Professional Documents

Culture Documents

Animesh

Uploaded by

Animesh GhoshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Animesh

Uploaded by

Animesh GhoshCopyright:

Available Formats

Design of a Hall Probe Pressure Transmitter using Bellows as Sensor

R. Sarkar, Animesh Ghosh, Lipika Ghosh and N. Mandal

Asansol Engineering College

Vivekananda Sarani, Kanyapur, Asansol-713305

E-mail: rajan_maa@rediffmail.com, ghoshanimesh.ghosh63@gmail.com,

nirupama_cal@rediffmail.com

Abstract: Bellows, an elastic type pressure sensor is

generally used as a local indicator. To transmit the

signal of bellows to a remote distance some

technique is needed. In the present paper a Hall

probe sensor has been used to convert the bellows

movement into voltage signal which can be

converted into 4 20 mA current signal and

transmitted to a remote indicator. It has been

observed that the transducer and transmitter

outputs against pressure have a very good linearity

and repeatability. The necessary theoretical

equations along with experimental results are

reported in the paper.

Keywords: pressure measurement, bellows, Pressure

transmitter, Magnet, Hall Probe.

I.

INTRODUCTION

Pressure is an important measuring and

controlling technical parameter during industrial

production process. In order to operate industrial

production well, pressure should be accurately

measured and controlled. Pressure can be

measured in terms of absolute or gauge. The

absolute pressure can be measured in terms of

height of a liquid column in a manometer

whereas the gauge pressure is measured by

different types of sensors [1-4]. As for example

bourdon tube, diaphragm, capsule, bellow

element etc. operate as primary sensing elements

for measuring positive or negative gauge

pressure. The sensors like strain gauge,

piezoresistance, LVDT, capacitive element,

inductive element etc. act as secondary sensors

to measure positive or negative gauge pressure.

The negative gauge pressure or vacuum pressure

can also be measured by many other sensors like

pirani gauge, ionization gauge, McLeod gauge

etc. In industrial application it is required to

transmit the measured pressure to a remote

distance. Hence in a pressure transmitter, the

change of sensor parameter due to the change of

fluid pressure is converted into an electric or

pneumatic signal by using a suitable transducer

and that signal after amplification is transmitted

to a remote receiver. Thus the pressure

transducer is a vital part of any pressure

transmitter and its performance determines the

reliability of operation of the transmitter. Many

works on development of reliable pressure

transducer are still being reported by different

groups of workers. B. Raveendran et al. [5] have

designed and developed a MEMS based wireless

modular pressure transmitter. A Bourdon tube

based pressure transmitter unit using an

improved inductance bridge network has been

studied by S.C.Bera et al. [6]. Y. Ruan et al. [7]

have developed a multipoint wireless pressure

transmitting system composed of pressure sensor

PTB203, A/D converter ADC0804, MCU

STC89C52, wireless communication module

CC1101, receiver module STC89C52, CC1101

and display module LCD1602. Zeng Mingru et

al. [8] have developed a HART Protocol based

intelligent pressure transmitter which is

compatible with both analog and digital signals.

K.Subramanian et al. [9] have developed MEMS

type capacitive pressure sensor with sensitivity

of the order of few fF/ kPa. Universal frequency

to digital converter (UDFC) technique has been

used by S.Y.Yurish [10] to develop an intelligent

digital pressure transducer. A multiplexed

frequency transmitter technique has been used by

R.Vrba et al. [11] to design a reliable pressure

transducer using ceramic diaphragm.

II.PRINCIPLE OF OPERATION

In the present paper, a hall probe based

pressure measurement technique has been

developed. In this technique a permanent magnet

is placed on the tip of the bellows with the Hall

probe sensor on the top of the outside fitting of

bellows chamber as shown in Fig.1. The

movement of the bellows tip is measured by a

hall probe sensor. With the change of pressure

the distance between magnet and the hall sensor

decreases and so the magnetic intensity at the

sensor increases. The Hall sensor senses this

increase of magnetic field intensity and

accordingly its output voltage increases with the

increase of pressure. This signal is nonlinearly

related with the movement of float. But for very

small movement of the bellows this voltage will

be almost linear. The experimental results are

reported in the paper. The block diagram of the

proposed transducer is shown in Fig.1.

Necessary mathematical equations have been

derived to explain the theory of operation of the

transducer as well as transmitter. A prototype

unit along with the signal conditioner has been

designed and fabricated. The experiments have

been performed to find out the static

characteristics of the sensor, transducer and

transmitter. The experimental results are reported

in the paper. A very good linearity and

repeatability of results with adjustable sensitivity

of the transducer has been observed.

where K 2 is the constant depending on the pole

strength of the magnet, its radius and

permeability of air which are all constants. Since

x a equation (3) is reduced to

Bx

Bx

K2

x2

(4)

K2

H h

(5)

The above equation is equally true for very low

pressure also.

Since at low pressure H h , so equation (5) is

reduced to

Bx

Fig. 1: Diagram of the proposed transducer along

with float and hall probe sensor

II. METHOD OF APPROACH

In the present paper the pressure is sensed by a

bellows. A magnet is placed on the top of the

bellows. And the hall probe on the bellows

chamber. The float movement of the bellows is

converted into voltage by a hall probe sensor.

Output

voltage

is

amplified

by

an

instrumentation amplifier INA101 and then

converted into 4-20 mA current signal using

signal conditioning circuit. This signal is then

transmitted to remote station with negligible loss.

Let the pressure is P and the corresponding

height of the bellows tip from reference is h . In

bellows the height of the tip is proportional to

pressure and is written as

P K1h

(1)

Bx

K2 X

x2 a2

3/ 2

(3)

2h

1 H

(6)

Vh of the hall

sensor is proportional to Bx if the current

passing through the sensor be kept constant and

hence it is given by

Vh K 3 Bx

(7)

where K 3 is the constant of proportionality.

Hence from equations (5) & (7)

Vh

K 2 K3

H h

(8)

K4

2h

1

H

H

K

K

K

where 4

2 3 is another constant.

Vh

or,

(9)

Therefore from equations (1), (8) and (9), the

output from hall probe is given by

Vh

K 2 K3

H P / K1

K4

2 KP

1

H

H

Vh a bP

Vh

(2)

where H is the total length of the hall probe

from reference. In the present work the magnet is

selected to be a circular permanent magnet. Let

the radius and width of the magnet be a and t

respectively. Hence magnetic field at the hall

probe due to magnet is

Now the output hall voltage

where K1 is the constant

Now the distance of the hall probe from the

magnet is

x H h

K2

H

(10)

(11)

(12)

Therefore output is linearly related with

pressure.

III.

DESIGN

In the present design a cylindrical permanent

magnet is selected of inner radius 0.011m ,

depth 0.008 m , width 0.011m . In our present

design, H 0.25 m . The output of hall sensor

is amplified by INA101 based instrumentation

amplifier. The gain of the instrumentation

amplifier is set by external resistor R1. This

output signal is first converted into amplified

voltage signal (V0) in the range 1-5 volt D.C.

and then into current signal ( I 0 ) in the range 420mA D.C. by a signal conditioner circuit as

shown in Fig.2. After calibration the output of

the transmitter becomes 4mA when V0 is 1 volt

and pressure P is zero psig and 20mA when V0

is 5 volt and pressure P is at maximum range

( P max ) of the bellows. Hence the transmitter

voltage output (V0) in volt and current output

( I 0 ) in mA may be written as,

4

P 1

P

max

and

V0

(13)

I 0 cV0

(14)

From (13) and (14),

I 0 K 4 K5 P

where

(15)

4c

Pmax

K 4 c and K 5

(16)

Fig.2. Block diagram of the proposed pressure

transmitter using bellows element as sensing

device

Fig. 3: Circuit diagram of hall probe based

pressure indicator

IV.

EXPERIMENT

The experiment is performed in two steps. In the

first step, the proposed transducer was designed,

fabricated and mounted on the outside cover of

bellows chamber as shown in Fig. 1. The bellows

with the above sensor was first fitted with a dead

weight tester and the dead weight of the dead

weight tester was increased in steps and in each

step the Hall voltage output is measured and the

characteristics of the hall sensor based transducer

unit is determined. The characteristic graph

obtained by plotting Hall voltage against

Pressure is shown in Fig. 4. Experiment was

repeated both in increasing and

decreasing modes for several times

and the standard deviation curve for

six observations is shown in Fig.6. In the

second step the output of the pressure transmitter

is taken in terms of current signal and he

characteristic is shown in Fig.7.

Fig. 4: Characteristic graph obtained by plotting

Hall voltage against Pressure

Fig. 5: Percentage deviation Curve of the Hall

Probe based Pressure Transducer

Fig. 6: Standard Deviation Curve of the Hall

Probe based Pressure Transducer

Fig.7: Characteristic graph of hall probe based

pressure transmitter

V. DISCUSSION

The characteristic of hall probe sensor is

nonlinear in nature. But change of hall probe

voltage is quite linear as shown in Fig.4. The

linear nature of the curve is due to the fact that

the movement of the tip of the bellows for the

entire pressure range is generally very small and

hall probe voltage due to small change of

distance between hall probe and magnet lies

almost in the linear zone. The percentage

deviation curves from linearity as shown in Fig 5

also indicate that the percentage deviation from

linearity also lies within the tolerable limit. A

very good repeatability of the experimental data

was also observed as shown by the standard

deviation curves in Figs. 6. The characteristic of

the whole transmitter is almost linear as shown

in Fig 7. The design of the system is very simple

and the hall probe & the permanent magnet are

now available at a very low cost. Hence the cost

of the pressure transmitter will be low.

References:

[1] J. P. Bentley, Principles of Measurement

Systems, 3rd ed., Longman Singapore

Publishers (pvt) Ltd., Singapore, 1995.

[2] E. O. Doeblin, Measurement System

Application and Design, 4th ed.,

McGraw-Hill, New York, 1990.

[3] B. G. Liptak, Process Measurement and

Analysis, 3rd ed., U. K. Butterworth

Heinman, Oxford, 1999.

[4] D. M. Considine, Process Instruments

and Control Hand Book, 2nd ed.,

McGraw-Hill, New York, 1974.

[5] Raveendran, B.; Subhash, K.M. Design

of modular pressure transmitter with

wireless capability IEEE Conference on

Electrical, Electronics and Computer

Science (SCEECS), 2012, pp 1 - 3

[6] Bera, S.C.; Mandal, N.; Sarkar, R.,

Study of a Pressure Transmitter Using

an Improved Inductance Bridge Network

and Bourdon Tube as Transducer IEEE

Transactions on Instrumentation and

Measurement, Vol 60 , Issue 4 , Year:

2011 , pp 1453 - 1460

[7] Yaocan Ruan; Minghao He; Shuran

Song; Tiansheng Hong Multipoint

wireless pressure detecting system 2nd

International Conference on Artificial

Intelligence, Management Science and

Electronic Commerce (AIMSEC), 2011

IEEE Conference, 2011 , PP 4091 4094

[8] Zeng Mingru; You Wentang; Qian Xin ,

The development of intelligent pressure

transmitter based on HART Protocol

IEEE

Conference

on

E-Health

Networking, Digital Eco systems and

Technologies (EDT), Vol. 1, 2010 , pp

121 124

[9] Kanakasabapathi Subramanian, Jeffrey

B. Fortin, and Kuna Kishore, Scalable

vertical diaphragm pressure sensors:

device and process design, design for

packaging IEEE Sensors Journal., vol.

6, no. 3, June 2006, pp.618-622

[10] S. Y. Yurish, Intelligent digital pressure

sensors and transducers based on

universal

frequency-to-digital

converters (UFDC-1), Sensors &

Transducers Journal., vol. 60, no. 10,

October 2005, pp. 432-438.

[11] Radimir Vrba, Miroslav Sveda and Karel

Marecek, Pressure transducer with

multiplexed frequency transmitter,

Slconi04 - Seoron for industry

Conference, New Orleans, Louisiaiib,

USA, 27th -29th January, 2004, pp. 07-10.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Wei Kuen Do PDFDocument7 pagesWei Kuen Do PDFAnimesh Ghosh100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Analysis music booklet elementsDocument13 pagesAnalysis music booklet elementsTD PrestonNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RESTRICTED JUDODocument13 pagesRESTRICTED JUDOryankp100% (1)

- IFR En Route Charts Guide PilotsDocument28 pagesIFR En Route Charts Guide PilotsNick Tsang100% (1)

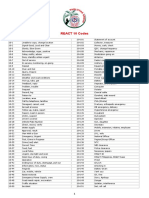

- React 10 Codes PDFDocument2 pagesReact 10 Codes PDFPaul Anselmo Dela Cruz100% (3)

- Memory and Tonality in Debussy's Prelude À L'après-Midi D'un Faune /cahiers DebussyDocument17 pagesMemory and Tonality in Debussy's Prelude À L'après-Midi D'un Faune /cahiers Debussymahler2010100% (1)

- An Introduction For Users and Manufacturers: Field Communication ProtocolDocument12 pagesAn Introduction For Users and Manufacturers: Field Communication ProtocolAnimesh GhoshNo ratings yet

- Tag MC LarenDocument34 pagesTag MC LarenelekossNo ratings yet

- Grade - 8 - Maths - Worksheet - Term 3Document50 pagesGrade - 8 - Maths - Worksheet - Term 3dheeraj yadavNo ratings yet

- Striking For Power and SpeedDocument142 pagesStriking For Power and Speedme100% (1)

- The Art of Knife DefenceDocument2 pagesThe Art of Knife Defencesteelbonnet100% (1)

- ZTE - GSM - WCDMA Cell Reselection & CS HandoverDocument112 pagesZTE - GSM - WCDMA Cell Reselection & CS HandoverMuhammad Haris100% (1)

- An Introduction to Fire Detection SystemsDocument59 pagesAn Introduction to Fire Detection SystemsMihai MateiNo ratings yet

- Honeywell Dcs ArchitectureDocument14 pagesHoneywell Dcs ArchitectureVanama MalaiNo ratings yet

- Honeywell Dcs ArchitectureDocument14 pagesHoneywell Dcs ArchitectureVanama MalaiNo ratings yet

- The Movement of The Jumping Front Kick. (Kan, 1991)Document4 pagesThe Movement of The Jumping Front Kick. (Kan, 1991)Animesh GhoshNo ratings yet

- NI Tutorial 6480Document4 pagesNI Tutorial 6480Animesh GhoshNo ratings yet

- Daily Current Affairs Quiz December 1 2021Document8 pagesDaily Current Affairs Quiz December 1 2021Animesh GhoshNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument25 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherAnimesh GhoshNo ratings yet

- NI Tutorial 3536Document6 pagesNI Tutorial 3536Animesh GhoshNo ratings yet

- Adjustable Speed Drives TutorialDocument13 pagesAdjustable Speed Drives Tutorialapi-3765150100% (2)

- Biomechanical Classification of Taekwondo Kicks: Figure 1: Graphical Representation of Three StyleDocument2 pagesBiomechanical Classification of Taekwondo Kicks: Figure 1: Graphical Representation of Three StyleAnimesh GhoshNo ratings yet

- Biomechanical Analysis of Punching Different Targets in Chinese Martial ArtsDocument1 pageBiomechanical Analysis of Punching Different Targets in Chinese Martial ArtsAnimesh GhoshNo ratings yet

- Biomechanical Analysis On Some Martial Art Aspects of Tai Chi ChuanDocument1 pageBiomechanical Analysis On Some Martial Art Aspects of Tai Chi ChuanAnimesh GhoshNo ratings yet

- Wave TrapDocument51 pagesWave Trapjayanta11302No ratings yet

- Digital Building Blocks OverviewDocument29 pagesDigital Building Blocks OverviewAnimesh GhoshNo ratings yet

- NI Tutorial 3408Document2 pagesNI Tutorial 3408Animesh GhoshNo ratings yet

- Kicking: Crossfit Journal Article Reprint. First Published in Crossfit Journal Issue 57 - May 2007Document4 pagesKicking: Crossfit Journal Article Reprint. First Published in Crossfit Journal Issue 57 - May 2007Animesh Ghosh0% (1)

- Moselhpour Waveform Generator PDFDocument16 pagesMoselhpour Waveform Generator PDFAnimesh GhoshNo ratings yet

- Fiber Optic Communications For Utility Systems PDFDocument19 pagesFiber Optic Communications For Utility Systems PDFAnimesh GhoshNo ratings yet

- NPN PNPDocument9 pagesNPN PNPganeshrudraNo ratings yet

- NI Tutorial 12953Document4 pagesNI Tutorial 12953Animesh GhoshNo ratings yet

- 4-20 Ma. Cálculo de Distancia MáximaDocument3 pages4-20 Ma. Cálculo de Distancia MáximaMarco Antonio Arroyo RiveraNo ratings yet

- Fieldbus and Remote Io ComparisonDocument30 pagesFieldbus and Remote Io Comparisonaromero888No ratings yet

- Fundamentals of Motion ControlDocument7 pagesFundamentals of Motion ControlAnimesh GhoshNo ratings yet

- Current Loop TutorialDocument13 pagesCurrent Loop TutorialNAVEED100% (2)

- Striking For Power and SpeedDocument12 pagesStriking For Power and SpeedAnimesh Ghosh0% (1)

- BJJ Pardoel Spider Guard SweepDocument1 pageBJJ Pardoel Spider Guard SweepGILBERTO DIAZNo ratings yet

- Vijay Tendulkar's Play Explores Hypocrisy of Urban Middle ClassDocument142 pagesVijay Tendulkar's Play Explores Hypocrisy of Urban Middle ClassAasthaDhuppadNo ratings yet

- Iec 62106-2009Document160 pagesIec 62106-2009luis.alvaradoNo ratings yet

- CertsDocument8 pagesCertsJomar Mapue PormentoNo ratings yet

- Low EMI For Power IsolationDocument14 pagesLow EMI For Power IsolationSuvadip BanerjeeNo ratings yet

- Programska Shema A1 TV: Najbolj Gledani Programi Informativni in Regionalni ProgramiDocument2 pagesProgramska Shema A1 TV: Najbolj Gledani Programi Informativni in Regionalni ProgramivpmkdNo ratings yet

- Two Channel DDS Signal Generator User ManualDocument6 pagesTwo Channel DDS Signal Generator User Manualanon_434678235No ratings yet

- Emotive Strings Manual EnglishDocument22 pagesEmotive Strings Manual EnglishEdson CarvalhoNo ratings yet

- Doble ParalelogramoDocument208 pagesDoble ParalelogramomiguelpaltinoNo ratings yet

- K Series Test Report 1984216Document29 pagesK Series Test Report 1984216EricNo ratings yet

- Ryanair Magazine January-February 2012Document154 pagesRyanair Magazine January-February 2012Sampaio RodriguesNo ratings yet

- Multiamp Firmware EvolutionDocument4 pagesMultiamp Firmware EvolutionJuanNo ratings yet

- Unmaintained Design Icons v2.0Document10 pagesUnmaintained Design Icons v2.0Dasnary Garay TejedaNo ratings yet

- GSM Micro Repeater User ManualDocument24 pagesGSM Micro Repeater User ManualJay Roelson Espiritu100% (1)

- At CmndsDocument107 pagesAt CmndsNaveen VengaldasNo ratings yet

- Teaching Listening Comprehension PDFDocument24 pagesTeaching Listening Comprehension PDFDaniela ChicaNo ratings yet

- Understanding The Global Positioning SystemDocument10 pagesUnderstanding The Global Positioning SystemAchutKiranCherukuriNo ratings yet

- Antena 20mhz - 6ghzDocument6 pagesAntena 20mhz - 6ghzCris VMNo ratings yet

- DxdiagDocument29 pagesDxdiagFlorim RamadaniNo ratings yet

- I Want To Live John Denver Song CELIZ Reflection PaperDocument2 pagesI Want To Live John Denver Song CELIZ Reflection PaperRashiel Jane CelizNo ratings yet

- NWCR 886Document3 pagesNWCR 886Влад РонгNo ratings yet

- Lecture 8. IntonationDocument70 pagesLecture 8. IntonationNguyễn Thị Thuỳ ThươngNo ratings yet