Professional Documents

Culture Documents

Steel Module8

Uploaded by

dash1991Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Module8

Uploaded by

dash1991Copyright:

Available Formats

Western Philippines University

College of Engineering and Technology

Civil Engineering Department

STRUCTURAL STEEL DESIGN

By Dr. Cesario A. Bacosa , Jr.

( Geotechnical and Structural Engineer)

Module 8 . Simple Lap Joint: Failure Modes

The simple lap joint shown in the figure below may fail in any of the possible failure modes: a) shearing

failure the bolt may be cut or sheared along its cross-sectional area, b) tension failure the plate will be torn along

its net cross section, c) bearing failure excessive contact pressure between the bolt and the plate may result in

enlargement of the hole or crushing of the bolt, and d) tear-out failure when the bolts are placed too close to the

edge of the plate or when they are spaced too close to each other in case there are more than one bolt in a row.

a) shearing failure

b) tension failure

c) bearing failure

d) shear tear-out failure

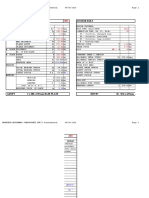

Example 901. Check bolt spacing, edge distances, bolt shear, bearing, tension and block shear strength for the

bearing-type connection shown. Assume A36 Steel and 20 mm diameter A325bolts with threads excluded from shear

plane.

12 mm plate

140x12 mm PL

3

5

7

035

35 70 35

Solution.

1) Check bolt spacing, edge distances

minimum spacing = 3d = 3(20) = 60 mm

actual spacing = 70 mm > 60 mm OK.

Table 510-10, assuming sheared edges, min. edge distance = 32 mm

actual edge distance = 35 mm > 32 mm

OK.

Table 510-6, assuming Standard size hole, h = 21 mm

(NSCP 510.4.8.1)

2) Compute shear strength

Table 510-7, threads excluded from shear plane bearing-type connections, Fv = 207 MPa

Nominal cross sectional area of bolt, Ab 4 (20)2 314 mm2

Shear capacity, Ps Fv Ab 207(314)103 65.0 kN/bolt

For four bolts, P 4(65.00) 260.00 kN

3) Check bearing of tension member

For holes near the edge of the member:

1.5d = 1.5(20) = 30 mm < 35 mm OK

Lc = Le h/2 = 35 21/2 = 24.5 mm

Bearing at bolt hole:

Pb 1.20Futd 1.2(400)(12)(20)103 115.20 kN/bolt

Shear tear-out:

Pr 0.30Fu Lct 0.3(400)(2 x24.5)(12)103 70.56 kN/bolt

(NSCP 510.4.7.1)

(NSCP 510.4.7.1)

(NSCP 510.5.1)

(controls)

(This result means that Lc is small enough so that it must be accounted for.)

For the other holes:

3d = 3(20) = 60 mm < 70 mm OK

(NSCP 510.4.7.1)

Lc = Le h = 70 21 = 49 mm

Bearing at bolt hole:

(NSCP 510.4.7.1)

Pb 1.20Futd 1.2(400)(12)(20)103 115.20 kN/bolt (controls)

Shear tear-out:

Pr 0.30Fu Lct 0.3(400)(2 x49)(12)103 141.12 kN/bolt

(NSCP 510.5.1)

(This result means that Lc is sufficient and need not be accounted for.)

The bearing strength for the tension member is,

Ra 2(70.56) 2(115.20) 371.52 kN

4) Check tensile strength of the tension member

Tension on the gross area:

P 0.60Fy Ag 0.60(250)(140 x12)103 252.00 kN (controls)

Tension on net area:

since all elements of cross section are connected, Ae = An

P 0.60Fu Ae 0.60(400)(140 2 x21)(12)103 282.24 kN

(NSCP 504.2.1)

(NSCP 502.2.1)

5) Block shear strength

12 mm plate

140x12 mm PL

3

5

7

035

35 70 35

Net shear areas: Anv 2(12)(35 70 1.5x21) 1764 mm2

Net tension areas: Ant 12(70 21) 588 mm2

Along net shear areas, Ps 0.30Fu Anv 0.30(400)(1764)103 211.68 kN

(NSCP 510.5.1)

Along net tension area, Pt 0.50Fu Ant 0.50(400)(588)103 117.60 kN

(NSCP 510.5.1)

Total block shear capacity = 211.68 + 117.60 = 329.28 kN

Of all the design strength investigated, the strength corresponding tensile strength is smallest.

Therefore, the design strength of the connection is 252.00 kN.

You might also like

- Steel Module 7Document5 pagesSteel Module 7dash1991No ratings yet

- Anchor Bolt CalculationDocument17 pagesAnchor Bolt CalculationSrinivasa Rao Venkumahanthi100% (6)

- 321 Chapter 5 Splice DesignDocument91 pages321 Chapter 5 Splice DesignHemant Ramesh NarkarNo ratings yet

- C4.tension Member Compatibility ModeDocument45 pagesC4.tension Member Compatibility ModejojomarbunNo ratings yet

- MC12X14 beam to column connection designDocument4 pagesMC12X14 beam to column connection designVinoth KumarNo ratings yet

- Design of Base PlateDocument14 pagesDesign of Base Plateruel galutanNo ratings yet

- Base Plate Design - For Staad Forces-Channel DesignDocument16 pagesBase Plate Design - For Staad Forces-Channel DesignSanthoshkumar RayavarapuNo ratings yet

- Tutorial 7 - Connections - Part ADocument28 pagesTutorial 7 - Connections - Part ACyrus HongNo ratings yet

- End Plate-Splice ConnectionDocument76 pagesEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Introduction To Connection Design For Steel StructuresDocument22 pagesIntroduction To Connection Design For Steel StructuresErick Auger100% (6)

- Steel Module 2Document5 pagesSteel Module 2dash19910% (1)

- Plinth beam design crusher houseDocument10 pagesPlinth beam design crusher houseSujay Santra67% (3)

- Connections Workbook Formulas SummaryDocument13 pagesConnections Workbook Formulas SummaryCamilo García0% (1)

- Seismic Design of Continuous Beam Interior SpanDocument7 pagesSeismic Design of Continuous Beam Interior Spandash1991No ratings yet

- AISC Tension MemberDocument3 pagesAISC Tension Membermodulor3dNo ratings yet

- Beam - Roof Beam - GM1Document20 pagesBeam - Roof Beam - GM1FrederickV.VelascoNo ratings yet

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil Aafaaq100% (3)

- Bolted or Riveted Tension MembersDocument39 pagesBolted or Riveted Tension MembersKristin Brienne Leander-Renomeron88% (8)

- 8 - Design For TorsionDocument34 pages8 - Design For TorsionACTION plusNo ratings yet

- SteelDesign Fastener Fu 455Document40 pagesSteelDesign Fastener Fu 455clam2014No ratings yet

- Corner Cast in Place AnchorDocument7 pagesCorner Cast in Place Anchorwaweng22No ratings yet

- Moment Connection Beam Column IS & BS SECTION FOR IS800Document29 pagesMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Connections in Steel Structures PDFDocument54 pagesConnections in Steel Structures PDFsmmsajediNo ratings yet

- Bolt Capacity2Document2 pagesBolt Capacity2abdul kareeNo ratings yet

- Fin Plate - Beam To ColumnDocument78 pagesFin Plate - Beam To ColumnHemant Ramesh NarkarNo ratings yet

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Structural Design Bolted Welded ConnectionsDocument52 pagesStructural Design Bolted Welded ConnectionsBergadamusNo ratings yet

- Structural Analysis and Design Lectures PDFDocument354 pagesStructural Analysis and Design Lectures PDFgongmaozheNo ratings yet

- Splice Connection - Full CapacityDocument14 pagesSplice Connection - Full Capacitykalpanaadhi75% (4)

- Moment Splice - BackupDocument74 pagesMoment Splice - BackupKiran AcharyaNo ratings yet

- Chapter 12 - Bolted ConnectionsDocument23 pagesChapter 12 - Bolted ConnectionsIbra100% (1)

- End Plate Beam To Column Moment ConnectionDocument84 pagesEnd Plate Beam To Column Moment Connectionakshay chauhanNo ratings yet

- Sample Splice For Plate Girder DesignDocument7 pagesSample Splice For Plate Girder DesignChandan SinghNo ratings yet

- Connection DesignDocument30 pagesConnection DesignAdil Rasheed KhanNo ratings yet

- RC04 Bending2Document40 pagesRC04 Bending2Cristhianares Lonjawon OboLightNo ratings yet

- Diagram Drawing Design Forces and DetailsDocument6 pagesDiagram Drawing Design Forces and Detailswaweng22No ratings yet

- Connections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)Document5 pagesConnections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)travis8zimmermannNo ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Design of Structural MembersDocument153 pagesDesign of Structural Membersquiron20100% (1)

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Steel TextbookDocument41 pagesSteel TextbookRutu RajNo ratings yet

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- CE 8601 Internal 2 Answerkey 2021Document10 pagesCE 8601 Internal 2 Answerkey 2021ci_balaNo ratings yet

- Base Plate BiaxilDocument26 pagesBase Plate BiaxilvijaystructuralNo ratings yet

- Notes On Anchor Bolt Design (ACI 318-08 APP D)Document6 pagesNotes On Anchor Bolt Design (ACI 318-08 APP D)Kai LeeNo ratings yet

- Embed Design - Core WallDocument39 pagesEmbed Design - Core Wallkalpanaadhi100% (1)

- Thickness of Slab Without BeamDocument37 pagesThickness of Slab Without BeamNarith SrunNo ratings yet

- RCC Slab Design Template As Per BSDocument1 pageRCC Slab Design Template As Per BSsudhir12345No ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsFrom EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapFrom EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNo ratings yet

- Cargo Ships Explained: Types and Uses of FreightersDocument1 pageCargo Ships Explained: Types and Uses of Freightersdash1991No ratings yet

- Public TransportDocument1 pagePublic Transportdash1991No ratings yet

- Cargo Transport VehiclesDocument43 pagesCargo Transport Vehiclesdash1991No ratings yet

- Modes of TransportationDocument2 pagesModes of Transportationdash1991No ratings yet

- Prescielle Dawn G. Aloot Other Modes: Transport Decks VesselDocument1 pagePrescielle Dawn G. Aloot Other Modes: Transport Decks Vesseldash1991No ratings yet

- RailDocument1 pageRaildash1991No ratings yet

- Pipelines: Oil Pipelines Are Made Front Steel or Plastic Tube With Inner Diameter Typically From 4 ToDocument1 pagePipelines: Oil Pipelines Are Made Front Steel or Plastic Tube With Inner Diameter Typically From 4 Todash1991No ratings yet

- Human-Powered: Mode of TransportDocument4 pagesHuman-Powered: Mode of Transportdash1991No ratings yet

- Study On The Effect of Different Curing Methods in Compressive Strength of ConcreteDocument42 pagesStudy On The Effect of Different Curing Methods in Compressive Strength of Concretedash199150% (4)

- Air TransportDocument1 pageAir Transportdash1991No ratings yet

- Human-Powered: Mode of TransportDocument4 pagesHuman-Powered: Mode of Transportdash1991No ratings yet

- BibliographyDocument1 pageBibliographydash1991No ratings yet

- Ce 51 Chapter 1Document3 pagesCe 51 Chapter 1dash1991No ratings yet

- Motor Vehicle Cargo Automobile: Operations IssuesDocument1 pageMotor Vehicle Cargo Automobile: Operations Issuesdash1991No ratings yet

- Termite ControlDocument48 pagesTermite Controldash1991No ratings yet

- RCD - USD Schedule of Reinforcement!!!!!!!!Document2 pagesRCD - USD Schedule of Reinforcement!!!!!!!!dash1991No ratings yet

- Termite ControlDocument48 pagesTermite Controldash1991No ratings yet

- Study On The Effect of Different Curing Methods in Compressive Strength of ConcreteDocument42 pagesStudy On The Effect of Different Curing Methods in Compressive Strength of Concretedash199150% (4)

- Ce 51 Chapter 5Document7 pagesCe 51 Chapter 5dash1991No ratings yet

- Seepage and Stability of A Dam in An Artesian SettingDocument1 pageSeepage and Stability of A Dam in An Artesian Settingdash1991No ratings yet

- Napier's Rules - Solving Spherical TrianglesDocument2 pagesNapier's Rules - Solving Spherical Trianglesdash1991No ratings yet

- Ce 51 Chapter 2Document4 pagesCe 51 Chapter 2dash1991No ratings yet

- Assignment in WSD TbeamsDocument3 pagesAssignment in WSD Tbeamsdash1991No ratings yet

- USD FootingDocument3 pagesUSD Footingdash1991No ratings yet

- Computation For RSD-WSD (SLABS)Document16 pagesComputation For RSD-WSD (SLABS)dash1991No ratings yet

- Computation For RCD-USD (SLABS)Document18 pagesComputation For RCD-USD (SLABS)dash1991No ratings yet

- 5THYEARDocument1 page5THYEARdash1991No ratings yet

- Ce 51 Chapter 1Document3 pagesCe 51 Chapter 1dash1991No ratings yet

- Ce 51 Chapter 3Document8 pagesCe 51 Chapter 3dash1991No ratings yet

- Highway Safety and Accident AnalysisDocument3 pagesHighway Safety and Accident Analysisdash1991100% (2)

- Ch3 Work and EnergyDocument25 pagesCh3 Work and EnergyahmadskhanNo ratings yet

- Three problems on mass transfer diffusion processesDocument15 pagesThree problems on mass transfer diffusion processesPasha Tan100% (1)

- Fatigue and Fracture PDFDocument31 pagesFatigue and Fracture PDFpericharla ravivarmaNo ratings yet

- Water Control Diagnostic Plots Canuku Base Case Study: Paula CruzDocument24 pagesWater Control Diagnostic Plots Canuku Base Case Study: Paula CruzLina M. Rodriguez Cortés100% (1)

- Roses Amend 12Document477 pagesRoses Amend 12Koert OosterhuisNo ratings yet

- Viscoelastic Modeling of Flexible Pavement With Abaqus PDFDocument143 pagesViscoelastic Modeling of Flexible Pavement With Abaqus PDFcabrel TokamNo ratings yet

- Units and Dimensions BansalDocument5 pagesUnits and Dimensions BansalPranav DarganNo ratings yet

- A Study On Cohesive Zone ModelDocument19 pagesA Study On Cohesive Zone ModelabishayNo ratings yet

- Spe 80945 MSDocument10 pagesSpe 80945 MSLuciano FucelloNo ratings yet

- Questions On Concepts Q5.1) : and andDocument23 pagesQuestions On Concepts Q5.1) : and andAlejandra Fajardo ApoloNo ratings yet

- Tappi 550Document8 pagesTappi 550Alberto Koji TakakuraNo ratings yet

- Tugas VeigaDocument17 pagesTugas VeigaPutra Tresna100% (2)

- Solution Set 3Document11 pagesSolution Set 3HaseebAhmadNo ratings yet

- Stefan-Boltzmann Law Experiment ResultsDocument21 pagesStefan-Boltzmann Law Experiment ResultsBenjamin LukeNo ratings yet

- Reflectarray AntennaDocument27 pagesReflectarray AntennaVISHNU UNNIKRISHNANNo ratings yet

- Strength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenDocument31 pagesStrength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenHani Aziz Ameen80% (15)

- Comprehensive List of Heat Transfer Fluids and PropertiesDocument3 pagesComprehensive List of Heat Transfer Fluids and PropertiesChris SmithNo ratings yet

- 1429 (Math and State)Document2 pages1429 (Math and State)Zameer HussainNo ratings yet

- What Is A Magnetic FieldDocument7 pagesWhat Is A Magnetic Fieldruxandra tudorascuNo ratings yet

- Proper Orthogonal DecompositionDocument10 pagesProper Orthogonal DecompositionKenry Xu ChiNo ratings yet

- Blackbody RadiationDocument2 pagesBlackbody RadiationstosicdusanNo ratings yet

- James Jeans: British Mathematician and AstrophysicistDocument4 pagesJames Jeans: British Mathematician and AstrophysicistMarcus AureliusNo ratings yet

- Mobil SHC Gear 320 WTDocument3 pagesMobil SHC Gear 320 WTAnonymous F2TxS3YoaNo ratings yet

- Study BG 462 9 Beams On Elastic FoundationDocument15 pagesStudy BG 462 9 Beams On Elastic Foundationmanish mehtaNo ratings yet

- Roger BakerDocument327 pagesRoger BakerfelipeplatziNo ratings yet

- Abaqus Analysis Intro-Summary PDFDocument20 pagesAbaqus Analysis Intro-Summary PDFHussein ZeinNo ratings yet

- dm16 RRDocument16 pagesdm16 RRioan dumitrescuNo ratings yet

- Assignment 1Document6 pagesAssignment 1Suru UniiNo ratings yet

- Pressure Meter and Dila To MeterDocument34 pagesPressure Meter and Dila To MeterNagarajHB100% (1)

- SBC Detailed ReportDocument36 pagesSBC Detailed ReportPraneeth Kumar100% (1)