Professional Documents

Culture Documents

Drying and Quality Characteristics of Tilapia Fish Fillets Dried With Hot Air Microwave Heating 2011 Food and Bioproducts Processing 1

Uploaded by

amandamendaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drying and Quality Characteristics of Tilapia Fish Fillets Dried With Hot Air Microwave Heating 2011 Food and Bioproducts Processing 1

Uploaded by

amandamendaCopyright:

Available Formats

food and bioproducts processing 8 9 ( 2 0 1 1 ) 472476

Contents lists available at ScienceDirect

Food and Bioproducts Processing

journal homepage: www.elsevier.com/locate/fbp

Drying and quality characteristics of tilapia sh llets dried

with hot air-microwave heating

Zhen-hua Duan a,b, , Li-na Jiang b , Ju-lan Wang a , Xiao-yang Yu b , Tao Wang b

a

b

Key Laboratory of Tropical Biological Resources of MOE, Hainan University, Haikou 570228, China

College of Food Science and Technology, Hainan University, No. 58, Renmin Road, Haikou 570228, China

a b s t r a c t

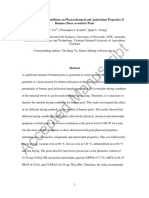

The aim of this work was to study the effect of hot air-microwave heating on the drying and quality characteristics

of fresh tilapia sh llets. Experimental drying curves were obtained at three microwave powers (200, 400 and 600 W)

after hot air drying at two air temperatures (40 and 50 C) and a constant air velocity of 1.5 m/s. Some quality indicators such as shrinkage, rehydration and recovery properties were investigated. Results showed that an increase in

microwave power resulted in a decrease in nal moisture content when drying for the same period of time. The higher

the hot air temperature, the higher the dehydration rate was. The shrinkage ratio and rehydration ratio increased as

the microwave power and air temperature increased. However, the recovery ratio decreased as the microwave power

and air temperature increased. Lower hot air temperature and microwave power are benecial to keep the quality of

tilapia llets.

2010 The Institution of Chemical Engineers. Published by Elsevier B.V. All rights reserved.

Keywords: Hot air-microwave drying; Tilapia; Shrinkage; Rehydration; Recovery

1.

Introduction

Tilapia is the common name now applied to three genera

and species of sh in the family Cichlidae: Oreochromis,

Sarotherodon, and Tilapia. Native to Africa and the Middle

East, these species have been distributed throughout the world

and have become the second most important food shes in the

world (Watanabe et al., 2002). Tilapias possess an impressive

range of attributes that make them ideal for aquaculture. They

grow rapidly, reproduce easily, adapt to a wide range of environmental conditions and accept articial feeds readily. They

have good-tasting esh with a mild avor, are widely accepted

as food sh, are used in many cuisines, and their consumption

is not restricted by religious observances.

Tilapia culture has expanded rapidly during the last decade

as a result of technological advances associated with the

intensication of culture practices. Global production was

inuenced by rapid expansion of tilapia culture in China, the

Philippines, Thailand, Indonesia, and Egypt. China is now the

leading producer having increased production from 18,000

tonnes in 1984 to 1,210,000 tonnes in 2007, more than 45% of

the total world production (Li et al., 2009). However, the quantity of the tilapia used for processing is too small to meet the

requirement of increased production, and it is highly perishable product as it consists of up to 80% of water (Duan et al.,

2005a; Li et al., 2009). Therefore, to solve the problems of high

enzymatic and bacterial activity in fresh sh, the use of processing and preservation technology is necessary.

Drying of sh is important (Bellagha et al., 2002; Bala

and Mondol, 2001), because it preserves sh by inactivating

enzymes and removing the moisture necessary for bacterial

and mold growth (Duan et al., 2004). Drying processes can

be broadly classied as thermal drying, osmotic dehydration,

and mechanical dewatering. Many researchers and applications focus on air drying (Aktas et al., 2007; Desmorieux and

Decaen, 2005; Duan et al., 2004; Gogus and Maskan, 2006). But

air drying has drawbacks of both long drying time required

and poor quality (Chou and Chua, 2001). Microwave energy

is widely used in agricultural products processing because

it heats quickly, is energy efcient, safe and harmless, and

easy to control (Duan et al., 2003; Zhang and Datta, 2005).

Microwave drying technology has become one of emerging

Corresponding author at: College of Food Science and Technology, Hainan University, No. 58, Renmin Road, Haikou, China. Tel.: +86

898 66289662; fax: +86 898 66279215.

E-mail addresses: dzhwjl@hotmail.com, dzh65@126.com (Z.-h. Duan).

Received 15 November 2009; Received in revised form 9 October 2010; Accepted 9 November 2010

0960-3085/$ see front matter 2010 The Institution of Chemical Engineers. Published by Elsevier B.V. All rights reserved.

doi:10.1016/j.fbp.2010.11.005

food and bioproducts processing 8 9 ( 2 0 1 1 ) 472476

areas in food drying (McLoughlin et al., 2003; Orsat et al., 2007),

especially hybrid drying technologies such as air-microwave

drying (Datta and Ni, 2002; Duan et al., 2005b). Microwave

heating of temperature sensitive materials offers a more

rapid method of moisture removal (McLoughlin et al., 2003).

Microwaves heat material simultaneously inside and outside,

and can produce high rates of evaporation. If heating is too

fast, fresh tilapia llets, which have high water content, may

be burst into pieces. However, few reports were focused on

investigating the air-microwave drying of tilapia llets. The

aim of this work was to study the effect of hot air-microwave

drying process on the drying and quality characteristics of

tilapia llets. Evaluation of quality characteristics was studied

by determining the changes of the shrinkage, rehydration and

recovery ratio. The results obtained may provide the important theory basis for developing the application technology of

hot air-microwave drying in tilapia processing.

2.

Materials and methods

2.1.

Sample preparation

2.4.

2.2.

Shrinkage ratio

The volume of the test sample was measured using an excluding method, and the clean sea sand was selected as lling

material (Shang et al., 2007). The mean particle diameter of

sand is about 0.6 mm. Five replicates were performed for each

sample and mean value was calculated. The shrinkage ratio

was calculated as:

Rs =

V0 Vt

V0

(1)

where Rs is the shrinkage ratio of the sample, V0 is the initial

volume of the sample before drying, Vt is the volume of the

sample during drying at time t.

Rrec =

(3)

2.5.

Moisture content

The moisture content of test sample was determined according to the vacuum oven method (AOAC, 2005). At regular time

intervals during the drying period, samples were taken out and

dried in a vacuum oven (Model ZKF030, Shanghai Experiment

Instrument Co. Ltd., China) until constant weight.

Drying procedure

The following procedure was chosen according the previous

results (Duan et al., 2005b, 2006). The fresh sh llets were

pre-dried using a digital constant temperature blast drying

oven (Model 101-2, Changzhou Huapuda Instrument Co. Ltd.,

China) for 4 h at 40 C, and 50 C with a constant air velocity of

1.5 m/s. The pre-dehydrated sh llets were immediately put

into a laboratory microwave drying oven (Model NJL07-3, Nanjing Microwave Equipment Co. Ltd., China) to continue to dry

for different times (2, 4, 6, 8, 10 min) at different microwave

powers (200, 400, 600 W). For every batch of dried sample,

the moisture content, shrinkage ratio, rehydration ratio and

recovery ratio were determined. At least three replicates were

performed for each batch of test samples and the results were

averaged.

2.7.

Statistical analysis

Analysis of variance was performed by the ANOVA procedures

(SPSS 10.0 for Windows). Differences among the mean values

of the various treatments were determined by the least signicant difference test, and the signicance was dened at

p < 0.05.

Results and discussion

Rehydration ratio

Dry test samples were weighed with an electronic balance

(Model BS124S, Sartorius Company, Germany). Dried samples

were then put into the 40 C of clean warm water to rehydrate

for 30 min (Shang et al., 2007), and they are moved from the

water for weighing. The temperature of the water was maintained to 40 0.5 C by temperature controller (Model 501,

Shanghai Experiment Instrument Factory, China). Three replicates were performed for each sample and mean value was

calculated. The rehydration ratio was calculated as:

Rreh =

m

mo

where Rrec is the recovery ratio of the sample, and mo is the

weight of the fresh sample before drying.

3.

2.3.

Recovery ratio

The recovery ratio was calculated using Eq. (3) (Duan et al.,

2006). Three replicates were performed for each sample and

mean value was calculated.

2.6.

Fresh tilapias (Oreochromis niloticus) were purchased from a

sh market in Haikou, China. They were quickly transported

to the laboratory in sealed polystyrene boxes containing ice.

Fish were cleaned, gutted, skinned and headed, then cut into

llets with the size of 30 mm 20 mm 3 mm. The sh llets

were rinsed by tap water, and then placed in single layer on a

stainless steel wire mesh for drying experiments.

473

m mt

mt

(2)

where Rreh is the rehydration ratio of the sample, m is the

weight of the sample after rehydration, mt is the weight of the

sample before rehydration.

3.1.

Effect of pre-drying on the drying curves of sh

llets during microwave drying

The drying curves of tilapia llets are shown in Figs. 1 and 2.

The moisture contents decreased with the increasing in

microwave power in the same conditions (air temperature,

air velocity and drying time) of pre-drying using hot air. The

decreased moisture content could be attributed to increased

evaporation of water both on the surface of and in the sh

llets due to increasing temperatures by microwave heating

(Duan et al., 2005b). However, the drying curves were different

signicantly under the different conditions of microwave powers. Effect of the microwave power on the moisture content of

pre-dehydrated sh llets was signicant (p < 0.05).

Comparing the curves between Figs. 1 and 2, the drying

rates in Fig. 2 can be seen to be greater than those of the curves

in Fig. 1. This is because the initial moisture contents are dif-

food and bioproducts processing 8 9 ( 2 0 1 1 ) 472476

1.6

90

1.4

80

1.2

shrinkage ratio (%)

moisture content (d.b)

474

1

0.8

0.6

200W

0.4

60

200W

50

400W

600W

40

400W

0.2

70

600W

30

0

0

0

time (min)

Fig. 1 The microwave drying curves of tilapia llets after

pre-drying at 40 C.

10

time (min)

10

Fig. 3 Effect of microwave drying on the shrinkage ratio of

tilapia llets after pre-drying at 40 C.

90

3.2.

Effect of pre-drying on the shrinkage ratio of sh

llets during microwave drying

Figs. 3 and 4 showed effects of temperature of pre-drying with

hot air on the shrinkage ratio of samples during microwave

drying period. First, as can be seen, shrinkage increased with

0.6

200W

0.5

moisture content (d.b)

400W

600W

0.4

0.3

0.2

0.1

0

0

10

time (min)

Fig. 2 The microwave drying curves of tilapia llets after

pre-drying at 50 C.

80

shrinkage ratio (%)

ferent for the two different air temperatures. The temperature

of pre-drying using hot air had evident impact on the moisture content of sh llets during the microwave drying period

(p < 0.05). It seemed to be concluded that the moisture content at the change-over between air drying and microwave

drying should be about 0.5 g H2 O/g. The higher hot air temperatures led to the higher drying rates of samples. Similar

results have been reported for drying of vegetables materials

(Mwithiga and Olwal, 2005). Therefore, both hot air temperature and microwave power are considered to be benecial to

improve the drying rate of sh llets.

The required drying time was less than 6 min for obtaining

the nal products of 12% of moisture content (wet basis) when

sh llets dried by microwave drying at 400 W after pre-dried

at 50 C for 4 h (Fig. 2). However, it at least required 19 h to dry

the fresh sh llet to nal products of the same moisture content with 50 C of hot air (Duan et al., 2006). Therefore, the hot

air-microwave drying may shorten greatly the required drying

time compared with the hot air drying of tilapia llets.

70

60

200W

50

400W

600W

40

30

0

10

time (min)

Fig. 4 Effect of microwave drying on the shrinkage ratio of

tilapia llets after pre-drying at 50 C.

the drying time. Shrinkage is highest during the rst 2 min

and then seems to be relatively constant. The shrinkage ratio

of samples dried at 200 W, 400 W and 600 W of microwave

power for 2 min after pre-drying at 40 C, were 54%, 62%

and 65%, respectively (Fig. 3). When microwave drying time

was constant, the shrinkage ratio increased slightly with the

microwave power increasing, but the inuence of microwave

power on the shrinkage ratio of pre-dried llets was not evident (p > 0.05). Second, the higher hot air temperature led to

the higher shrinkage ratio of sh llets (p < 0.05). The shrinkage

ratios of the sh llets pre-dried with hot air between 40 C and

50 C were 42% and 58%, respectively. In addition, the inuence of pre-drying at 40 C was more than that at 50 C on the

shrinkage ratio of samples during microwave drying period by

comparing the differences of Figs. 3 and 4.

This is because moisture content of samples pre-dried for

4 h at 40 C was higher than that at 50 C. Much more moisture was removed rapidly during microwave drying due to

the instantaneous heating of microwaves (Duan et al., 2005b),

which resulted in greater changes of shrinkage ratio under the

same drying condition. With the microwave drying continued,

the moisture content of samples decreased, the difference of

moisture content between two temperatures was reduced, so

the changes in shrinkage ratio decreased accordingly. Therefore, temperature of pre-drying before microwave drying was

the main factor affecting the shrinkage ratio of dried llets.

475

food and bioproducts processing 8 9 ( 2 0 1 1 ) 472476

120

70

200W

rehydration ratio (%)

100

60

400W

600W

50

recovery ratio (%)

80

60

40

20

40

30

200W

20

400W

10

0

0

10

600W

time (min)

10

time (min)

Fig. 5 Effect of microwave drying on the rehydration ratio

of tilapia llets after pre-drying at 40 C.

Fig. 7 Effect of microwave drying on the recovery ratio of

tilapia llets after pre-drying at 40 C.

3.3.

Effect of pre-drying on the rehydration ratio of

tilapia llets during microwave drying

60

100

rehydration ratio(%)

80

60

200W

40

400W

600W

20

0

0

10

time (min)

Fig. 6 Effect of microwave drying on the rehydration ratio

of tilapia llets after pre-drying at 50 C.

recovery ratio (%)

50

Normally rehydration curves are plotted for a dry sample

(a nal product) immersed in water for different lengths of

time (Giri and Prasad, 2007). However, the nal moisture content of a dry sample depends on the specic requirement of

product, such as semi-dried products. Therefore, the rehydration ratios of samples of varying moisture content were

compared, here. Inuences of pre-drying with different air

temperature (40 C, 50 C) on the rehydration ratio of samples

during microwave drying were showed in Figs. 5 and 6. As can

be seen from Fig. 5, the rehydration ratio increased with the

extension of microwave drying when the microwave power

was constant. The similar result can also be derived from Fig. 6.

On the other hand, the rehydration ratio increased with the

increase in microwave power when microwave drying time

was unchanged. As can be seen from Fig. 5, the rehydration

ratio of samples dried at 200 W, 400 W and 600 W of microwave

power for 4 min after pre-drying at 40 C, were 40%, 53% and

73%, respectively.

However, the increase in the rehydration ratios was signicantly different between values shown in Figs. 5 and 6

(p < 0.05). Different temperatures of pre-drying brought different changes of the rehydration ratio of sh llets during

microwave drying period. When the fresh tilapia llets were

dried through microwave drying after pre-dried at 50 C, the

increase values of the rehydration ratio at 50 C were much less

than those at 40 C, resulted from microwave power increased.

40

30

200W

20

400W

10

600W

0

0

10

time (min)

Fig. 8 Effect of microwave drying on the recovery ratio of

tilapia llets after pre-drying at 50 C.

As can be seen from Fig. 6, the rehydration ratio of samples

dried at 200 W, 400 W and 600 W of microwave power for 4 min

after pre-drying at 50 C, were 72%, 75% and 82%, respectively.

So, the effect of the microwave power on the rehydration ratio

was closely related to the temperature of pre-drying. The lower

the temperature of pre-drying, the more rapid the increase in

rehydration ratio.

3.4.

Effect of pre-drying on the recovery ratio of tilapia

llets during microwave drying

In general, recovery curves are plotted for a dry sample (a

nal product) immersed in water for different lengths of time.

However, the nal moisture content of a dry sample depends

on certain specic requirement of products. Therefore, the

recovery ratios of samples of varying moisture content were

compared. Figs. 7 and 8 showed the effect of different predrying temperature (40 C, 50 C) on the recovery ratio of

samples. The recovery ratio decreased slightly with the extension of microwave drying time when the microwave power

was constant, and the change trends were very at, which

showed that the microwave drying time was not the main

factor affecting the recovery ratio. On the other hand, the

recovery ratio reduced with the increase in microwave power

when microwave drying time was xed. As can be seen from

Fig. 7, the recovery ratio of samples dried at 200 W, 400 W

and 600 W for 8 min after pre-drying at 40 C were 52%, 45%

and 42%, respectively. The recovery ratio-drying time curve at

476

food and bioproducts processing 8 9 ( 2 0 1 1 ) 472476

200 W was higher than the other two curves; the latter two

were relatively closer. Therefore, decreasing the microwave

power resulted in increase in the recovery ratio. Comparing

Figs. 7 and 8, all the recovery ratios of sh llets pre-dried at

40 C were higher than those at 50 C when the microwave drying time and power was xed (p < 0.05). So, the temperature of

pre-drying was important factors affecting the recovery ratio.

4.

Conclusion

Hot air drying followed by microwave drying can decrease

remarkably drying time for drying fresh tilapia llets compared with hot air drying. The moisture content at the

change-over between air drying and microwave drying should

be about 0.5 g H2 O/g. Hot air-microwave drying technology can

be used for dehydration of fresh tilapia llets due to decrease

drying time and improve quality (rehydration ratio). Effects

of microwave power and hot air temperature on drying characteristic of sh llets during the hot air-microwave drying

were signicant. An increase in microwave power resulted

in a decrease in moisture content of llets; the difference is

obvious in starting point for the microwave drying regarding

moisture content due to the two different air temperatures.

The inuence of the hot air temperature on the shrinkage

ratio and the rehydration ratio was signicant. The shrinkage

ratio and the rehydration ratio increased with increase of air

temperature. In addition, the lower the temperature of predrying, the more rapid the increase in rehydration ratio. These

may have resulted from the difference in the initial moisture

content for the microwave drying due to the two different air

temperatures. However, the change of the recovery ratio was

contrary to those of the shrinkage and rehydration ratio, the

recovery ratio decreased with increase of microwave power

and air temperature.

Acknowledgements

The authors wish to thank the nancial support provided by

the National Natural Science Foundation of China (Grant Nos.

30660145 and 31060218), the National Key Technologies R&D

Program (Grant No. 2007BAD76B06), and the Natural Science

Foundation of Hainan Province, China (Grant No. 309006) for

the research work.

References

Aktas, T., Fujii, S., Kawano, Y., Yamamoto, S., 2007. Effects of

pretreatments of sliced vegetables with trehalose on drying

characteristics and quality of dried products. Food Bioprod.

Process. 85 (3), 178183.

AOAC, 2005. Ofcial Methods of Analysis. AOAC International,

Maryland, USA.

Bala, B.K., Mondol, M.R.A., 2001. Experimental investigation on

solar drying of sh using solar tunnel dryer. Dry. Technol. 19

(2), 427436.

Bellagha, S., Amami, E., Farhat, A., Kechaou, N., 2002. Drying

kinetics and characteristic drying curve of lightly salted

Sardine (Sardinella aurita). Dry. Technol. 20 (7), 15271538.

Chou, S.K., Chua, K.J., 2001. New hybrid drying technologies for

heat sensitive foodstuffs. Trends Food Sci. Technol. 12 (10),

359369.

Datta, A.K., Ni, H., 2002. Infrared and hot-air-assisted microwave

heating of foods for control of surface moisture. J. Food Eng.

51 (4), 355364.

Desmorieux, H., Decaen, N., 2005. Convective drying of spirulina

in thin layer. J. Food Eng. 66, 497503.

Duan, Z.H., Shang, J., Xu, S., 2006. Study on characteristics of

hot-air drying of tilapia and changes of its main components.

Food Sci. 27 (12), 479482.

Duan, Z.H., Yi, M.H., Wang, Z.G., 2005a. Processing technique of

tilapia. Fish Sci. Technol. Inform. 32 (6), 250252.

Duan, Z.H., Zhang, M., Hao, J., 2003. Preparation of crispy bighead

carp slices. Sci. Technol. Food Ind. 2, 4447.

Duan, Z.H., Zhang, M., Hu, Q.G., 2005b. Characteristics of

microwave drying of bighead carp. Dry. Technol. 23 (3),

637643.

Duan, Z.H., Zhang, M., Tang, J., 2004. Thin layer hot-air drying of

bighead carp. Fisheries Sci. 23 (3), 2932.

Giri, S.K., Prasad, S., 2007. Drying kinetics and rehydration

characteristics of microwave-vacuum and convection hot-air

dried mushrooms. J. Food Eng. 78, 512521.

Gogus, F., Maskan, M., 2006. Air-drying characteristics of solid

waste (pomace) of olive oil processing. J. Food Eng. 72, 378382.

Li, J., Li, B.S., Li, W., 2009. Study on tilapia pickling technique.

Modern Food Sci. Technol. 25 (6), 646649.

McLoughlin, C.M., McMinn, W.A.M., Magee, T.R.A., 2003.

Microwave vacuum drying of pharmaceutical powders. Dry.

Technol. 21 (9), 17191733.

Mwithiga, G., Olwal, J.O., 2005. The drying kinetics of kale

(Brassica oleracea) in a convective hot air dryer. J. Food Eng.

71, 373378.

Orsat, V., Yang, W., Changrue, V., Raghavan, G.S.V., 2007.

Microwave-assisted drying of biomaterials. Food Bioprod.

Process. 85 (3), 255263.

Shang, J., Duan, Z.H., Feng, A.G., 2007. Effect of pre-treatment of

low-concentration salt on the drying of tilapia llets with hot

air. Food Sci. Technol. 32 (4), 111114.

Watanabe, W.O., Losordo, T.M., Fitzsimmons, K., Hanley, F., 2002.

Tilapia production systems in the Americas: technological

advances, trends, and challenges. Rev. Fish Sci. 10 (3), 465498.

Zhang, H., Datta, A.K., 2005. Heating concentrations of

microwaves in spherical and cylindrical foods. Part two: in a

cavity. Food Bioprod. Process. 83 (1), 1424.

You might also like

- Osmotic Dehydration Combined With Microwave Drying of Tilapia Fillets The Impacts of Osmosis DehydraDocument10 pagesOsmotic Dehydration Combined With Microwave Drying of Tilapia Fillets The Impacts of Osmosis Dehydrafrancisco cadenaNo ratings yet

- Maisaroh 2022 IOP Conf. Ser. Earth Environ. Sci. 1116 012065Document15 pagesMaisaroh 2022 IOP Conf. Ser. Earth Environ. Sci. 1116 012065lp manaluNo ratings yet

- vu2016Document34 pagesvu2016ARCILLA, NICO ANDREI SALAVERIANo ratings yet

- Kinetic Model and Temperature Effect of Caulerpa Lentillifera DryingDocument11 pagesKinetic Model and Temperature Effect of Caulerpa Lentillifera DryingJULIENNE MAXINE DOLOTNo ratings yet

- Banana ChipsDocument5 pagesBanana Chipsbikram limbuNo ratings yet

- Microwave Freeze Drying of Sea Cucumber (Stichopus Japonicus) 2010 Journal of Food EngineeringDocument7 pagesMicrowave Freeze Drying of Sea Cucumber (Stichopus Japonicus) 2010 Journal of Food EngineeringamandamendaNo ratings yet

- Drying kinetics of Üryani plum in a convective hot-air dryerDocument7 pagesDrying kinetics of Üryani plum in a convective hot-air dryerJanela FloresNo ratings yet

- Carranza-Concha 2012 Effects of Drying and Pretreatment On The Nutritonal and Functional Quality of RaisinsDocument6 pagesCarranza-Concha 2012 Effects of Drying and Pretreatment On The Nutritonal and Functional Quality of RaisinsMildred CullenNo ratings yet

- Pradana 2019 IOP Conf. Ser. Earth Environ. Sci. 292 012070 PDFDocument8 pagesPradana 2019 IOP Conf. Ser. Earth Environ. Sci. 292 012070 PDFBrian BuenoNo ratings yet

- PyrolysisDocument5 pagesPyrolysisRaineSanchezLabiosoNo ratings yet

- Drying Characteristics of Mango Slices Using The Refractance Window™ Technique PDFDocument7 pagesDrying Characteristics of Mango Slices Using The Refractance Window™ Technique PDFcedu126No ratings yet

- Drying Characteristics PDFDocument6 pagesDrying Characteristics PDFoffayevNo ratings yet

- Blanching of BananaDocument9 pagesBlanching of BananaRaihanul HaqueNo ratings yet

- Changes in Textural and Optical Properties of Oyster Mushroom During Hot Air DryingDocument5 pagesChanges in Textural and Optical Properties of Oyster Mushroom During Hot Air DryingPaulina BulsaraNo ratings yet

- Drying Kinetics of Fresh and Osmotically Pre-Treated Papaya (Carica Papaya L.)Document7 pagesDrying Kinetics of Fresh and Osmotically Pre-Treated Papaya (Carica Papaya L.)Rajan PandaNo ratings yet

- Effect of pre-treatments on melon cell structureDocument7 pagesEffect of pre-treatments on melon cell structureraguerreNo ratings yet

- Características de Secado de Los Pescados de Sardina Secados Con Calentamiento Por MicroondasDocument7 pagesCaracterísticas de Secado de Los Pescados de Sardina Secados Con Calentamiento Por MicroondasJulian Andres Rodriguez PovedaNo ratings yet

- TratDocument11 pagesTratElizabeth BennetNo ratings yet

- Microwave/air and Microwave ®nish Drying of Banana: Medeni MaskanDocument8 pagesMicrowave/air and Microwave ®nish Drying of Banana: Medeni MaskanSỹ TrươngNo ratings yet

- Drying of Oyster MushroomDocument8 pagesDrying of Oyster MushroomKarthik VijayakumarNo ratings yet

- 4 Drying and Rehydration Behaviour of BambDocument8 pages4 Drying and Rehydration Behaviour of BambHouse DoctorNo ratings yet

- Modelling Pleurotus SpeciesDocument6 pagesModelling Pleurotus Speciesds6178500No ratings yet

- Convective and Microwave Drying Characteristics of Sorbus Fruits Sorbus Domestica L 2015 Procedia Social and Behavioral SciencesDocument10 pagesConvective and Microwave Drying Characteristics of Sorbus Fruits Sorbus Domestica L 2015 Procedia Social and Behavioral SciencesMildred CullenNo ratings yet

- Apel Dan Karakteristik PDFDocument9 pagesApel Dan Karakteristik PDFFaisal Azis RamadhanNo ratings yet

- Experimental and Theoretical Analysis of Drying Carrots: Ahmet Kaya, Orhan Aydın, Cevdet DemirtaşDocument11 pagesExperimental and Theoretical Analysis of Drying Carrots: Ahmet Kaya, Orhan Aydın, Cevdet DemirtaşMara RoNo ratings yet

- Evaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementDocument7 pagesEvaluation of Some Thin Layer Drying Models of Persimmon Slices Diospyros Kaki L 2012 Energy Conversion and ManagementMildred CullenNo ratings yet

- Optimization of Baker's Yeast Drying in Industrial Continuous Fluidized Bed DryerDocument6 pagesOptimization of Baker's Yeast Drying in Industrial Continuous Fluidized Bed DryerMohamadMostafaviNo ratings yet

- Energy and Quality Aspects For Fixed Deep Bed Drying of PaddyDocument10 pagesEnergy and Quality Aspects For Fixed Deep Bed Drying of PaddyPhuwanai PalakachenNo ratings yet

- Statistical Modelling of Drying Characteristics of Unripe Plantain (Musa Paradisiaca) SlicesDocument10 pagesStatistical Modelling of Drying Characteristics of Unripe Plantain (Musa Paradisiaca) SlicesIJEMR JournalNo ratings yet

- Effect of Moisture Variation On The Thermal Properties of Mucuna PruriensDocument10 pagesEffect of Moisture Variation On The Thermal Properties of Mucuna PruriensDielNo ratings yet

- Author's Accepted ManuscriptDocument11 pagesAuthor's Accepted Manuscriptchaima rekikNo ratings yet

- ETHANOl-VIT C-10.1016@j.foodchem.2019.05.145Document9 pagesETHANOl-VIT C-10.1016@j.foodchem.2019.05.145Mộng Cầm PhanNo ratings yet

- Drying of Bananas Assisted by Microwave EnergyDocument9 pagesDrying of Bananas Assisted by Microwave Energymohamadi42No ratings yet

- Artticulo Nutricion LDocument7 pagesArtticulo Nutricion LMirleidis TapiaNo ratings yet

- Mask An 1998Document13 pagesMask An 1998Camila Durán SalasNo ratings yet

- Influence of Different Drying Techniques On Drying Parameters of MangoDocument9 pagesInfluence of Different Drying Techniques On Drying Parameters of MangoletyNo ratings yet

- Banana PDFDocument9 pagesBanana PDFhoaNo ratings yet

- Microwave Drying of Sprouted Horse Gram (Macrotyloma Uniflorum) : Mathematical Modeling of Drying KineticsDocument7 pagesMicrowave Drying of Sprouted Horse Gram (Macrotyloma Uniflorum) : Mathematical Modeling of Drying KineticsKrishnaMurthyTPNo ratings yet

- Drying GingerDocument10 pagesDrying GingerWinda Putri HaryantiNo ratings yet

- Drying Characteristics of Sardine Fish Dried WithDocument8 pagesDrying Characteristics of Sardine Fish Dried WithSESILIA AGUSTIN SNo ratings yet

- Mass Transfer in Bioreactors PDFDocument48 pagesMass Transfer in Bioreactors PDFGiovanniNo ratings yet

- Mathematical Modelling On Thin Layer Microwave Drying of Apple Pomace With and Without Hot Air Pre-DryingDocument9 pagesMathematical Modelling On Thin Layer Microwave Drying of Apple Pomace With and Without Hot Air Pre-DryingJohnathan Ortega MenesesNo ratings yet

- Effects of Pretreatments On Explosion Puffing Drying Kinetics of Apple ChipsDocument7 pagesEffects of Pretreatments On Explosion Puffing Drying Kinetics of Apple ChipsSantiago Sebastián Peralta HurtadoNo ratings yet

- 1 s2.0 S0023643818306005 MainDocument6 pages1 s2.0 S0023643818306005 MainValentina EscobarNo ratings yet

- Innovative Food Science and Emerging Technologies 48 (2018) 248-257Document10 pagesInnovative Food Science and Emerging Technologies 48 (2018) 248-257Hombre EXNo ratings yet

- 0022 0981 (88) 90063 9 PDFDocument5 pages0022 0981 (88) 90063 9 PDFHestiawati HakimmNo ratings yet

- Industrial Crops and Products Volume 70 Issue 2015 (Doi 10.1016/j.indcrop.2015.03.047) Taghian Dinani, Somayeh Havet, Michel - Effect of Voltage and Air Flow Velocity of Combined Convective-ElectrDocument10 pagesIndustrial Crops and Products Volume 70 Issue 2015 (Doi 10.1016/j.indcrop.2015.03.047) Taghian Dinani, Somayeh Havet, Michel - Effect of Voltage and Air Flow Velocity of Combined Convective-ElectrRois AmienNo ratings yet

- Desorption Isotherms of Dioscorea Schimperiana (Hairy Yam) An Experimental and Modeling ApproachDocument9 pagesDesorption Isotherms of Dioscorea Schimperiana (Hairy Yam) An Experimental and Modeling ApproachInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drying Characteristics and Quality Evaluation of Kiwi Slices Under Hot Air Natural Convective Drying MethodDocument9 pagesDrying Characteristics and Quality Evaluation of Kiwi Slices Under Hot Air Natural Convective Drying MethodNovanto GuruhNo ratings yet

- Prot Hon 2001Document7 pagesProt Hon 2001Viverly Joy De GuzmanNo ratings yet

- Quality Starchy Food - MicrowaveDocument7 pagesQuality Starchy Food - MicrowaveMarin KalistaNo ratings yet

- Technology Processing For BlueberryDocument5 pagesTechnology Processing For BlueberryDevana DoanarestaNo ratings yet

- Effect of Infrared and Conventional Drying Methods On Physicochemical Characteristics of Stored White RiceDocument9 pagesEffect of Infrared and Conventional Drying Methods On Physicochemical Characteristics of Stored White RiceBen MrNo ratings yet

- Drying Characteristics of Sardine Fish Dried WithDocument8 pagesDrying Characteristics of Sardine Fish Dried With0901EE201067 KUNAL JOLLY SAXENANo ratings yet

- Drying of EggplantDocument12 pagesDrying of EggplantsubhashNo ratings yet

- Science Investigatory ProjectDocument13 pagesScience Investigatory ProjectMedrano, SophiaNo ratings yet

- 20 PDFDocument10 pages20 PDFK V SATHEESHKUMAR MECHNo ratings yet

- 20 PDFDocument10 pages20 PDFK V SATHEESHKUMAR MECHNo ratings yet

- Preparation, Characterization, Properties, and Application of NanofluidFrom EverandPreparation, Characterization, Properties, and Application of NanofluidNo ratings yet

- Thermal and Energetic Studies of Cellular Biological SystemsFrom EverandThermal and Energetic Studies of Cellular Biological SystemsA. M. JamesNo ratings yet

- (It Bus) Computer HistoryDocument6 pages(It Bus) Computer HistoryRica Elaine LubasanNo ratings yet

- SQL SlidesDocument65 pagesSQL SlidescopsamostoNo ratings yet

- Department of Computer Engineering Academic Year 2020-21 Class: SE Computer & IT Subject: 22226 PCI (Programming in C) MCQ Unit 1: Program Logic Development MCQ Question Bank With AnswersDocument8 pagesDepartment of Computer Engineering Academic Year 2020-21 Class: SE Computer & IT Subject: 22226 PCI (Programming in C) MCQ Unit 1: Program Logic Development MCQ Question Bank With AnswersVooovoNo ratings yet

- The BCA (1) 23Document36 pagesThe BCA (1) 23Aurobind DasNo ratings yet

- Analysis of Structure of C Type Hydraulic PressDocument10 pagesAnalysis of Structure of C Type Hydraulic PressShubhamNo ratings yet

- Thermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Document1 pageThermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Mohamed MaltiNo ratings yet

- SPCU3C14Document20 pagesSPCU3C14ming tsaoNo ratings yet

- Using Topcon GR-3 GPS for Topographic SurveysDocument4 pagesUsing Topcon GR-3 GPS for Topographic SurveysFranco BaldiNo ratings yet

- TDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemDocument12 pagesTDT4171 Artificial Intelligence Methods Task 5 Creating A Decision Support SystemKermess McNo ratings yet

- An Intelligent Algorithm For The Protection of Smart Power SystemsDocument8 pagesAn Intelligent Algorithm For The Protection of Smart Power SystemsAhmed WestministerNo ratings yet

- Ch01Document33 pagesCh01sakali aliNo ratings yet

- Pioneer Deh-1300 1350 1390mpDocument71 pagesPioneer Deh-1300 1350 1390mpJorge LavezziNo ratings yet

- Matrix Inversion Note in Mathematics MagazineDocument2 pagesMatrix Inversion Note in Mathematics Magazinejuan carlos molano toroNo ratings yet

- MATLAB ApplicationsDocument252 pagesMATLAB Applicationsmadhuri nimseNo ratings yet

- Accelerate your career with online coursesDocument22 pagesAccelerate your career with online coursesAYEDITAN AYOMIDENo ratings yet

- Martillo Hyd Atlas Copco SB 150Document12 pagesMartillo Hyd Atlas Copco SB 150Nain murilloNo ratings yet

- Splunk Skills Assessment-UpdatedDocument14 pagesSplunk Skills Assessment-Updatedtsegay.csNo ratings yet

- Mammography View ChapterDocument60 pagesMammography View ChapterSehar GulNo ratings yet

- Evaluation of Lathyrus SativusDocument16 pagesEvaluation of Lathyrus SativusSAMI DHAOUINo ratings yet

- Multi-Band Booster With HRLB - In-Band Routed DCN Solution GuideDocument26 pagesMulti-Band Booster With HRLB - In-Band Routed DCN Solution GuideAchintha AluthmanageNo ratings yet

- Presentation On Power Grid InertiaDocument47 pagesPresentation On Power Grid InertiajorjijonNo ratings yet

- UMTS Chap6Document33 pagesUMTS Chap6NguyenDucTaiNo ratings yet

- 01238-00-AD TY96 Installation ManualDocument42 pages01238-00-AD TY96 Installation ManualJohan SwanepoelNo ratings yet

- AminesDocument31 pagesAminesJoseph YayenNo ratings yet

- UNIT3 - Introduction To IC Technology - 290617 - EditedDocument82 pagesUNIT3 - Introduction To IC Technology - 290617 - EditedKISHAN SHUKLANo ratings yet

- 3-Lecture 03 Translational Mechanical System3-SDocument23 pages3-Lecture 03 Translational Mechanical System3-SHamza KhanNo ratings yet

- Essential Statistics For The Behavioral Sciences 1st Edition Privitera Solutions ManualDocument7 pagesEssential Statistics For The Behavioral Sciences 1st Edition Privitera Solutions Manualspinifexcandock8zf100% (26)

- Active Heating and CoolingDocument16 pagesActive Heating and Coolinga_j_sanyal2590% (1)

- QPCR Analysis DifferentlyDocument12 pagesQPCR Analysis DifferentlyIan SaundersNo ratings yet

- Calentador Catalitico de TuberíasDocument2 pagesCalentador Catalitico de TuberíasDavid RomeroNo ratings yet