pagesAN6780blueword66No ratings yet

- Basics of Motor Control CentersDocument72 pagesBasics of Motor Control CentersRaihanKhan100% (1)

- RL User ManualDocument31 pagesRL User ManualMano CadenaNo ratings yet

- Laserati 8008 Preinstallation-Guide EN PDFDocument15 pagesLaserati 8008 Preinstallation-Guide EN PDFHUGONo ratings yet

- Catalog Altistart 48 2006 enDocument50 pagesCatalog Altistart 48 2006 enwawinNo ratings yet

- Caracteristicas Del Scr-c106Document5 pagesCaracteristicas Del Scr-c106Anonymous G1o4z1C5nXNo ratings yet

- 2 SC 3311Document3 pages2 SC 3311Jose Antonio Rojas BautistaNo ratings yet

- Carrier38CKC 50HzDocument20 pagesCarrier38CKC 50HzAaron LeveyNo ratings yet

- Triac 2n6073aDocument7 pagesTriac 2n6073aJorge MoralesNo ratings yet

- STR-A6151 Al 6159 PDFDocument7 pagesSTR-A6151 Al 6159 PDFJosé BenavidesNo ratings yet

- ATRT-01 S3/ATRT-01B S3: Transformer Turns Ratio TestersDocument4 pagesATRT-01 S3/ATRT-01B S3: Transformer Turns Ratio TestersedgarcooNo ratings yet

- DCRM Meggertm1800Document14 pagesDCRM Meggertm1800parmindra2011No ratings yet

- 802600r4 Lift PDFDocument20 pages802600r4 Lift PDFEliane SouzaNo ratings yet

- Advantage NEMADocument28 pagesAdvantage NEMAJorge Sebastian Cifuentes UnibazoNo ratings yet

- BTB08-600BW3G, BTB08-800BW3G Triacs: Silicon Bidirectional ThyristorsDocument6 pagesBTB08-600BW3G, BTB08-800BW3G Triacs: Silicon Bidirectional ThyristorsZdravko RusevNo ratings yet

- Power Supplies and Power RequirementsDocument2 pagesPower Supplies and Power RequirementsKristen CollierNo ratings yet

- Vickers Electrics Db3 ManualDocument138 pagesVickers Electrics Db3 ManualRana M. ZubairNo ratings yet

- The Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkDocument6 pagesThe Load Monitoring and Protection On Electricity Power Lines Using GSM NetworkPrashant Sangulagi100% (1)

- C 4458Document4 pagesC 4458Josimar ReyesNo ratings yet

- Altivar 61 For Medium Voltage MotorsDocument34 pagesAltivar 61 For Medium Voltage MotorsEduard NurmetovNo ratings yet

- Altistart™ 48: Panel-Mount Soft StartsDocument40 pagesAltistart™ 48: Panel-Mount Soft StartsYasser SayedNo ratings yet

- Netsure 801Document6 pagesNetsure 801Glenn NnelgNo ratings yet

- Toshiba Grt100 Template Manual Enu Tu2.30 v1.000Document20 pagesToshiba Grt100 Template Manual Enu Tu2.30 v1.000jaime anibal navarrete aburtoNo ratings yet

- 2SC3068Document4 pages2SC3068byronzapetaNo ratings yet

- Adc0804 NDocument56 pagesAdc0804 NAnkit DhimanNo ratings yet

- TB 01000001 eDocument61 pagesTB 01000001 eRicardo LopezNo ratings yet

- PTC Motor Starters: 8EA SeriesDocument4 pagesPTC Motor Starters: 8EA SeriesMahmoudNo ratings yet

- Uc 3842Document56 pagesUc 3842Miguel TorresNo ratings yet

- Altistart 22 Enclosed Soft Starts 8800BR10031Document8 pagesAltistart 22 Enclosed Soft Starts 8800BR10031masWIDINo ratings yet

- Tl2843 PWM ControllersDocument27 pagesTl2843 PWM ControllersZxdIaminxXzlovewithzxXzyouzxNo ratings yet

- From Iec 60439 To Iec 61439Document10 pagesFrom Iec 60439 To Iec 61439zbyszko201234100% (1)

- H56886 TB Design 0807Document12 pagesH56886 TB Design 0807algotrNo ratings yet

- LionRock Brochure (20130801-V5) 60HZDocument10 pagesLionRock Brochure (20130801-V5) 60HZYahia Yohan KimNo ratings yet

- HGM6300D V2.1 enDocument34 pagesHGM6300D V2.1 enSteven BaynesNo ratings yet

- Metal-Enclosed Medium Voltage Power Factor Correction SystemDocument16 pagesMetal-Enclosed Medium Voltage Power Factor Correction SystemYigit SarıkayaNo ratings yet

- Eq. Divididos 5 A 20 TR Solo Frio R-410Document125 pagesEq. Divididos 5 A 20 TR Solo Frio R-410Leon HernandezNo ratings yet

- Diesel Generators Sets Specs (D 26)Document6 pagesDiesel Generators Sets Specs (D 26)Elias EliasNo ratings yet

- RoboticAutomatic Tool Changer PDFDocument36 pagesRoboticAutomatic Tool Changer PDFTesfahun GirmaNo ratings yet

- HAT600 V2.0 en PDFDocument38 pagesHAT600 V2.0 en PDFArmando RivasNo ratings yet

- 0201Document80 pages0201Ashenafi Gebremeskel MezgeboNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Naplan Year 9 PracticeDocument23 pagesNaplan Year 9 PracticetonynuganNo ratings yet

- 100G OTN Muxponder: Cost-Efficient Transport of 10x10G Over 100G in Metro NetworksDocument2 pages100G OTN Muxponder: Cost-Efficient Transport of 10x10G Over 100G in Metro NetworkshasNo ratings yet

- Backpacking South America Travel Guide 2020Document59 pagesBackpacking South America Travel Guide 2020sarthak.j6969No ratings yet

- Morris 2Document22 pagesMorris 2IsmaelLouGomezNo ratings yet

- Massage Intake FormDocument2 pagesMassage Intake Formapi-253959832No ratings yet

- Custard The DragonDocument4 pagesCustard The DragonNilesh NagarNo ratings yet

- Distribution System ReliabilityDocument8 pagesDistribution System Reliabilityabera alemayehuNo ratings yet

- Roger Ghanem, David Higdon, Houman Owhadi (Eds.) - Handbook of Uncertainty Quantification-Springer International Publishing (2017)Document2,035 pagesRoger Ghanem, David Higdon, Houman Owhadi (Eds.) - Handbook of Uncertainty Quantification-Springer International Publishing (2017)Jaime Andres Cerda Garrido100% (1)

- ?????Document89 pages?????munglepreeti2No ratings yet

- The Book of JonahDocument2 pagesThe Book of JonahJames Hampton BeltonNo ratings yet

- The 5 TibetansDocument3 pagesThe 5 TibetansValentin100% (2)

- JC 1010Document19 pagesJC 1010mcsmiley11No ratings yet

- LEC - 19 - Task of Bitcoin MinersDocument36 pagesLEC - 19 - Task of Bitcoin MinersKarunesh AnandNo ratings yet

- ENDOCRINE-BOARD REVIEW Dr. SchearDocument57 pagesENDOCRINE-BOARD REVIEW Dr. SchearNayara PataroNo ratings yet

- Defeat Cancer NaturallyDocument94 pagesDefeat Cancer NaturallyRknuviprasys Low100% (3)

- Geometry CheatsheetDocument5 pagesGeometry CheatsheetMarilyn CitadelNo ratings yet

- Anna Kingsford, Edward Maitland - The Perfect Way, or The Finding of Christ (1909)Document484 pagesAnna Kingsford, Edward Maitland - The Perfect Way, or The Finding of Christ (1909)Momir Miric100% (1)

- TM 55 1520 400 14 PDFDocument227 pagesTM 55 1520 400 14 PDFOskar DirlewangerNo ratings yet

- S01 Hydraulic and Eletric DiagramDocument18 pagesS01 Hydraulic and Eletric DiagramgadeharogNo ratings yet

- Fiber Testing and OTDR Basics: Brett Isley Terriitory Sales ManagerDocument54 pagesFiber Testing and OTDR Basics: Brett Isley Terriitory Sales ManagerTuppiNo ratings yet

- Estericlean Agroalimentaria Registro NSFDocument1 pageEstericlean Agroalimentaria Registro NSFwilber jovany monzon uriasNo ratings yet

- Seminar 2 of 2021-Multispectral Spectroscopy-Aster Imagery Processing For Mineral ExplorationDocument15 pagesSeminar 2 of 2021-Multispectral Spectroscopy-Aster Imagery Processing For Mineral Explorationmartin nyakinyeNo ratings yet

- Related Literature BioplasticsDocument19 pagesRelated Literature BioplasticsJames LimNo ratings yet

- Ground Investigation ReportDocument49 pagesGround Investigation Reportjoemacx6624No ratings yet

- Squad3.fire NSD GPMDocument7 pagesSquad3.fire NSD GPMMac CorpuzNo ratings yet

- Comsol ProfileDocument4 pagesComsol ProfilePrashant KumarNo ratings yet

- 14 Parabola Formula Sheets QuizrrDocument9 pages14 Parabola Formula Sheets QuizrrChandanNo ratings yet

- Features and Highlights - : CapableDocument2 pagesFeatures and Highlights - : CapableaarianNo ratings yet

- Lesson Plan 3Document3 pagesLesson Plan 3api-547884261No ratings yet

- Speaking With Confidence: Chapter Objectives: Chapter OutlineDocument12 pagesSpeaking With Confidence: Chapter Objectives: Chapter OutlinehassanNo ratings yet